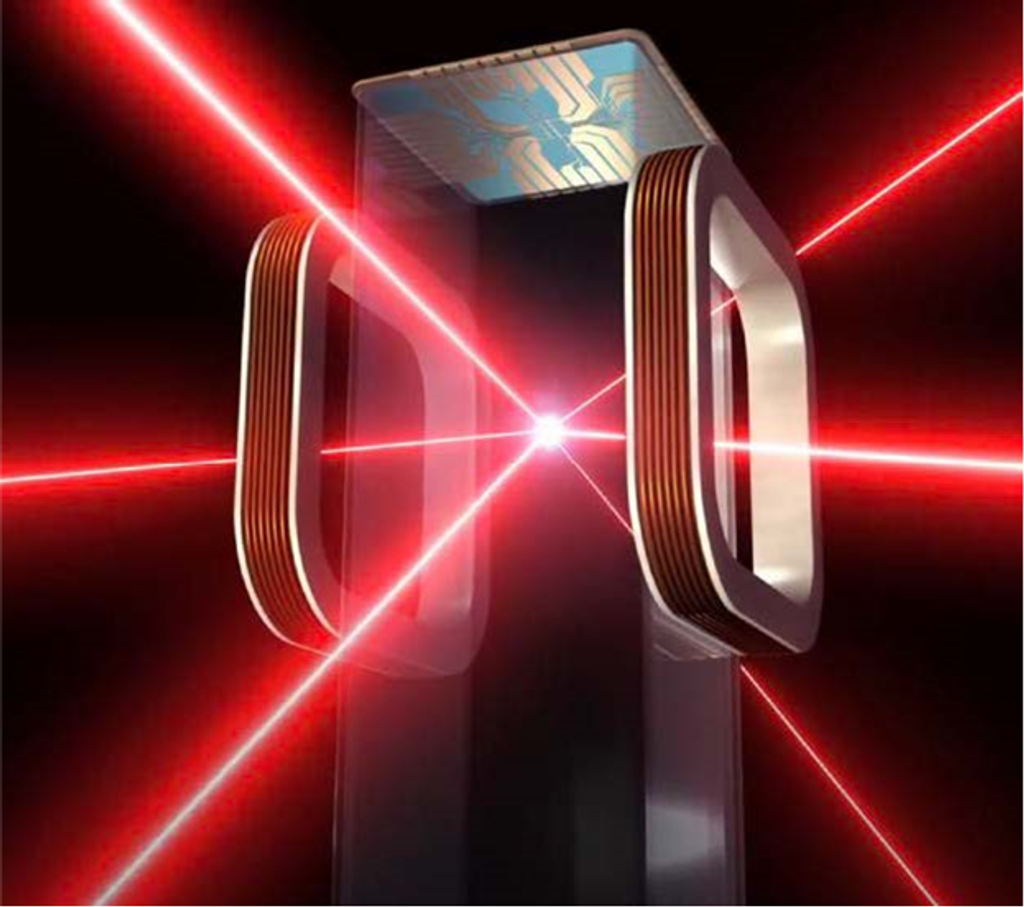

The scene inside a NASA test facility sometimes looks a lot like the set of a science fiction movie. That’s certainly the case with a 1 megawatt electric machine with an integrated power electronics system university students are now testing with NASA support.

This innovative hybrid electric technology isn’t fictional. It’s reality, and it could someday help single-aisle commercial aircraft reduce fuel consumption and produce fewer carbon emissions.

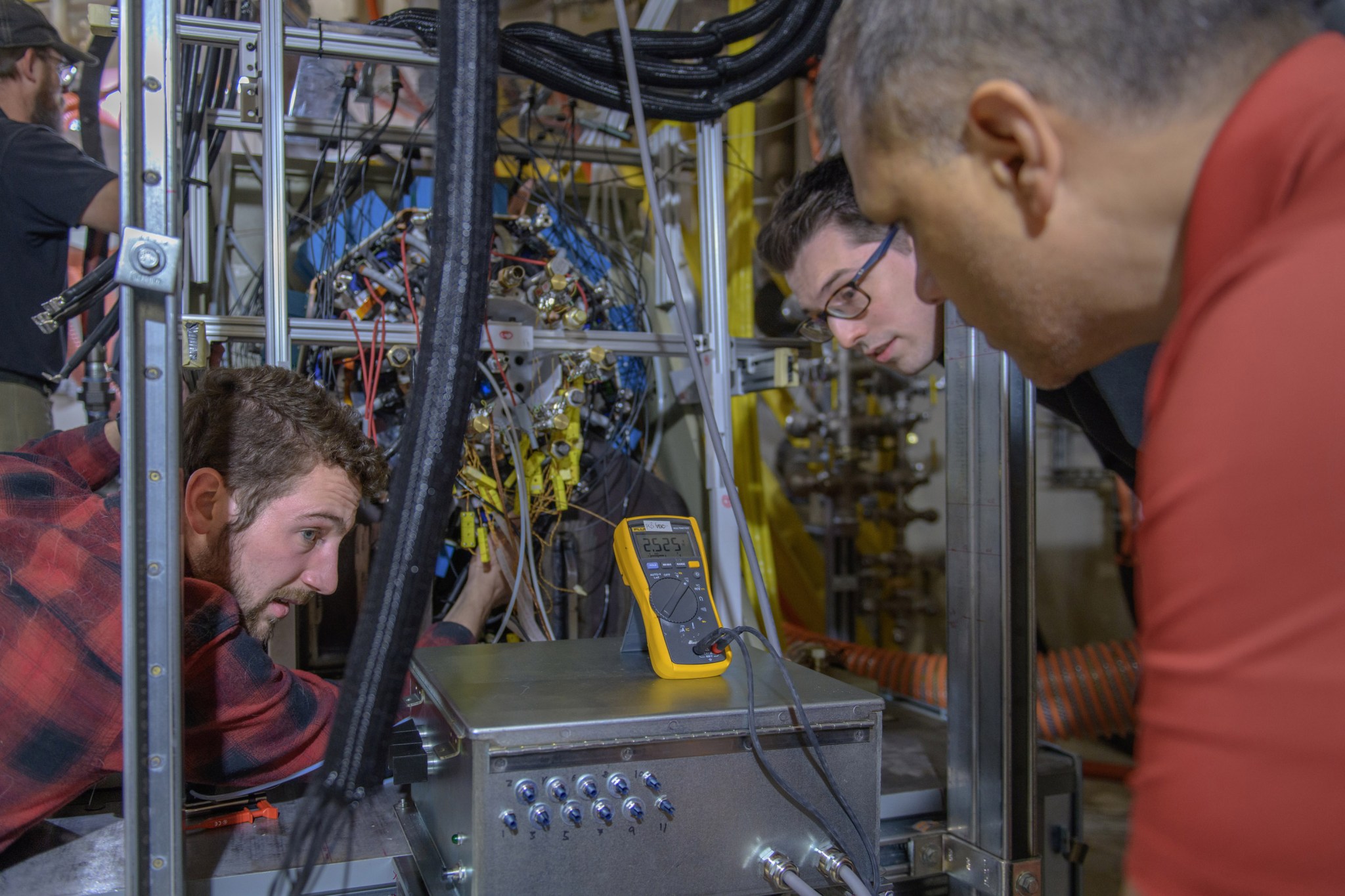

The machine, which can operate as a motor or generator, is being tested in NASA’s Electric Aircraft Testbed (NEAT) in Sandusky, Ohio. It’s the capstone deliverable for a project led by The Ohio State University and its academic partners, one of five university teams that were awarded in 2017 during the very first round of NASA’s University Leadership Initiative (ULI).

“It’s amazing that a faculty and student team from these universities advanced their revolutionary ideas in five years by designing, building, and testing a 1 megawatt electric machine that is now being tested at a nationally significant NASA facility,” said Koushik Datta, project manager for the ULI. “It’s an excellent example of universities advancing leading-edge technologies and furthering U.S. global leadership in aviation.”

This university project is one part of NASA’s strategy under ULI to tap the research power of universities, engage their students, and help research one potential approach in reducing aircraft emissions as part of the United States’ and international community’s goal to achieve net zero carbon emissions by 2050.

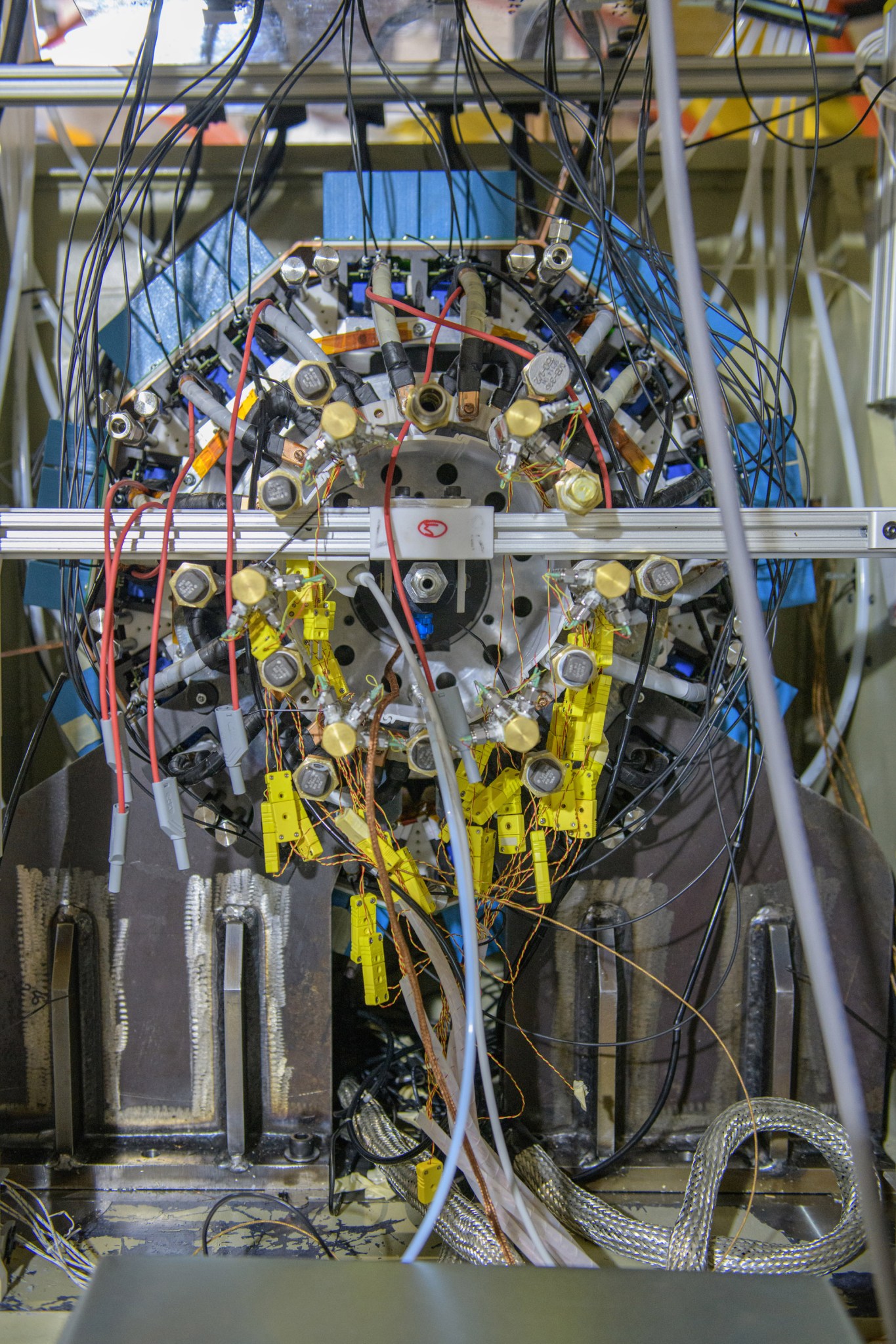

The Ohio State University performed the power electronics work on the 1 megawatt electric machine, and led the team of additional universities that also made major contributions. The University of Wisconsin was responsible for designing and building the machine. The University of Maryland and North Carolina Agricultural and Technical State University performed thermal designs for the machine including electronics, and The Georgia Institute of Technology led a system level study of how the technology could improve fuel economy with a hybrid electric aircraft.

“The work is based on close collaborations between multiple universities and multiple teams at NASA,” said Jin Wang, professor at Ohio State. “A group of very talented and hardworking students have been trained through this process.”

Although challenging in many aspects, the team integrated the electric power systems on the machine to save weight by reducing structure, and sharing systems such as thermal management to gain efficiency.

“Five years ago, this university-led team set out to advance hybrid electric technologies with a very challenging set of performance targets. Having working hardware ready for us to test is extremely exciting,” said Amy Jankovsky, NEAT project manager. “NASA is very proud to work with the students and professors to see how this very high-performance machine behaves at sea level and at altitude. Our initial round of testing checked out and everything is working well with performance data beginning to come in. Testing will continue into the first quarter of 2023.”

Brian Newbacher

NASA’s Glenn Research Center