There’re more than three dimensions to the story of how NASA’s aeronautical innovators use 3D printing as a tool to help transform aviation in the 21st century.

Exotic metals, advanced composite materials, elegant design engineering, savings in manufacturing, rapid prototyping, high fidelity models, and so much more are all part of the tale of what is more technically known as additive manufacturing.

NASA, as you might expect, was an early adopter of the technology, using it long before a consumer could order an affordable 3D printer from an online store.

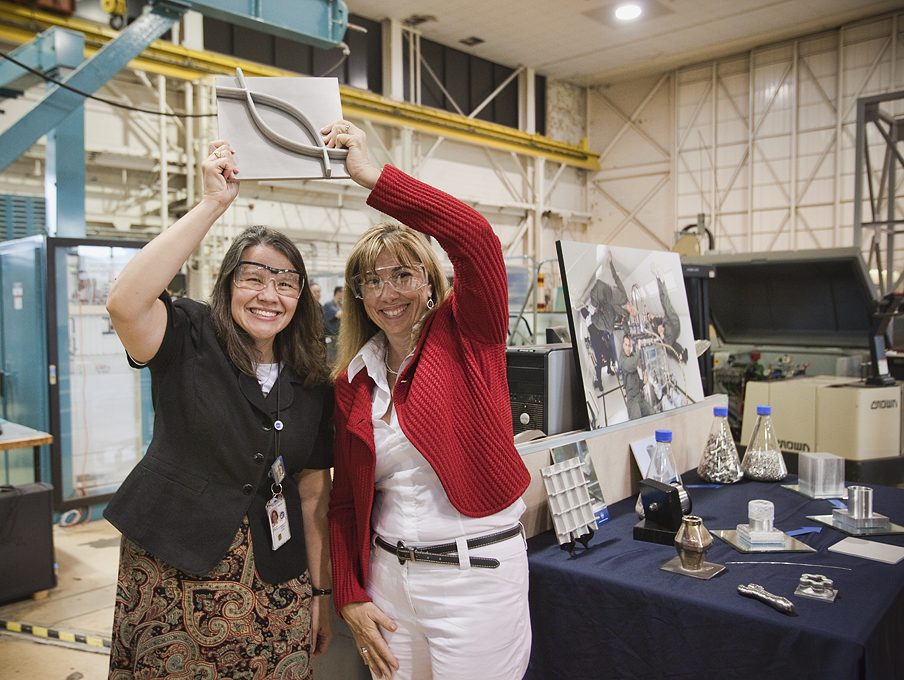

“We recognized the potential value and got into this game long before the term ‘3D printing’ was even coined,” said Karen Taminger, a materials research engineer at NASA’s Langley Research Center in Virginia.

Although NASA was using the technology to make plastic models as far back as the late 1980s and early 1990s, it was in 2001 that NASA’s aeronautics researchers acquired their first large-scale, metal additive machine for use in research, Taminger said.

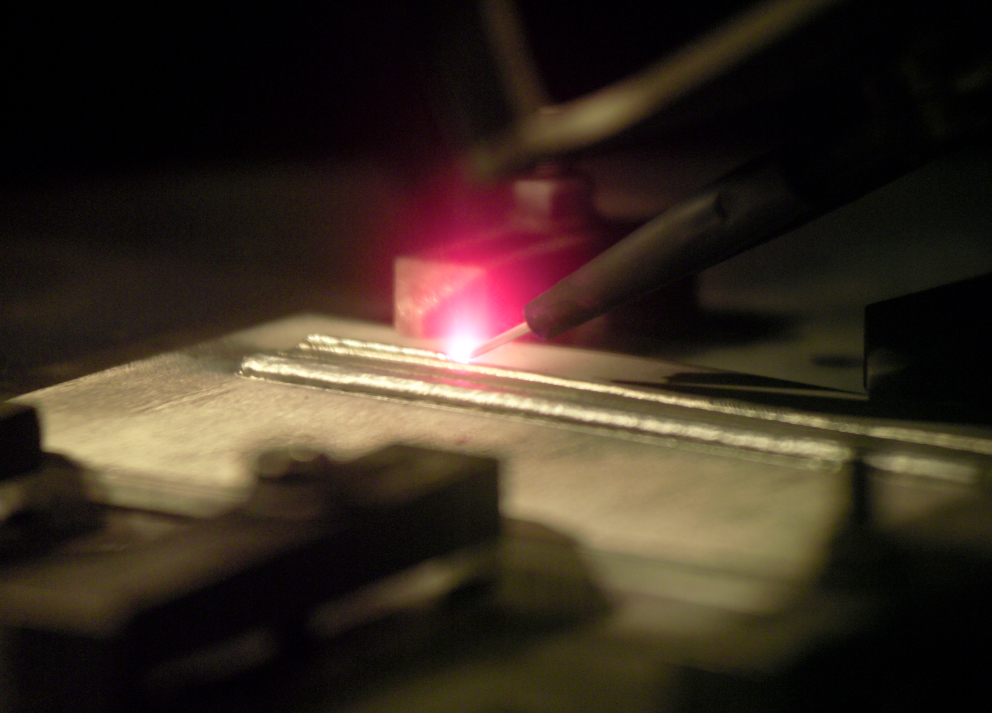

Developed during the late 1990’s, there was a process called Laser Engineered Net Shaping (LENS) that fed metallic powder into a laser beam, which together was moved in three dimensions to create a product layer by layer.

The LENS process was very slow but extremely precise, taking an hour to complete one cubic centimeter. The whole idea intrigued NASA’s aeronautics researchers, but as they studied the device more closely they decided LENS wasn’t going to cut it.

“We wanted something faster and bigger,” Taminger said.

Before 3D: EBF3

The solution became known as Electron Beam Freeform Fabrication, or EBF3. Instead of a laser, which reflects too much energy off of aluminum alloys used in aviation to build aircraft, an electron beam was directed at the metallic material.

As research with the device continued during the first decade of the century, the many benefits and potential uses for EBF3 – or more generally what we now call 3D printing – within NASA and the aerospace industry became clear.

For example, 3D printers can more easily create parts with complex geometries than using conventional means – even complex parts where it’s not possible at all to use conventional means.

Saving money is a big benefit as well. Often it can take less time to print something, or the final part may require less material to produce than by conventional means, which can also have environmental benefits.

Taminger is fond of pointing out the long-accepted way to make some 300-pound airplane parts out of titanium is to begin with a 6,000-pound block of titanium. It must then be formed and machined down to the right shape, which requires many gallons of coolant and generates 5,700 pounds of titanium chips to recycle – itself not a cheap process.

Another key benefit of using the process in aviation manufacturing is with aircraft or engine assembly. Theoretically, for example, a wing could be made as one giant part, instead of building many smaller parts to fasten together.

In doing so, different metal alloys could be fed into the wing at various locations to give it strength where it needed it and weight savings in other locations. With less fasteners there are fewer opportunities for cracks to form.

Another example: With 3D printing the interior of a jet engine could include complex shapes made of exotic alloys that reduce the part count, introduce cooling passages to help improve the extreme environment, and improve combustion efficiency.

“We’re always thinking about 3D printing as enabling something you couldn’t otherwise build,” she said, noting that while there are many ideas out there for what can be done, most remain theoretical and have yet to find their way into operation.

“Safety is always the number one goal. So, the Federal Aviation Administration (FAA) has asked us to help them with a certification process for 3D manufacturing and the resulting parts,” Taminger said.

So far the FAA has only certified for flight two or three structural metallic parts made through 3D printing, and none of those are safety critical. But the need to certify such parts is coming soon, especially considering the millions of dollars private industry is investing in the technique.

Composite 3D Printing

While one part of NASA aeronautics is working with industry and the FAA to determine 3D printing’s future as a manufacturing technique, others are using the technology to study how to use other types of materials in 3D printers.

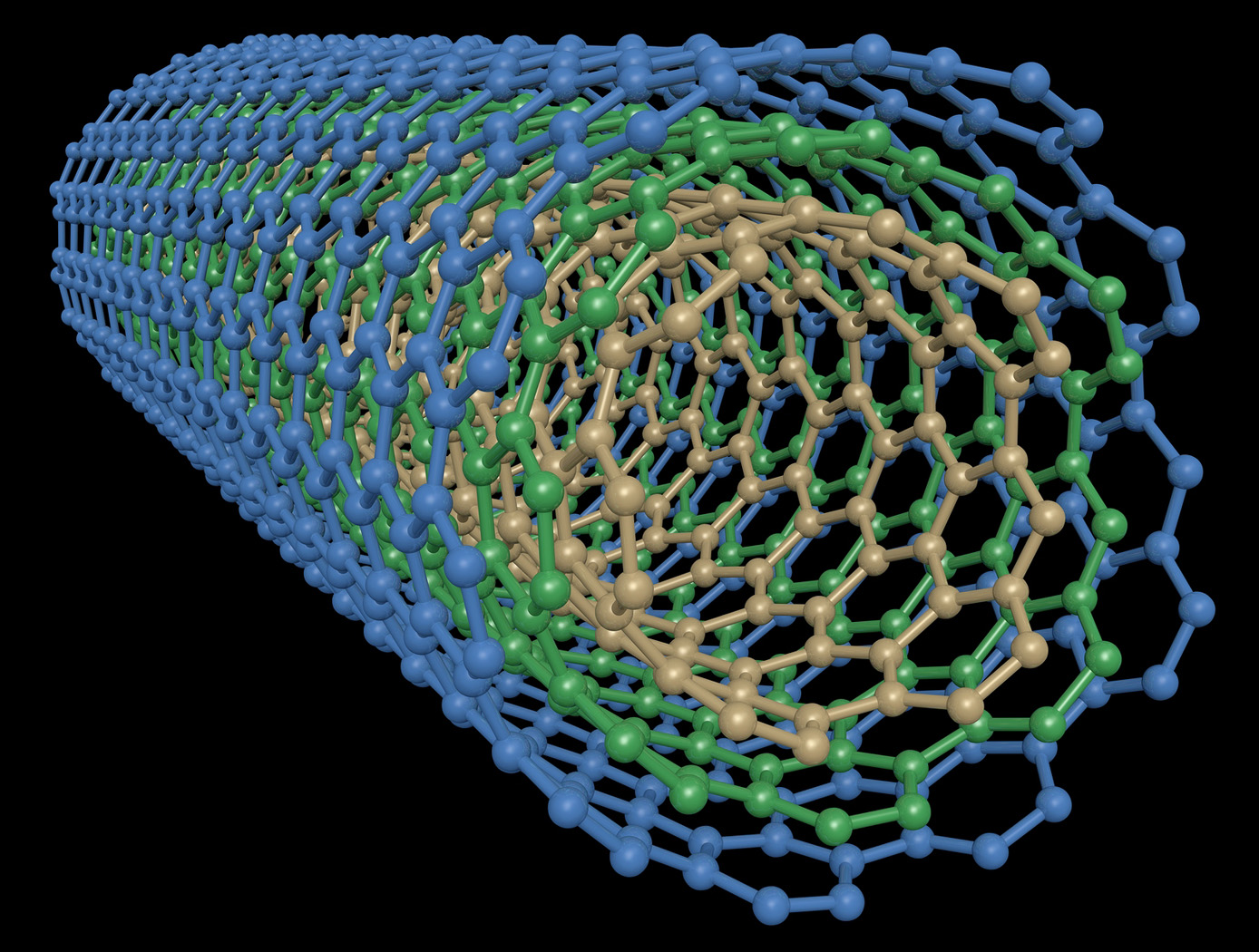

For example, there is great interest in the use of carbon nanotubes for enabling lighter structures for airliners, something NASA has been studying in general since 2000. The material is particularly strong and stiff, and it also has other unique thermal and electrical properties that could be advantageous in designing future aircraft.

Combine the exotic carbon nanotube yarns with the engineering plastic materials, and the result is a composite material with many welcome, multifunctional properties – including as a feedstock for a 3D printer, if one could be made to handle the material.

“When we started looking into 3D printing this material four years ago, we found there was no machine available to do that. So, we took an off-the-shelf, commercially available, open source machine and adapted it for our use and pushed the envelope on printing multifunctional components,” said Mia Siochi, a senior materials scientist at Langley.

Siochi said the science behind the printed part’s properties and the quality of the printed materials to be used in critical aviation products isn’t fully understood yet. They are still learning how to use these materials with 3D printers and what parts can be made with the required quality that can actually be used.

“The hype has gone way ahead of the understanding of what can and can’t be done. You hear a lot of buzz, but there are still nagging questions to be answered,” Siochi said.

3D Model Making

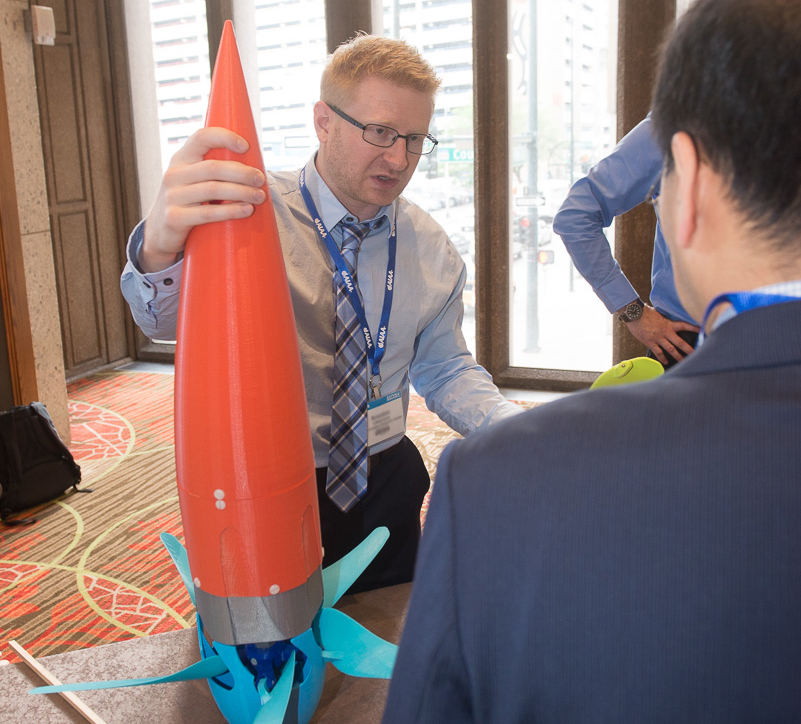

Even as the envelope-pushing research is underway, many 3D printers found throughout NASA’s aeronautical research field centers are being used for the same reason as hobbyists and others across the nation: model making.

A recent example of this can be found at NASA’s Armstrong Flight Research Center in California.

There a team of researchers are working on a method for reducing the noise that comes from an airplane while hardware such as its wing flaps and landing gear are deployed for takeoff and landing.

Part of a potential solution, which completed flight tests at Armstrong in October, was to install a Landing Gear Noise Reduction fairing.

The hardware, which has thousands of tiny holes drilled into it, essentially covers the landing gear strut. Test results hope to show the cover more efficiently moves the airflow around the landing gear, reducing noise.

Here’s where 3D printing played a big role in the project.

Before the noise-reducing fairing could be made, the research team wanted to ensure the proposed design would present no problems in terms of its size and shape.

“We were going to be spending a lot of money and a lot of time on that hardware, and when these things come in and they don’t fit, we’re in trouble,” said Mike Yandell, a structures engineer for the Aerostructures Branch at Armstrong.

Having taken a 3D scan of the landing gear itself, a virtual model was created from which the noise reduction fairing was designed. That 3D model, in turn, was sent out to be printed by a commercial vendor.

After taking delivery on the full-size model, and with everything checking out just fine, the actual flight-test article, which was not 3D printed, was ordered.

“That’s something we still need to work on,” Siochi said, referring to the use of models. “We can build a model out of plastic or some other material, and that’s very helpful to make a prototype of a part.”

“We need to keep working toward enabling 3D printers to work with materials that will result in certified parts that have the needed structural performance and are just as safe to use as traditionally made parts today,” Siochi said.