In This Week’s Star

- NASA’s Cassini Spacecraft Ends Historic Exploration of Saturn

- NASA Astronaut Shane Kimbrough Shares Space Station Experiences

- Marshall Center Director Todd May to Hold All-Hands Meeting Sept. 26

- NASA Tests First 3-D Printed Rocket Engine Part Made with Two Different Alloys

- NASA’s Dragonfly Project Demonstrates Robotic Satellite Assembly

- Safety Week 2017: Changing to Meet New Demands

- Registration Open to Race the International Space Station at Annual Duathlon

- Greenway Under Development at Marshall

- This Week in NASA History: Saturn I SA-7 Launches – Sept. 18, 1964

- Obituaries

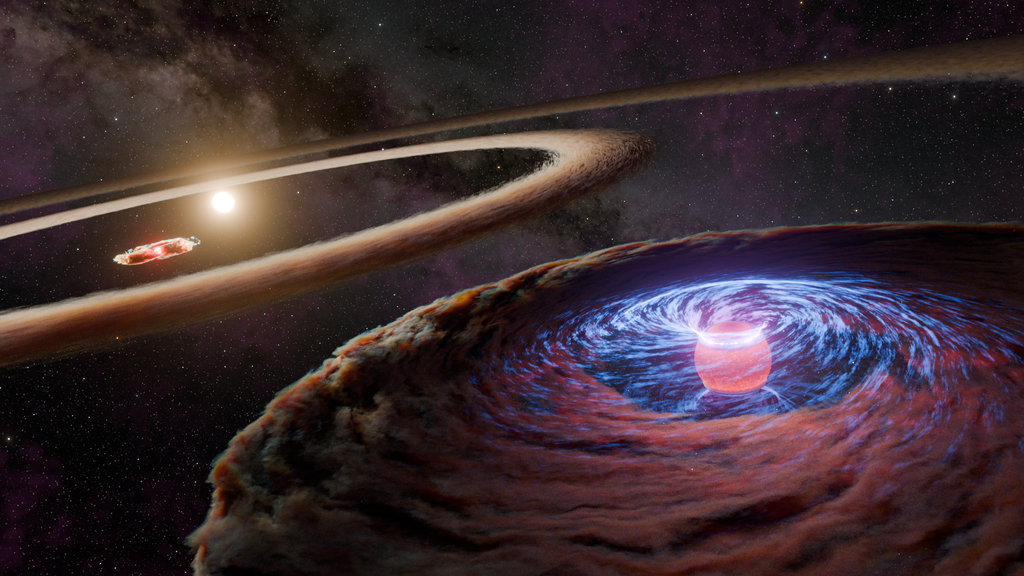

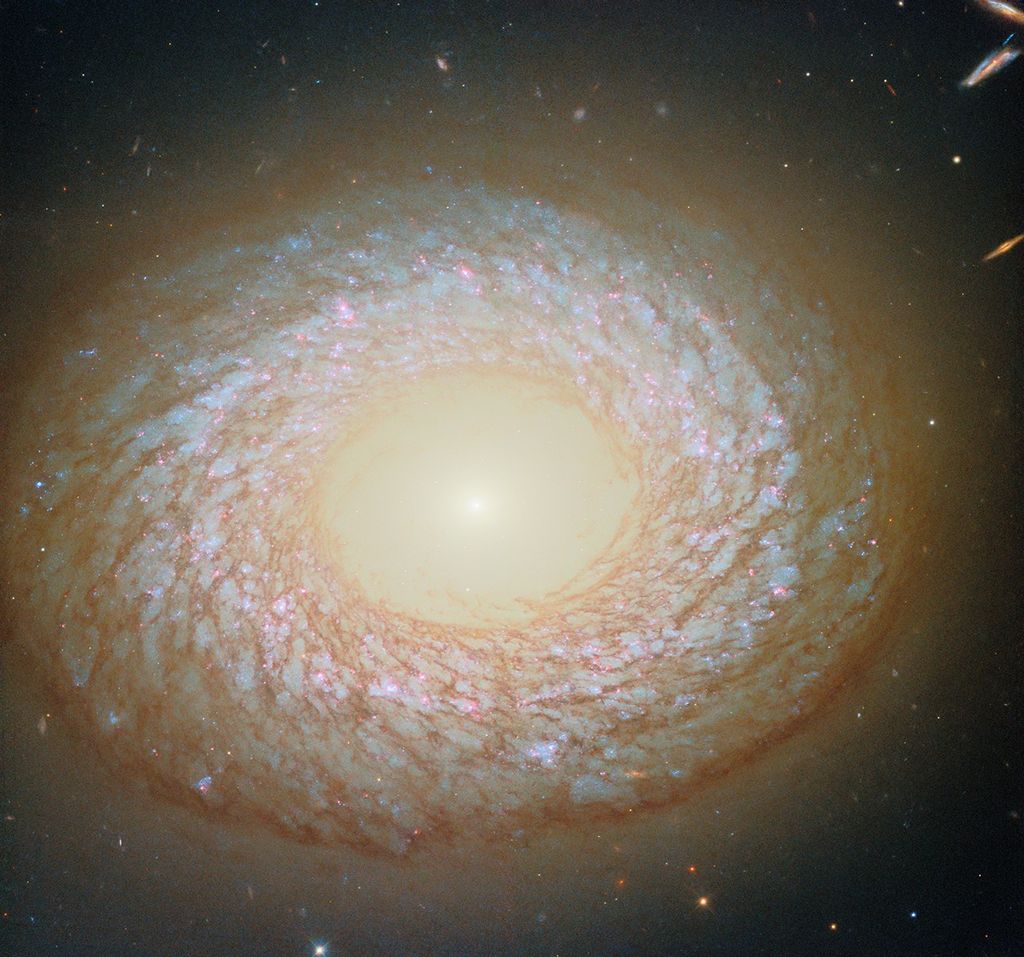

NASA’s Cassini Spacecraft Ends Historic Exploration of Saturn

A thrilling epoch in the exploration of our solar system came to a close Sept. 15, as NASA’s Cassini spacecraft made a fateful plunge into the atmosphere of Saturn, ending its 13-year tour of the ringed planet.

“This is the final chapter of an amazing mission, but it’s also a new beginning,” said Thomas Zurbuchen, associate administrator for NASA’s Science Mission Directorate at NASA Headquarters. “Cassini’s discovery of ocean worlds at Titan and Enceladus changed everything, shaking our views to the core about surprising places to search for potential life beyond Earth.”

Telemetry received during the plunge indicates that, as expected, Cassini entered Saturn’s atmosphere with its thrusters firing to maintain stability, as it sent back a unique final set of science observations. Loss of contact with the Cassini spacecraft occurred at 6:55 a.m. CDT with the signal received by NASA’s Deep Space Network antenna complex in Canberra, Australia.

“It’s a bittersweet, but fond, farewell to a mission that leaves behind an incredible wealth of discoveries that have changed our view of Saturn and our solar system, and will continue to shape future missions and research,” said Michael Watkins, director of NASA’s Jet Propulsion Laboratory, which manages the Cassini mission for the agency. JPL also designed, developed and assembled the spacecraft.

Cassini’s plunge brings to a close a series of 22 weekly “Grand Finale” dives between Saturn and its rings, a feat never before attempted by any spacecraft.

“The Cassini operations team did an absolutely stellar job guiding the spacecraft to its noble end,” said Earl Maize, Cassini project manager at JPL. “From designing the trajectory seven years ago, to navigating through the 22 nail-biting plunges between Saturn and its rings, this is a crack shot group of scientists and engineers that scripted a fitting end to a great mission. What a way to go. Truly a blaze of glory.”

As planned, data from eight of Cassini’s science instruments was beamed back to Earth. Mission scientists will examine the spacecraft’s final observations in the coming weeks for new insights about Saturn, including hints about the planet’s formation and evolution and processes occurring in its atmosphere.

“Things never will be quite the same for those of us on the Cassini team now that the spacecraft is no longer flying,” said Linda Spilker, Cassini project scientist at JPL. “But, we take comfort knowing that every time we look up at Saturn in the night sky, part of Cassini will be there, too.”

Cassini launched in 1997 from Cape Canaveral Air Force Station and arrived at Saturn in 2004. NASA extended its mission twice — first for two years, and then for seven more. The second mission extension provided dozens of flybys of the planet’s icy moons, using the spacecraft’s remaining rocket propellant along the way. Cassini finished its tour of the Saturn system with its Grand Finale, capped by the Sept. 15 intentional plunge into the planet to ensure Saturn’s moons — particularly Enceladus, with its subsurface ocean and signs of hydrothermal activity — remain pristine for future exploration.

While the Cassini spacecraft is gone, its enormous collection of data about Saturn — the giant planet, its magnetosphere, rings and moons — will continue to yield new discoveries for decades to come.

“Cassini may be gone, but its scientific bounty will keep us occupied for many years,” Spilker said. “We’ve only scratched the surface of what we can learn from the mountain of data it has sent back over its lifetime.”

The Cassini-Huygens mission is a cooperative project of NASA, the European Space Agency and the Italian Space Agency. JPL, a division of California Institute of Technology in Pasadena, manages the mission for NASA’s Science Mission Directorate in Washington.

NASA Astronaut Shane Kimbrough Shares Space Station Experiences

NASA astronaut Shane Kimbrough presents highlights from his Expedition 49-50 mission aboard the International Space Station Sept. 19 to students from the U.S. Space & Rocket Center‘s Space Camp and team members at NASA‘s Marshall Space Flight Center. While serving as commander of the station, Kimbrough conducted four spacewalks, during which he installed new batteries and relay boxes, and helped move a pressurized mating adapter for future commercial crew spacecraft visiting the outpost. He also contributed to hundreds of experiments in biology, biotechnology, physical science and Earth observations. One of these experiments was the Microgravity Expanded Stem Cells investigation, results of which could lead to the treatment of diseases and injury in space and provide a way to improve stem cell production for medical therapies on Earth. (NASA/MSFC/Fred Deaton)

Marshall Center Director Todd May to Hold All-Hands Meeting Sept. 26

By Jonathan Deal

NASA’s Marshall Space Flight Center team members are encouraged to attend an all-hands meeting with Marshall Center Director Todd May at 1 p.m. Sept. 26 in Morris Auditorium, Building 4200.

May will update the workforce about Marshall’s plan to thrive implementation, mentoring initiatives, the employee viewpoint survey results and President Trump’s nomination of Jim Bridenstine as NASA Administrator.

Marshall team members unable to attend can watch the all-hands meeting live on Marshall Desktop TV. May will answer questions from the audience and questions submitted by email at the all-hands. To submit a question by email, click here.

Deal, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

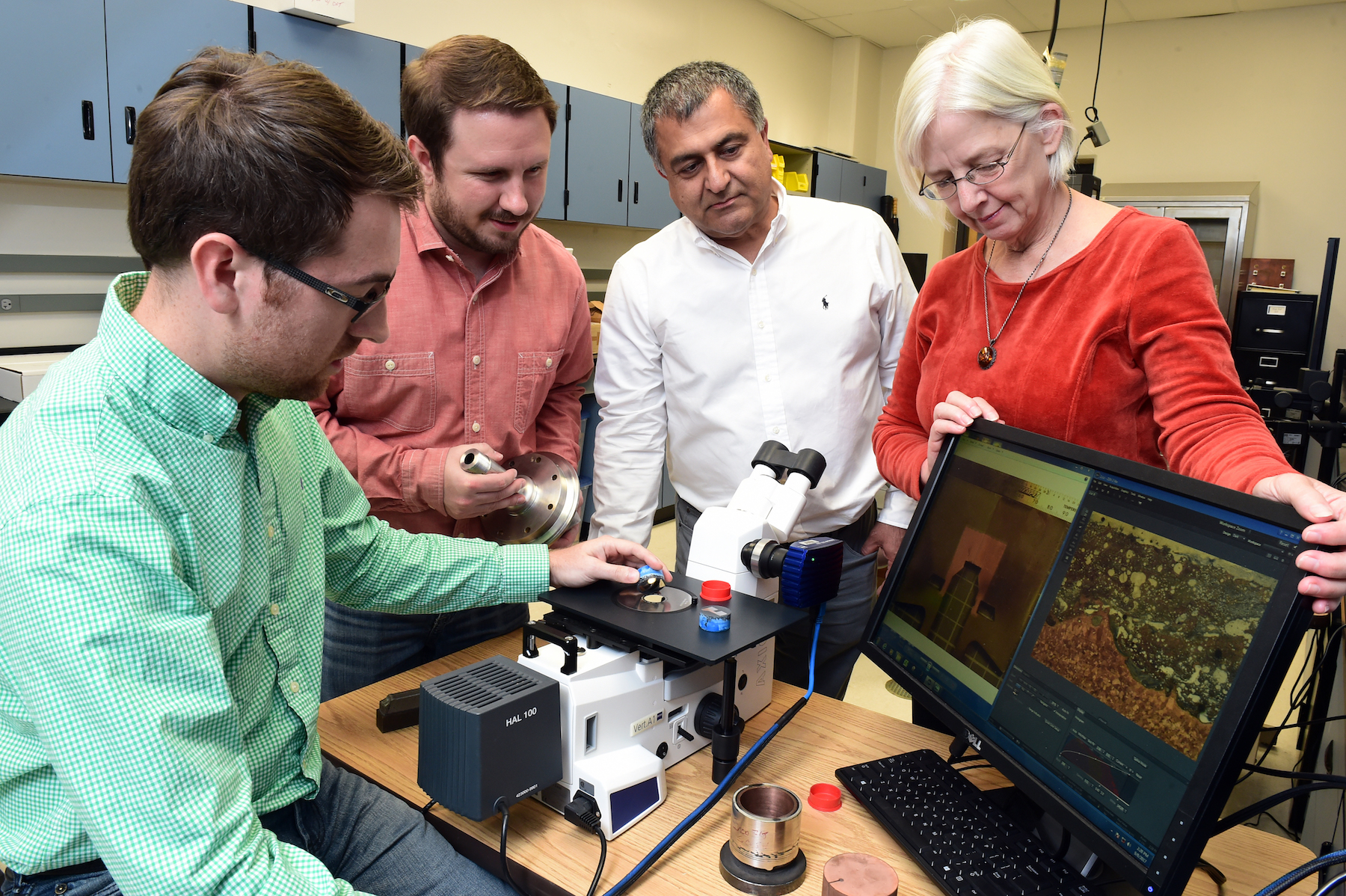

NASA Tests First 3-D Printed Rocket Engine Part Made with Two Different Alloys

By Amanda Adams

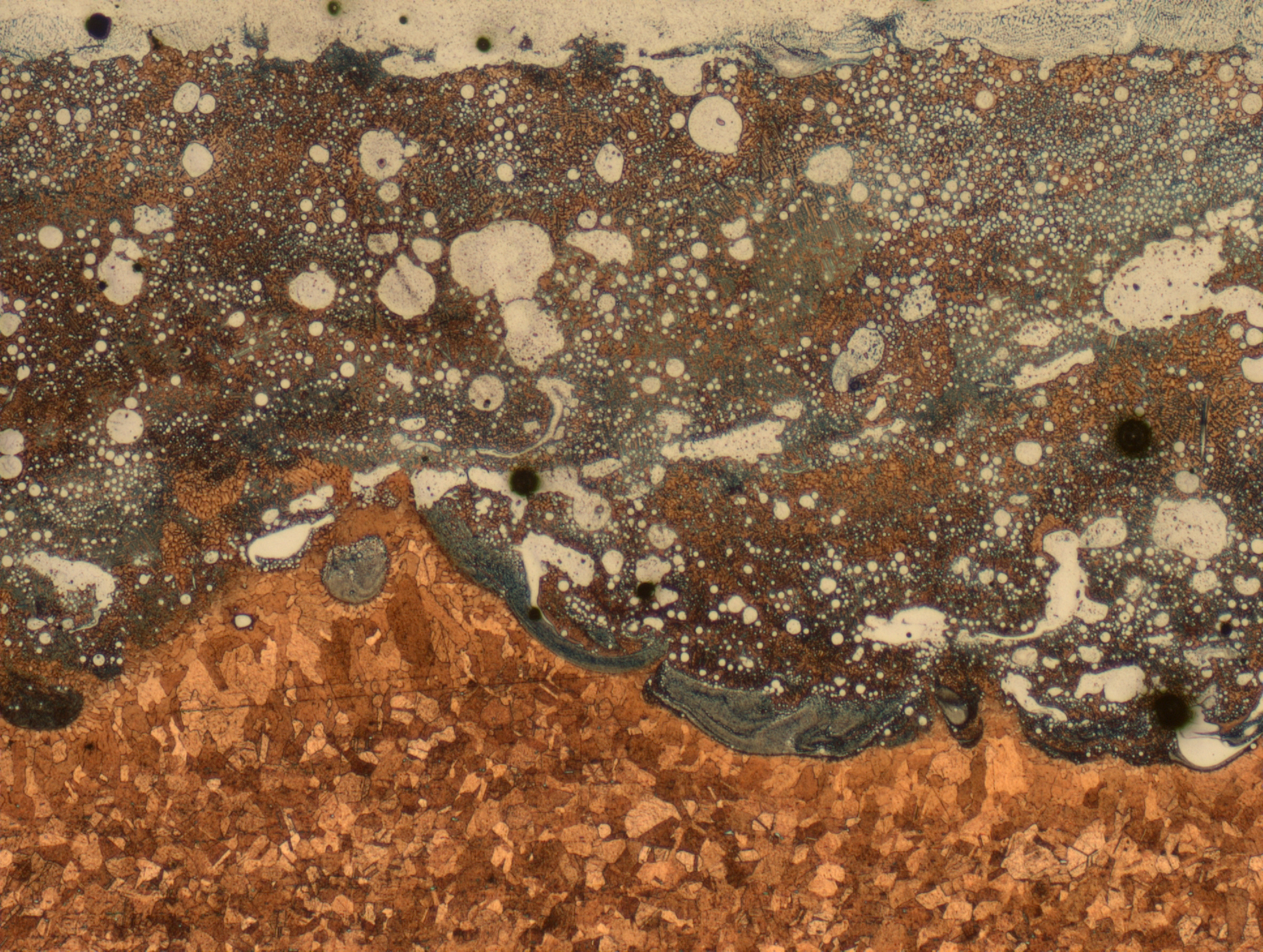

Engineers at NASA’s Marshall Space Flight Center tested NASA’s first 3-D printed rocket engine prototype part made of two different metal alloys through an innovative advanced manufacturing process. NASA has been making and evaluating durable 3-D printed rocket parts made of one metal, but the technique of 3-D printing, or additive manufacturing, with more than one metal is more difficult.

“It is a technological achievement to 3-D print and test rocket components made with two different alloys,” said Preston Jones, director of the Engineering Directorate at Marshall. “This process could reduce future rocket engine costs by up to a third and manufacturing time by 50 percent.”

Engineers at Marshall, led by senior engineer Robin Osborne, of ERC Inc. of Huntsville supporting Marshall’s Engine Components Development and Technology branch, low-pressure, hot-fire tested the prototype more than 30 times during July to demonstrate the functionality of the igniter. The prototype, built by a commercial vendor, was then cut up by University of Alabama in Huntsville researchers who examined images of the bi-metallic interface through a microscope. The results showed the two metals had inter-diffused, a phenomenon that helps create a strong bond.

A rocket engine igniter is used to initiate an engine’s start sequence and is one of many complex parts made of many different materials. In traditional manufacturing, igniters are built using a process called brazing, which joins two types of metals by melting a filler metal into a joint creating a bi-metallic component. The brazing process requires a significant amount of manual labor leading to higher costs and longer manufacturing time.

“Eliminating the brazing process and having bi-metallic parts built in a single machine not only decreases cost and manufacturing time, but it also decreases risk by increasing reliability,” said Majid Babai, advanced manufacturing chief, and lead for the project in Marshall’s Materials and Processes Laboratory. “By diffusing the two materials together through this process, a bond is generated internally with the two materials and any hard transition is eliminated that could cause the component to crack under the enormous forces and temperature gradient of space travel.”

For this prototype igniter, the two metals — a copper alloy and Inconel — were joined together using a unique hybrid 3-D printing process called automated blown powder laser deposition. The prototype igniter was made as one single part instead of four distinct parts that were brazed and welded together in the past. This bi-metallic part was created during a single build process by using a hybrid machine made by DMG MORI in Hoffman Estates, Illinois. The new machine integrated 3-D printing and computer numerical-control machining capabilities to make the prototype igniter.

While the igniter is a relatively small component at only 10 inches tall and 7 inches at its widest diameter, this new technology allows a much larger part to be made and enables the part’s interior to be machined during manufacturing — something other machines cannot do. This is similar to building a ship inside a bottle, where the exterior of the part is the “bottle” enclosing a detailed, complex “ship” with invisible details inside. The hybrid process can freely alternate between freeform 3-D printing and machining within the part before the exterior is finished and closed off.

“We’re encouraged about what this new advanced manufacturing technology could do for the Space Launch System program in the future,” said Steve Wofford, manager for the SLS liquid engines office at Marshall. “In next generation rocket engines, we aspire to create larger, more complex flight components through 3-D printing techniques.”

Adams, an ASRC Federal/Analytical Services employee supports the Office of Strategic Analysis & Communications.

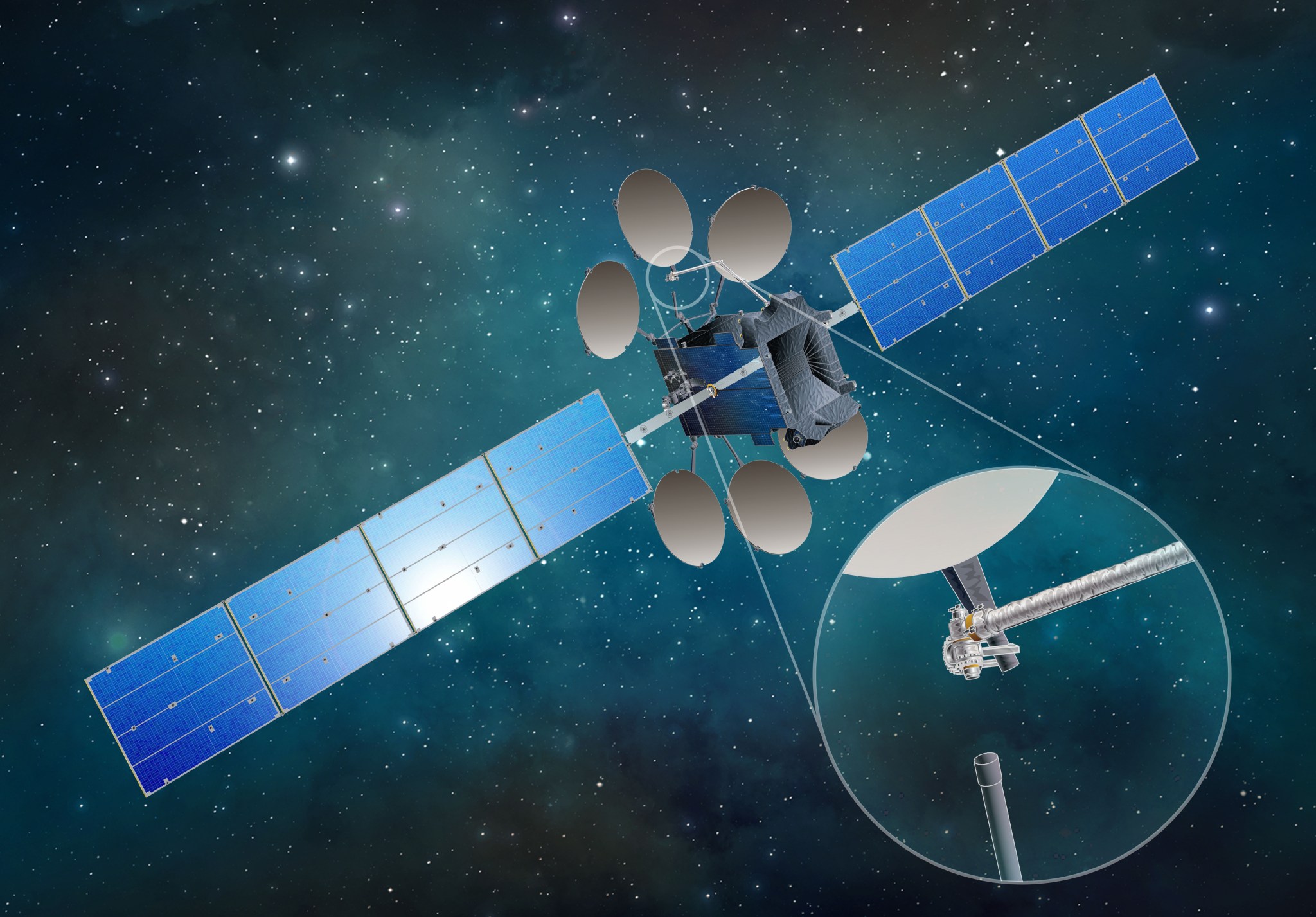

NASA’s Dragonfly Project Demonstrates Robotic Satellite Assembly

By Rick Smith

A revolutionary NASA Technology Demonstration Mission project called Dragonfly, designed to enable robotic self-assembly of satellites in Earth orbit, has successfully completed its first major ground demonstration.

“Dragonfly has taken a crucial step toward rewriting the book on what we can do in Earth orbit — and what that means for a robust space infrastructure,” said John Lymer, chief architect of robotics and automation for Space Systems Loral of Palo Alto, California, which leads the Dragonfly venture for NASA and conducted the testing at its Pasadena facility.

A lightweight robotic system with a dexterous 3.5-meter arm that’s able to clamp down, carry items or operate controls from either end of the “limb,” Dragonfly can install delicate satellite antenna, yet also assemble satellites too massive to be launched to space in their final flight-ready state.

These disassembled satellites may be stowed more efficiently or even launched in pieces via multiple flights, enabling mission planners to maximize cargo space and reduce mass. That shift would dramatically reduce launch costs and lead to less expensive, higher-performing satellites.

Dragonfly is one of three NASA tipping point projects seeking cutting-edge solutions under the umbrella of the TDM program’s In-space Robotic Manufacturing and Assembly portfolio. These projects help the agency determine whether technologies have been sufficiently matured to pursue flight demonstrations or for infusion into future exploration missions.

“NASA relies on commercial innovation as exemplified by the Dragonfly team,” said Trudy Kortes, TDM program executive at NASA Headquarters. “Transformative technologies such as these will, in time, lead to more affordable, safer human access to space and more efficient, longer-lasting satellites, probes and other space hardware.”

During the August ground demonstration, Dragonfly’s initial focus was the installation and reconfiguration of large antenna reflectors on a simulated geostationary satellite. The antennas are designed to focus the satellite signal to receivers on the ground. Additional demonstrations are planned through 2018 to further refine its processes and capabilities, including more fluid robotic arm movement and its ability to make even more precise reflector alignments.

Over time, the system will integrate 3-D printing technology, enabling the automated manufacture of new antennae and even replacement reflectors as needed. Should a piece of hardware be damaged, or come to the end of its lifecycle, engineers could remotely remove and recycle the outdated component, replacing it with a new one.

“This is a major step forward in overhauling how we manage satellites in orbit,” said Al Tadros, vice president for space infrastructure and civil space at Space Systems Loral. He envisions a healthy space infrastructure servicing industry, including commercial refueling platforms designed to service geostationary satellites and cargo missions to other planets.

Lymer concurred. “Being able to build what we need when we need it; change out hardware and components; even reconfigure old satellites for new tasks when they finish their initial missions, using affordable robotic technology,” he said. “We’re no longer at the mercy of launch costs and launch windows.”

Partnering with Space Systems Loral on the Dragonfly project are NASA’s Langley Research Center; NASA’s Ames Research Center; Tethers Unlimited of Bothell, Washington; and Space Systems Loral affiliate MDA US Systems LLC of Pasadena, California. Technology Demonstration Missions are funded by NASA’s Space Technology Mission Directorate. The program is managed for the agency by NASA’s Marshall Space Flight Center.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Safety Week 2017: Changing to Meet New Demands

By Rick Smith

Schedule of Safety Week Events: “Flexible Friday,” Sept. 29

- Organizational Meetings — 9-11 a.m.

- Video: “Office Stretching for Stress Reduction” — 9-11 a.m.

- Presentation: “Yoga for Stress Reduction” — 11 a.m.-noon

- Presentation: “Stress Response & Mitigation” — 11 a.m.-noon

- Presentation: “Resilience & Mental Toughness” — Noon-1 p.m.

- Presentation: “Your Safety & Well-being During Times of Change” — 1-2 p.m.

- SATERN Safety Culture Training — 1-2 p.m.

- Dedicated Housekeeping — 2-3 p.m.

Editor’s Note: NASA’s Marshall Space Flight Center will mark Safety Week Sept. 25-29, with each day focused on a unique safety-related theme. This is the final installment in the Star’s series previewing those themes and planned events associated with them.

Marshall will conclude Safety Week 2017 on Friday, Sept. 29. The theme that day is “Flexible,” focusing on our willingness to adapt to new requirements and changing demands, all the while adhering to safety guidelines to ensure the continued health and well-being of the people around us and those whose flight missions we support.

Preston Jones, director of Marshall’s Engineering Directorate, said the trick to flexibility is knowing when it should be applied. “There are times when we can be flexible and other times when we can’t,” he said. “Human spaceflight can be unforgiving, so we have to be far more rigorous in our processes where flight crews are concerned. Sometimes we can adjust our safety posture based on our data and analysis of what is an acceptable risk, and other times we must further mitigate the risks.

“It’s never one-size-fits-all. It’s our job to adapt — to effectively quantify risk and make the best decisions we can, knowing that at day’s end, safety remains Job 1.”

A series of presentations touching on the ability to adapt to new challenges will cap off Safety Week Sept. 29. Team members are encouraged to visit ExplorNet anytime that day to watch short video clips demonstrating Office Stretching for Stress Reduction techniques for improving balance and muscle health.

New and advanced yoga students may take part in “Yoga and Stress Reduction” in Building 4315 from 11 a.m. to noon. Led by Leah Fox, a safety and occupational health specialist in Marshall’s Safety and Mission Assurance Directorate, the class will offer pointers on controlling breathing, meditation and precise body control — all means of reducing stress, lowering blood pressure and improving balance.

Lisa Hall, an organization development specialist in Marshall’s Office of Human Capital, will lead a lunch-and-learn session on “Stress Response & Mitigation” from 11 a.m. to noon in Building 4203, Room 1201. Hall will demonstrate techniques for increasing mental and physical resilience to stressful situations.

Marshall organization development specialist Mat Park will lead a second lunch-and-learn session, “Resilience & Mental Toughness,” from noon to 1 p.m. in Building 4203, Room 1201. Building on the U.S. Navy Seals’ resiliency curriculum, the course offers tips for increasing mental toughness during challenging periods through goal-setting, visualization and positive self-talk.

Park also will lead “Your Safety and Well-being During Times of Change” from 1 to 2 p.m. in Building 4203, Room 1201. Participants will learn positive psychology practices for increasing one’s happiness in times of stress and change.

Unsure which course might be right for you? Jones encourages team members to visit the Safety Week site on ExplorNet to learn more about each class.

The most important thing, Jones emphasizes, is simply to take part. “Be vigilant. Be engaged. Avoid complacency,” he said. “The key is to recognize that being safety-conscious is the right thing to do. If each of us comes away from Safety Week applying just one thing we’ve learned, it’s been a success.”

All Marshall personnel should set aside housekeeping time in their offices, laboratories or shops. Personnel are required to visit SATERN before the close of Safety Week to complete Safety Culture Training. Event organizers will email out training module links in coming weeks. Learn more on ExplorNet.

Safety Week 2017 is organized by the Safety and Mission Assurance Directorate.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Registration Open to Race the International Space Station at Annual Duathlon

The International Space Station travels approximately 17,000 mph, orbiting the planet in just over 90 minutes.

NASA’s Marshall Space Flight Center is inviting athletes of all ages and capabilities to race the station by finishing a specially designed course in the same amount of time it takes for the station to complete a circuit of the Earth.

Registration is open for the sixth annual Racin’ the Station duathlon at Marshall on Sept. 30. Participants with access to Redstone Arsenal can register online until Sept. 28. The registration cut off for those without access is Sept. 26.

The event is organized by the Team Rocket Triathlon Club in Huntsville and by the Marshall Association, a professional employee service organization at Marshall whose members include civil service employees, retirees and contractors. Proceeds from the registration fee for the event go to the Marshall Association scholarship fund.

“One of NASA’s missions is to learn how to live and work in space,” said Kent Criswell, integration lead for the Space Launch System’s Upper Stage at Marshall and the race’s founder and director. “This race is a small and fun way to highlight our support and show our appreciation to the astronauts’ dedication. Sharing this passion with the surrounding community and other agencies on Redstone Arsenal reminds us about the important work we do and that the funds raised help the next generation of space explorers achieve their academic goals.”

The timed course begins at 8:30 a.m. with a 3.14 km run, followed by a 23 km bicycle ride, and finishes with another 3.14 km run, with the start and finish line near Marshall’s Wellness Center, Building 4315. Race organizers arranged the distance to coincide with the number pi or π, which is approximately 3.14. The race is officially over when the last person crosses the finish line. It is followed by lunch and an awards ceremony at 11 a.m.

The race is designed for athletes of any ability. Participants can even form two-person relay teams, in which one does the running portions and a partner handles the cycling.

Racers will pass many U.S. Army and Marshall facilities on Redstone Arsenal, including the Payload Operations Integration Center, the command post of space station science. At race headquarters in Activities Building 4316, participants can learn about NASA programs, including the International Space Station, the Space Launch System, the United Launch Alliance Atlas IV and Delta V rockets and U.S. Army exhibits of Unmanned Aerial Vehicles.

“Many people who want to race don’t have access to Redstone Arsenal or even know what we do out here,” said Criswell. “This event provides a unique opportunity for them to learn about all of Team Redstone’s work here while participating in a healthy activity and getting to meet some of the engineers and scientists who work on America’s space program.”

Because the race is held on Redstone, a federal installation, participation is restricted to U.S. citizens. Prizes will be awarded in multiple categories. For details on the race, including course maps, distances, requirements to access Redstone and to register, email ISSduathlon@gmail.com and visit the Racin’ the Station Duathalon websites: www.imathlete.com/events/RacintheStation

Or

teamrockettri.org/racin-the-station-duathlon/

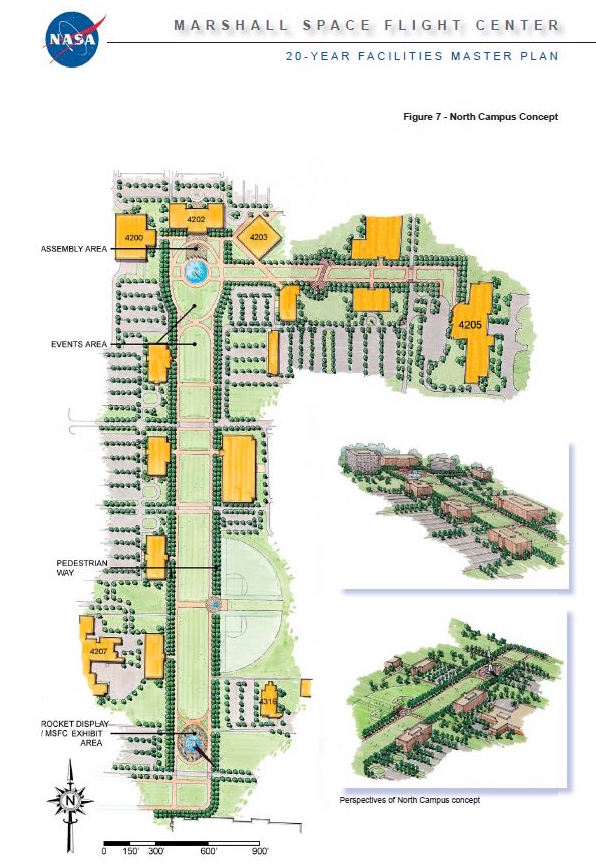

Greenway Under Development at Marshall

By Derek Hooper

Master planners at NASA’s Marshall Space Flight Center are currently developing a greenway plan to connect the Marshall campus. Planners expect the greenway to “take shape” as Building 4221 nears completion. The greenway is part of Marshall’s 25-year master plan, originally created in 2010.

A greenway is a grassed area set aside in an urban setting with sidewalks, benches, walking trails and bicycle paths where people can enjoy natural surroundings. Aside from being a place to walk or bike, the path is meant to encourage and better the environment.

“The concept behind the master plan is to create a more campus-like environment, the same that you’d see at a university, to try to make everything more accessible to people where they could walk between buildings,” said John Green, master planner in Marshall’s Facilities Management Office.

Running from north to south, the greenway will begin at the Building 4200 complex and end east of Building 4610. It is intended to unify the majority of Marshall’s facilities and provide a setting for both permanent and temporary exhibits or events.

The Building 4200 complex will serve as a courtyard at the head of the greenway with an open space featuring installments highlighting the history of NASA and Marshall. In the courtyard, there will be two paths dedicated to each decade since 1960 when Marshall was founded. One path will be dedicated to the history of Marshall, while the other will illustrate NASA’s history.

The overall master plan is either updated or revalidated every five years. In 2015, the current plan was revalidated and remains on track for completion. Over the next couple of years, planners will develop an updated master plan which incorporates the greenway concept and other essential elements of the current plan.

“That’s one thing about the master plan — it’s a plan — but you have to adjust for different reasons,” said Green.

The greenway will be installed incrementally as buildings are constructed or demolished alongside its path. Once it comes together, the Marshall workforce will be able to navigate along the greenway and experience the natural elements Marshall has to offer.

Hooper, a 2017 summer intern, supported the Office of Strategic Analysis & Communications.

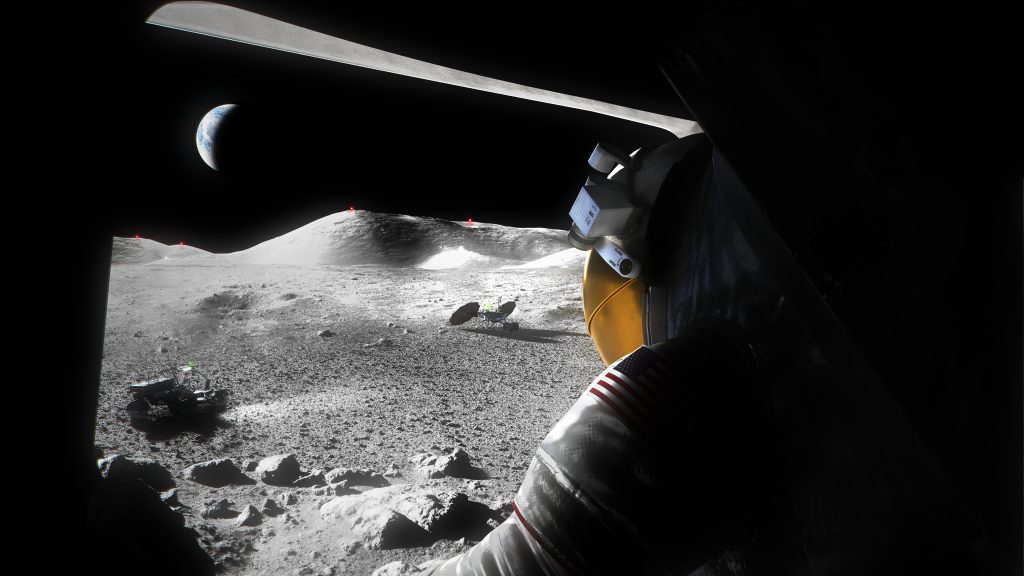

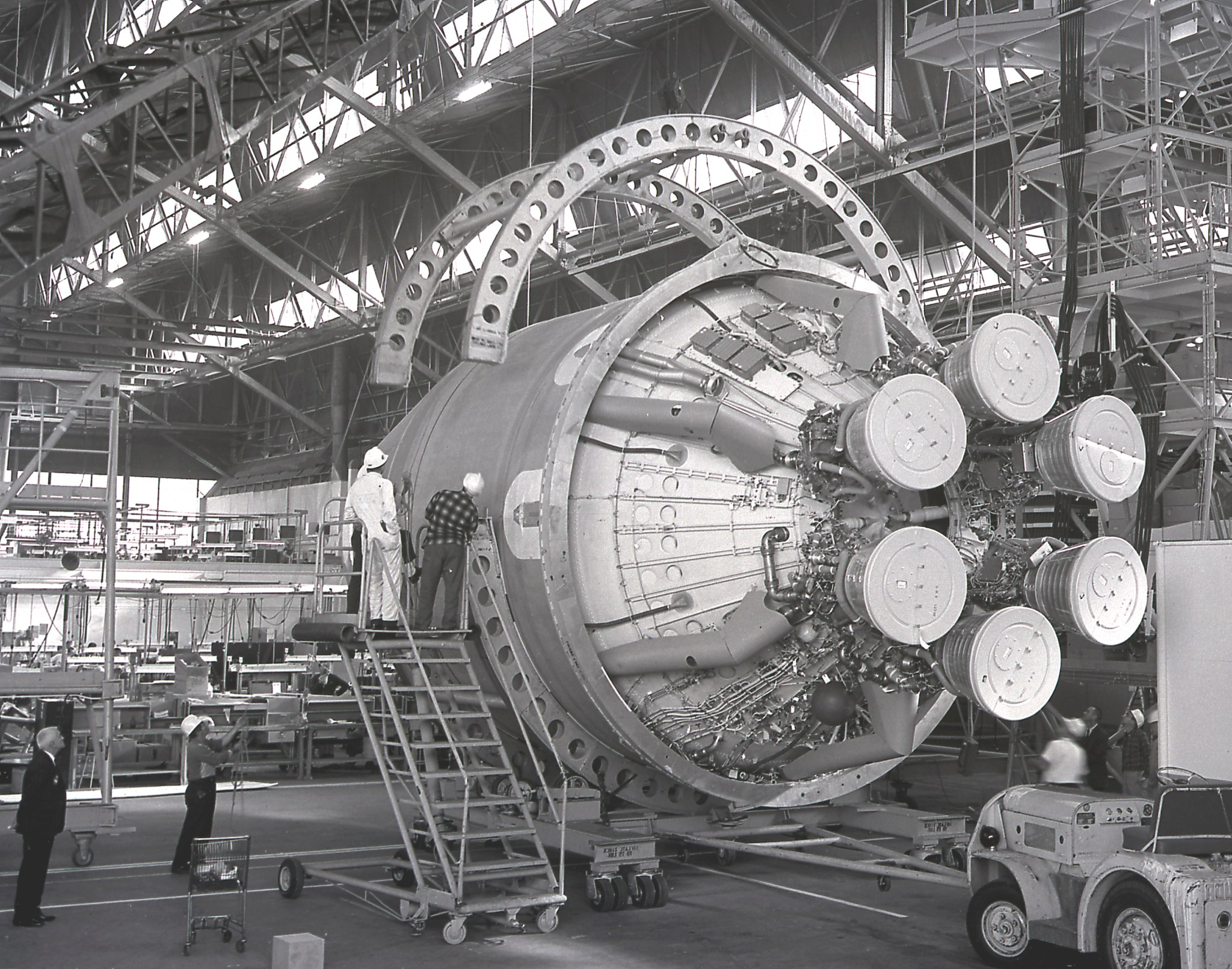

This Week in NASA History: Saturn I SA-7 Launches – Sept. 18, 1964

This week in 1964, the Saturn I SA-7 mission launched from NASA’s Kennedy Space Center. The second stage of the Saturn I, the S-IV, consisted of a circular cluster of six RL-10 engines, which employed liquid oxygen and liquid hydrogen as propellants to produce a combined thrust of 90,000 pounds. Here, the Saturn I S-IV stage of the SA-7 rocket is being prepared for shipment to Cape Canaveral, Florida, for its Sept. 18, 1964, launch. Today, Marshall is developing NASA’s Space Launch System, the most powerful rocket ever built, capable of sending astronauts to Mars and deeper into space than ever before. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

Obituaries

Teddy W. Stephens, 79, of Huntsville, died Sept. 11. He retired from the Marshall Center in 1999 as an aerospace engineer. He is survived by his wife, Elsie M. Stephens.

Orea A. Norton, Sr., 83, of Hazel Green, Alabama, died Friday, Sept. 15. He retired from the Marshall Center in 1995 as a materials engineer. He is survived by his wife, Kim Norton.