OpenVSP Snap-To

These guides will introduce the OpenVSP Snap-To feature and demonstrate how to use this capability for interactive or manual collision detection among components.

Introduction

Snap-To is an interactive collision detection function that enables components to be placed at a fixed, normal distance from another set of components or to check a model for clearance or collision. In this tutorial, the Snap-To function is introduced and demonstrated to provide a general sense of operation.

Interactive Collision Detection

Snap-To may be controlled interactively by dragging individual component parameters using “Alt/Option + Drag”. This is a quick way of manipulating component placement and design to reach your target minimum distance. However, you may notice that the reliability of Snap-To using this method is dependent on certain settings.

First, even though you are using Snap-To outside of the feature window, the settings chosen in Snap-To still apply. For example, if you are trying to snap a component to the surface of another with all other geometries hidden but the Snap-To Set is “All”, then the component will snap to the nearest geometry in the entire model. The target minimum distance in the Snap-To window is also enforced.

Secondly, the update speed of the GUI will affect how easily Snap-To can find a solution. Recall that the parameter sliders in OpenVSP have variable ranges where much larger or smaller steps are taken with each “update” as the component changes depending on the range. With very large steps, Snap-To may skip over a solution to the next available. This can be corrected by re-dragging the slider in the proper direction until you find the placement you needed. Alternatively, you can decrease the slider range using the left and right collapse range buttons (>|<) and Snap-To will have an easier time of catching the solution.

Manual Collision Detection

Working from the Snap-To window, you will have access to all of the settings that drive the collision detection process including the geometry Set, the target distance, and the manipulated parameter. You may also check the clearance of all components in the Set with a single click!

To perform a manual collision detection or Snap operation, select the desired parameter to be altered from the dropdown menus or simply drag the parameter button to the window to select the variable automatically. Choose your desired target minimum distance and Set and then click “Increase” or “Decrease” as needed to change the model.

Note that the manual collision detection method tends to be more reliable than the interactive “click-and-drag” mode because the manual mode is not dependent on the slider range for updates.

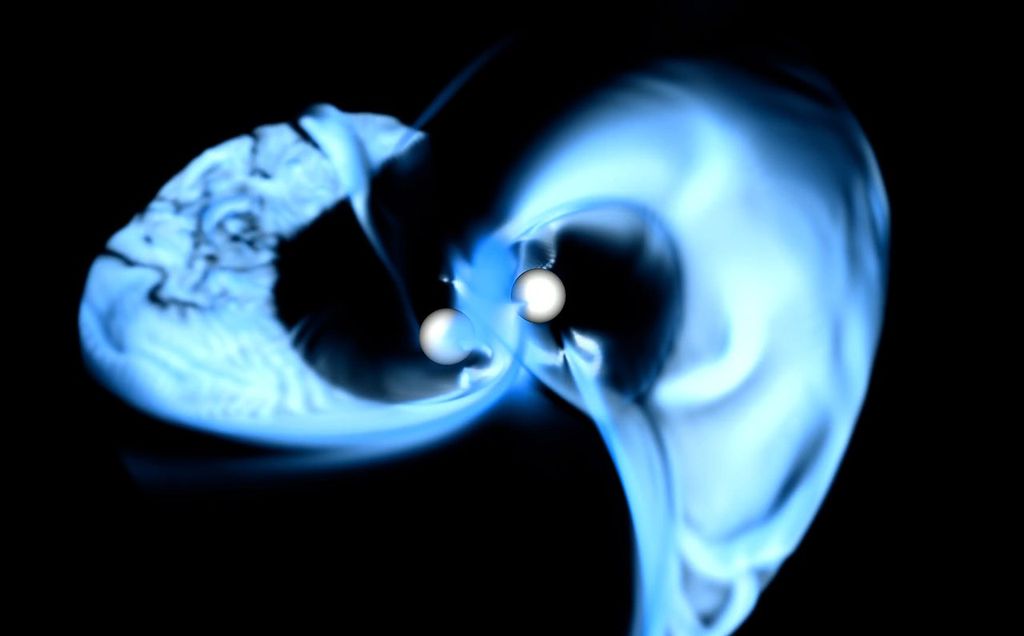

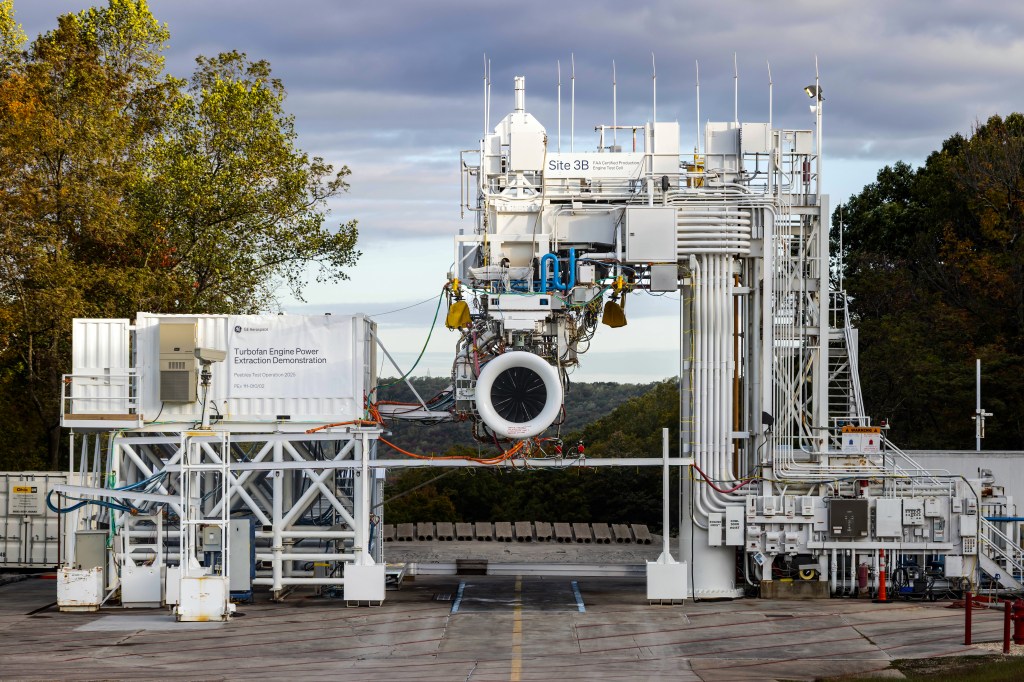

Rotor Collision Example

In this tutorial, the Snap-To feature is used to demonstrate how a model may be queried for component collision in a “real-world” application such as rotor strike. The demonstration shows how a seemingly small change to a model parameter, from a certain orientation, can have a significant impact on the aircraft. Snap-To can be a very powerful tool for checking a model for impact and clearance.