The Zero Gravity Research Facility is NASA’s premier facility for ground-based microgravity research and the largest facility of its kind in the world. It provides researchers with a near-weightless environment for a duration of 5.18 seconds.

Facility Overview

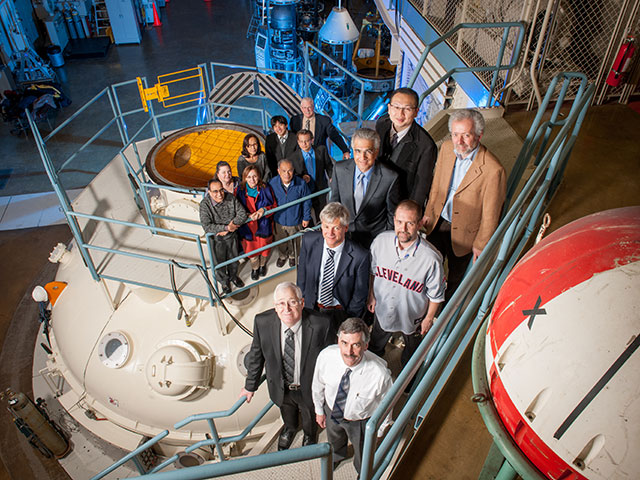

The Zero Gravity Research Facility is NASA’s premier facility for ground-based microgravity research and the largest facility of its kind in the world. The facility is one of two drop towers located at NASA’s Glenn Research Center in Cleveland and has been operational since 1966. It was originally designed and built during the space race era of the 1960s to support research and development of spaceflight components and fluid systems in a weightless or microgravity environment. The facility is currently used by NASA-funded researchers from around the world to study the effects of microgravity on physical phenomena such as combustion and fluid physics, to develop and demonstrate new technology for future space missions, and to develop and test experiment hardware designed for flight aboard the International Space Station or future spacecraft.

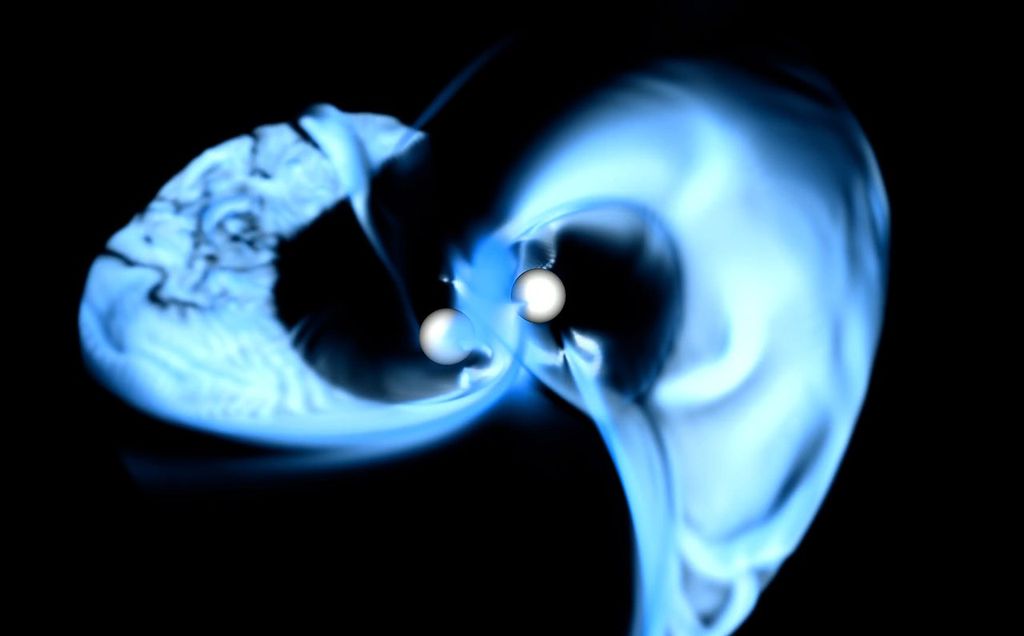

The Zero Gravity Research Facility provides researchers with a near-weightless or microgravity environment for a duration of 5.18 seconds. Microgravity, which is the condition of relative near weightlessness, can only be achieved on Earth by putting an object in a state of free fall. NASA conducts microgravity experiments on Earth using drops towers and aircraft flying parabolic trajectories. Allowing the experiment hardware to free fall a distance of 432 feet (132 meters) creates the microgravity environment at the facility.

The free fall is conducted inside of a 467-foot- (142-meter-) long steel vacuum chamber. The chamber is 20 feet (6.1 meters) in diameter and resides inside of a 28.5-foot- (8.7-meter-) diameter concrete lined shaft, which extends 510 feet (155 meters) below ground level. A five-stage vacuum pumping process is used to reduce the pressure in the chamber to a pressure of 0.05 torr (760 torr = standard atmospheric pressure). Evacuating the chamber to this pressure reduces the aerodynamic drag on the freely falling experiment vehicle to less than 0.00001 g. To prepare for a drop, an overhead crane is used to position the experiment vehicle and release mechanism at the top of the vacuum chamber. Once in position, the drop vehicle is connected to the facility control room via an umbilical cable.

This cable allows the experiment to be monitored and controlled from the control room until the release sequence is initialized. It takes approximately one hour to evacuate the vacuum chamber. Once the chamber is evacuated, the release sequence is initiated. Remotely fracturing a specially designed bolt allows the experiment to begin its 132-meter free fall. During the drop, the experiment operates autonomously with all experiment power, data acquisition, and control functions located on the freely falling experiment vehicle.

After falling for just over 5 seconds, the experiment vehicle is stopped in the decelerator cart, located at the bottom of the chamber. The decelerator cart is 11 feet (3.3 meters) in diameter and nearly 20 feet (6.1 meters) deep. It is filled with 1/8” (3 mm) diameter expanded polystyrene beads. These beads dissipate the kinetic energy of the 2,500-pound experiment vehicle, which is traveling at about 113 mph (50.5 m/s) when it enters the decelerator cart. The experiment vehicle is stopped in about 15 feet (4.6 meters) of expanded polystyrene and experiences a peak deceleration rate approaching 65g.

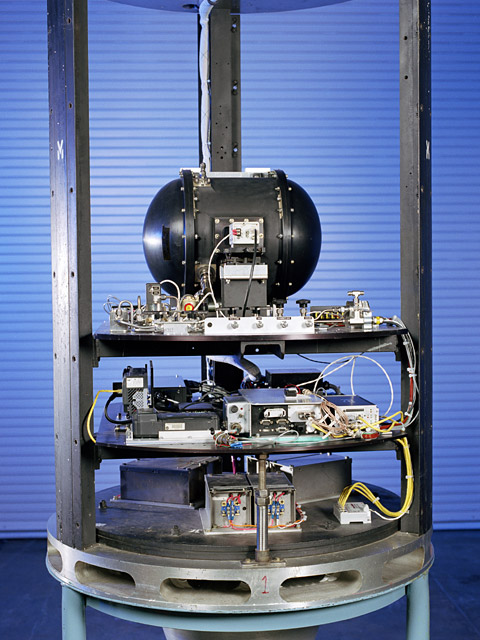

The experiment drop vehicle serves as a load bearing structure and protects the experiment hardware from the shock loads experienced during the deceleration. The typical drop vehicle used is cylindrical in shape. It is 42 inches (1 meter) in diameter and has an overall length of 13 feet (4.0 meters). The drop vehicle gross weight is limited to a maximum of 2,500 pounds (1,130 kg).

Quick Facts

- Take a virtual tour of our Zero Gravity Research Facility.

- Watch the video on Zero G: Where microgravity research is conducted at the 5.2 second drop tower at NASA Glenn Research Center.

- The Zero Gravity Research Facility provides a near-weightless or microgravity environment for a duration of 5.18 seconds. This is accomplished by allowing the experiment vehicle to free fall, in a vacuum, a distance of 432 feet (132 meters). The facility can provide a microgravity test environment for a fraction of the cost of conducting an experiment in space and provides the best gravity levels of any of NASA’s ground-based low-gravity facilities.

- Experimental drop vehicles used in the facility can accommodate payloads up to 1,000 pounds (455 kg).

- The free fall is conducted inside of a 467-foot- (142-meter-) long steel vacuum chamber. Chamber pressure is reduced to 0.05 torr (760 torr = standard atmospheric pressure).

- The Zero Gravity Research Facility was originally designed and built during the space race era of the 1960s to support research and development of spaceflight components and fluid systems in a weightless environment.

- Microgravity, which is the condition of relative near weightlessness, can only be achieved on Earth by putting an object in a state of free fall. NASA conducts microgravity experiments on Earth using drops towers and aircraft flying parabolic trajectories.

| Operational Parameters | |

|---|---|

| Microgravity Duration | 5.18 seconds |

| Free Fall Distance | 432 feet (132 m) |

| Gravitational Acceleration | <0.00001 g |

| Mean Deceleration | 35 g |

| Peak Deceleration | 65 g |

| Vacuum Level | 0.05 torr |

| Experimental Drop Vehicles | |

|---|---|

| Cylindrical, 42 in. (1 m) diameter by 13 feet (4 meters) tall | |

| 7 Available Drop Vehicles | |

| Gross Vehicle Weight | 2500 lbs. (1130 kg) |

| Experimental Payload Weight | up to 1000 lbs. (455 kg) |

| Experimental Payload Diameter | up to 38 in. (.97 m) in diameter |

| Experimental Payload Height | up to 66 in. (1.6 m) tall |

Capabilities

Operational Parameters

- Microgravity duration: 5.18 seconds

- Free fall distance: 432 feet (132 m)

- Gravitational acceleration: <0.00001 g, best gravity levels

of any of NASA’s ground-based microgravity facilities

- Mean deceleration: 35 g

- Peak deceleration: 65 g

- Vacuum level: 0.05 torr

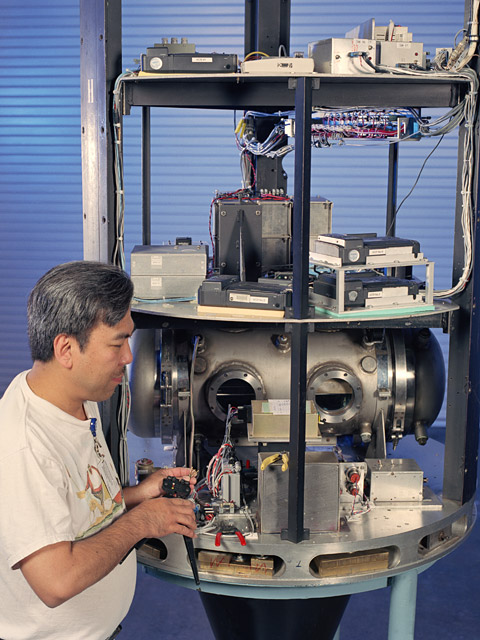

Experimental Drop Vehicle

- Diameter: 42 in. (1 m)

- Total height: 13 feet (4 m)

- Gross vehicle weight: 2,500 lbs. (1130 kg)

- Payload diameter: up to 38 in. (.97 m)

- Payload height: up to 66 in. (1.6 m)

- Payload weight: up to 1,000 lbs (455 kg)

- Seven available drop vehicles

Instrumentation/Data Acquisition

- Video cameras, analog and digital recording capabilities

- Analog-digital data acquisition, 32 channels

- 24 VDC battery power

- Programmable logic controller

- Pressure transducers

- Flow meters

- Thermocouples

- Radiometers

- Lasers

Mode of Operation

- Provides a microgravity test environment for a fraction of the cost of conducting an experiment in space

- Can accommodate NASA, government, and private industry research programs

- Two drops per day

- Engineering staff to perform or consult on payload design

- Technical staff to perform electrical and mechanical integration of payloads and drop preparations

- Third-party safety review of experiments is required

Contact

Zero Gravity Research Facility

Facility Manager: Ernest Williams

216-433-3554

Ernest.T.Williamsii@nasa.gov

Test Facility Management Branch

Acting Chief: Tony Doglio

216-433-2402

James.A.Doglio@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center in Cleveland provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

/Hubble%20Space%20Telescope%20(A).png)