It may be cold in upstate New York, but NASA engineers are turning up the temperature in Buffalo for a series of tests that will provide critical data on the heating conditions at the base of NASA’s new rocket, the Space Launch System (SLS).

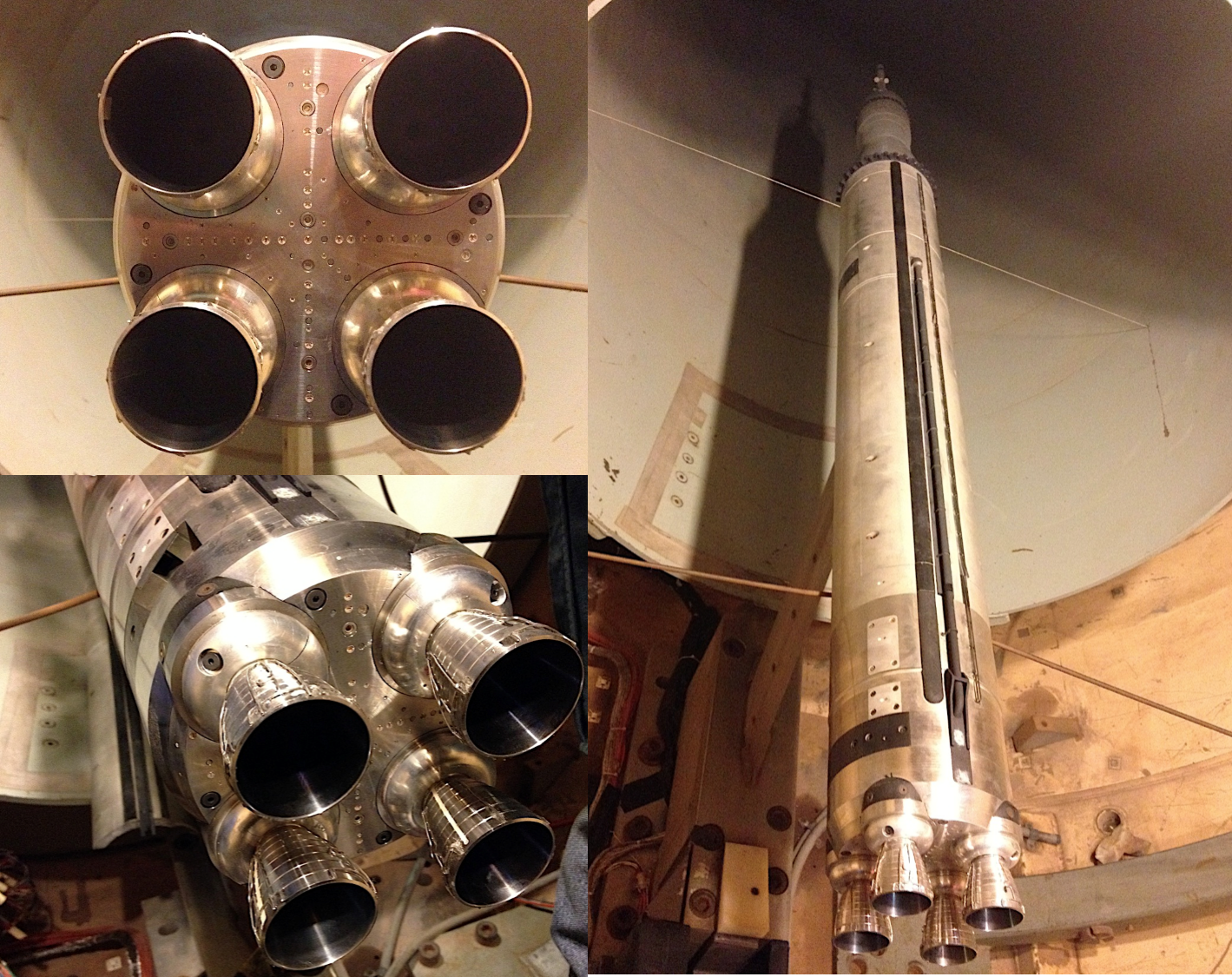

A team of engineers at NASA’s Marshall Space Flight Center in Huntsville, Alabama, is working in close collaboration with CUBRC Inc. of Buffalo to design, build and test 2-percent scale models of the SLS propulsion system. That includes two five-segment solid rocket boosters and four core stage RS-25 engines, and a 2 percent, or 6.5-foot-tall, scale model of the entire rocket. The models are fired for short durations — around 50-150 milliseconds per test.

SLS will be the most powerful rocket ever built for deep space missions, including to an asteroid and eventually Mars.

“There’s a lot of complex work that goes in to such a short-duration test,” said Manish Mehta, lead engineer for the SLS Base Heating Test Program at Marshall, where the SLS Program is managed for the agency. “The timing of the propulsion systems and shock tunnel have to be precise. Although this test program has been technically challenging, there’s no heritage data that we can fall back on to predict SLS base environments because this vehicle has never been flown before.

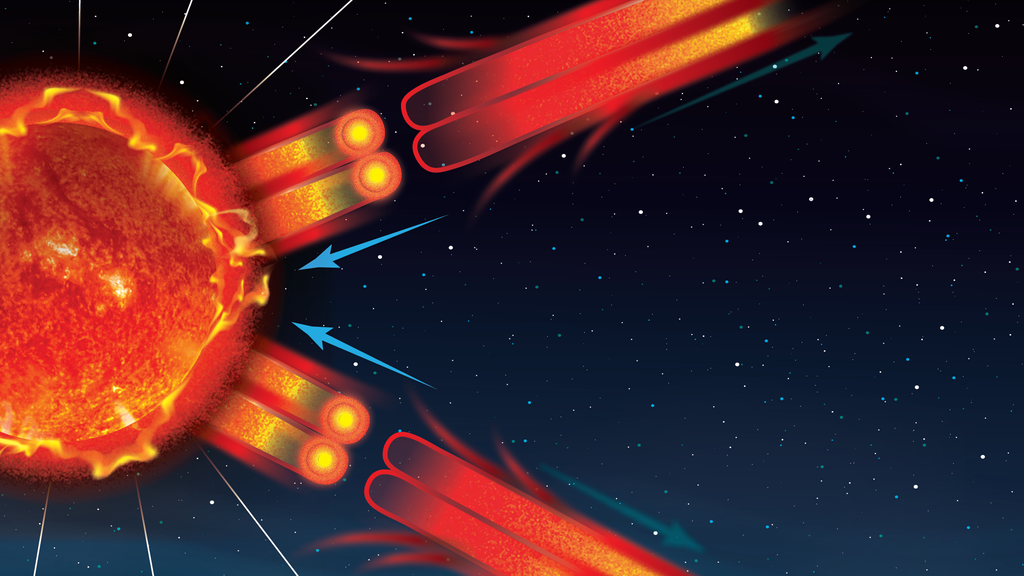

“There are four engines and two booster rocket plumes that are firing into the base,” he said. “This results in highly complex flow physics, which is not something you can develop analytically and predict very accurately.”

Testing of the mini models will provide data on the convective heating environments the base of the rocket will experience upon ascent for both planned and unplanned flight conditions. Data from the test series will be used to verify flight hardware design environments and set specifications for the design of the rocket’s base thermal protection system. The system keeps major hardware, wiring and crews on future missions safe from the extreme heat the boosters and engines create while burning during ascent.

Testing for the core stage in normal ascent scenarios was completed first, followed by testing with the entire SLS model in early January. The full-stack configuration has 200 heat flux and pressure sensors within the aft section of the rocket to collect data on the base flow environment. More than 30 test cases have been performed, with about 85 total scheduled for the entire test series. The testing is planned to conclude early this summer.

The test program uses new technology that wasn’t available during past human spaceflight programs, such as high-speed visible light and infrared cameras, laser diagnostics and new designs of the model propulsion systems that more adequately simulate the SLS full-scale systems.

“It’s great to be working on hardware and stretching our engineering skills on coming up with solutions to technical issues we’ve experienced along the way,” said Mehta. “I think we’ve done well.”

The models took about a year and a half to design and build to flight specifications and performance. For the test series, which began in August 2014, the replicas are loaded with propellant, pressurized with hydrogen and oxygen lines and ignited in one of CUBRC’s shock tunnels. The shock tunnel replicates both supersonic and hypersonic flight conditions, matching what the rocket’s environment will be like during ascent, including temperature, pressure and velocity.

“We like to say we’re duplicating a flight test on the ground,” said Aaron Dufrene, technical lead at CUBRC. “What’s great about the design of these models is we can run them dozens, even hundreds, of times and reuse most all of the hardware every single time.”

“That’s why NASA historically started doing this short-duration testing technique,” added Mark Seaford, a Marshall engineer who works on the test project. “Since you are testing at a much smaller scale, in this case 2 percent, the heating goes up at the throat of the nozzles. We can’t run it for a substantial length of time or the hardware would be compromised under the heat. We really had to challenge ourselves in the design process to get the right materials to minimize that risk.”

The first flight test of the SLS will feature a configuration for a 70-metric-ton (77-ton) lift capacity and carry an uncrewed Orion spacecraft beyond low-Earth orbit to test the performance of the integrated system. As the SLS evolves, it will provide an unprecedented lift capability of 130 metric tons (143 tons) to enable missions even farther into our solar system.

For more information on SLS, visit: