Image above: The refurbishment of the Vehicle Assembly will include removing seven Apollo-era platforms from High Bay 3 and replacing them with modern versions that can adapt to different kinds of rockets. Photo credit: NASA/Jim Grossmann

Image above: The refurbishment of the Vehicle Assembly will include removing seven Apollo-era platforms from High Bay 3 and replacing them with modern versions that can adapt to different kinds of rockets. Photo credit: NASA/Jim Grossmann

› Larger image

Image above: A closer look at the huge platforms that will be removed from the VAB’s High Bay 3. This one was taken out to make room for the Ares I-X vehicle ahead of its flight test in 2009. Photo credit: NASA

Image above: A closer look at the huge platforms that will be removed from the VAB’s High Bay 3. This one was taken out to make room for the Ares I-X vehicle ahead of its flight test in 2009. Photo credit: NASA

› Larger image

Image above: Workers pull large bundles of cable from inside the VAB to make room for new lines, including much smaller fiber-optic infrastructure. More than 50 miles of cabling will be taken out during the work. Photo credit: NASA/Jim Grossmann

Image above: Workers pull large bundles of cable from inside the VAB to make room for new lines, including much smaller fiber-optic infrastructure. More than 50 miles of cabling will be taken out during the work. Photo credit: NASA/Jim Grossmann

› Larger image

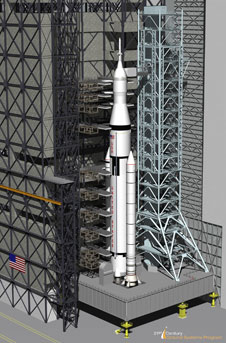

Image above: A look at the future of the VAB, with High Bay 3 outfitted to stack and process the Space Launch System for deep space missions. Concept credit: NASA

Image above: A look at the future of the VAB, with High Bay 3 outfitted to stack and process the Space Launch System for deep space missions. Concept credit: NASA

› Larger image The Vehicle Assembly Building at NASA’s Kennedy Space Center in Florida has been a landmark to the technological advancements of sending men to the moon and astronauts into space for more than 45 years. But the VAB, as it is best known, is due for major renovations to continue processing launch vehicles and support the subsequent launching of a new generation of astronauts into orbit and deeper into space than ever before.

“This is home improvement, VAB style,” said Jose Lopez, who is managing the effort to refurbish a structure that was once the biggest in the world. “We’re going for more flexibility and reliability with modern equipment. That building has many systems that haven’t been touched up since it was built (in 1965).”

Although the work is massive simply because of the scale of the VAB, Lopez said now is the time to do it and take advantage of the pause in rocket processing that is to end in a couple years.

“When the shuttle program was in place, you couldn’t take down the cranes for a long period of time, or take on heavy infrastructure projects,” Lopez said.

Before another generation of rocket processing kicks in, Lopez said, the VAB must be outfitted with everything it needs to host these rockets and spacecraft assembly for another 40 years.

The effort will touch most areas of the architectural behemoth in one way or other. For instance, High Bay 3 will see the seven work platforms designed for the Apollo/Saturn V removed. In their place will be a series of 10 platforms that can be relocated and fitted with inserts designed for processing different kinds of rockets.

Like everything else inside the VAB, the platforms are not run-of-the-mill items. They are expected to weigh about 90,000 pounds and be outfitted with commodities essential for rockets, such as nitrogen and helium along with electrical and networking cables.

Simply put, no longer will a high bay be suitable for only one kind of rocket design.

“If you can fit in the big rocket, you can definitely fit in the smaller rockets,” Lopez said.

The VAB is slated to host NASA’s Space Launch System, or SLS, as it is readied for test flights in 2017 and 2021. The SLS will rival the Saturn V for sheer size and power and is designed for several variations that the platforms would have to accommodate. Commercial companies with much smaller rockets also are expected to use the VAB’s unique facilities.

“The main thing we’re doing there is an evolvable approach where we can handle any one of these SLS vehicles, but also handle any of the commercial vehicles,” said Scott Colloredo, chief architect of the Ground Systems Development and Operations Program that is overseeing the VAB modifications. “By supporting one, it helps us to support the other.”

The five primary overhead cranes in the VAB will see their antiquated control systems modernized, too. The cranes, anchored to the VAB’s framework at the top of the structure, were used to lift the shuttles and rocket stages from the floor of the transfer aisle to their place on the launch platforms. They routinely hoisted the 100-ton shuttles more than 16 stories off the ground safely and lowered them onto the side of the external fuel tank for launch.

Two of the cranes can lift 325 tons, another two are rated for 250-ton loads and the fifth one is designed to hold 175 tons. They will be crucial again in the future to stack the SLS components into a launch configuration.

The doors, the largest in the world, are due for new braking systems and other modifications that will reduce wear-and-tear on the tracks and systems.

The renovation calls for removing a great deal of the infrastructure inside the VAB, some of which was installed when the structure was built in 1965. New systems, all up to modern building and safety codes, are to be installed.

More than 150 miles of Apollo-era cabling will be removed during the work and replaced with modern lines. About 70,000 feet of cabling already has come out. In some cases, that means replacing thick bundles of copper wiring with a few fiber-optic lines no wider than a pinky finger.

The fire suppression system has corroded in many important areas and is not big enough under current regulations. So its vast network of pipes, spigots and pumps, will be taken out entirely beginning next year and replaced with new equipment and piping. The work should be finished by the end of 2014, Lopez said.

There is plenty of evidence that other water and drainage pipes in the VAB are also corroding, so they will be replaced, along with boilers and chillers that feed hot and cold water into the facility.

Battery backups for the electrical system also are slated for replacement.

The renovation is focusing on the building interior systems, but the building itself is in very good shape.

The work would have had to be done at some point soon whether rockets were being processed or not, Lopez said. Doing it all while keeping the structure’s systems up and able to handle normal processing demands would have been an exceptional and expensive challenge, though.

“It would have been like putting a new car engine in your trunk while keeping the same engine in the front still going,” Lopez said.

6 min read