In This Week’s Star

- NASA Conducts Test of SLS Rocket Core Stage for Artemis I Moon Mission

- Marshall Team Members Recognized With Demo-2 Agency Honor Awards

- New NASA Challenge Offers Prizes for Sprouting Astronaut Food Systems

- 22 Teams Crack Code, Qualify for Final Stage of NASA Space Robotics

- Artemis Generation Students Design 3D-Printed Launch, Landing Pad for Lunar Missions

- A Fanfare for Uncommon Men, Women: Marshall, SpaceX Teams Celebrate Engines of Success

- Marshall 2020 Year in Review

- On the Hunt for a Missing Giant Black Hole

- Starting the New Year With Wellbeing: A Message From Employee Assistance Program Coordinator Terry Sterry

- This Week in NASA History: Saturn I, S-I Stage Build-up – Jan. 18, 1961

NASA Conducts Test of SLS Rocket Core Stage for Artemis I Moon Mission

NASA conducted a hot fire test of the core stage for the agency’s Space Launch System rocket at NASA’s Stennis Space Center on Jan. 16. The hot fire is the last test of the Green Run test series for the core stage.

The test plan called for the rocket’s four RS-25 engines to fire for a little more than eight minutes, the same amount of time it will take to send the rocket to space following each Artemis mission launch. The test team successfully completed the countdown and ignited the engines at 4:27 p.m. CST, but the engines shut down a little more than one minute into the hot fire.

In that 67.2-second period, the stage generated 1.6 million pounds of thrust, and test teams loaded more than 733,000 gallons of liquid oxygen and liquid hydrogen into the stage’s two immense tanks to ignite the engines.

“Saturday’s test was an important step forward to ensure the core stage of the SLS rocket is ready for the Artemis I mission and to carry crew on future missions,” said NASA Administrator Jim Bridenstine, who attended the test. “Although the engines did not fire for the full duration, the team successfully worked through the countdown, ignited the engines, and gained valuable data to inform our path forward.”

Test teams reported on Jan. 19 that initial data and preliminary inspections indicated the rocket hardware is in excellent condition following the test. The team determined the early engine shutdown was triggered by test parameters that were intentionally conservative to ensure the safety of the core stage during the test.

The preprogrammed parameters are designed specifically for ground testing of the Artemis I flight hardware to ensure the core stage’s thrust vector control system safely moves the engines. There is a thrust vector control system that gimbals, or pivots, each engine, and there are two actuators that generate the forces to gimbal each engine. The actuators in the thrust vector control system are powered by Core Stage Auxiliary Power Units. As planned, the thrust vector control systems gimbaled the engines to simulate how they move to direct thrust during the rocket’s ascent during flight.

“Seeing all four engines ignite for the first time during the core stage hot fire test was a big milestone for the Space Launch System team,” said John Honeycutt, SLS program manager at NASA’s Marshall Space Flight Center. “We will analyze the data, and what we learned from the test will help us plan the right path forward for verifying this new core stage is ready for flight on the Artemis I mission.”

Data analysis is continuing to help the team determine if a second hot fire test is required. The team can make slight adjustments to the thrust vector control parameters and prevent and automatic shutdown if they decide to conduct another test with the core stage mounted in the B-2 Test Stand at Stennis.

For the latest on Green Run, visit the Artemis blog.

Marshall Team Members Recognized With Demo-2 Agency Honor Awards

Jody Singer, director of NASA’s Marshall Space Flight Center, addresses awardees during the virtual Demo-2 Agency Honor Awards Ceremony on Jan. 7. “Our people, you, are the most important part of what we do,” she said. “The folks we are celebrating today are exceptional members of our team.” More than 200 Marshall civil servants, contractors, and teams were recognized for their contributions to the historic mission, which successfully launched the Falcon 9 rocket carrying NASA astronauts Robert Behnken and Douglas Hurley aboard SpaceX’s Crew Dragon spacecraft from the agency’s Kennedy Space Center on May 30, 2020. “Your extraordinary achievements from the beginning of the program through the successful launch of the Demo-2 mission, including the Crew-1 mission, have paved the way for a new era in human exploration,” Singer said. See a full list of winners here. (NASA)

New NASA Challenge Offers Prizes for Sprouting Astronaut Food Systems

By Amanda M. Adams

Astronauts need hearty nutrients to maintain a healthy diet in space, but like anyone, they want their food to taste good, too! As NASA develops concepts for longer crewed missions to Mars and beyond, the agency will need innovative and sustainable food systems that check all the boxes.

In coordination with the Canadian Space Agency, NASA has opened the Deep Space Food Challenge, a NASA Centennial Challenge managed within the Space Technology Office at NASA’s Marshall Space Flight Center. The goal is to generate novel food production technologies or systems that require minimal resources and produce minimal waste, while providing safe, nutritious, and tasty food for long-duration human exploration missions.

“We are excited to coordinate with the Canadian Space Agency to conduct this challenge and push the boundaries of food technology production that will help keep our future explorers healthy, knowing that some of these technologies could also have great terrestrial applications,” said Jim Reuter, associate administrator for NASA’s Space Technology Mission Directorate at the agency’s headquarters.

Advanced food systems will have benefits on Earth, too. Solutions from this challenge could enable new avenues for food production around the world, especially in extreme environments, resource-scarce regions, and in new places like urban areas and in locations where disasters disrupt critical infrastructure.

“With the Deep Space Food Challenge, we are asking Canadians to find innovative ways to produce food in deep space that could also help those living in remote regions with harsh environments, such as Canada’s northern communities,” said Lisa Campbell, president of the Canadian Space Agency. “Together with our partners, we are leading on space innovations that will also improve the lives of Canadians.”

Interested participants from the United States can compete for part of a prize purse of up to $500,000 from NASA in Phase 1 of the competition by designing food systems that can provide adequate nutrition for future long-duration mission explorers. Depending on the technologies presented, a possible second phase, involving a kitchen demonstration, could follow. The Canadian Space Agency will host a parallel competition with a separate application and judging process, as well as its own prize purse, for participating Canadian teams. Qualifying teams from other countries may compete but will not be eligible for monetary prizes.

“We need to provide food that meets the caloric and nutritional requirements for our astronauts, but we want to go a step further,” said Grace Douglas, subject matter expert for the challenge and advanced food technology lead scientist at NASA’s Johnson Space Center. “The variety, acceptability, and nutritional content of the food system has the potential to go beyond just sustaining the human body to promote psychological and physiological health. Additionally, preparing food must be easy enough that it will not detract from the astronauts’ primary mission of research and exploration.

To learn more about the challenge, visit the official webpage, here. Participants interested in competing in the challenge must register by May 28, 2021.

Adams, an LSINC Corporation employee, supports Marshall’s Office of Strategic Analysis & Communications.

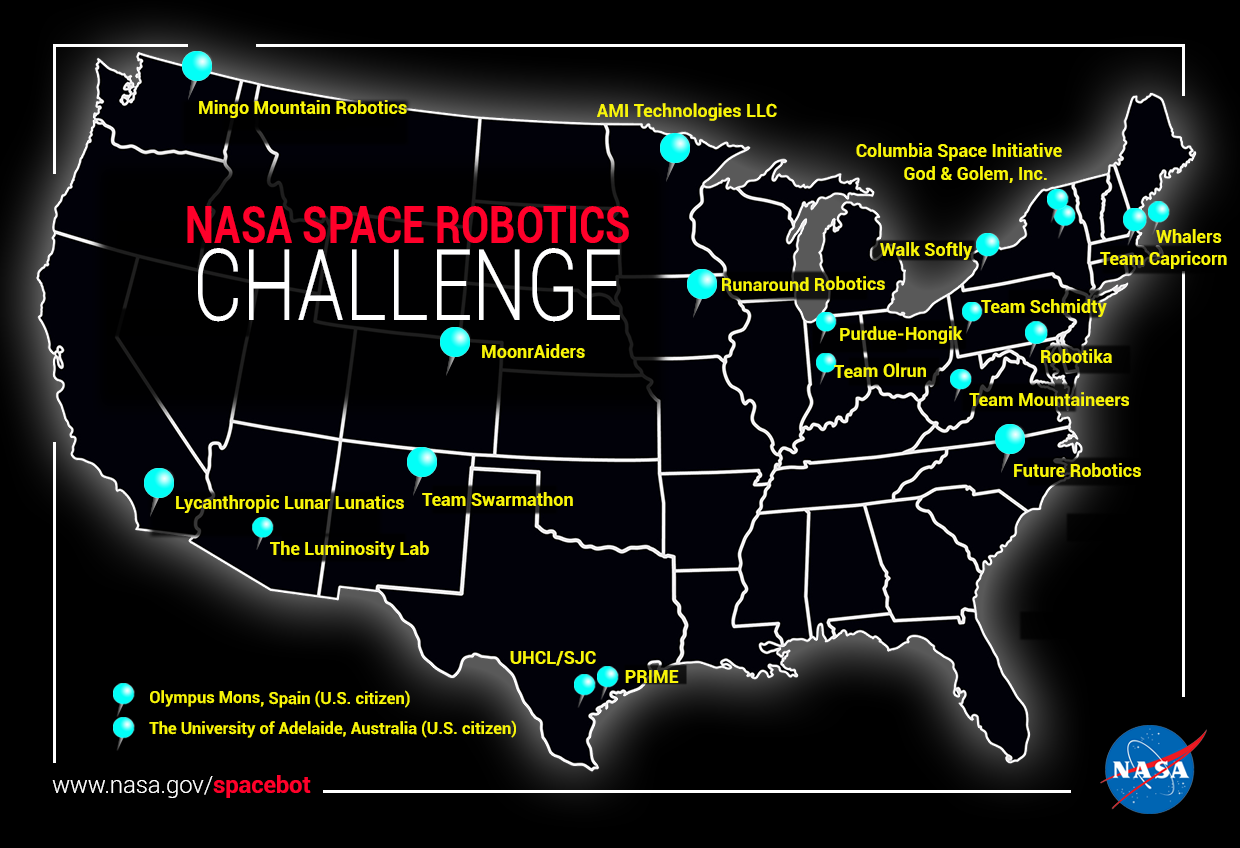

22 Teams Crack Code, Qualify for Final Stage of NASA Space Robotics

By Amanda M. Adams

NASA, in partnership with Space Center Houston – the official visitor center of NASA’s Johnson Space Center– has selected 22 qualifying teams to compete in the competition round of Phase 2 of the Space Robotics Challenge. Eligible teams will advance to the final virtual competition round, which will begin in late January.

Phase 2 of the Space Robotics Challenge, a NASA Centennial Challenge, is a $1 million prize competition to advance autonomous robotic operations for space exploration missions on the surface of other worlds, such as the Moon and Mars. While many of NASA’s planetary surface robotic systems already have some autonomous capabilities that can fulfill a desired concept of operations, the agency envisions a future when humans and robots are working and living together on other worlds.

For the qualification round of the challenge, teams were asked to submit solutions for three tasks demonstrating autonomous operations of robotic systems in a virtual lunar environment. These complicated tasks focused on in-situ resource utilization and included identifying, collecting, and returning resources to a lunar processing plant.

Teams were awarded prize money based on their score and number of tasks completed. Out of 114 registered teams, 22 teams successfully addressed the NASA needs and submitted qualifying entries, allowing them to move on to the final competition round.

“We are excited with the effort that these 22 teams have put into the challenge,” said Kimberly Hambuchen, Robotic Systems Technology Branch chief at Johnson. “This challenge was no easy task – we intentionally made it very difficult to complete. Even in the midst of a global pandemic, the exemplary work of these teams could enhance future Artemis missions relying on the use of lunar resources. We look forward to seeing how they advance their software submissions for the final round of competition.”

Six teams completed the three tasks or met the threshold score for the maximum award of $15,000:

- Olympus Mons, Barcelona, Spain (U.S. Citizen)

- Robotika, Annapolis, Maryland

- Runaround Robots, Cedar Falls, Iowa

- Team Capricorn, Worcester Polytechnic Institute, Worcester, Massachusetts

- Team Mountaineers, West Virginia University, Morgantown

- Walk Softly, Niskayuna, New York

One team completed two tasks and qualified for a $10,000 award:

- Mingo Mountain Robotics, Kettle Falls, Washington

Nine teams completed one task and qualified for a $5,000 award:

- AMI Technologies LLC, Edina, Minnesota

- Future Robotics, Franklin, North Carolina

- God & Golem, Inc., New York

- Lycanthropic Lunar Lunatics, Ramona, California

- MoonrAlders, Johnstown, Colorado

- Team Swarmathon, University of New Mexico, Albuquerque

- The University of Adelaide, Australia (U.S. Citizen)

- UHCL/SJC, University of Houston – Clear Lake and San Jacinto College, Texas

- Whalers, Nantucket, Massachusetts

Six additional teams qualified to compete in the competition round:

- Columbia Space Initiative, New York

- Team Schmidty, Bridgeville, Pennsylvania

- The Luminosity Lab, Tempe, Arizona

- Team Olrun, Evansville, Indiana

- PRIME, Cypress, Texas

- Purdue-Hongik Team, West Lafayette, Indiana

The competition round will require participants to develop fully autonomous operations, navigation, and decision-making capabilities that will be tested on multi-unit planetary robotic systems within a simulated lunar environment. The top 10 scoring competitors in the competition round will be awarded prizes from a pool of $625,000. Prizes will be awarded to competitors that meet or exceed a given threshold score.

Phase 1 of the challenge concluded in June 2017 and focused on NASA’s R5 humanoid robot operating in a virtual Mars environment. It consisted of two challenge rounds and tasked competitors with advancing the capabilities of humanoid robot dexterity to better enable robots to work alongside, and independent of, astronauts.

The Space Robotics Challenge is supported by subject matter experts at Johnson. Centennial Challenges are part of the Prizes, Challenges, and Crowdsourcing program within NASA’s Space Technology Mission Directorate and are managed at NASA’s Marshall Space Flight Center. Space Center Houston is working with NASA to manage the challenge competitors. The challenge is a part of Space Center Houston’s Innovation Gateway community science initiative. This program empowers the public with authentic learning experiences that contribute to real scientific research.

For information about the Space Robotics Challenge, visit here.

Adams, an LSINC Corporation employee, supports Marshall’s Office of Strategic Analysis & Communications.

Artemis Generation Students Design 3D-Printed Launch, Landing Pad for Lunar Missions

By Will Bryan

When it comes to the future of space exploration, it is only fitting that the next generation of engineers and scientists play a vital role in imagining that future. A team of undergraduate students from 10 colleges and universities across the United States – members of the Artemis Generation – are turning their creative ideas into reality. They designed a reusable landing pad that could be 3D printed from materials found on the Moon.

The novel concept – called the Lunar Plume Alleviation Device, or Lunar PAD – focuses on solving the problems caused when the force of an engine’s powerful exhaust meets the dusty lunar surface. The design features a series of petal-like channels that send exhaust upward and outward, minimizing the amount of dust lofted during launch and landing. The student team presented a paper on the Lunar PAD concept Jan. 12 at the American Institute of Aeronautics and Astronautics’ 2021 SciTech Forum.

“When you look at this publication, the diversity of students and schools is very unique,” said John Dankanich, chief technologist at NASA’s Marshall Space Flight Center. “There is a clear advantage in engaging a wide range of diverse teams to develop innovative solutions that address NASA technology gaps.”

The students first proposed their landing pad solution during the summer 2019 NASA Proposal Writing and Evaluation Experience – a 12-week training course crafted by Dankanich to expand and diversify the pool of high-quality, selectable proposals for new concepts and technologies that meet NASA’s needs. Their top-ranking proposal won funding and support from NASA subject matter experts to mature the concept, called Dust DEVILS at the time. In June 2020, the team again presented to Marshall experts at a virtual Design Readiness Review and secured funding to print and test a subscale version of the pad.

“The proposal addressed a technology pain point, as the project enables a safe and reusable landing pad required for sustainable lunar exploration,” Dankanich said. “The team worked many hundreds of hours, engaged NASA subject matter experts, and went from concept formulation to a preliminary design. They then turned that design into reality with the subscale construction, all in a few short months.”

The pad is comprised of essentially two layers. A “roof” where a rocket launches from or lands on, and a series of channels below that to safely redirect the exhaust. Slits in the roof allow exhaust from rockets to travel into the carefully designed channels that direct the exhaust flow to the edge of the launch pad where it exits through specialized vents. A central cone and dividers support the weight of the rocket and pad roof. A wall surrounds the structure, capturing any lunar dust particles that become mobilized during a launch or landing.

To test the complex design and its ability to be 3D-printed, the team is working with experts from Marshall’s Moon-to-Mars Planetary Autonomous Construction Technologies project, or MMPACT. They built a subscale prototype pad at Camp Swift in Bastrop, Texas, from Oct. 16-20 using a cement-based material and a gantry print system developed by ICON, an Austin, Texas-based construction technologies company and MMPACT partner.

Dankanich described Mike Fiske, an MMPACT project lead, as “one of his heroes, for not just mentoring the Lunar PAD team, but truly making them a part of the NASA team.” Fiske coordinated with NASA subject matter experts and other government, industry, and academic partners in support of the project.

“It has been a pleasure working with these students over the last year and helping to advance the state of the art in planetary launch and landing pads,” said Fiske, an in-space manufacturing engineer with Jacobs Engineering Group Inc. in Marshall’s Space Technology Development Branch.

Fiske and the Lunar PAD team are tentatively planning a return to Camp Swift in late February, to see how their prototype holds up under the extreme high-temperatures and stresses created by a rocket engine. Instrumentation to measure temperature, strain, and exhaust flow behavior was integrated into the pad during printing. The Sounding Rocketry Team at Texas A&M University in College Station will assist with hot fire testing.

In addition to the hot fire test, material samples will be evaluated through partnerships with MMPACT, NASA’s White Sands Test Facility, and the University of Alabama in Huntsville. The tests will help the team make adjustments for a possible future full-scale prototype.

Bryan, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

A Fanfare for Uncommon Men, Women: Marshall, SpaceX Teams Celebrate Engines of Success

By Rick Smith

When the big ring of nine Merlin engines on the Falcon 9 rocket rumbled to life, propelling NASA’s SpaceX Crew-1 spacecraft and its occupants to their historic rendezvous with the International Space Station, most spectators were watching for the customary bloom of smoke and fire.

Steve Gaddis, NASA’s Marshall Space Flight Center lead for the agency’s Commercial Crew Program, and his team were also listening, anticipating the musical sound of success. At 6:27 p.m. on Nov. 15, 2020, they heard it.

SpaceX and NASA test engineers at Marshall spent months reviewing data from Merlin engine tests performed at the SpaceX test facility in McGregor, Texas, prior to delivery to NASA’s Kennedy Space Center for the launch. It’s teamwork Marshall knows well; workers there developed the most powerful engines ever built, from the Apollo and space shuttle eras through today’s mighty Space Launch System engines.

“We conduct critical design reviews for all elements, components, and subsystems of the engines our commercial partners use to propel their rockets,” said Gaddis, who is also deputy manager of the program’s Launch Vehicle Systems Office at Marshall.

He compared the task to a symphony orchestra rehearsing for a big performance. Each test engineer on the team is a virtuoso, he suggested, a subject matter expert – and mastering a new engine is like playing a new work by a master composer.

“We have the A-team here,” he said, “from our vehicle and systems engineers to subject matter experts in turbopump design, rotordynamics, structural resonance, flow-induced vibration, materials and processes, the whole nine yards.”

But it’s not enough to perform flawlessly in one’s own area. Each contributor has to play in sync with all the rest. “Our team identifies even the most minute performance issues and brings recommended safety and reliability solutions back to the whole team – which tweaks interrelated components and refines the design as needed,” Gaddis said.

Even small changes to one component can have ripple effects, fundamentally changing design and safety specifications across the entire engine. Change one note and the whole composition has to be reconsidered.

“Everyone plays their part,” said Mark Darden, a Marshall engineer who specializes in rotordynamic analysis. “The work, when it’s most successful, is a grand compromise, a give-and-take approach to find balance.”

It all comes down to vibration and stability. “These are massively intricate machines, each with precise vibration characteristics,” he said.

Fellow Marshall dynamics engineer Tony Fiorucci agreed. “Even the slightest imbalance or vibration outside margins can be catastrophic, hence the rigor of testing and analysis,” he said.

It is fitting that such checkout work is performed at Marshall. At the turn of the century, engine designers there sought to deliver Fastrac, an innovative turbopump rocket engine that would offer NASA and its partners an alternative to the space shuttle main engine, then the workhorse of the agency’s shuttle fleet. The Fastrac program was shuttered in 2001, but SpaceX leveraged much of the design and technology to aid development of its original Merlin 1A engine.

Darden and Fiorucci, colleagues at Marshall for more than three decades, are quick to note they stand on the shoulders of giants – leveraging decades of engine test data and analytical techniques from the Saturn V’s F-1 engines, the RS-25s that powered the shuttle, and countless unique engine development efforts along the way.

“We’ve banked a long history of criteria, strategy, and proven methodologies,” Fiorucci said. “Since we began partnering with SpaceX, we’ve added hundreds more engine tests to our database, refining our expertise and continuing our consistent build methodology reaching back to the earliest days of U.S. rocket engine development.”

That legacy anchored Marshall engine tests “from qualification and acceptance testing to integration, checkouts, and shipping to Kennedy for launch,” sad Aerodyne Industries propulsion systems engineer Crystal Klemmer, part of the Jacobs team at Marshall that supported Merlin testing and monitored engine performance during the launch.

“It felt surreal to be on console for the Crew-1 launch,” she said. “It’s one thing to watch on TV. It’s a completely different experience to have streaming data, several audio channels, and procedures and sequences to monitor. It’s a huge accomplishment for SpaceX and for NASA.”

That accomplishment was self-evident as the Crew-1’s engines thundered to life – a fanfare for uncommon men and women of talent, vision, and meticulous skill.

“Music to our ears,” Gaddis said.

The Commercial Crew Program unites NASA and industry to develop and fly new generations of crewed space transportation systems, extending humanity’s reach into the solar system and forging a path back to the Moon and on to Mars. Learn more here.

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

Marshall 2020 Year in Review

2020 was a year unlike any other – but NASA’s Marshall Space Flight Center continued to move the agency’s Artemis program forward, while studying the far reaches of the universe and teaching the next generation of scientists and explorers back on Earth.

On the Hunt for a Missing Giant Black Hole

The mystery surrounding the whereabouts of a supermassive black hole has deepened.

Despite searching with NASA’s Chandra X-ray Observatory and Hubble Space Telescope, astronomers have no evidence that a distant black hole estimated to weigh between 3 billion and 100 billion times the mass of the Sun is anywhere to be found.

This missing black hole should be in the enormous galaxy in the center of the galaxy cluster Abell 2261, which is located about 2.7 billion light-years from Earth.

Nearly every large galaxy in the universe contains a supermassive black hole in their center, with a mass that is millions or billions of times that of the Sun. Since the mass of a central black hole usually tracks with the mass of the galaxy itself, astronomers expect the galaxy in the center of Abell 2261 to contain a supermassive black hole that rivals the heft of some of the largest known black holes in the universe.

Using Chandra data obtained in 1999 and 2004, astronomers had already searched the center of Abell 2261’s large central galaxy for signs of a supermassive black hole. They looked for material that has been superheated as it fell toward the black hole and produced X-rays, but did not detect such a source.

Now, with new, longer Chandra observations obtained in 2018, a team led by Kayhan Gultekin from the University of Michigan in Ann Arbor conducted a deeper search for the black hole in the center of the galaxy. They also considered an alternative explanation, in which the black hole was ejected from the host galaxy’s center. This violent event may have resulted from two galaxies merging to form the observed galaxy, accompanied by the central black hole in each galaxy merging to form one enormous black hole.

When black holes merge, they produce ripples in space-time called gravitational waves. If the huge amount of gravitational waves generated by such an event were stronger in one direction than another, the theory predicts that the new, even more massive black hole would have been sent careening away from the center of the galaxy in the opposite direction. This is called a recoiling black hole.

Astronomers have not found definitive evidence for recoiling black holes and it is not known whether supermassive black holes even get close enough to each other to produce gravitational waves and merge; so far, astronomers have only verified the mergers of much smaller black holes.

The galaxy at the center of Abell 2261 is an excellent cluster to search for a recoiling black hole because there are two indirect signs that a merger between two massive black holes might have taken place. First, data from the Hubble and Subaru optical observations reveal a galactic core – the central region where the number of stars in the galaxy in a given patch of the galaxy is at or close to the maximum value – that is much larger than expected for a galaxy of its size. The second sign is that the densest concentration of stars in the galaxy is over 2,000 light-years away from the center of the galaxy, which is strikingly distant.

Read the full story here.

NASA’s Marshall Space Flight Center manages the Chandra program. The Smithsonian Astrophysical Observatory’s Chandra X-ray Center controls science from Cambridge Massachusetts and flight operations from Burlington, Massachusetts.

Read more about Chandra here, and see more images and multimedia here.

Starting the New Year With Wellbeing: A Message From Employee Assistance Program Coordinator Terry Sterry

Dear Marshall family,

Welcome to a new year! Was it just me, or did the holiday season seem to come and go much more quickly this year, as compared with other years? I’ve heard from many of you that the holidays were different this time, primarily because of COVID-19, and less enjoyable in some cases, because of limitations or illness. I’ve also heard from some of you that you lost loved ones over the holiday season, and to each of you I offer my most sincere condolences. We can get past COVID-19 disrupting holiday gatherings, but the loss of a loved one is a different matter altogether. It takes time even to begin to process the loss, and much more time to learn to live without that person that we love. If you have suffered the recent loss of a loved one, please find someone that you can talk with about the loss and who will be there for you as you go forward.

Many of you have expressed concern and distress related to the events at the U.S. Capitol Building on January 6. The assault on the Capitol, and events leading up to it, have heightened the anxieties, fears, frustrations, and anger of many, and seem to have further polarized some in their thinking. Wouldn’t it be great if we could all take a step back, take a deep breath, and approach our friends, loved ones, and neighbors on local and national issues with a greater focus on unity and cooperation? Some of you will no doubt scoff at this, or laugh out loud, but I think we can. I believe that it begins with each of us dedicating ourselves to making things better within our own sphere of influence. I don’t pretend to know the answers to our nation’s problems, but I am convinced that this step, although not suggested to always be either easy or simple, is a step in the right direction.

There are also things that we can do to help reduce our own angst over these types of events, such as:

- Limit exposure to news coverage and social media. It’s very important to be informed, but don’t allow yourself to be consumed by it.

- Don’t believe everything you see and hear, particularly on social media.

- Stay engaged with your support system. Talk with people that you know well and trust not to push for more divisiveness. Don’t allow yourself to become isolated during these difficult times.

- Keep doing the healthy things that help you deal with stress.

- Bear in mind that the extremity of bad behaviors that we see in the news is representative of only a tiny proportion of the population. They can be dangerous, of course, but they are not “everyone.”

- If you know that someone has very strong views and are on the opposite end of the continuum from you, this might be a good time to limit interactions with that person – at least until things calm down a little.

- One of the best ways that we can influence others is to treat them with dignity and respect. Another is to listen for understanding, rather than argue.

Keep in mind that Marshall’s Employee Assistance Program is here for you, if you begin to feel overwhelmed by these or other issues, or if you would simply like to have a private discussion about pretty much anything related to wellbeing. Contact me directly by email at terry.w.sterry@nasa.gov or by phone at 256-544-7549 if I can be of assistance.

Be safe and well,

Terry Sterry

Licensed psychologist and Marshall Employee Assistance Program coordinator

For more information on Marshall’s Employee Assistance Program, visit the Employee Assistance Program page on Inside Marshall. For more information on NASA’s coronavirus response and teleworking, visit NASAPeople.

This Week in NASA History: Saturn I, S-I Stage Build-up – Jan. 18, 1961

This week in 1961, NASA’s Marshall Space Flight Center engineers readied the first stage of the Saturn I rocket for checkout in Building 4705. The Saturn I S-I stage employed eight clustered H-1 engines capable of producing 1.5 million pounds of thrust. Originally developed under the U.S. Army Ballistic Missile Agency, 10 Saturn I rockets were flown prior to being replaced by the Saturn IB. Here, the S-I stages for the Saturn I SA-1, right, and SA-2, left, are assembled in Building 4705. Today, Marshall is playing a vital role in the Artemis program by developing the SLS, the backbone of NASA’s exploration plans and the only rocket capable of sending humans to the Moon and Mars. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)