For almost 60 years, a lock system connecting the Gulf of Mexico and Pearl River to NASA’s Stennis Space Center near Bay St. Louis, Mississippi, has provided critical waterway passage for flight hardware and other infrastructure deliveries on site.

The lock system also has enabled the center to maintain necessary water levels in the seven-and-a-half-mile canal system connecting its large test stands. A months-long project now is underway to ensure that essential lock access and function continues as the site supports NASA’s mission to explore the secrets of the universe for the benefit of all.

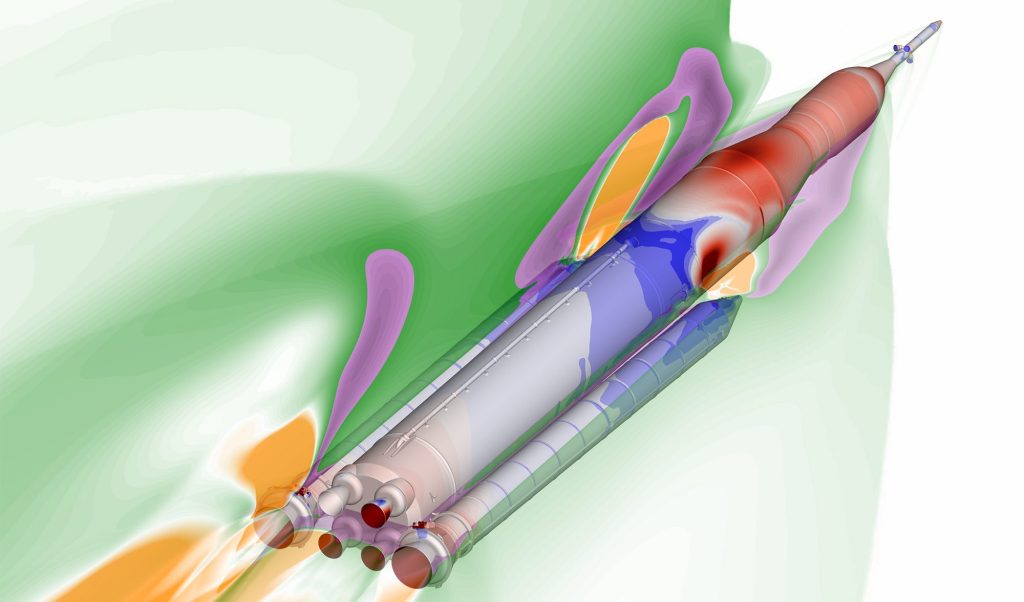

Waterway access to NASA Stennis was instrumental in selecting Hancock County, Mississippi, as the location for NASA’s Stennis Space Center. The access has proved vital for delivering flight hardware and other equipment during the Apollo and Space Shuttle Programs, as well as for current Space Launch System and Artemis testing.

The lock system also allows NASA Stennis to maintain a constant water level in its canal waterways. This is key in allowing propellant barges to connect to test stands to support various test operations. Without the constant water level, barges would need various amounts of ballast to compensate for changing elevations.

During the current project, a key part of the lock infrastructure, constructed and installed in the 1960s, is undergoing its first-ever upgrade. The lock system’s miter gates were removed in November for a complete inspection and refurbishment of the structural steel. The gates are expected to be reinstalled in May with the system restored to full operation in June.

“The lock system has a perfect operation record,” said NASA project manager Dale Woolridge. “It has never failed. We have never had a gate lock up or get to where we could not move it. We have never had a situation where we were trying to get a vessel through the lock system where the gates could not operate properly, and the vessel had to hold. However, we were beginning to experience leaking during the opening and closing of the gates, so it was time to get this project done to continue with a successful operation moving forward.”

Typically, the water level of the NASA Stennis canal system is about 16 to 18 feet higher than the Pearl River. When a vessel travels to NASA Stennis, the lock system and miter gates allow operators to raise the watercraft from the lower river level to the higher canal level.

Previous work on the lock system was performed with the gates in place. The NASA project manager credits the original design, skilled operations, and regular maintenance of the lock system for the gates exceeding their 50-year design life.

For the current project, implemented through the United States Corp of Engineer and performed by contract work. The design team first had to confirm if the structure could be lifted. The four gates – two upper (canal side) and two lower (Pearl River side) gates – each weigh 270,000 pounds, are seven feet thick, and measure 60 feet by 40 feet. After confirming the gates could be removed, crews welded lifting logs in place for each gate. The gates then were lifted with a crane on a floating barge.

“The Corps is doing a great job,” Woolridge said. “The contractor did a great job getting the gates out. There is a lot of risk in lifting something that big.”

Stop logs were installed to act as a detainer wall to keep the canal system at the proper water level prior to the removal of the gates. Woolridge has worked as a NASA project manager for 23 years, overseeing large projects such as the design and construction of the site’s Emergency Operations Center. He called the current project his favorite.

“It was very interesting to me,” he said. “As a civil engineer, this is what I like. Refurbishment of the structure reduces risks to the perfect operational record. We cannot have a piece of spaceflight hardware meant for the Moon trapped on Earth due to a broken lock gate.”

C. Lacy Thompson

Stennis Space Center, Bay St. Louis, Mississippi

228-342-7050

calvin.l.thompson@nasa.gov