Audience

Educators, Students

Grade Levels

Grades 5-8, Grades 9-12

Subject

Engineering Design, Human Space Exploration, Life Science, Life Support, Living and Working in Space

Type

Hands-on Activities, Lesson Plans / Activities

Introduction

As NASA sets its sights on returning to the Moon and preparing to travel to Mars, it is laying the foundation for human exploration deeper into the solar system by creating a Moon-orbiting outpost called Gateway.

Gateway is a vital component of the Artemis program. This lunar-orbiting outpost will be humanity’s first space station beyond low-Earth orbit with a minimum 15-year lifespan. It will provide extensive capabilities for long-term exploration, research in deep space, and ultimately help prepare humans for future missions to Mars. Gateway will host living quarters for crew, workplaces for science and research, and space for astronauts to prepare for lunar surface missions.

Gateway features a modular design, offering a building-block approach to deep space exploration. Its two primary habitation elements, Habitation and Logistics Outpost (HALO) and Lunar I-Hab, will provide living quarters for astronauts. HALO will also serve as the backbone for command, control, and power, featuring crucial docking ports. Lunar I-Hab will expand living spaces and provide additional docking ports, making Gateway a flexible and expandable outpost for lunar missions.

Efficient water recovery and recycling are critical for sustaining astronauts on long missions and significantly reducing reliance on Earth-based resupply. Just like the International Space Station, Gateway will employ robust water filtration and temperature sterilization to ensure safe drinking water. Throughout this process, water quality will be frequently checked and closely monitored for bacteria, pollutants, and proper pH levels, adhering to the International Space Station standard of 6.0 to 8.5 pH with no odor or bad taste.

In this activity, participants will design and test a water filtration system, using various filtering materials, to provide the cleanest water possible that falls withing the acceptable pH range.

![]() Grade Range: 6-12

Grade Range: 6-12

![]() Time Needed: 60 Minutes

Time Needed: 60 Minutes

![]() Materials List

Materials List

Ensure that students have:

-

- Safety glasses

- Metric ruler

- Scissors

- 5 litmus paper strips

- pH color chart

- 4 large clear plastic cups with a hole punched below the rim

- 3 paper plates

- Mesh bag

- 600 mL of clean water with a pH level of 6.5 to 7.5

- Metric liquid measuring cup

- Water filtration system structure:

- 2-liter bottle

- 10 layers of cheesecloth

- Rubber bands

- 600 mL of gray water:

- Italian dressing

- Tap water or bottled water with a pH level of 6.5 to 7.5

- Optional: Vinegar

- Assorted materials for filtration layers:

- Aquarium gravel

- Play sand

- Activated carbon or charcoal

- Marbles

- Cotton balls

- Coffee filters, wadded up

- Packing peanuts or any other packaging materials.

![]() Safety

Safety

Ensure students are practicing safe handling techniques when using scissors. Always maintain active monitoring to prevent accidents and provide support as needed.

Activity Procedure

Preparation

In this activity, students will work as a team to design, build, and test a model water filtration device that produces clean water with a pH level between 6.5 and 8.5 using three different types of filtration materials, conduct a control trial, and document the results.

- Gather and prepare all supplies listed on the materials list.

- If presenting videos or web-based resources, test the links and the classroom technology ahead of time.

- Divide the class into teams of three to four students.

- Provide context for this activity using the Background Information. Facilitate a discussion of the importance of water filtration systems for producing clean water on Earth and in space, highlighting both their similarities and key differences in design and function.

- Explain the details of the challenge, including the design constraints and your expectations for teamwork and classroom management.

- Prepare one water filtration system structure and the gray water for each team as follows:

Water filtration system structure

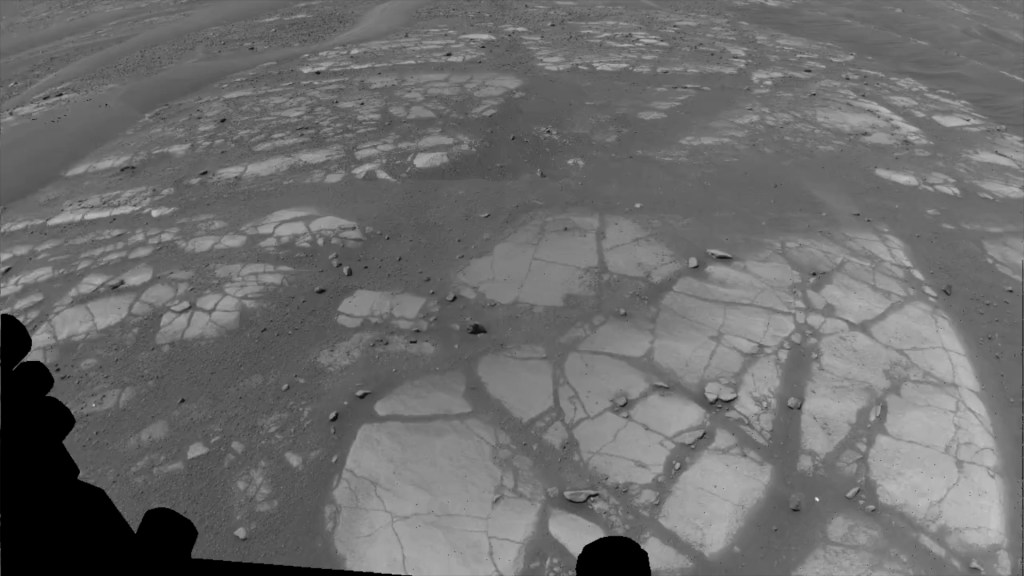

- Cut off the bottom of the 2-liter bottle, just above the curve – See this example diagram

- Cover the mouth of the bottle with at least 10 layers of cheesecloth and secure with a rubber band.

- Punch a hole just below the rim of each of the 4 large plastic cups. This will allow air pressure to escape as water drips into the cups.

These structures can be reused in subsequent class periods.

Gray water

- Test your tap water before making the gray water solution. Your clean water should have a pH level between 6.5 and 7.5. If the pH level falls outside this range, use store-bought drinking water.

- Mix 100 mL of Italian salad dressing mixed with 500 mL of water (total of 600 mL supply) in a large, clean container.

- Ensure that the pH level of the gray water is around 4. If it is not, add vinegar until the pH measures approximately 4.

Design Constraints

- Choose three different types of materials for your filtration layers. Each material should be layered to a depth of 5 to 8 cm within the water filtration system.

- Use a new cup for each of the four trials. One for the control trial with clean water, and one for each test trial using the gray water

Testing Requirements

- Place the bottle upside down over one of the four plastic cups.

- Record your hypothesis, observations, and results, including the pH level.

- Pour the water into the top of the device and let it drip through the layering materials into the plastic cup. Initiate with the control trial (using clean water), followed by three test trials (using gray water).

- Use a litmus paper strip to test the pH of the water in the paper cup. Use a pH color chart to determine the pH level.

Challenge Questions

- What challenges did your team face when completing this activity? How did you address these challenges?

- How did the function of your water filtration device change throughout the trials?

- Which filtration material do you think worked the best? Why?

- If you were to design another water filtration device, what modifications or improvements would you consider implementing based on your previous experience and observations?

- If your water filtration device were to be used in space rather than on Earth, what modifications would be necessary to ensure its functionality in a microgravity environment?

Extensions

- Add another iteration of the design challenge for teams to create a new water filtration device using what they learned from the first iteration and incorporating different materials or adjusting the filtration layer thickness.

- Ask teams to retest their previously filtered water through their water filtration device. Does repeating the filtration process further clean the water?

Career Connection

Building Gateway, our upcoming lunar-orbiting outpost, requires a team of people with diverse expertise and specialized skills working together. Below are just a few examples.

- Advanced Manufacturing Technicians use cutting-edge tools and technology — like robotics, 3D printing, and computer-aided design — to build high-performance parts for aerospace systems. They help turn innovative designs into precise, reliable components for space missions.

- Toxicologist Technicians are responsible for monitoring and analyzing various environmental samples, including water, air, and surfaces, for potential contaminants. Their expertise in toxicology and chemical safety ensures that the water filtration systems effectively remove contaminants, maintaining a safe and sustainable water supply for the crew.

Download Activity

Explore Related Activities

Habitation with Gateway: Assessing Structural Integrity Activity