SLS (Space Launch System) RS-25 Core Stage Engine

Powering America’s Exploration of Deep Space: The Engines Behind NASA’s Space Launch System

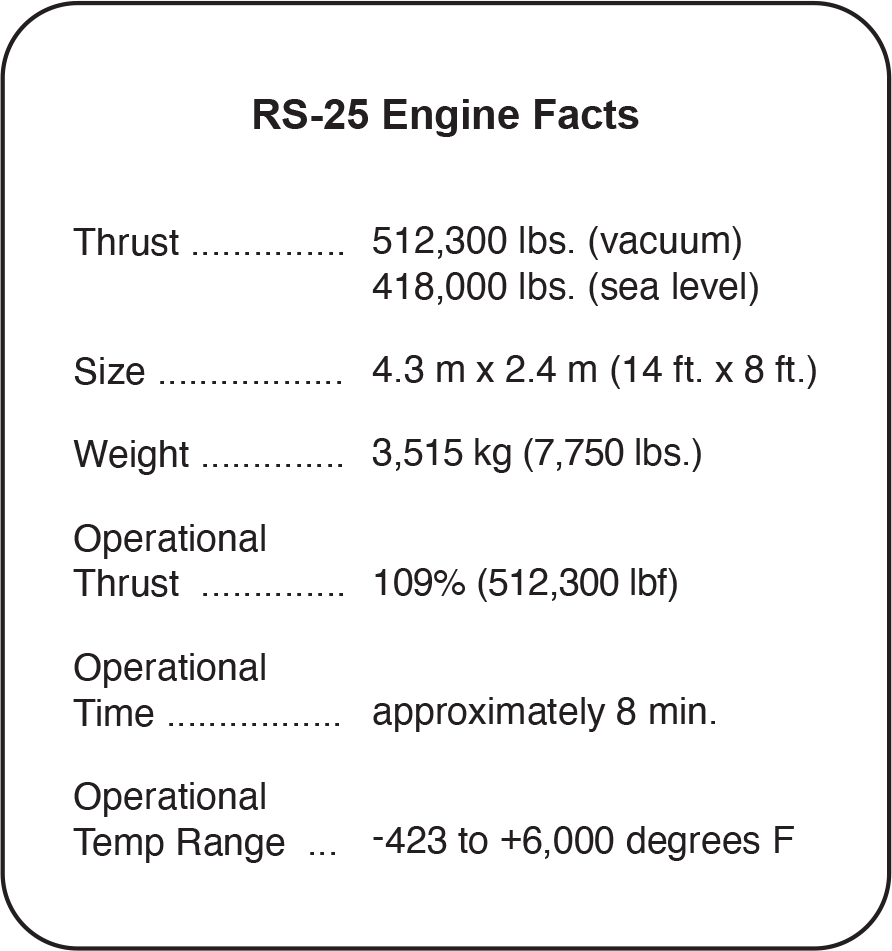

NASA’s SLS (Space Launch System), the most capable rocket in the world, is powered by RS-25 engines that combine proven performance with advanced engineering and technology. SLS will launch astronauts on the Artemis missions to the Moon and eventually expeditions to Mars.

The SLS Program is taking advantage of hardware and cutting-edge manufacturing techniques with new designs and new technologies to improve affordability. SLS is designed to be flexible and evolvable to meet a variety of crew and cargo mission needs. It’s

the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch. SLS Block 1, which launched Artemis I and will launch Artemis II and III, uses four RS-25 engines in the core stage, along with two solid rocket boosters. It can carry 27 metric tons (t) or 59,525 pounds (lbs.) to the Moon.

RS-25 Core Stage Engine Evolution

The RS-25 powered the space shuttle for over three decades and completed 135 missions. It is one of the most tested large rocket engines in history, with more than 3,000 starts and more than 1 million seconds of total ground test and flight firing time.

During the Space Shuttle Program, the RS-25 underwent several design updates to improve service life, durability, reliability, safety, and performance. SLS takes advantage of that technology investment and experience and builds on it using contemporary technologies and processes to improve manufacturability, affordability, and performance.

The SLS Program began with an inventory of 16 RS-25 flight engines – built by L3Harris Technologies – transferred from the shuttle program.

Two shuttle-era ground test RS-25 engines were fired in a series of tests from 2015 to 2017 to adapt the remaining flight engine inventory to SLS performance requirements and operating environments. The tests also served to certify new controllers and test fire components for a restarted engine production program.

The RS-25 rocket engine test era for SLS began Jan. 9, 2015, with a 500-second hot fire of RS-25

developmental engine No. 0525 on the Fred Haise Test Stand at NASA’s Stennis Space Center in Bay St. Louis, Mississippi. NASA tested the first SLS flight engine on March 10, 2016.

During the shuttle program, the RS-25s routinely operated in flight at 104.5%, or approximately 491,000 lbf, of their original 100% rated thrust level but were tested up to 111% thrust or approximately 522,000 lbf. To meet the demands of SLS missions, more power and performance would be required.

Between 2015 and 2019, multiple engine tests were conducted to demonstrate the capability of the system to perform at the new SLS operating conditions, including 109% thrust for the first four flights and 111% thrust for the new-production engines to come. During these tests, new and more capable engine controllers were tested for every engine. In the process, the RS-25 engine was tested at thrust levels up to 113% to allow for operating safety margins.

That test program led to the successful Artemis I flight in November 2022. At full throttle, the four liquid hydrogen/ liquid oxygen-fueled engines produced over two million lbs. of vacuum thrust, generating 10 times the equivalent thrust-to-weight power density of the largest commercial jet engine. Engine thrust and mixture ratio control valves were within 0.5 percent of pre-flight predicted values.

Internal pressures and temperatures were within two percent of pre-flight predicted values. The engines and core stage performed as expected throughout the flight. The four engine controllers each executed 82 commands during countdown through the flight profile with no errors.

The remaining 12 shuttle-era engines completed adaptation processing in spring 2024 to ready them for the next three SLS flights. In addition to new controllers, each engine received additional insulation to protect it from the hotter launch environment of being closer to the twin solid rocket boosters.

A final series of hot fire tests required to certify new- production RS-25s for flight ended with a successful engine test fire on April 3, 2024. Overall, SLS-related testing totals 69 engine starts for 34,149 seconds.

Including Artemis I SLS core stage ground testing and flight, RS-25 engines have accumulated a total of 38,367 seconds of operating time.

Engine manufacturer L3Harris Technologies is under contract to produce 24 new RS-25 engines. The first engine is complete with five more in production. The new engines will use a simplified design, new manufacturing technologies, new inspection technologies, and processes that reduce handling and support labor, hardware defects, and production time.

One of the most promising technologies is selective laser melting (SLM). This technology uses a high-energy laser and metal powder to produce parts more quickly and at lower cost than is possible with conventional manufacturing methods. Because they are made of fewer separate parts, engine design is simplified, and manufacturing time and cost is reduced.

Every new RS-25 engine produced will be hot fire tested once prior to flight. The first new engines will make their debut on Artemis V, the second flight of the more powerful Block 1B SLS variant. The new engines, in addition to reducing production cost and time, will contribute almost 1,000 lbs. to the Block 1B 38-t (84,000-lbs.) lunar payload capability.

A later evolution, Block 2, will use advanced solid or liquid propellant boosters, to provide up to 43 t (95,000 lbs.) of lift capacity to deep space. In each configuration, SLS will continue to use the same core stage design and four RS-25 engines.

For more information about SLS, visit:

https://www.nasa.gov/artemis

https://www.nasa.gov/sls

https://www.twitter.com/NASA_SLS

https://www.facebook.com/NASASLS

https://www.instagram.com/nasaartemis

National Aeronautics and Space Administration

George C. Marshall Space Flight Center

Huntsville, AL 35812

www.nasa.gov/marshall

MSFC-03-2025-SLS-4963