Pegasus Hypersonic Experiment Project (PHYSX)

Imagine a new generation of aircraft capable of flying at 3,750 mph—fast enough to travel from Los Angeles to New York City in just over 45 minutes. To make this vision a reality, NASA has been pioneering research into hypersonic flight, defined as speeds exceeding five times the speed of sound.

One such effort was the Pegasus Hypersonic Experiment, led by NASA’s Dryden (now Armstrong) Flight Research Center in Edwards, California.

This experiment featured a specially designed, data-collecting “glove” installed on the first-stage wing of the Pegasus Space Launch Vehicle. During flight, the vehicle reached speeds of Mach 8 and altitudes up to 200,000 feet. The glove was bonded to the right wing, wrapping from the underside over the leading edge and onto the upper surface—though it did not cover the entire wing.

The primary objective was to study how air flows over the Pegasus wing, with a focus on the transition from smooth (laminar) to turbulent airflow. Understanding when and why this transition occurs is critical, as it has major implications for vehicle performance.

Turbulent airflow increases friction, generating more heat that can damage aircraft surfaces—as seen in the hypersonic X-15 program. It also produces greater aerodynamic drag, which can reduce speed and fuel efficiency.

The Pegasus glove experiment collected critical data on temperature, heat transfer, and pressure, along with detailed reconstructions of the vehicle’s flight path. This information was unique—unavailable through ground-based wind tunnels, which were unable to fully replicate the extreme speeds and atmospheric conditions encountered by the Pegasus booster.

A secondary objective was to give engineers hands-on experience in instrumenting and testing hypersonic vehicles—an essential step toward future high-speed flight development.

The Pegasus Hypersonic Experiment exemplified NASA’s commitment to advancing revolutionary technologies that reduce the cost and complexity of aeronautics and space missions. It supported broader efforts to transform how aircraft are designed, built, and operated.

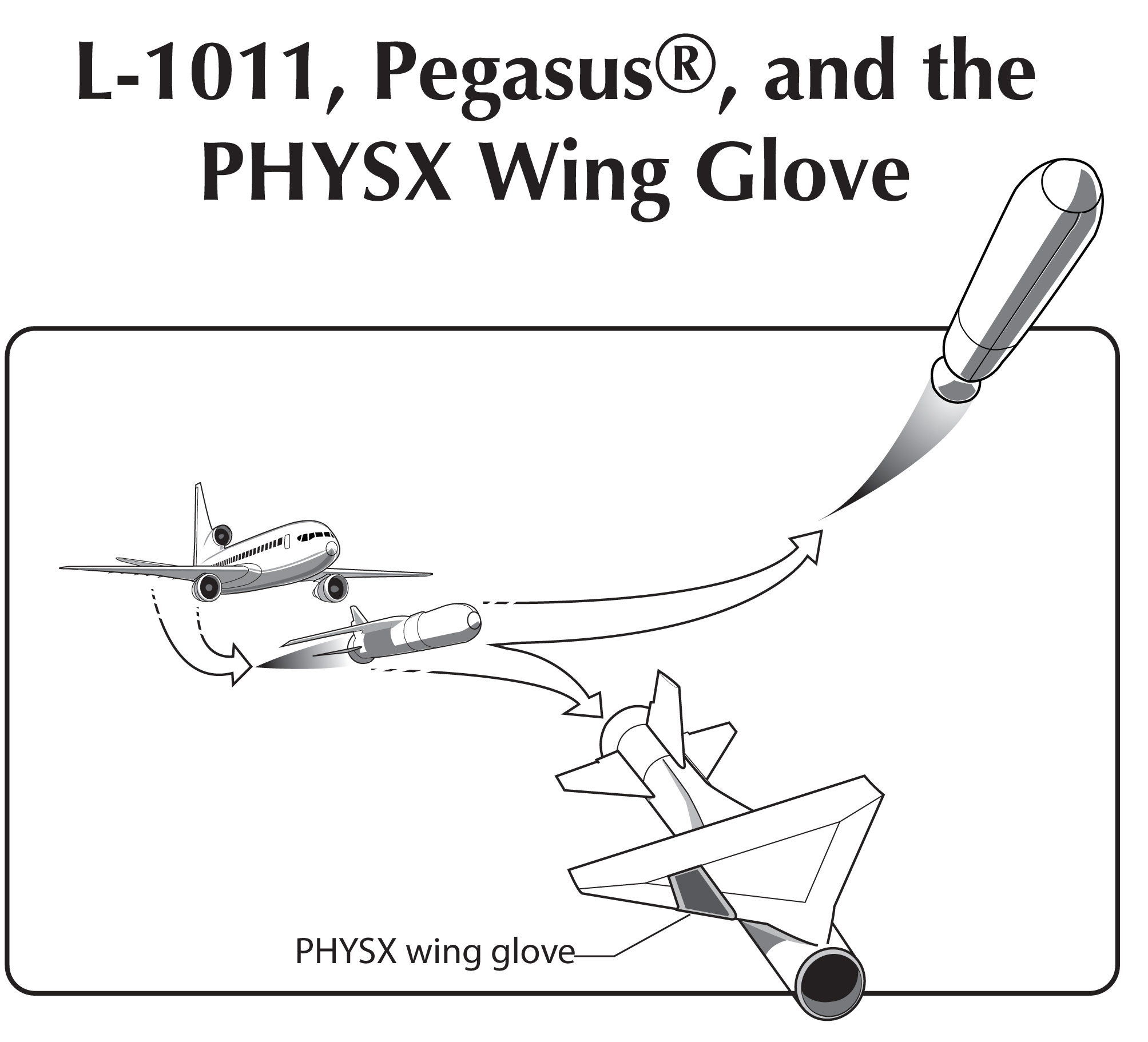

Flight Scenario

The hypersonic glove experiment flew in 1998 as part of a Pegasus booster mission launched from Cape Canaveral Air Station in Florida. The primary objective of the mission was to deploy a commercial satellite payload. The glove experiment served as a secondary payload and was carefully designed not to interfere with the booster’s main task.

After the first-stage Pegasus booster was released from its L-1011 mothership, the instrumented glove began collecting data on flight at hypersonic speeds and high altitudes. For approximately 90 seconds—until the booster’s first stage burned out and separated—the glove’s sensors gathered vital data.

All data collected were transmitted to the ground in real time via radio. To enable this, engineers at NASA’s Langley Research Center in Hampton, Virginia, developed a custom system for data acquisition, compression, and transmission. This system was successfully tested in January 1995 using Dryden’s F-15 aircraft during flights over Edwards Air Force Base in California.

Glove

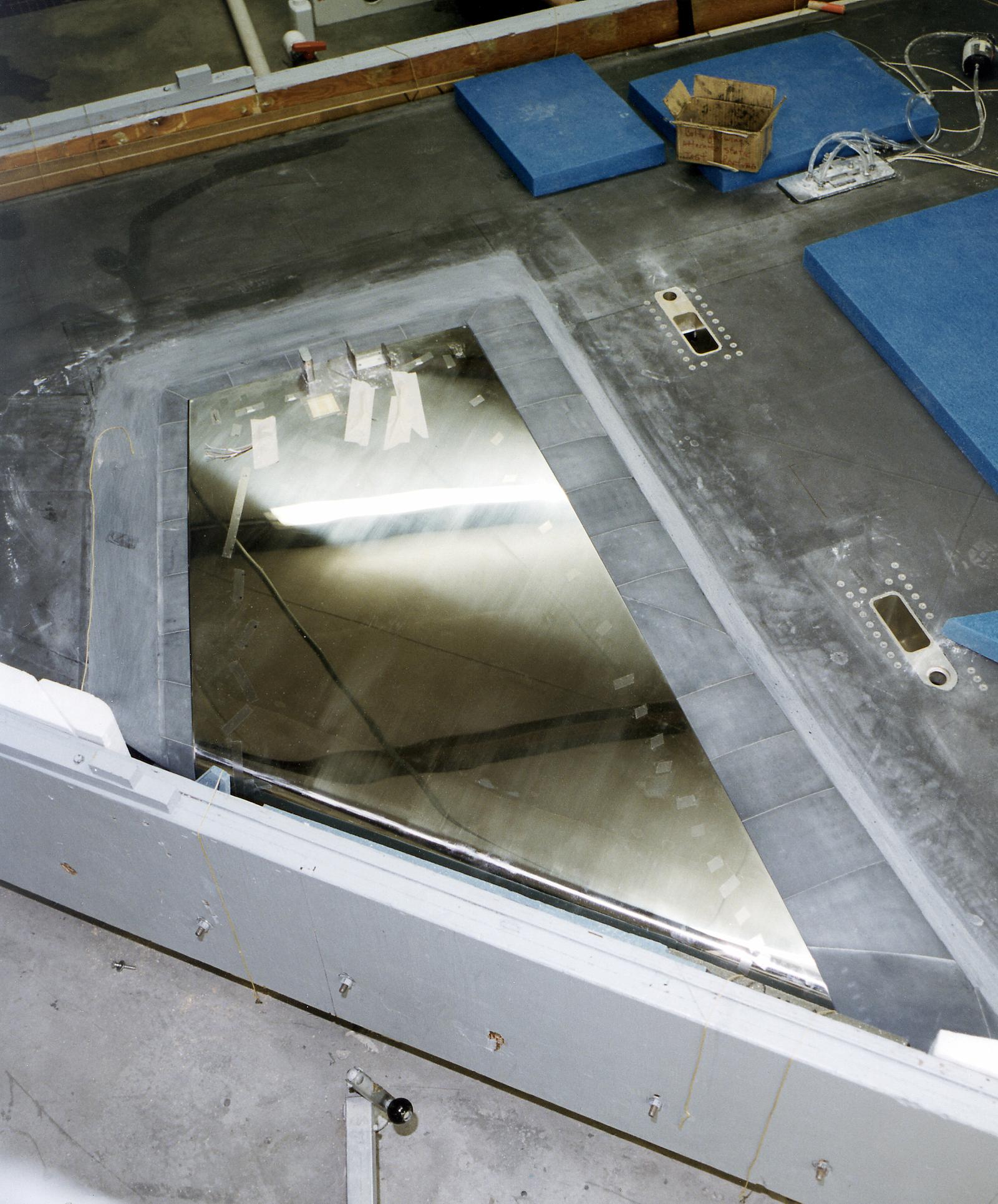

Two Pegasus Hypersonic Experiment gloves were produced for the program: one for flight aboard the Pegasus booster rocket and another designated for ground-based thermal testing. Both gloves were constructed from nickel-plated steel.

The ground-test glove was mounted on a plywood and fiberglass frame for a series of thermal tests that concluded on May 30, 1996. To simulate flight conditions, the glove was painted flat black to maximize heat absorption, then pre-cooled and heated in Dryden’s Flight Loads Laboratory. These tests replicated the intense thermal environment the glove would face during the first-stage flight. The results confirmed that the glove was durable enough to withstand the extreme heat generated at speeds of Mach 8.

The flight-test glove was mounted on a balsa wood structure and integrated into a drag-reducing thermal protection system made from Space Shuttle tile material. This system helped blend the glove smoothly into the Pegasus wing while dissipating heat. NASA’s Ames Research Center in California’s Silicon Valley supplied the thermal protection materials. The glove was installed on the Pegasus wing at Dryden, while the Pegasus booster was attached to its L-1011 launch aircraft at Orbital Sciences Corporation’s Vehicle Assembly Building at Vandenberg Air Force Base, California.

The glove carried an array of traditional and high-frequency sensors designed to function under the extreme conditions of hypersonic flight. These sensors measured acceleration, airflow, pressure, temperature, and strain, providing engineers with vital aerodynamic and thermal data. Many of the sensors were first tested during a Pegasus flight in July 1994, confirming they would not disrupt airflow or be affected by in-flight vibrations—ensuring accurate data collection.

Roles and Responsibilities

Dryden managed the glove experiment, including design, integration, and flight testing. Langley was responsible for the aerodynamic design of the glove and development of the sensor and instrumentation systems. Additional support came from NASA’s Ames; Goddard Space Flight Center in Greenbelt, Maryland; and Kennedy Space Center in Florida. Orbital Sciences Corporation in Dulles, Virginia, built the Pegasus launch vehicle, and Vandenberg Air Force Base served as the pre-launch assembly site.

Pegasus Background

First launched in 1990, Orbital Sciences Corporation’s Pegasus rocket supported a diverse range of missions, including space technology validation, Earth science and space physics experiments, hypersonic flight research, Earth imaging, communications, and planetary exploration.

The three-stage Pegasus launch vehicle was carried to an altitude of approximately 40,000 feet by the company’s L-1011 “Stargazer” aircraft. Once released, the rocket free-fell in a horizontal position for five seconds before igniting its first-stage motor. Thanks to aerodynamic lift generated by its delta wing, Pegasus was capable of achieving orbit within about 10 minutes, reaching altitudes hundreds of miles above Earth. The vehicle could carry payloads of up to 1,100 pounds.