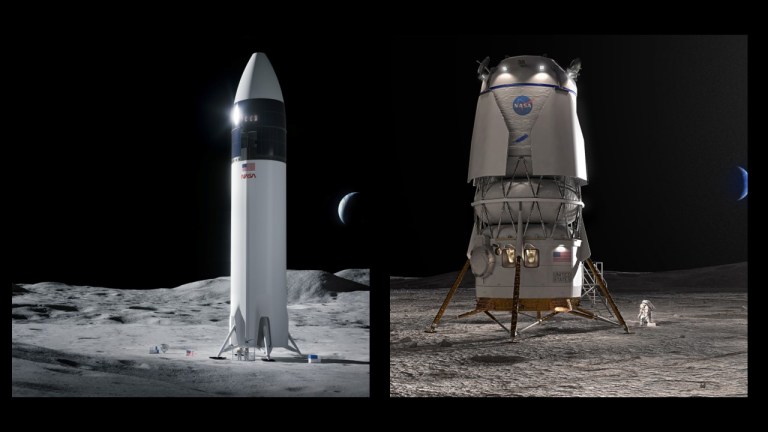

Lander Systems

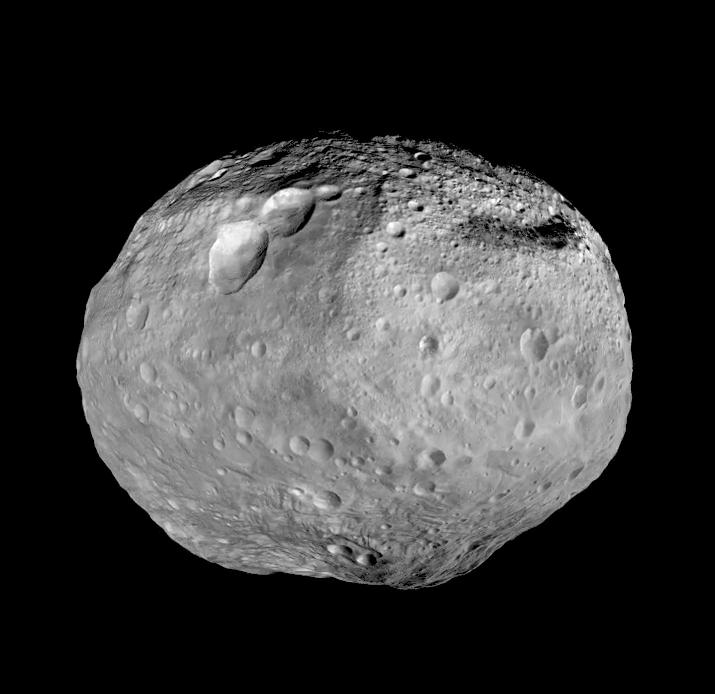

A leader in Lander Systems, Marshall Space Flight Center has the capability to help you land anywhere in the solar system.

Contents

Overview

Advanced Manufacturing

Unique expertise in applying state-of-the-art advanced manufacturing methods to support development and production of Lander systems

Docking and Rendezvous Testing

State-of-the-art testing facility for simulating docking and berthing, with experience testing almost every U.S. docking and berthing mechanism ever developed

Flight Mechanics and Analysis

Cutting-edge, in-house-developed open-source simu-lation and software tools simulate integrated design elements from launch pad to mission completion

Extensive experience in the design, development, analysis, testing, and certification of GN&C algorithms for human-rated systems

Flight Software Development and Hardware-in-the-Loop Testing

State-of-the-art facilities for flight software development, testing, and formal verification

Real-time hardware-in-the-loop capabilities enable launch vehicle integrated software and avionics hardware systems to be modeled, simulated, and tested early, before finalizing designs

Propulsion Systems, Subsystems, and Components

Propulsion testing facilities enable testing of components, subsystems, subscale motors, and full-scale engines under a variety of configurations and conditions

Modeling and testing capabilities for lander systems, including Plume-Surface Interaction

Cutting-edge propulsion capabilities including 3D printed rotating detonating rocket engines

Space Environmental Effects and Lunar Environment Testing

Test capabilities to characterize the effects of the space environment on materials and systems, from low Earth orbit to deep space. Simulated elements of the space environment include charged particle radiation, plasma, high vacuum, solar ultraviolet (VUV, NUV), atomic oxygen, impact, thermal extremes, Lunar/Martian surface environments including regolith simulants, all either individually or in combinations

Structural Strength and Dynamics Testing

Multiple facilities provide proof, limit, failure, development, qualification, and flight acceptance testing

Decades of experience developing instrumentation for structural and propulsion-related test articles to maximize data return using high-speed data acquisition, visible and thermal imaging, and high-definition audiovisual capture systems

Concept and Trade Studies

Rapid development and analysis of physics-based models to yield an end-to-end design capability for preliminary concepts

Decades of experience in both launch vehicle and space systems design

Cryogenic Fluid Management (CFM)

Design and development of prototype CFM hardware, the creation and use of analytical models to predict subsystem performance, and the execution of ground-based tests using liquid oxygen, liquid hydrogen, and liquid methane to demonstrate the performance, applicability, and reliability of CFM subsystems

In-space Cryogenic Propellant Transfer

Development of systems enabling on-orbit refueling of cryogenic propellants

Do Business with Us

MSFC Partnerships Office

Nick Case

nicholas.l.case@nasa.gov

256.544.8789