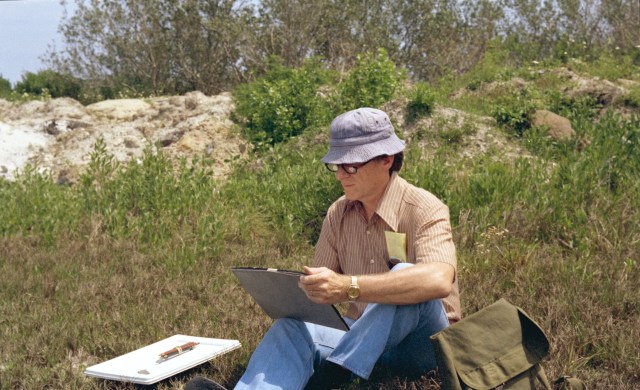

Glenn Bazemore is a mechanical engineer working on the Nancy Grace Roman Space Telescope Team. He also aims to become an astronaut.

Name: Glenn Bazemore

Title: Mechanical Integration Engineer

Formal Job Classification: RST Mechanical Integration Engineer

Organization: Integration Branch (Code 568.0)

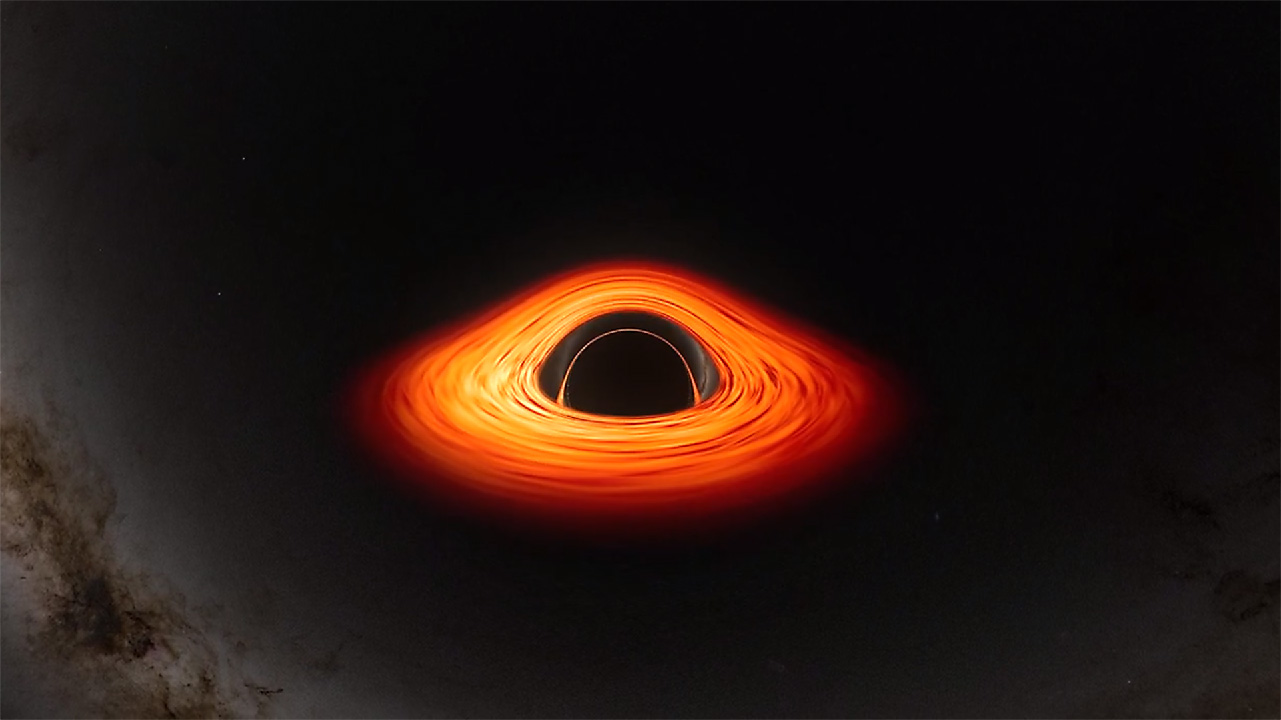

Glenn Bazemore is a mechanical engineer working on the Nancy Grace Roman Space Telescope Team. He also aims to become an astronaut. Since childhood, Bazemore has been creating and tinkering. As evidenced through his hobbies just as much as through his work, Bazemore’s problem-solving prowess helps him contribute to NASA’s next flagship telescope, which is set to probe important questions in infrared astrophysics.

What is your role here at NASA and on the Roman mission?

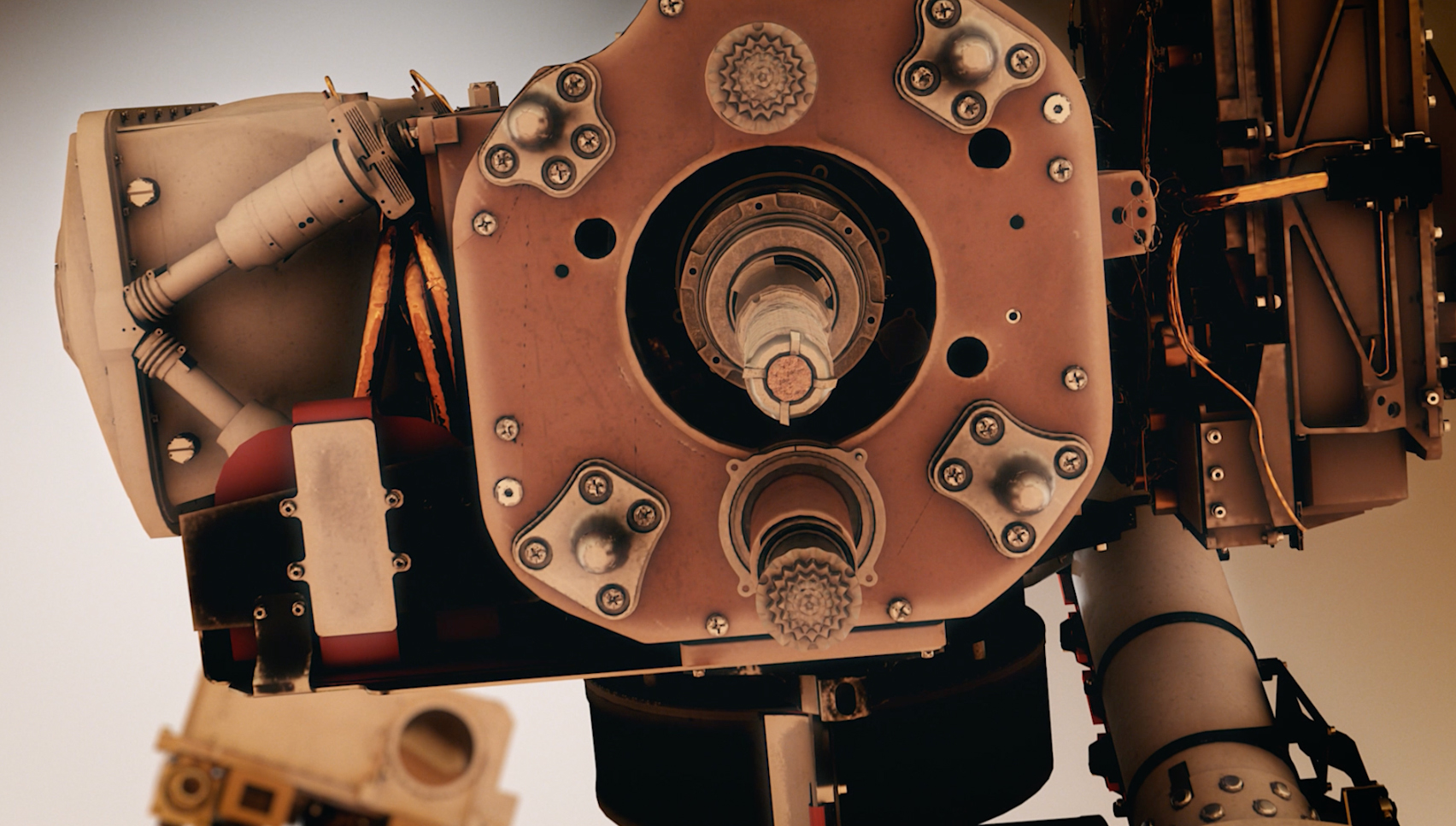

On Roman, I helped with a subsystem inside its Wide Field Instrument (WFI) called the simplified Relative Calibration System (sRCS). This sub-system will be used to help scientists accurately measure light output from cosmic entities like galaxies and stars. I assisted heavily on the main sRCS that will fly on Roman, and I ran the mechanical integration on the flight spare unit, which has just completed environmental testing (TVAC) and is heading into storage.

What got you interested in mechanical engineering?

My interest began when I was five years old and stayed home from school, sick. My dad sat me in front of the TV, and I watched VHS tapes of Star Wars, the original trilogy, all the way through. Afterward, I wanted to be a Jedi. I looked into the closest thing, and learned it was an astronaut. I am still actively pursuing becoming an astronaut, but I am currently an aerospace mechanical engineer.

My family made me the man I am today. I started by rebuilding Kodak video cameras. Our family had an old camcorder. For days, I took it apart and put it together to make it work. Then I got into robotics and remote control or RC airplanes. My dad took me to the hobby store to buy model rockets, and every week we went and launched them. That got me interested in the analysis side, as I would add and remove components from the rockets and RC planes to see how they would affect the performance or flight path.

Would you say that you’re a visual learner?

I was always a cause-and-effect person. I used to go to church and throw paper airplanes, adding staples and weights to make them fly longer and farther. They would get stuck on our church’s hanging lights.

Every Friday at school there was a show and tell. One week, I made a submarine out of water bottles. It had a periscope and everything – I was really proud of it. The night before show and tell, I put it in the bathtub to make sure it would work, but it broke in half! My dad helped me shorten it. That’s when I learned about the coefficient of drag and how mass affects scaling. I took it to school it the next day, and it worked. Later I added motors on it and entered it in a Boy Scout science competition, where it won first place.

What sort of creative projects have you done?

I’m always inventing stuff. During my undergrad years at Old Dominion University, Virginia, I got a job as a student ambassador at the entrepreneurship center. It was 2016, and I scraped together my first paycheck to buy a 3D printing pen. Over the summer, I started drawing stuff and got to see my ideas come together visually in real time.

When I went back to school, there was a broken 3D printer at work. The deal was if I could fix it, I could use it. That was the last night of full sleep I got in my life. I woke up the next day and worked to get that MakerBot running.

The next summer, I bought a Monoprice 3D printer, which I afforded by selling custom made fidget spinners, and my whole world opened up – I realized I could make anything! I did not have a lot of toys, so this allowed me to reconnect with my inner child and 3D model and print things I never had access to. I made so much I was just giving things out as presents, and I started to see the business side of it. The first thing I sold was an action figure scaled Battlestar Galactica Viper MK2 through a sci-fi Facebook group. To this day, I’m still friends with the group and have grown my business to include a variety of sci-fi and mechanical needs.

What advice would you give to your younger self?

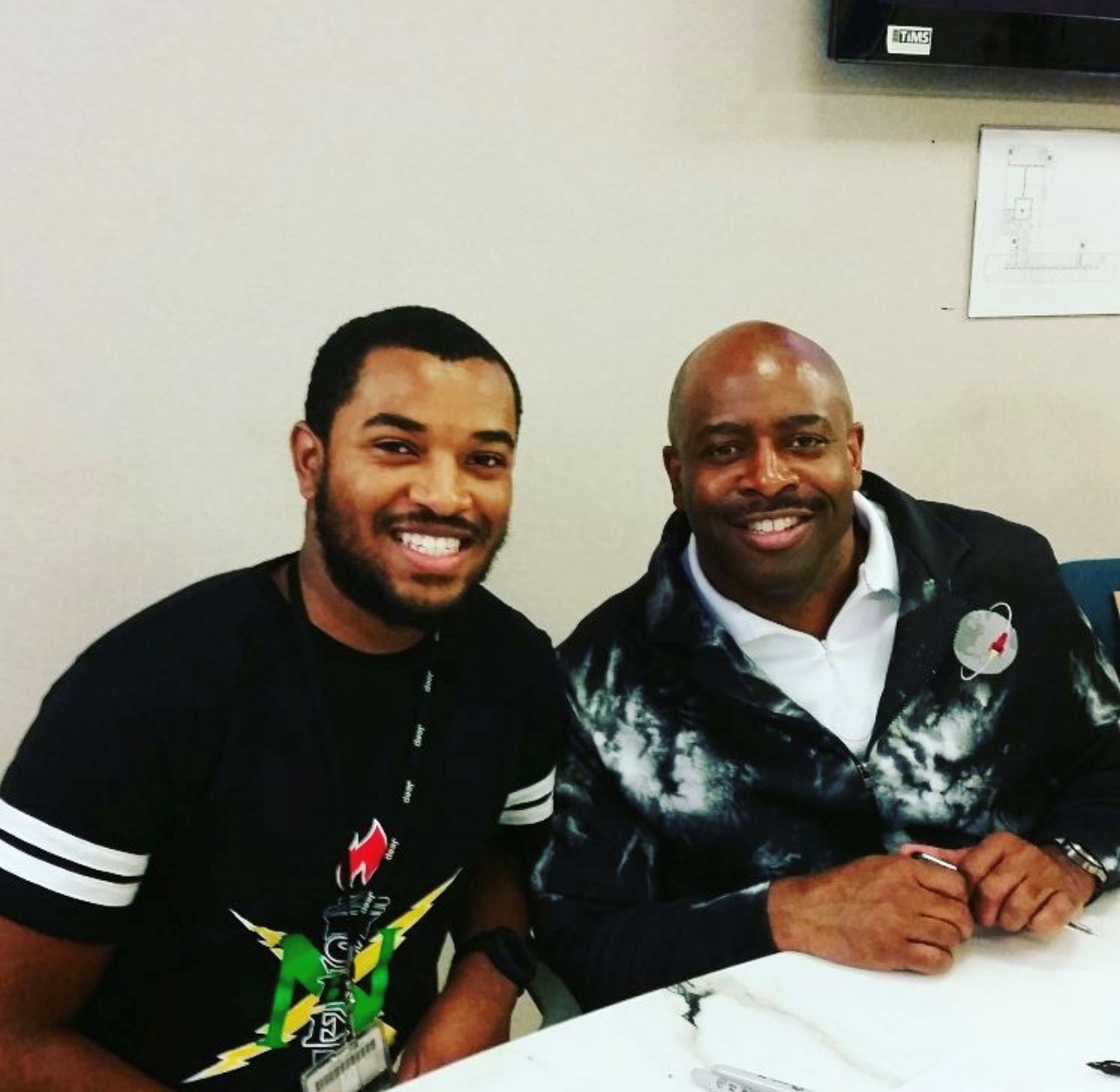

When high school came around, people were trying to fit in. I saw a poster for a science symposium, and I ended up going to it. I waited in line for an hour and a half to meet Leland Melvin, one of the few Black astronauts. He said, “We need more Black people in space and engineering. You should do this.” I eventually attended Virginia’s Air and Space Grant Consortium for a few months before getting a NASA internship at Goddard in space systems my senior year of high school. My first internship was in mission safety assurance, but after much talking and meeting Leland Melvin a second time, I was offered a mechanical internship, which led me to my current position in mechanical integration.

So, my advice is: don’t change. Don’t try and fit in. If you see something that interests you, go do it! I would also tell myself what my mom still tells me to this day: “When things look bleak, believe that you are meant to do great things and have faith.”

What are some hobbies you like to do?

I’m really a nerdy person. I collect Legos and action figures. I go to comic cons. The last one I went to was in January; MAGFest at the National Harbor, Fort Washington, Maryland. I dressed up like a mix between The Mandalorian and Jurassic Park. I called it the Jurassalorian. You think people are going to say something, but then you remember everyone else is also in costume! My helmet even had a spigot to connect to a water bottle, so I was never dehydrated. In a crowd of Mandalorians, I looked completely different.

By Nora Lowe

NASA’s Goddard Space Flight Center, Greenbelt, Md.

Conversations With Goddard is a collection of Q&A profiles highlighting the breadth and depth of NASA’s Goddard Space Flight Center’s talented and diverse workforce. The Conversations have been published twice a month on average since May 2011. Read past editions on Goddard’s “Our People” webpage.