Leveraging space station technology platforms for economic benefit on the ground

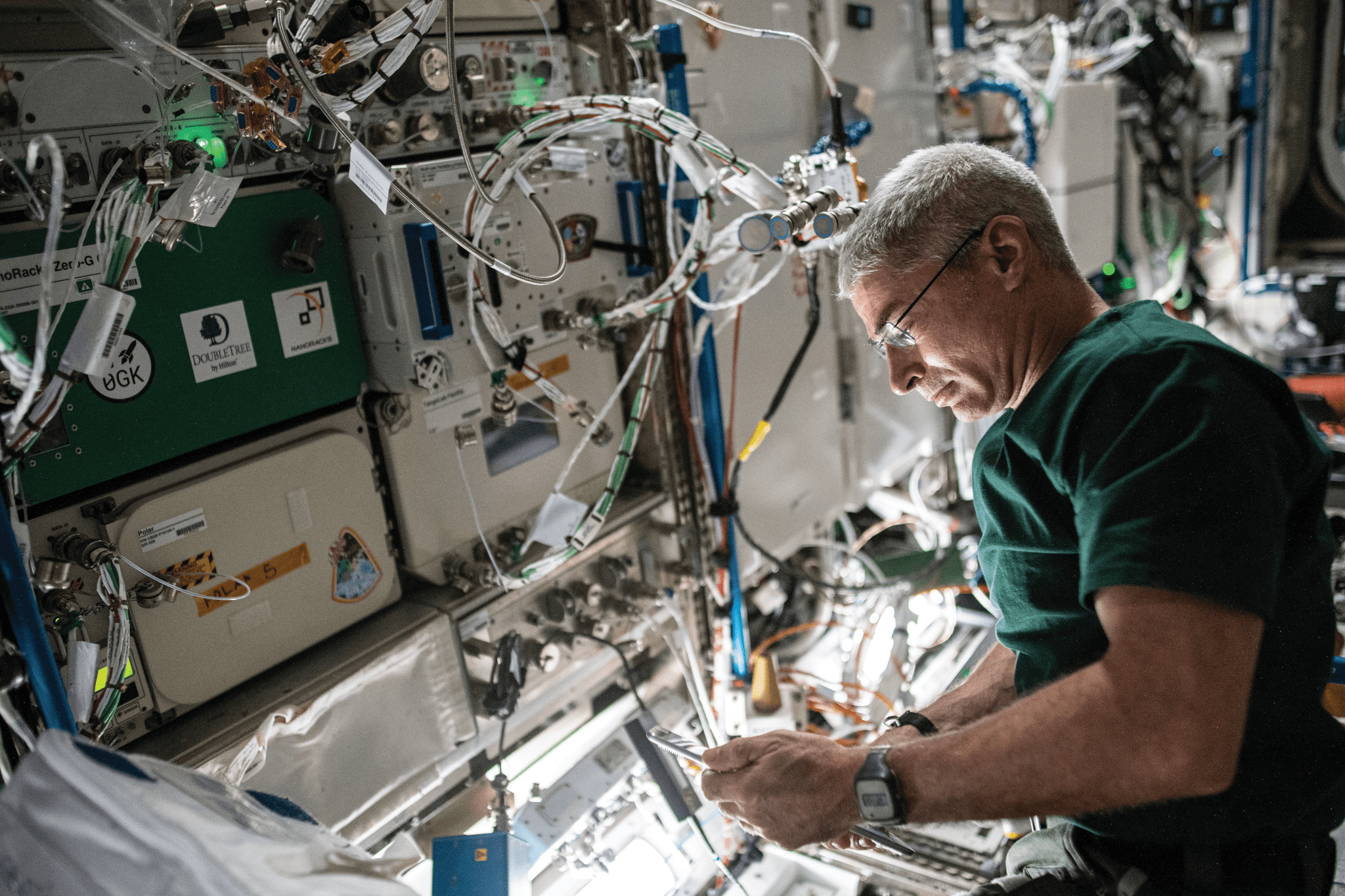

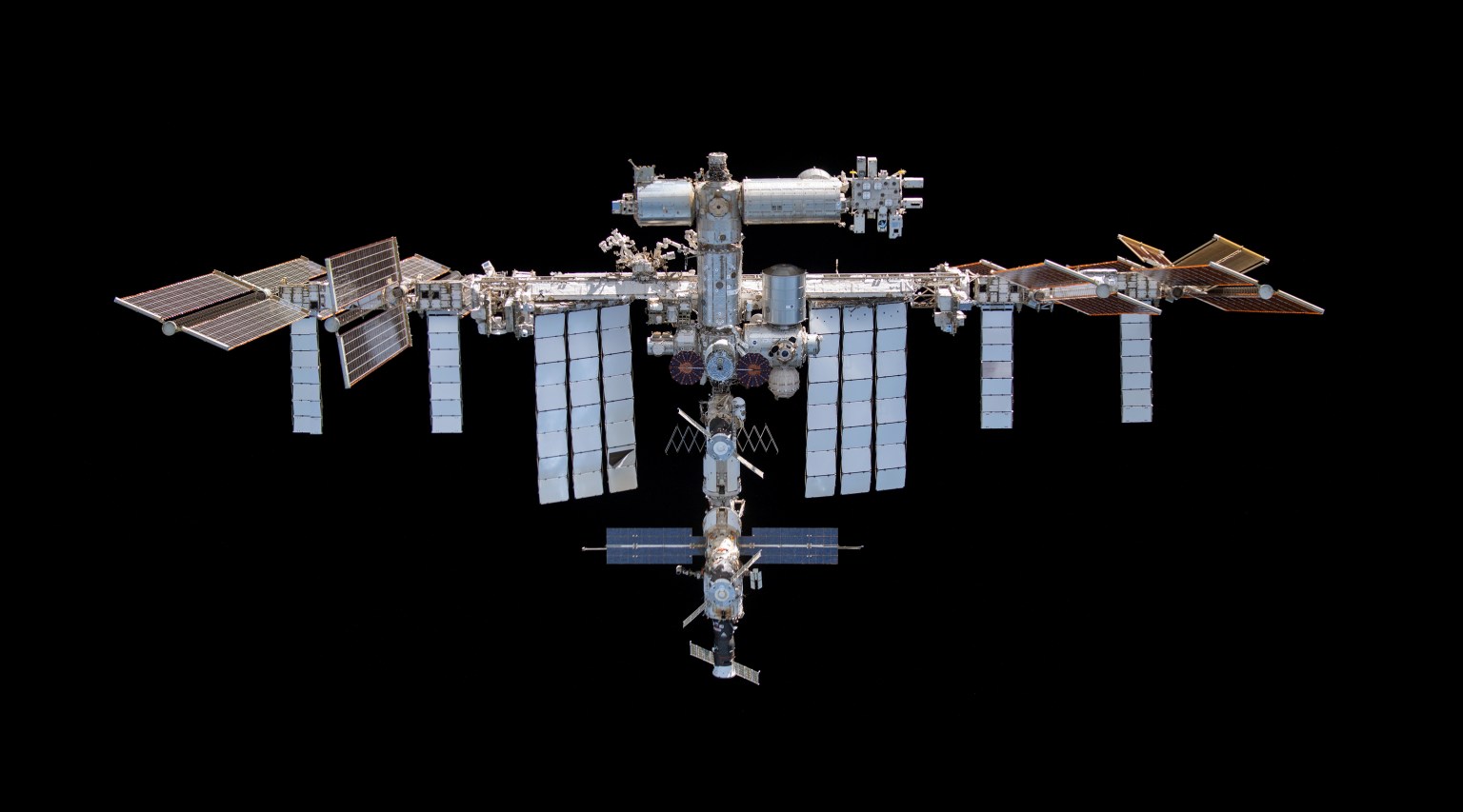

The International Space Station provides platforms for small businesses, entrepreneurs, and researchers to test their science and technology in space. Not only has the station’s capacity for research, development, and manufacturing in low-Earth orbit increased, the cost continues to fall. Together, these factors are advancing development of new and improved products as well as spawning new commercial ventures and providing growth for existing ones.

“We are walking through the door to the second golden age of space and seeing the beginnings of a growth surge in space-based businesses,” says Andrew Rush, president and chief operating officer of Redwire Space. “In many ways, the space station has been responsible for opening that door. NASA’s support of the development and demonstration of new technology and new uses of space has enabled entirely new sectors – in-space manufacturing and commercial research and development among them – to move forward.”

The space station is helping to fuel growth of the space industry as a whole.

In the past several years, Redwire has acquired Made in Space and Techshot, companies focused on in-space manufacturing and space research, thus becoming one of the major players in this burgeoning economy. Its facilities include the station’s BioFabrication Facility (BFF) and ADvanced Space Experiment Processor-2 (ADSEP-2), which support in-house efforts to create a complete set of cardiac tissues, and the Multi-use Variable-g Platform (MVP), which produces varying levels of artificial gravity for research on different diseases. In addition, the company has its own plant growth facility and manages research in the space station’s Advanced Plant Habitat.

Another Redwire focus has been using microgravity to create better turbine parts. The Turbine Ceramic Manufacturing Module (Turbine CMM) demonstrates manufacturing a type of turbine blade called a blisk, whereas Turbine Superalloy Casting Module (Turbine SCM) tests a manufacturing device that processes heat-resistant alloy parts in microgravity. Manufacturing in microgravity could allow production of these components with lower mass and stress. The parts show increased strength compared to those made on Earth. That increased strength could improve the performance of turbine engines in industries such as aerospace and power generation.

“The space station is pivotal to businesses developing space-based products and services because it provides rapid access to space and return capability,” says Rush. “The unique environment of the space station has been invaluable to Redwire’s development of in-space manufacturing technology and capabilities. It is the only cost-effective, accessible, and rapid platform to develop, test, and operate technologies that are revolutionizing so many critical areas for the benefit of humanity.”

Capitalizing on this growing space economy has enabled the company to expand to more than 500 employees and eight facilities in the United States and internationally.

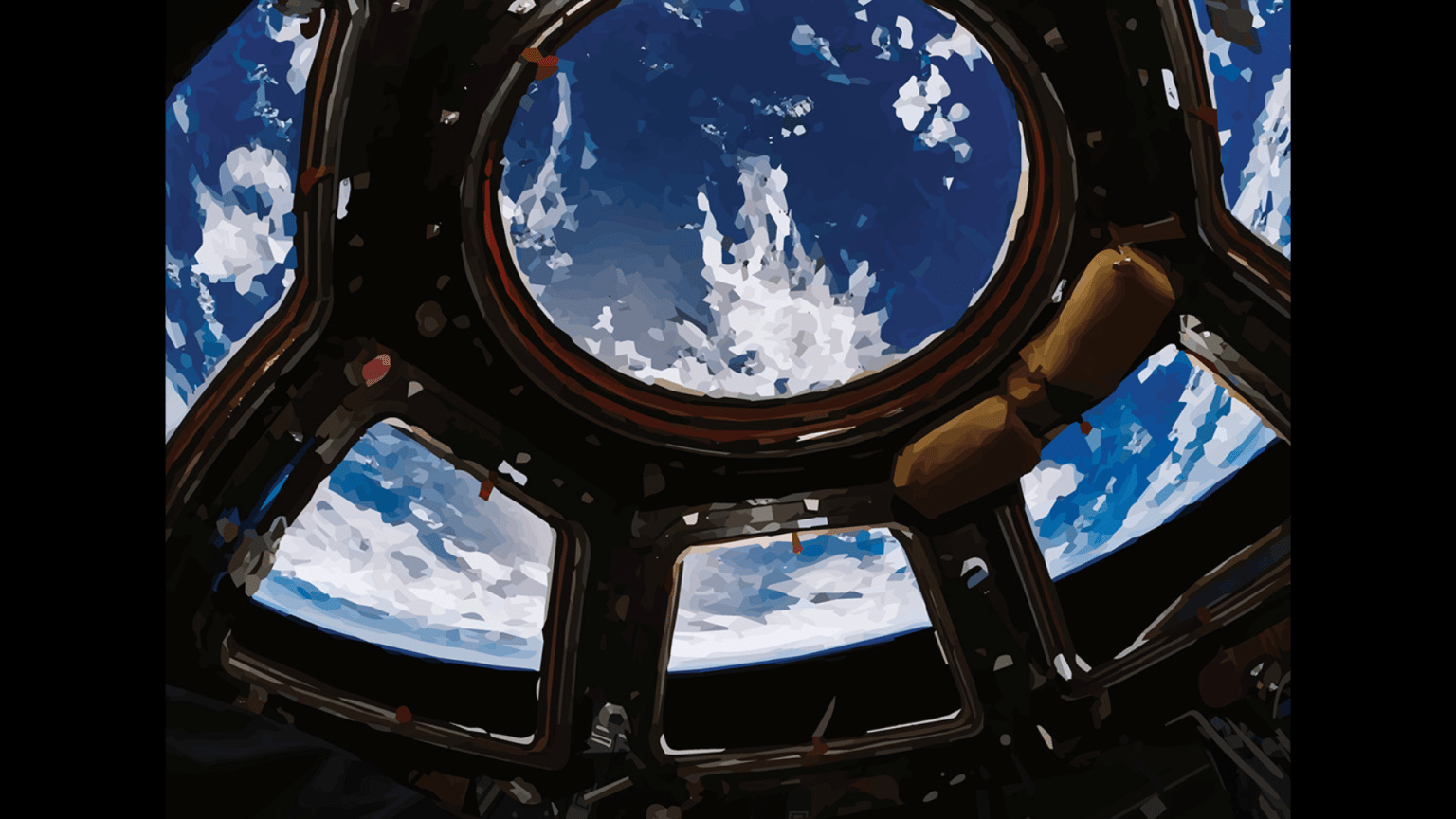

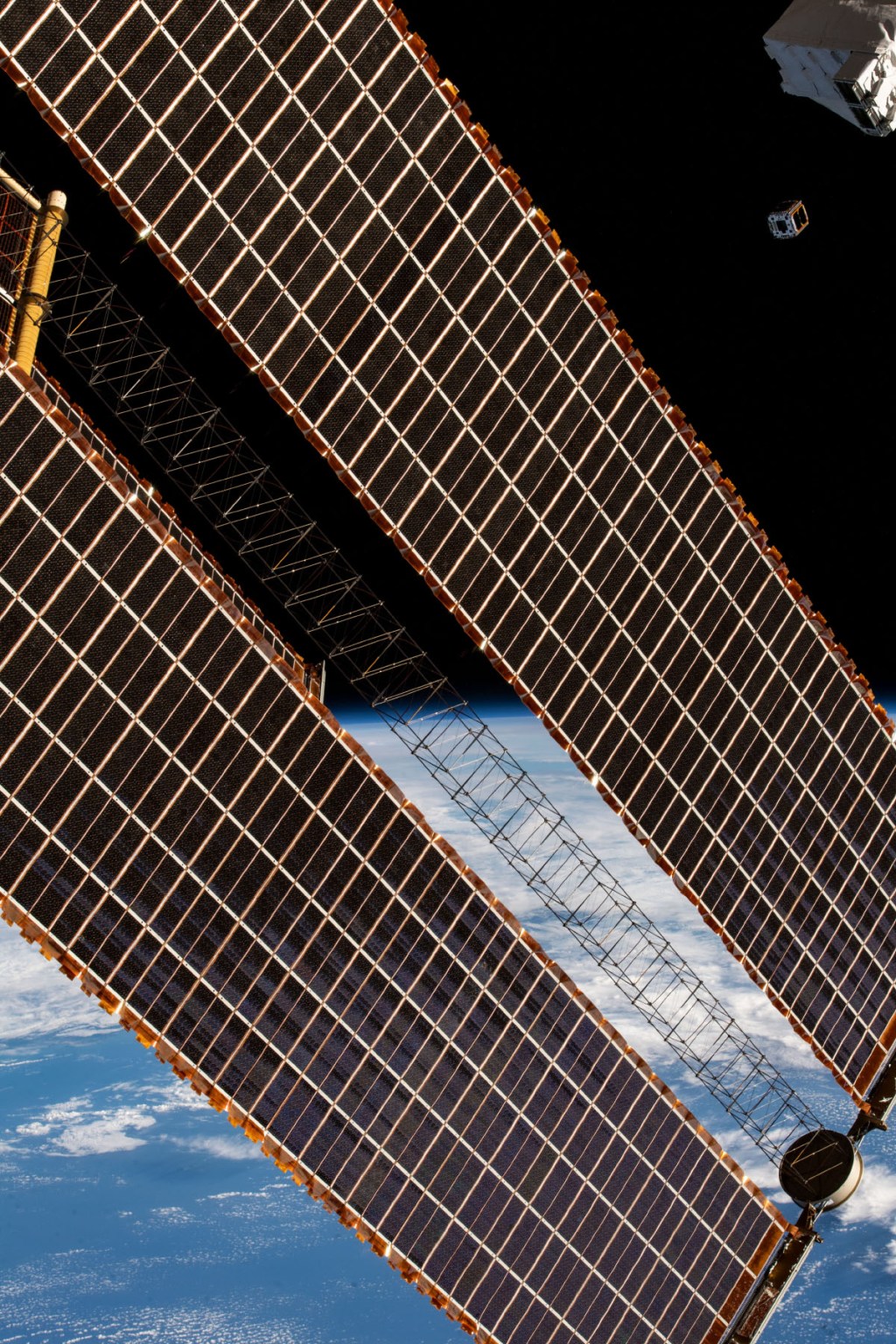

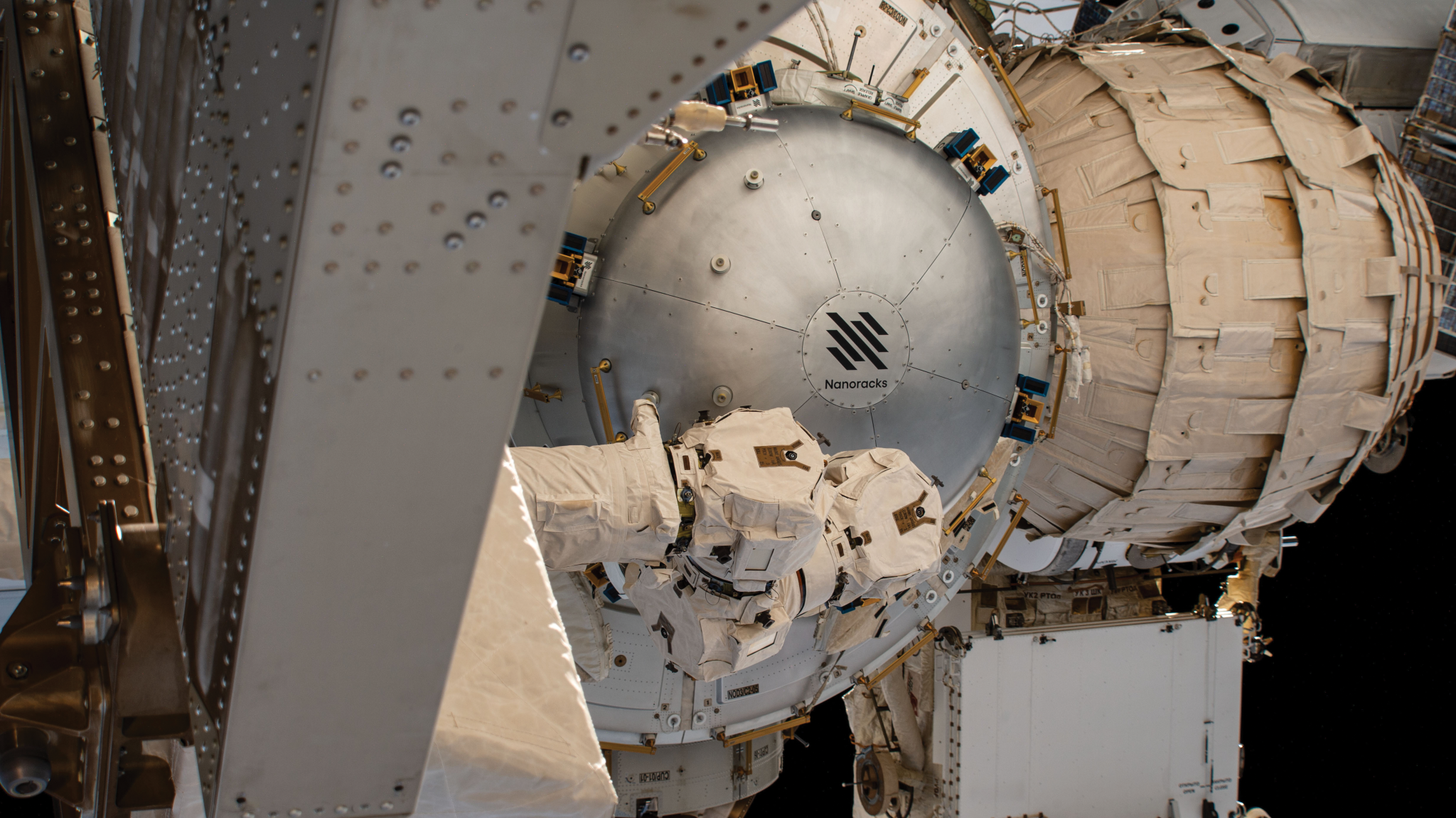

Houston-based Nanoracks is another company built largely on space technology. It has developed a multipurpose platform used on station for research on plant growth, radiation exposure, and materials and physical sciences. The company took a big step forward in 2020 with the launch of the Bishop Airlock, the station’s first commercially owned and operated airlock. The airlock adds a variety of capabilities, including deployment of small satellites called CubeSats and other external payloads and support for small exterior and internal payloads. It is much larger than the existing research airlock and therefore can accommodate more and larger payloads.

Another commercial provider, Space Tango, has an automated, reconfigurable research and development (R&D) and manufacturing platform called TangoLabs. This platform facilitates plant and agricultural science, organoid observation and growth, and flow chemistry, according to communications manager Danielle Rosales.

“The space station is currently the only in-space platform for microgravity R&D,” says Rosales. “We cannot do it anywhere else. It is a necessary incubator as we continue to identify the best pathways to manufacture health and technology products in space.” It also provides a pathway for Space Tango to grow as a company.

Another area of space research with commercial potential is the development of high-tech fabrics. The first scientific test of commercial fabrics on the space station was the ESA (European Space Agency) SpaceTex-2 investigation, which tested fabrics that provide higher evaporative heat loss compared to conventional cotton fabrics. The fabrics, provided by Swiss performance fabric manufacturer Schoeller Textil AG, are a first step toward developing products for use in space. On Earth, warm, humid environments promote growth of bacterial, viral, and fungal skin infections and rashes, and these faster-drying textiles could help reduce these problems. Quick-drying clothing could help athletes, firefighters, and the military.

Several commercial entities even have plans for developing their own space stations. A first step in that direction is a module, developed by Axiom, that attaches to the space station, nearly doubling its useable volume. Axiom also is launching private astronaut missions, which are privately funded, fully commercial flights to the space station, on commercial launch vehicles. They are dedicated to outreach, commercial research, or approved commercial and marketing activities.

“There always will be applied and fundamental research that NASA and other agencies want to do that need a microgravity platform,” says Mike Read, manager of NASA’s ISS Business and Economic Development Office. “But the International Space Station is going to be the last U.S.-government-led platform in low-Earth orbit. That is why we’re enabling the Axioms of the world to put a module on station and leverage its power, propulsion, and all of the space station infrastructure to build out their segment. Once it is built out, we can start thinking about separating the Axiom segment and comfortably retiring station.”

NASA has signed agreements with three other companies to develop space stations and other commercial space destinations: Blue Origin, Nanoracks, and Northrop Grumman Systems Corporation.

“Once these other platforms are up there, we can move facilities and customers into them to take advantage of that volume,” Read adds. “If we are going to develop the demand, we need a place to put it. We can provide scalability to some degree on the space station, but likely not enough for a company to turn a profit.”

The space station has also enabled commercial collaborations around the world. Bartolomeo, an external platform sponsored by ESA (European Space Agency) and developed by Boeing and Airbus, has 12 active and one passive payload sites with power management, payload commanding, data management and temporary storage, and flight environment determination functions. Potential applications include Earth observation, robotics, materials science, and astrophysics.

ESA’s International Commercial Experiments service, or ICE Cubes, developed in partnership with Space Applications Services and Belgium, offers an affordable, modular platform for experiments. The first investigations the facility hosted included plant biology, microbial bio-mining, and using a person’s heart rate to change a piece of kaleidoscopic artwork.

A Japan Aerospace Exploration Agency (JAXA) experimental facility on the space station – the Japanese Experiment Module (JEM), or Kibo — expands use of the space station for commercial technical demonstrations.

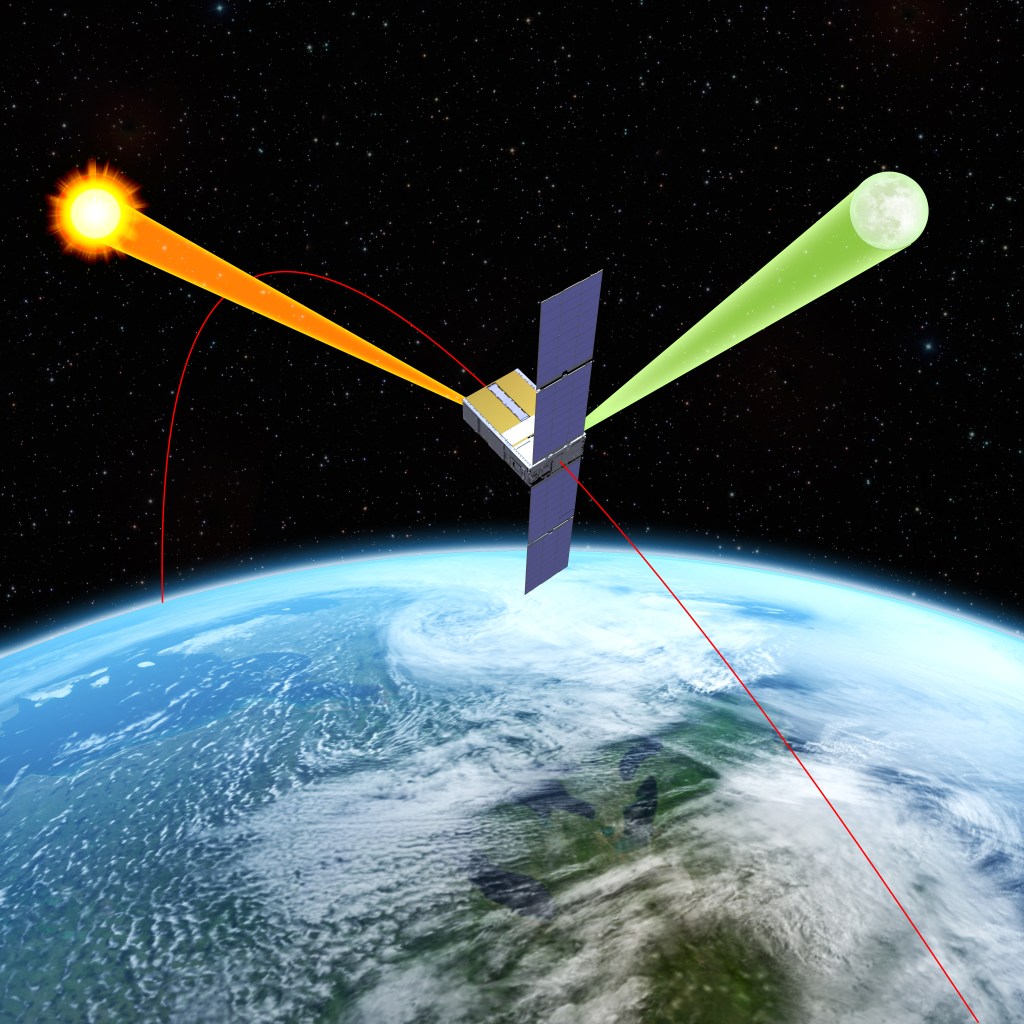

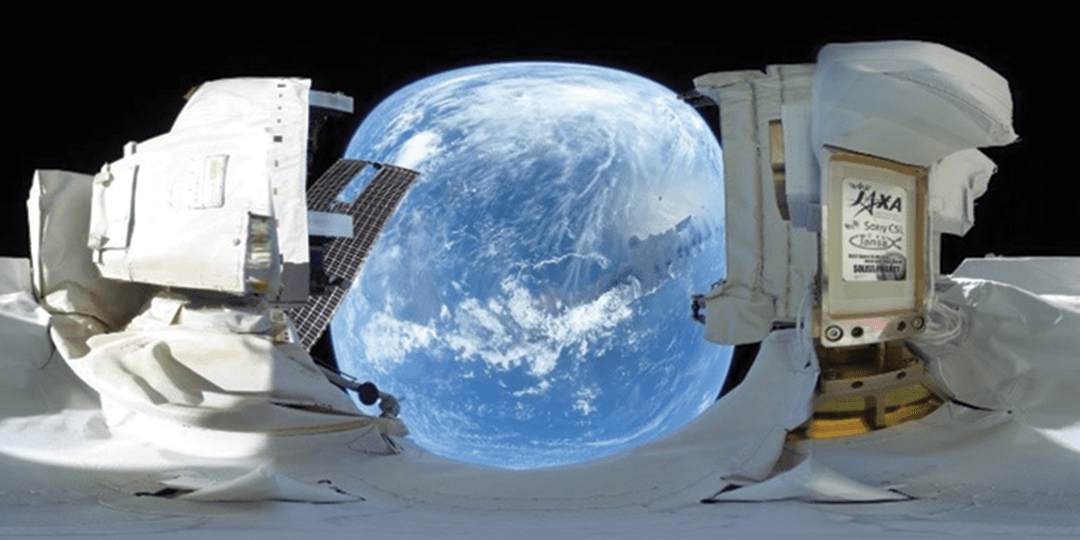

In March 2020, JAXA, along with Japan’s National Institute of Information and Communications Technology (NICT) and Sony Computer Science Laboratories, Inc. (Sony CSL), successfully created a bidirectional laser communication link between an optical communications system on the exterior of Kibo, called SOLISS, and the ground. JAXA and Sony Corporation have worked together since 2016 on research to establish real-time, mass-data communication systems for inter-satellite and satellite-to-ground communications. JAXA, NICT, and Sony CSL continue to conduct detailed analysis and evaluation of the experimental results and anticipate commercialization of the technology in the near future.

Laser communication offers greater ability than radio waves to scale bandwidth, and bidirectional laser communication could greatly increase data transmission speed. Demand continues to grow for faster transmission. This technology soon could help connect more people on Earth, especially those in remote locations.

“These commercial entities are leading the way, working with us, not for us,” said Read. “NASA is in a unique place to enable an economy off the Earth, to create an environment where companies see opportunity. We’ve been fairly successful so far and it is fantastic to be about to take things operational.”

The space station has validated many commercial hardware facilities for researchers to use. In total, there are now more than 30 of these commercial facilities available for space station partners to leverage. The validation of these commercial facilities helps to not only drive research and development on the space station, but also furthers business models in low-Earth orbit and beyond.

“I believe the space station has proven the value of microgravity as a resource,” says Redwire’s Rush. “Its potential to revolutionize fields as diverse as medicine, agriculture, communications, and manufacturing will only drive more commercial interest in the International Space Station and future commercial space stations.”