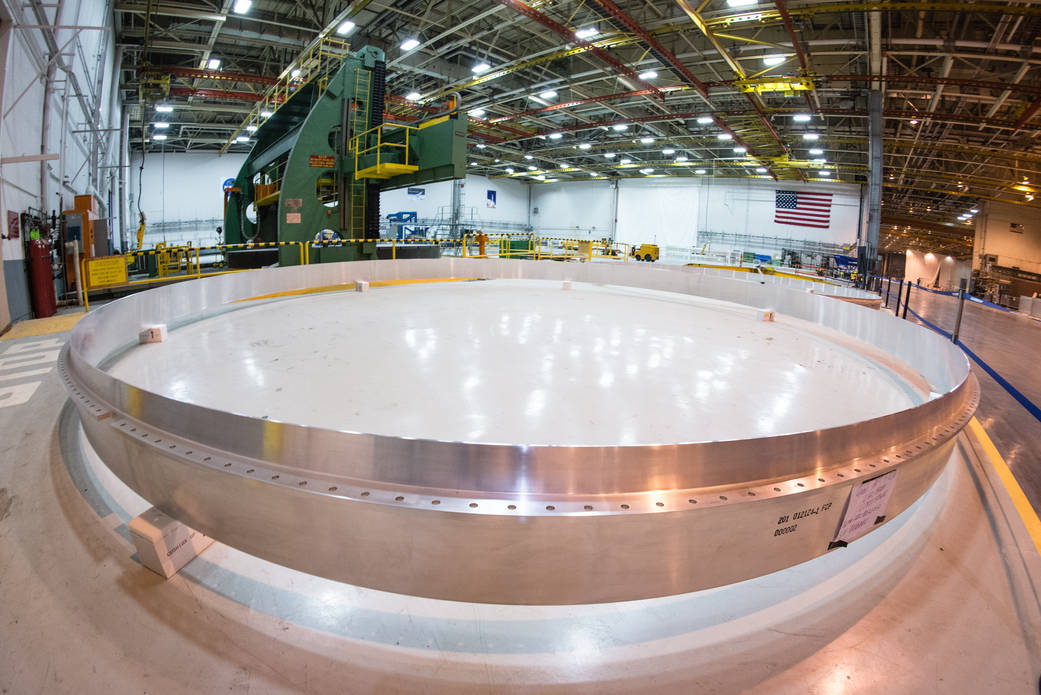

At NASA’s Michoud Assembly Facility in New Orleans, all of the flight rings for the Space Launch System’s first mission, EM-1, have been welded. The rings were made using the Segmented Ring Tool, which uses a friction-stir-weld process to produce segmented support rings for the SLS core stage. The core stage, towering more than 200 feet tall with a diameter of 27.6 feet, will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines. The rings connect and provide stiffness between domes and barrels. The Boeing Co. is the prime contractor for the SLS core stage, including avionics. For more information on SLS, click here.

Image credit: Boeing