Two small businesses are benefitting from NASA’s expertise as they develop heat shield technologies, cargo delivery systems, and new protective materials for spacecraft and space stations in the growing commercial industry of low Earth orbit operations.

The two American companies – Canopy Aerospace Inc. of Littleton, Colorado and Outpost Technologies Corp. of Santa Monica, California – recently announced progress in the development of a new heat shield manufacturing capability and a new cargo transportation system for potential use on the International Space Station and future commercial space stations.

“These projects are a great example of how NASA is supporting a growing commercial space industry,” said Angela Hart, manager of NASA’s Commercial Low Earth Orbit Development Program at the agency’s Johnson Space Center in Houston. “There is an entire ecosystem emerging where companies are working together and innovating to meet NASA’s needs and also positioning themselves to reach new customers, so that NASA can be just one of many customers in low Earth orbit.”

The companies work with NASA’s Commercial Low Earth Orbit Development Program through SBIR (Small Business Innovation Research) contracts funded by NASA’s Space Technology Mission Directorate. Both contracts are part of an innovative pilot program known as SBIR Ignite, focused on small businesses with commercially viable technology ideas aligned with NASA mission needs that can help support the expanding aerospace ecosystem.

Improving heat shields, saving time

Canopy Aerospace Inc., a venture-funded startup, is collaborating with NASA to develop a new manufacturing system that can improve production of ceramic heat shields – otherwise referred to as thermal protection systems (TPS). In the vacuum of space, spacecraft and space station hardware must withstand extreme cold and heat environments. Upon re-entry to Earth’s atmosphere, these craft in low Earth orbits are exposed to temperatures as high as 3,000 degrees Fahrenheit.

To protect spacecraft and space stations during re-entry, engineered TPS are required. NASA developed the first TPS types under the Space Shuttle Program, and similar technologies are still used today to protect the Orion spacecraft as it returns to Earth from space. Canopy’s RHAM (Reusable Heatshields Additive Manufacturing) platform builds on the shuttle program’s heritage methods, but utilizes novel materials, new binding, and heat treatment processes to create a new type of ceramic heat shield and produce it at scale in the commercial sector.

As more companies enter the commercial space market, improved heat shield manufacturing methods are critical to driving down launch costs, shortening lead times, and enabling new mission capabilities for future spacecraft.

Transporting cargo, saving space

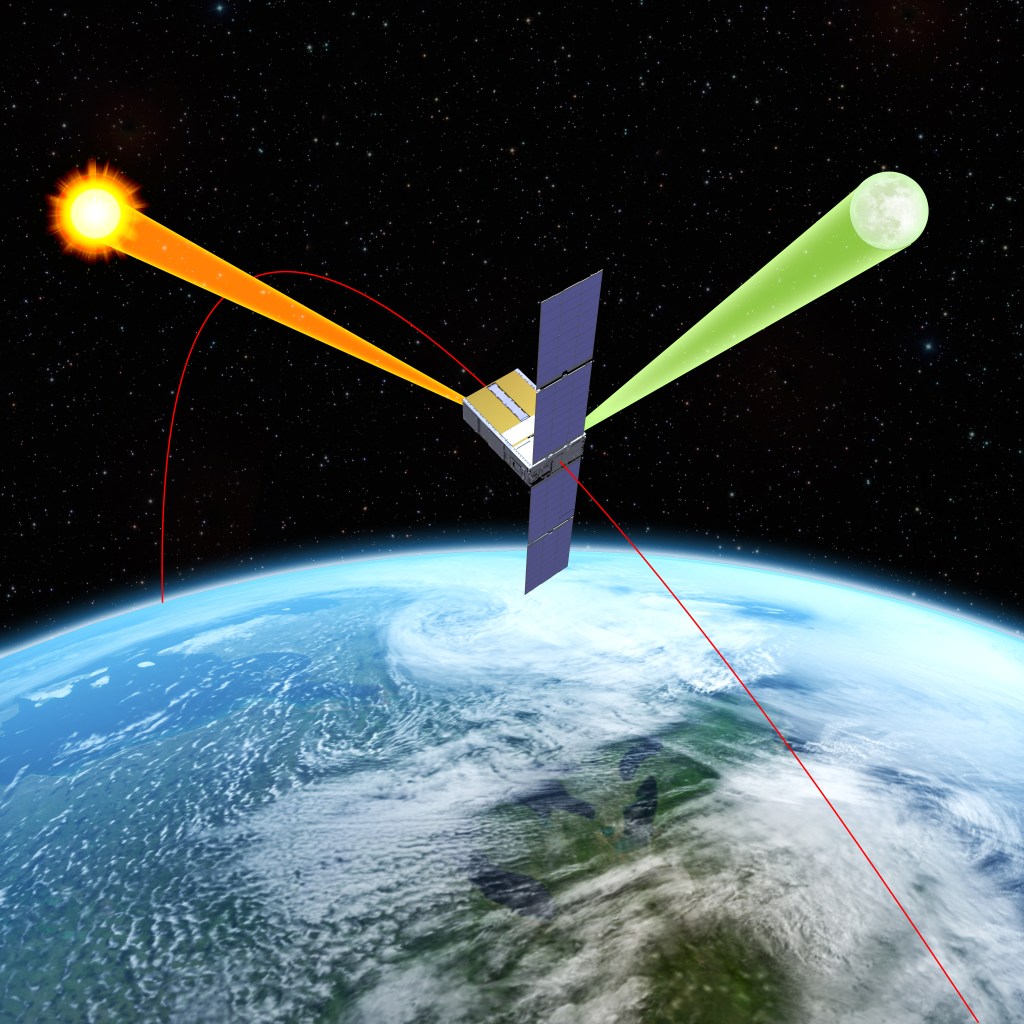

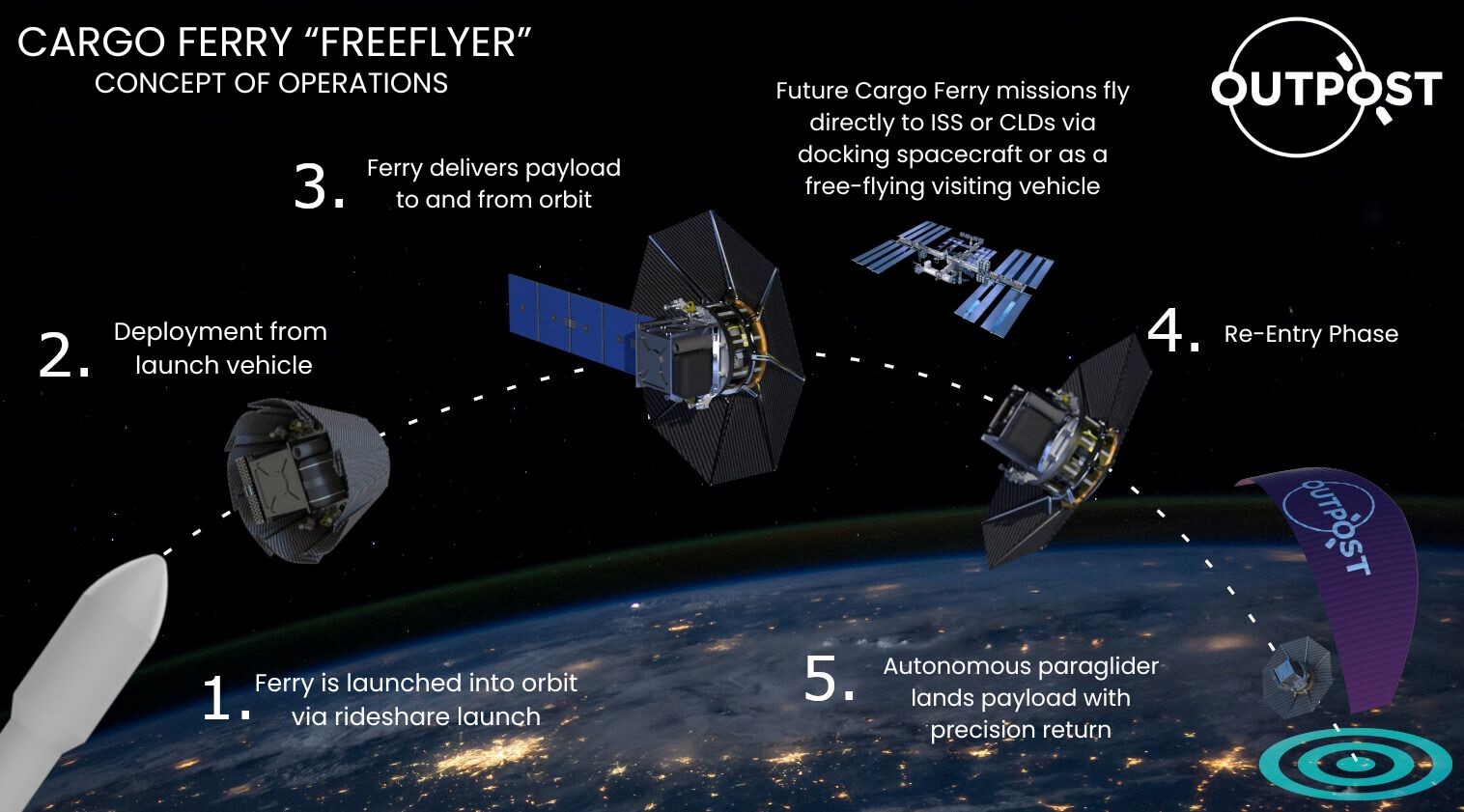

Outpost Technologies Corp. is collaborating with NASA to develop a new cargo transport vehicle, named Cargo Ferry. The reusable vehicle consists of a payload container for cargo, solar array wings to power the vehicle, a deployable heat shield to protect it on re-entry to Earth’s atmosphere, and a robotic paraglider system to deliver it safely to the ground with “landing pad” precision.

Cargo Ferry could transport non-human cargo including science and hardware from space stations back down to Earth more frequently, freeing up vital research and stowage space on board the station. Commercial space stations are expected to be smaller than the International Space Station, thus systems like Cargo Ferry could offer a more versatile and adaptable solution for cargo transportation.

NASA is supporting the design and development of multiple commercial space stations with three funded partners, as well as several other partners with unfunded agreements through NASA’s Collaborations for Commercial Space Capabilities-2 project.

NASA’s commercial strategy for low Earth orbit will provide the government with reliable and safe services at a lower cost and enable the agency to focus on Artemis missions to the Moon in preparation for Mars while also continuing to use low Earth orbit as a training and proving ground for those deep space missions.

For more information about NASA’s commercial space strategy, visit:

https://www.nasa.gov/humans-in-space/commercial-space/

Joshua Finch

Headquarters, Washington

202-358-1100

joshua.a.finch@nasa.gov

Rebecca Turkington

Johnson Space Center, Houston

281-483-5111

rebecca.turkington@nasa.gov