In May 1961, the fledgling U.S. space program had just 15 minutes of manned spaceflight. Yet the decision on the big goal had already been made: Before 1970, NASA would land a man on the Moon and bring him home.

Bigger rockets with more powerful engines than the small Mercury-Redstone rocket, that launched the first two Americans into space, were needed. Bigger engines meant more complexity and unknown problems to the young engineers in charge of developing them.

One of those young engineers was 28-year-old Sonny Morea, and one of those challenges was called combustion instability — a problem that plagued the massive F-1 engine led by program manager Morea.

“It was a disaster because once we had that instability, it would burn through the thrust chamber in milliseconds. The hardware went all over the place,” said Morea. Five F-1 engines powered the Saturn V’s first stage and were tasked with launching the 36-story-tall, 6.5-million pound rocket.

It was a disaster because once we had the instability, it would burn through the trust chamber in milliseconds

Sonny Morea

NASA Engineer

In the simplest view, combustion instability can be thought of as pressure swings in the engine caused by the multiple streams of liquid oxygen and rocket fuel combining and igniting at extremely high pressures in such a way that causes violent vibrations. In the Saturn V’s first stage engine, those pressure swings could cause destruction in fractions of a second.

Morea helped form a team of combustion experts from across the country to solve the problem. After more than three years, they had an answer.

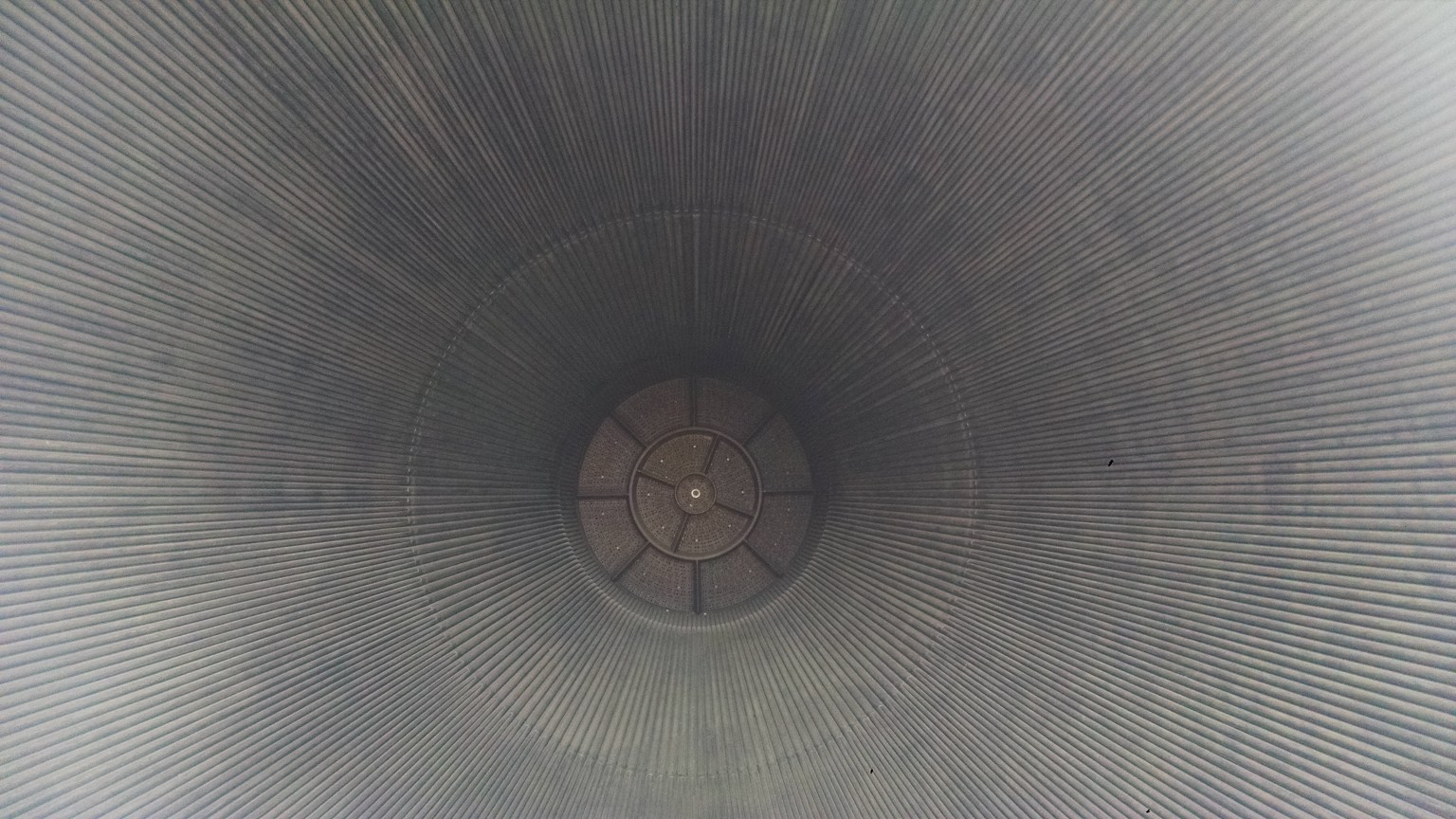

The solution resided in an earlier engine. The earlier engine did not experience the combustion instability issues the F-1 was having. The team determined that was due to the design of the injector plate through which the liquid oxygen and rocket fuel were fed into the combustion chamber. The injector plate on the engine was curved, fed by pods on the outside of the plate. Those pods acted as small rocket engines outside the thrust chamber, which resulted in the initial combustion taking place in smaller pockets in the large combustion chamber.

For Morea’s team, though, it was too late in development to change the shape of the flat F-1 injector plate. Instead, they added copper dividers, called baffles, between injector holes to create compartments on the plate and, hopefully, stabilize the engine. After multiple test firings, the solution appeared to work.

The next challenge was determining how the engine would react if instability did arise. The team took, literally, an explosive approach. They placed a small bomb in the center of the F-1 and ignited it at the same time they ignited the engine. The idea was to drive the engine unstable to determine if the baffles would stabilize the engine.

“And lo and behold, that’s what happened. The baffles seemed to solve the problem,” Morea said.

Multiple tests and multiple “bombings” during the tests gave the team a high level of confidence that the engines with the baffles would dampen out the vibrations should they arise. They had done all they could do, and that gave the astronauts great confidence as well.

From 1967 to 1973, 65 F-1 engines propelled 13 Saturn V rockets off the launch pad and on the way into space without any combustion instability problems.

As NASA and the country celebrate the 50th anniversary of the Apollo program, the stories, the lessons and the ingenuity of the Saturn and Apollo teams are once again powering America’s way to the Moon. NASA will return to the Moon by 2024, landing the first woman and the next man on the Moon’s South Pole. With Artemis, NASA will also be able to establish a sustainable human presence on the Moon by 2028 to uncover new scientific discoveries, demonstrate new technological advancements and lay the foundation for private companies to build a lunar economy.