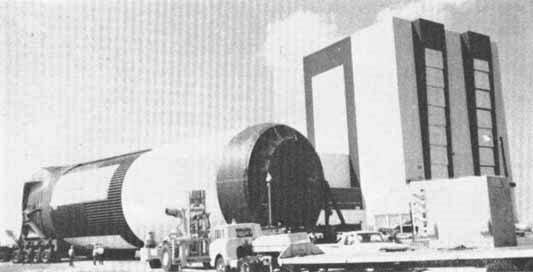

As Lao Tzu famously said, “Every journey begins with a single step.” In NASA’s case, the long journey to the Moon began with a slow crawl. On Aug. 26, 1967, the first flight-qualified Saturn V Moon rocket, SA-501, made the slow 3.5-mile ride from the Vehicle Assembly Building (VAB) to Launch Pad 39A at NASA’s Kennedy Space Center (KSC) in Florida. It took engineers one year to assemble and test the 363-foot-tall rocket in the VAB – including destacking the vehicle twice to respond to technical issues – to prepare it for the rollout. The Apollo spacecraft atop the rocket also endured its challenges, including a thorough inspection of its wiring following the fatal Apollo 1 fire. Once at the pad, the vehicle underwent several months of preparation for the Apollo 4 unpiloted test mission, the first launch from KSC.

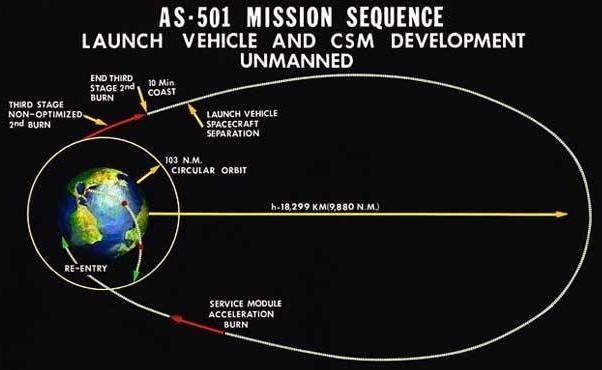

Mission sequence for the uncrewed SA-501 test mission, later designated as Apollo 4.

With President John F. Kennedy’s deadline approaching for landing a man on the Moon by the end of the decade, NASA Associate Administrator for Manned Space Flight George E. Mueller decided on a bold approach for the Saturn V rocket’s first flight. Instead of the more conservative method of first testing each rocket stage individually, and then flying the complete rocket, he chose the “all-up” approach, in which all the rocket’s stages would be tested on a single flight. The goals of the SA-501 mission thus included testing the three stages of the Saturn V as well as testing the Apollo spacecraft in a highly elliptical Earth orbit, with the main objectives to test the Service Module’s main engine and most importantly the Command Module’s heat shield at near-lunar return velocities. But before the flight could take place, workers needed to assemble the components of the rocket and spacecraft, a process that took one year, overcoming significant challenges along the way.

Left: Ground crews unload the first component of the SA-501 Saturn V to arrive at NASA’s Kennedy Space Center (KSC) in Florida, the S-IVB third stage, from its Super Guppy transport plane. Right: The S-IC first stage of SA-501 arrives at KSC’s Vehicle Assembly Building.

As the first components for the first flight Saturn V vehicle, SA-501, arrived at KSC in the summer of 1966, engineers continued testing the facility verification non-flight vehicle, SA-500F, at Launch Pad 39A since May 25, 1966. On Aug. 14, a Super Guppy cargo aircraft delivered the first component of SA-501, the S-IVB third stage, from the McDonnell Douglas facility in Sacramento, California. Engineers in the VAB immediately began inspection and checkout of the stage. The following week, the spool-shaped S-II stage simulator, often called the spacer, arrived. It took the place of the actual S-II stage, significantly delayed in its delivery, during stacking tests. The Instrument Unit (IU), used to guide the rocket during its ascent, also arrived in late August. The Spacecraft Lunar Module (LM) Adapter (SLA) that enclosed the LM during launch arrived by Super Guppy on Sept. 6. On Sept. 12, the same day that Charles “Pete” Conrad and Richard F. Gordon lifted off on their Gemini-XI mission, the S-IC first stage arrived by barge from NASA’s Marshall Space Flight Center in Huntsville, Alabama. On Sept. 20, the two stages of the Lunar Module (LM) Test Article-10R (LTA-10R) arrived by Super Guppy cargo aircraft from the Grumman Aircraft Engineering Corporation facility in Bethpage, New York. The LTA-10R served to simulate the mass properties of the LM on this test flight, with instrumentation to monitor vibrations and accelerations during the mission.

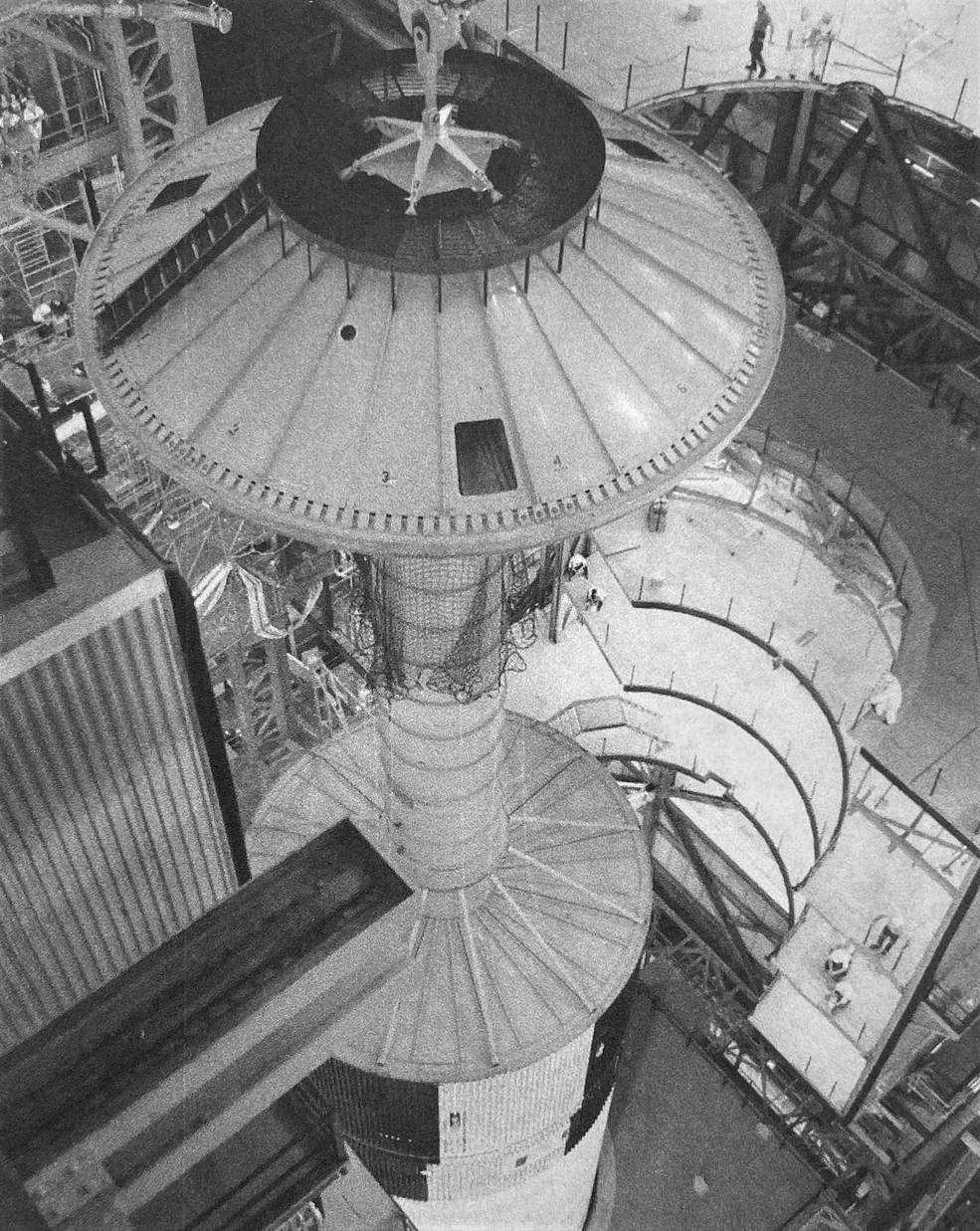

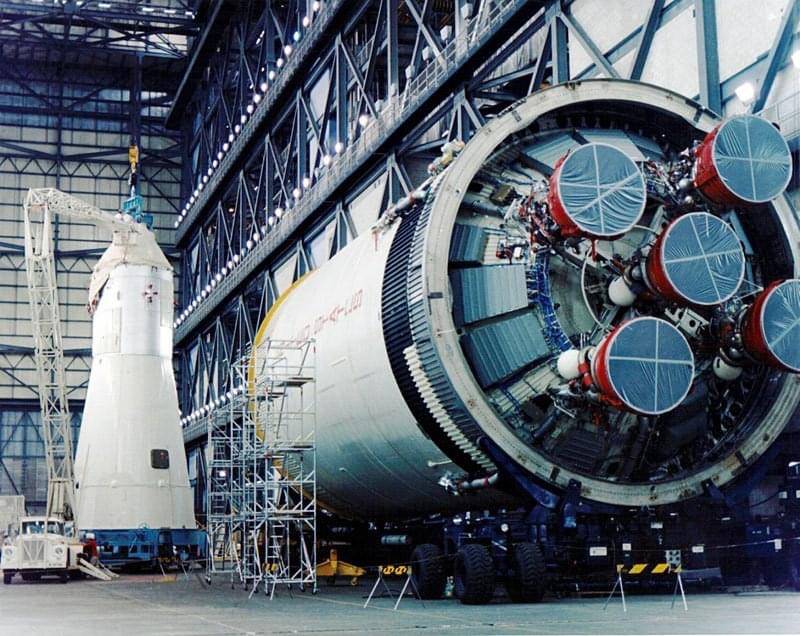

Left: Workers stack the SA-501’s S-IC first stage on Mobile Launcher-1 in High Bay 1 of the Vehicle Assembly Building at NASA’s Kennedy Space Center in Florida. Middle left: Workers stack the S-II second stage spacer onto the first stage. Middle right: Workers stack the S-IVB third stage onto the S-II spacer. Right: Workers lower the Instrument Unit onto the S-IVB third stage.

On Oct. 14, the SA-500F vehicle returned to the VAB’s High Bay 1 from its five-month checkout at Launch Pad 39A. By Oct. 21, workers had destacked the rocket from Mobile Launcher 1 (ML-1), clearing the way for them to stack SA-501’s S-IC first stage just six days later. They added the S-II spacer on Oct. 31, the S-IVB third stage on Nov. 1, and finally the IU the next day.

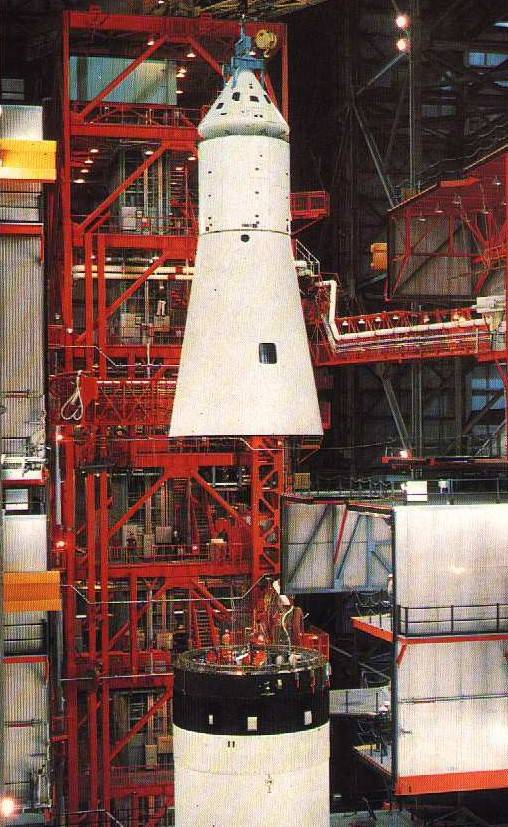

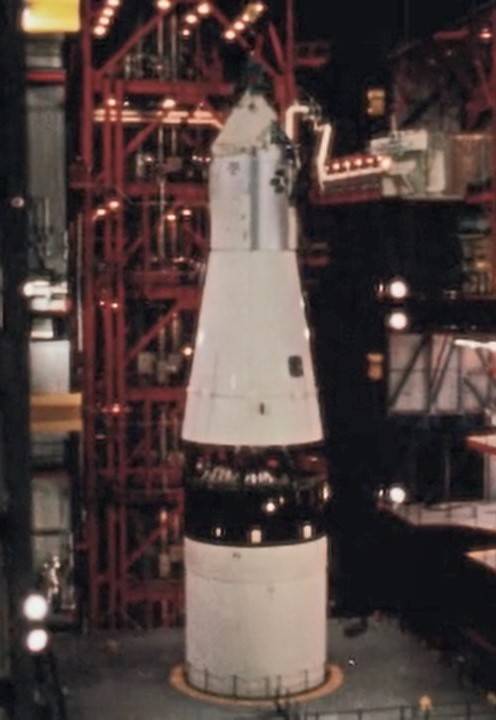

Left: Ground crews in the Vehicle Assembly Building (VAB) lower the facility verification spacecraft onto the S-IVB third stage of the SA-501 vehicle. Middle: The S-II second stage for SA-501 arrives at the VAB. Right: The complete SA-501 vehicle, with the facility verification spacecraft in place of the actual Command and Service modules.

Because the flight Apollo spacecraft had not yet arrived at KSC, on Nov. 28 workers topped off SA-501 with the M-11 non-flight facility verification spacecraft instead, allowing them to check out support equipment. Those tests completed, they destacked the verification spacecraft, replacing it on Jan. 12, 1967, with the flight spacecraft that arrived just before Christmas. The tardy S-II stage finally arrived at KSC by barge from the Mississippi Test Facility, now NASA’s Stennis Space Center, in Bay St. Louis, on Jan. 21, and workers temporarily stowed it in the VAB’s transfer aisle. The Apollo 1 fire on Jan. 27 placed all assembly work on hold as managers decided on future plans.

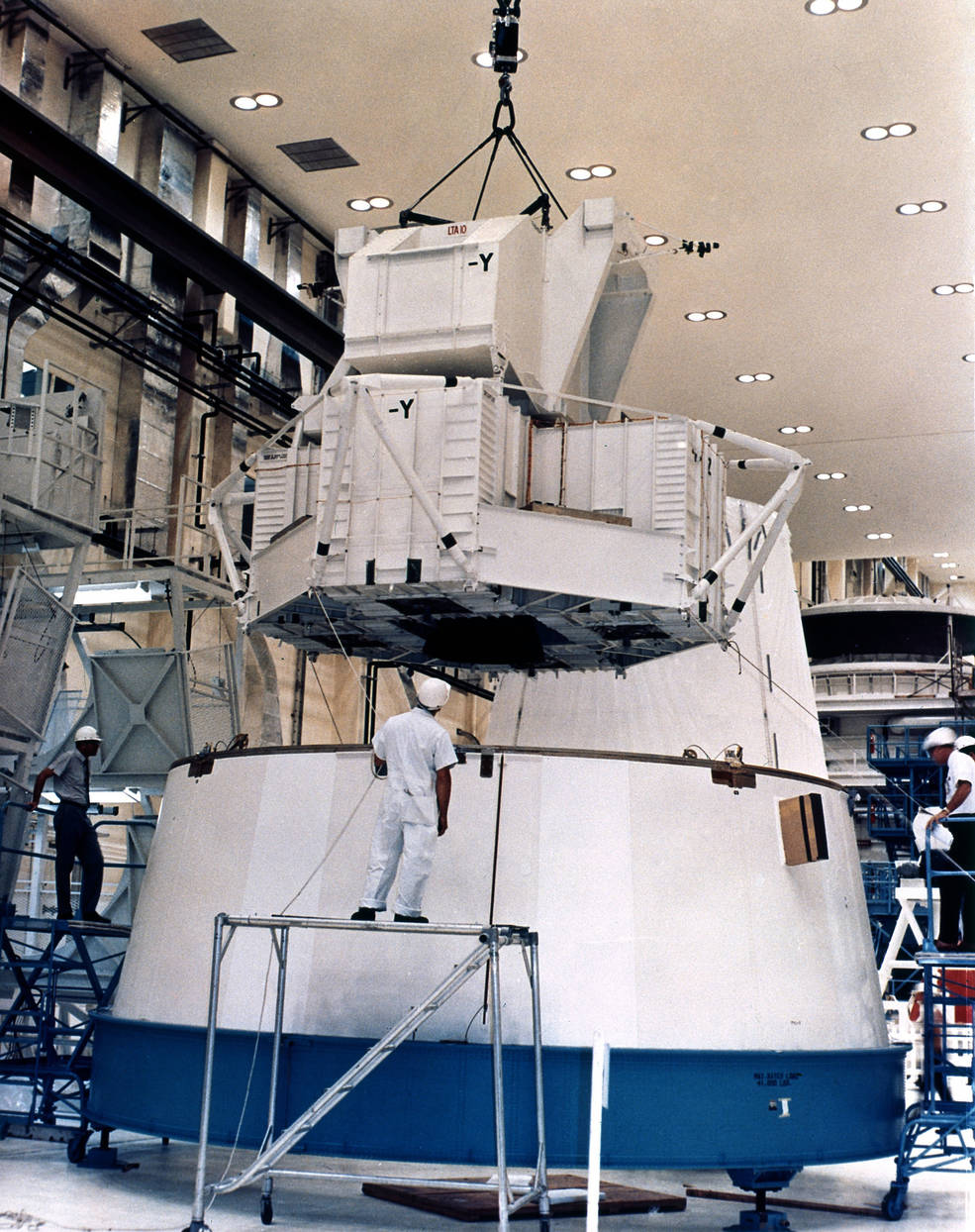

Left: In the Manned Spacecraft Operations Building (MSOB) at NASA’s Kennedy Space Center, workers lower the Lunar Test Article-10R into the base of the Spacecraft Lunar Module Adapter. Middle: Workers in the MSOB mate the Command and Service Modules for the SA-501 mission. Right: The integrated spacecraft for the SA-501 mission rolls out of the MSOB on its way to the Vehicle Assembly Building.

Meanwhile, in KSC’s Manned Spacecraft Operations Building (MSOB), engineers began preparing the Apollo spacecraft for flight. After mating the two stages of LTA-10R on Nov. 20, they installed the LM mass simulator in the SLA. The Service Module (SM-020) and Command Module (CM-017) for the mission arrived by cargo aircraft on Dec. 21 and 24, respectively, from the North American Aviation plant in Downey, California. The original SM-017 assigned for this mission suffered a catastrophic fuel tank rupture in October, and workers replaced it with SM-020 assigned to a later mission. After testing in the MSOB, engineers mated the two modules on Dec. 28, stacked it on top of the SLA, and trucked the assembled spacecraft to the VAB on Jan. 12, 1967, for mating with the Saturn V rocket.

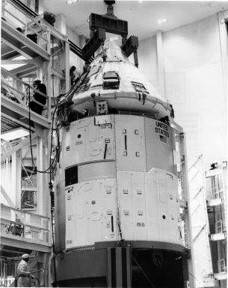

Left: Workers in the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center in Florida hoist the Apollo spacecraft for the SA-501 mission, with the bottom of the Lunar Test Article-10R visible, in preparation for stacking it onto the rocket. Middle: Workers lower the spacecraft onto the S-IVB third stage. Right: Workers remove the spacecraft from the rocket, with the S-II spacer partially visible, during the first destacking operations in February 1967.

In the aftermath of the Jan. 27 Apollo 1 fire, on Feb. 13 workers removed the spacecraft from the rocket and returned it to the MSOB so engineers could inspect the CM for any possible wiring issues similar to the one that caused the fire. This also provided an opportunity to destack the S-IVB and the S-II spacer, replacing the latter on Feb. 23 with the newly-arrived actual S-II stage. They added the S-IVB the next day, and with the flight spacecraft still in the MSOB where safety engineers recorded more than 1,400 wiring discrepancies, on April 6 they topped the rocket once again with the M-11 facility verification spacecraft to continue testing.

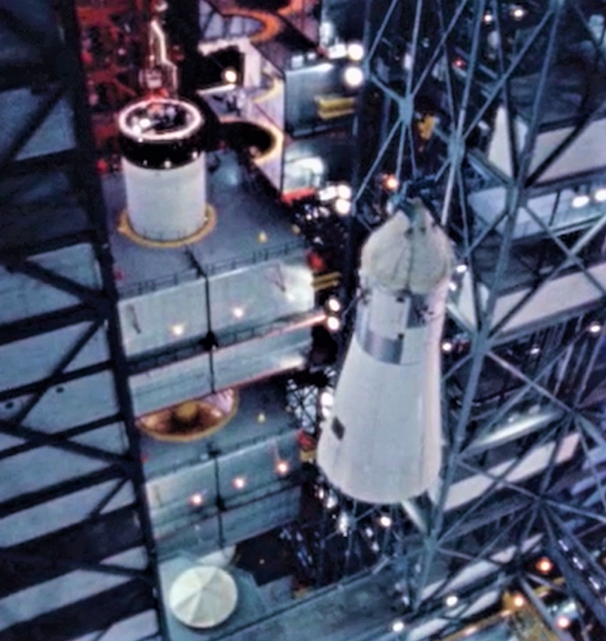

Workers in the Vehicle Assembly Building stack the S-II second stage, left, and the S-IVB third stage for the final time in June 1967.

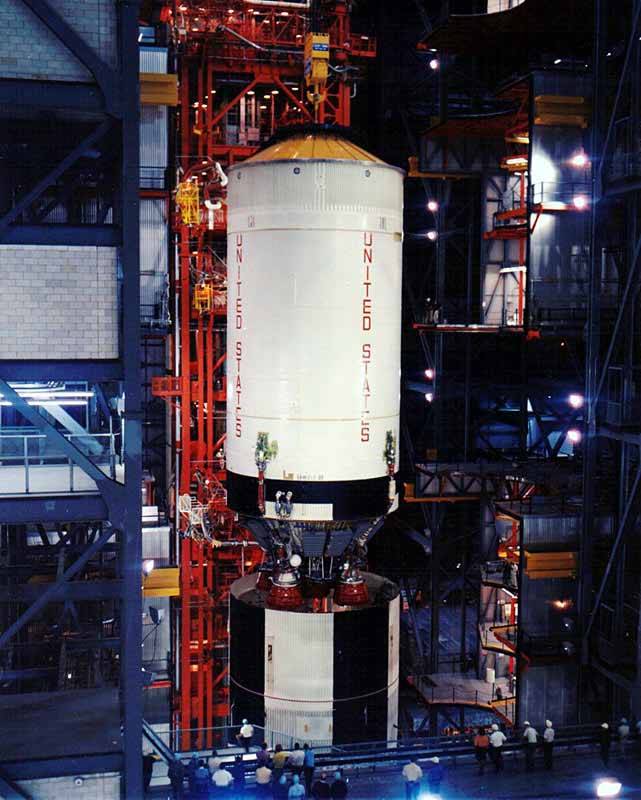

Left: In June 1967, workers prepare to lift the Apollo 4 spacecraft for mating with the SA-501 rocket for the final time, with the S-II second stage for the SA-502 Apollo 6 mission at right. Middle: Workers stack the Apollo 4 spacecraft. Right: Shortly before the rollout, workers install the Launch Escape System tower atop the Command Module.

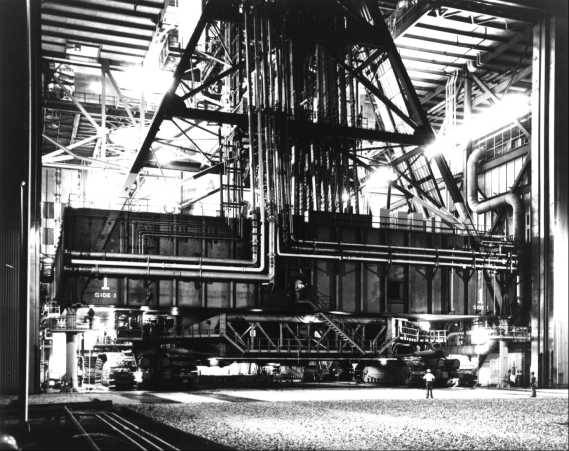

Meanwhile, on May 24, engineers at the North American plant found hairline cracks in propellant tank welds of another S-II stage. The next day, workers in the VAB began the second destack of the rocket, removing the S-II stage on June 3 for detailed inspections. Extensive X-ray and dye penetrant tests revealed no cracks, and workers began re-assembling the rocket on June 18. Engineers in the MSOB finished the wiring work in CM-017, reassembled it with its other components, and returned it to the VAB where ground crews stacked the spacecraft for the final time on June 20. The stacking, unstacking, and restacking process had taken eight months. Engineers completed a series of integrated tests to prepare the vehicle for its rollout to the launch pad. In the meantime, in the VAB’s High Bay 3, on March 29, workers stacked the S-IC first stage of the SA-502 vehicle on ML-2 for the Apollo 6 mission, another uncrewed test of the Saturn V rocket and Apollo spacecraft planned for early 1968. After a stack-destack-restack round initially using the S-II spacer due to the late arrival of this S-II stage, workers finished assembling the three-stage rocket for Apollo 6 on July 14, marking the first time that two Saturn V rockets stood side by side in the VAB.

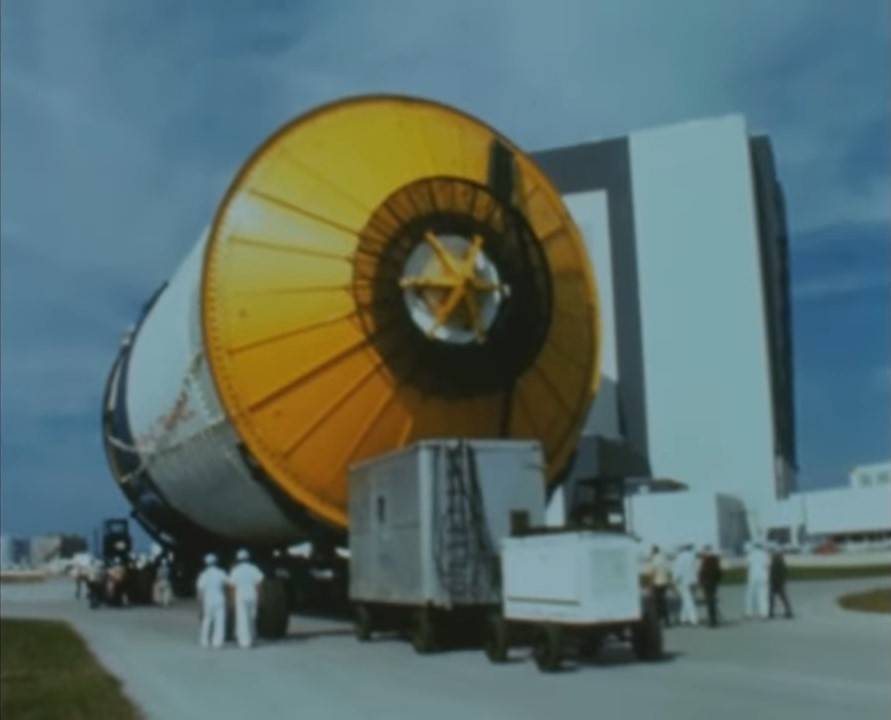

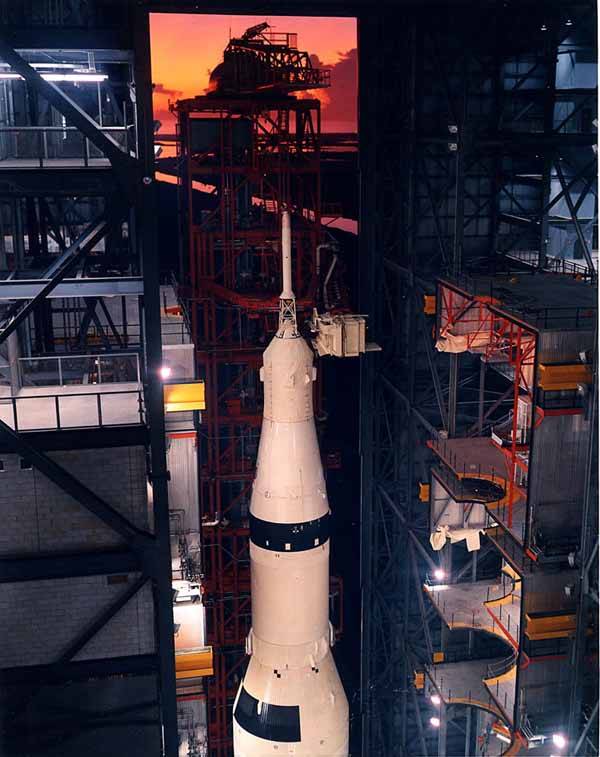

Left: In the VAB, the crawler transporter positions itself below Mobile Launcher 1 in preparation for rollout of SA-501 to the launch pad – note the worker in the foreground for size comparison. Right: From inside the VAB looking out, SA-501 for the Apollo 4 mission prepares to rollout to Launch Pad 39A.

Left: The SA-501/Apollo 4 stack, reflected in the water, begins the slow trek to Launch Pad 39A. Middle: Apollo 4 passes a palm tree en route to the pad. Right: Apollo 4 has passed the Mobile Service Structure, at left, as it nears the pad.

On the morning of Aug. 26, 1967, the crawler transporter rolled underneath ML-1 and picked it up from its six mount mechanisms. The first flight-ready Saturn V exited the VAB to begin its slow rollout to Launch Pad 39A, with reporters from around the world witnessing the historic event. The 18-million-pound combination of the rocket, the mobile launcher, the launch umbilical tower, and the crawler transporter moved at less than one mile per hour to make the 3.5-mile trip in about five hours. Having delivered the rocket to the pad, the crawler transporter backed away, rolled to pick up the Mobile Service Structure (MSS) parked nearby, and returned to the pad. The MSS, containing work platforms at various levels, encased the rocket giving engineers access to the vehicle to service it.

Left: The SA-501/Apollo 4 stack on Launch Pad 39A. Right: The Mobile Service Structure approaches the Saturn rocket.

After several months of integrated tests at the pad, Apollo 4 flew its successful nine-hour test flight on Nov. 9, 1967, paving the way for future missions that achieved President John F. Kennedy’s goal of “landing a man on the Moon and returning him safely to the Earth” before the end of the decade.