Lynn Rothschild

NASA Ames Research Center

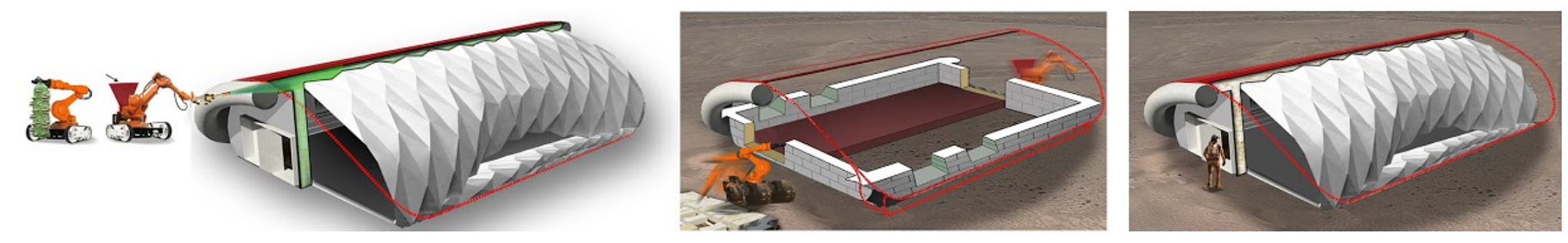

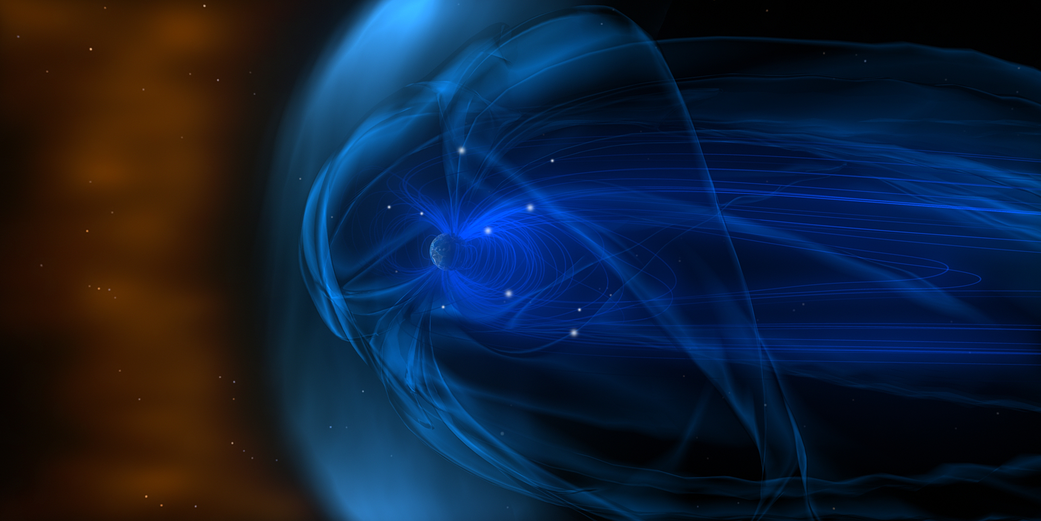

A turtle carries its own habitat. While reliable, it costs energy in transporting mass. NASA makes the same trade-off when it transports habitats and other structures needed for human and other applications on lunar and planetary surfaces “on the back” of its missions. During Phase 1, we identified a novel biology-based solution to in situ production of usable components for space exploration: using fungal mycelial composites to grow structures off-planet, from habitats to furniture. In Phase 1, we delivered the biological strains needed to produce the mycelia appropriate to engineering uses, a fabrication process to form the mycelia into blocks and stools, an adhesive to join the blocks into components, and mechanical testing to characterize the strength of the parts. We developed architectural designs, and a mission architecture to implement the concept on Mars. The results have attracted wide attention from the press and the project, through the participation of the 2018 Stanford-Brown-RISD iGEM team, was nominated for best manufacturing project and best new composite part in the premier student synthetic biology competition. Phase 2 will continue to develop the Phase 1 concept, but now intensifying our focus towards lunar habitats with feet forward to Mars implementation. We will continue to develop the technology by developing a novel prototype which uses the mycelia to fill a lightweight porous scaffold coated with nutrient hydrogel enclosed in plastic sheets (“bag”) or a living cyanobacterial feedstock. Key technology parameters (choice of fungi, growth conditions and speed, pore size) will be tested in the miniature prototypes. Selected prototype habitats will be tested for their mechanical properties, and then in a planetary simulator to assess resistance to specific challenging lunar and Martian conditions and to gauge the degree to which developed capabilities can be delivered in those conditions. More complete structures, including infrastructure for a habitat like plumbing and air handling components, will be conceptualized and progress towards such designs will be undertaken. A mission architecture that will be flexible, as is appropriate for the flexible nature of the components themselves, and the potential broad outlines of a systems engineering scheme for lunar implementation will be created in response to those of our development goals that appear to be most viable. As we develop a pathway to implementation, key knowledge gaps in the technology, habitat design and mission architecture will be identified in close step with developments in understanding human needs in such habitats and systems in the lunar context. This will include an estimate of mass and other factors required for implementation as the design is refined from Phase 1. Finally, we will expand our assessment of the use of this revolutionary fabrication and building approach for immediate terrestrial applications in stressed environments where rapid and lowcost applications to house people are in dire need; for example, in areas of dislocation due to war or environmental change, endemic poverty, and other adverse factors; and for furniture for earth and space. We envision future enhancements to the mycelial structure; some will be explored now at no cost to the NIAC proposal. The capabilities of the mycelia will be developed using bioengineering augmentation; for example, production of useful polymers will be considered. We envision a future that includes the addition of cyanobacteria that can produce oxygen, bacteria that can provide sensing capabilities (e.g., sensing of environmentally relevant gases like oxygen for crew health support), and decoration of the mycelia with proteins for assorted chemical transformation functions. Enhancements such as these can result in “living architecture” in the true sense of the word, because of sensitivity and near real-time adaptability to internal and external environmental changes.