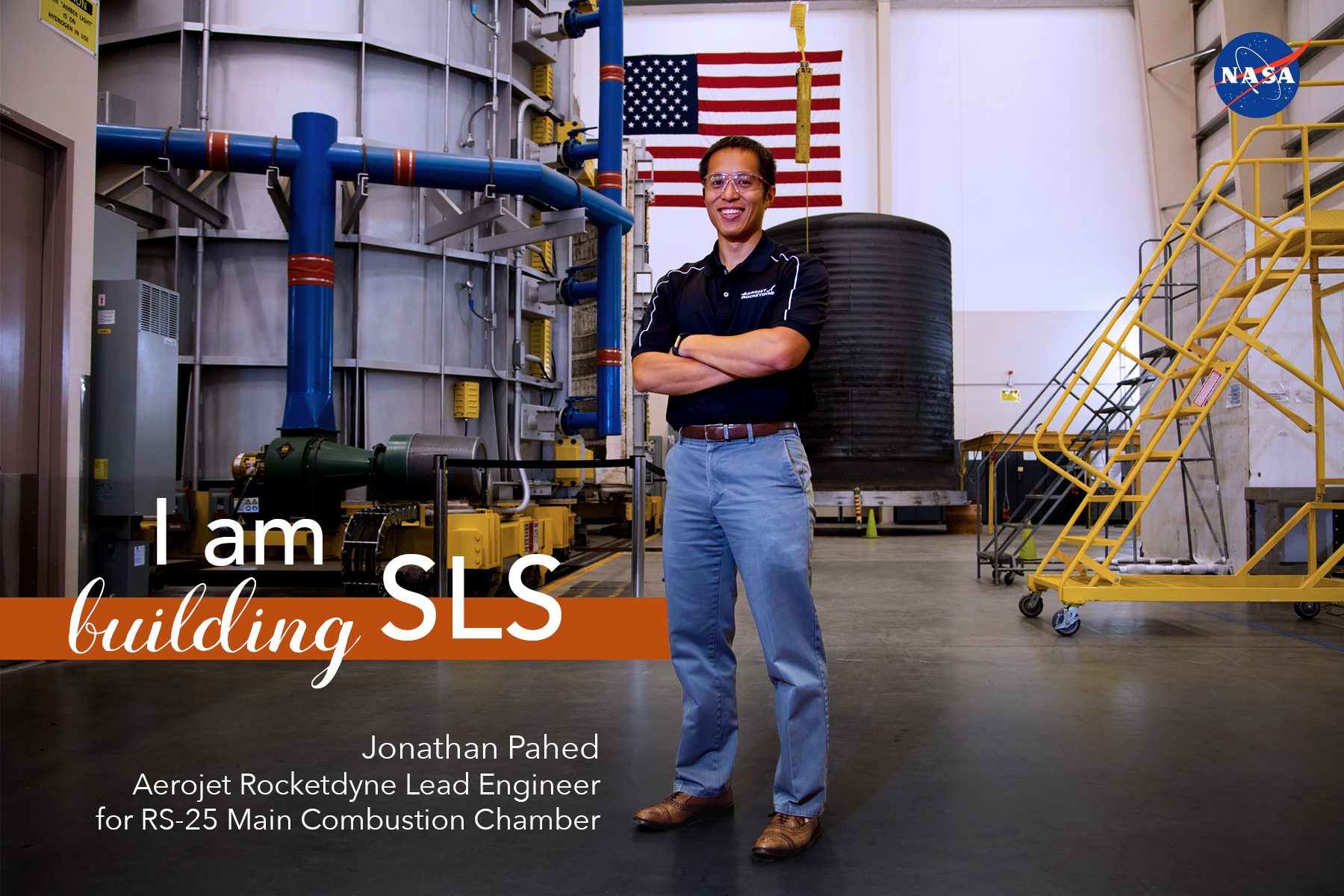

SLS Engineer Reduces Engine Costs with Innovative Manufacturing

Jonathan Pahed, Aerojet Rocketdyne Lead Engineer for RS-25 Main Combustion Chamber

From hiking to biking to running to rock climbing, I love a good adventure. My greatest adventure so far is working on engines for NASA’s deep space rocket, the Space Launch System (SLS.)

As the lead engineer for the RS-25 main combustion chamber, I’m focused on new and improved ways of building the combustion chamber to save time and reduce costs. The main combustion chamber is one of the most critical and complex parts of the engine because it is where the entire thrust of the engine begins. Inside the chamber, the fuel and oxidizer mix and combust, then the high-pressure gas is accelerated out of the nozzle producing the thrust that powers the rocket.

I am a component product engineer and my team of about 20 engineers is a group of experts that have followed the chamber from design to testing and will continue to work with it through launch, flight and future missions. Deep space exploration isn’t just one flight; there will be many flights of SLS. We have begun the smart manufacturing of engines for future flights once the 16 proven engines from the space shuttle era have been used for the first four missions. I enjoy telling people I work for a company that helps send humans to the Moon and Mars and push the human race farther than it’s ever been.

We have updated the fabrication method of the chamber, and the new design reduces complexity by eliminating numerous piece parts and welds. The chamber is made in less time for less money using a metal bonding technique called Hot Isostatic Pressure — or HIP bonding.

The innovative bonding process has reduced costs by around 50 percent and shortened the build time from more than three years to around 18 months. Our work is improving the overall quality of America’s new deep space rocket.

Before supporting SLS, I earned a degree in mechanical engineering at California State University in Los Angeles in 2009 and a master’s degree in mechanical engineering from the University of California Los Angeles in 2017.

When I’m not working on the most powerful rocket in the world, I am highly entertained with my two favorite hobbies of all: spending time with my wife, Alison, and playing with our 1-year-old son Benjamin. I can’t wait to share stories with Benjamin when he is older about how his dad helped build the world’s most powerful rocket.