They were perhaps some of the most visible images of the end of each Apollo mission: Giant orange and white parachutes unfurled high above the spacecraft, gently descending toward the ocean. As NASA continues to build the Orion spacecraft and head toward its first unmanned test flight in 2014, it will once again descend under parachutes to a water landing. But even though the orange and white chutes remain, their design and testing is quite different than in the past.

Orion will be the most advanced spacecraft ever flown, and its parachutes have been designed with a return from exploration missions in mind. The spacecraft will weigh more than 21,000 pounds as it descends through the air. Each of the main chutes only weighs 300 pounds, so it is quite a feat of engineering that they are able to catch the heavy weight of the spacecraft underneath them.

“Because each of our main parachute chutes has a large diameter of 116 feet, it gives us a huge surface area to capture air and provide a smooth descent toward the ground,” said Chris Johnson, NASA’s project manager for the Orion parachute assembly system.

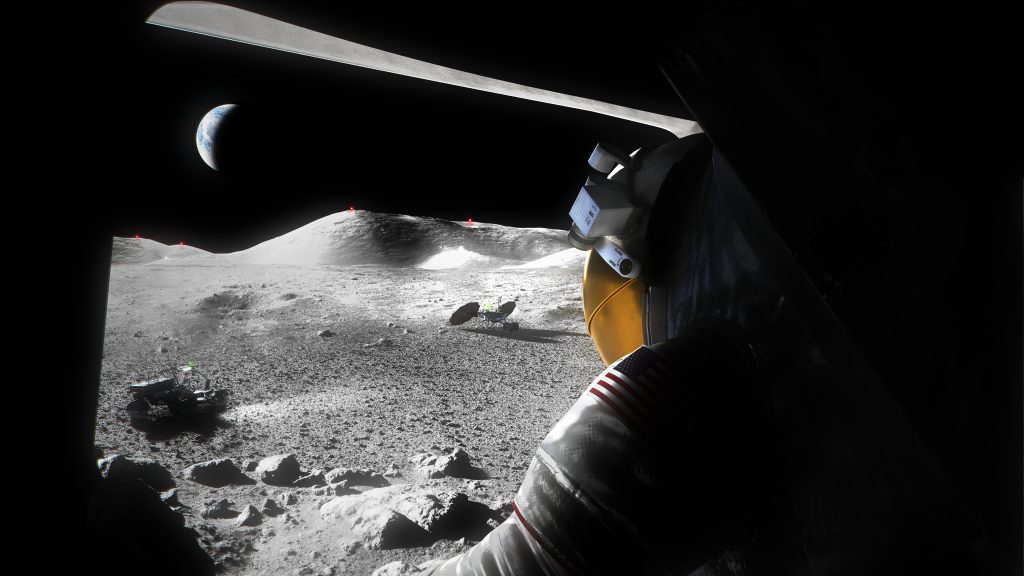

Johnson adds that safety of the crew is the key driver in parachute design and performance. Because of that, NASA’s engineers have tested Orion’s parachutes high above the Arizona desert at the U.S. Army Yuma Proving Ground. Each test has taken a look at different conditions or failures that could happen as each chute is deployed. The teams have basically pushed the parachute system to its limits to prove that – even if things don’t go according to plan – Orion’s parachutes will work as designed.

Orion’s parachutes are deployed in a series. The first ones that appear are the drogue chutes, two smaller chutes that help stabilize and slow down the spacecraft. These drogues are deployed at approximately 20,000 feet and each one is 23 feet in diameter. Those are cut away after approximately 30 seconds, and three pilot chutes are briefly deployed, which help pull out and deploy the main parachutes.

For even more stability and safety, the main chutes inflate in stages, with what are called “reefs” keeping the canopy of the chutes bound until the proper time. Initially, the chutes are opened and held to 3.5 percent of their full capacity by the first set these reefs. They are cut, and the chutes are opened to 11 percent of their capacity and held there by another set of reefs. Once that second reef is cut on each chute, all three canopies open to full diameter.

At Yuma, the engineers have been testing what happens if a drogue fails to deploy, or if one of the reefing stages is skipped. In all cases, Orion’s parachutes have performed well, and the spacecraft touched down as expected. This has demonstrated that not only is the design of the parachutes acceptable, but the models and analysis the engineers have completed are also working as expected and are reliable.

NASA’s team also has been testing the actual material that makes up the parachutes. Orion’s parachutes are made of Kevlar and nylon, and the goal has been to make them as rugged as possible, while still keeping them lightweight. Engineers at NASA’s Johnson Space Center in Houston have been ensuring that the parachute material holds up to the extreme environment of a spacecraft descent and that normal wear and tear on the material – even in intense scenarios – doesn’t impact how they operate.

“The canopy itself is nylon, but the risers and other cords that attach to the chute are Kevlar, and the spacecraft is metal, so you have the potential for the material to rub and to degrade during the deployment process or even as Orion descends toward the ground,” said Koki Machin, NASA’s chief engineer for the Orion parachute assembly team.

“The chutes themselves are an extremely lightweight, delicate collection of pieces that absolutely must act together simultaneously or fail with disastrous results. They must assemble themselves in midair at a variety of possible velocities and orientations,” Machin said. “They are amazing pieces of technology.”

Another challenge: How do you pack these enormous parachutes into the top of the spacecraft? After all, Orion has to take its chutes with it on whatever journey it goes on. The answer to that question comes down to a technique anyone who has packed for vacation has learned: You just have to squeeze them in.

“The parachute manufacturer has this enormous tool that pushes and compresses the parachutes down to where we basically end up with a small square block of parachute with a density close to that of wood,” Machin said. “We are then able to place each of the chutes into the parachute compartment at the top of the spacecraft.”

NASA continues to practice recovery methods for Orion once it is in the water, but the teams are also looking at the best way to recover the parachutes after splashdown. The teams recently used NASA’s Neutral Buoyancy Laboratory in Houston to examine how long the parachutes floated in the water, and the best ways to approach the chutes and get them out of the water.

“We verified that the drogues actually sink fairly quickly, with the main chutes staying afloat a bit longer,” Johnson said. “We believe the best way to secure the chutes after landing will be for a small team to approach the chutes and attach a buoy onto the top of the parachutes to keep them from totally sinking. That allows for a larger team to come back later and attempt to recover all of the chutes from the water.”

Eventually, the recovery teams will test the parachutes and the spacecraft in the open waters of the ocean to verify the best approach for recovering the crew and Orion and its chutes. All of this testing – in the skies, in the water, and in the labs – is helping ensure that Orion is the safest spacecraft ever designed in all phases of the flight – launch, orbit and the return home.