Serena Ferraro

California Institute of Technology

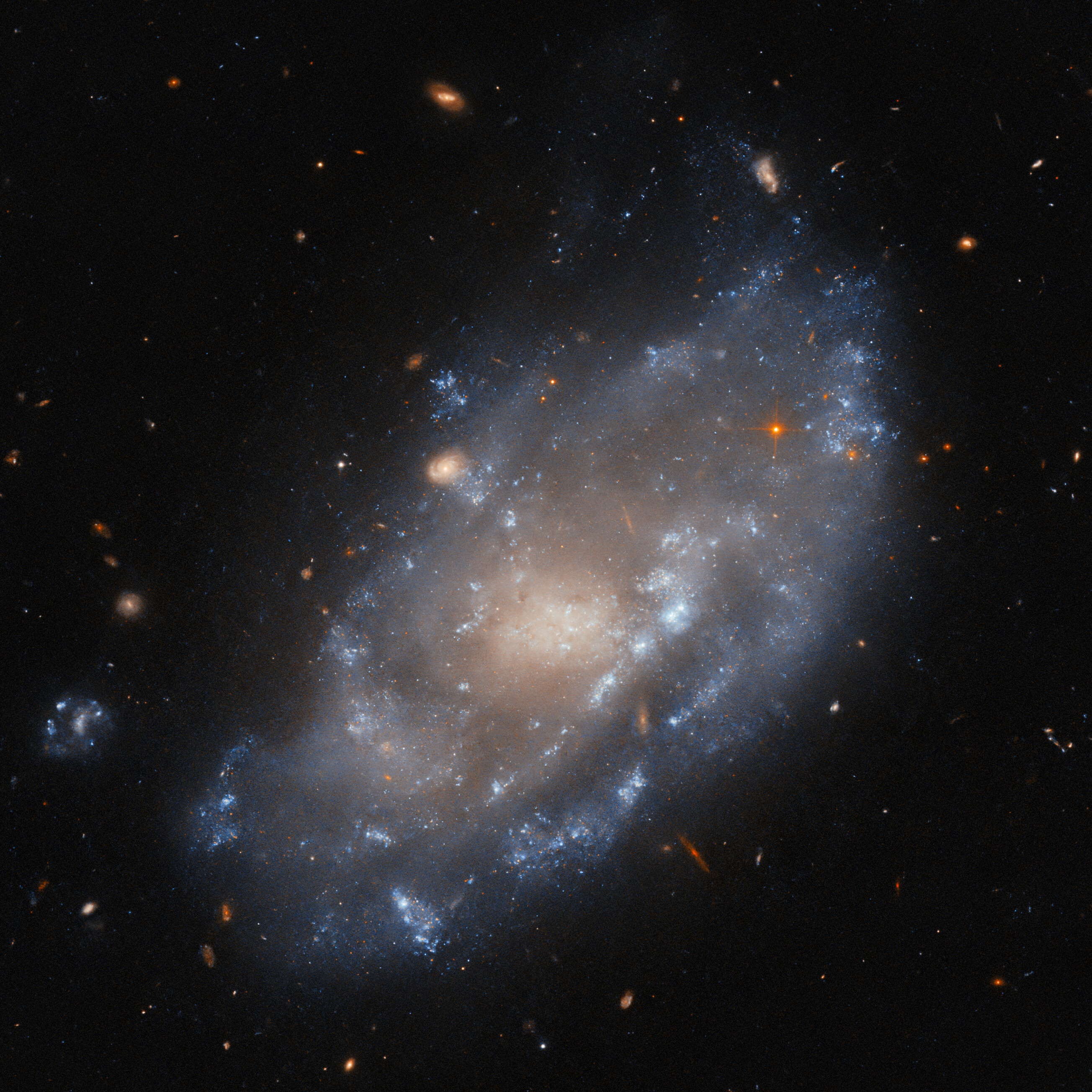

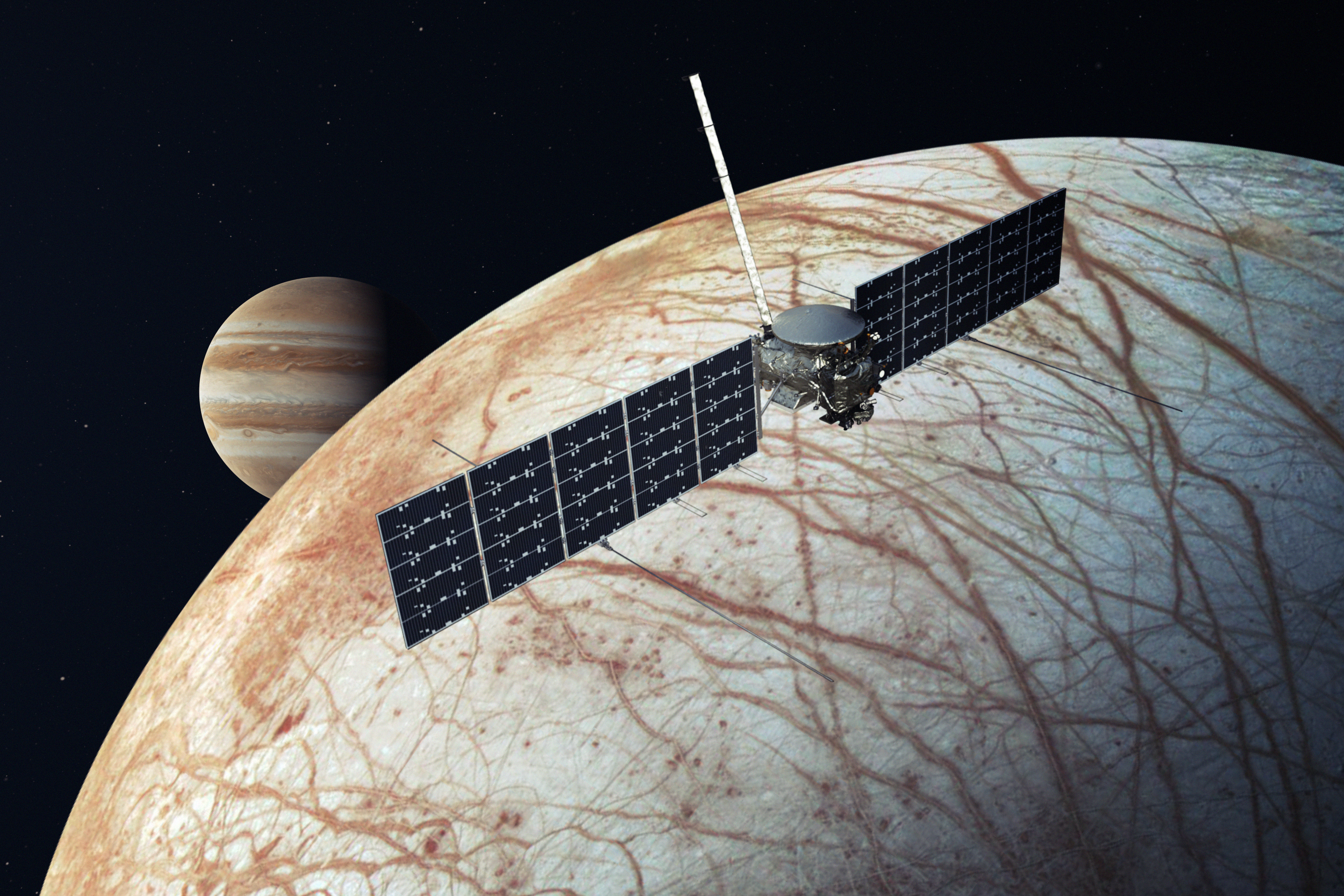

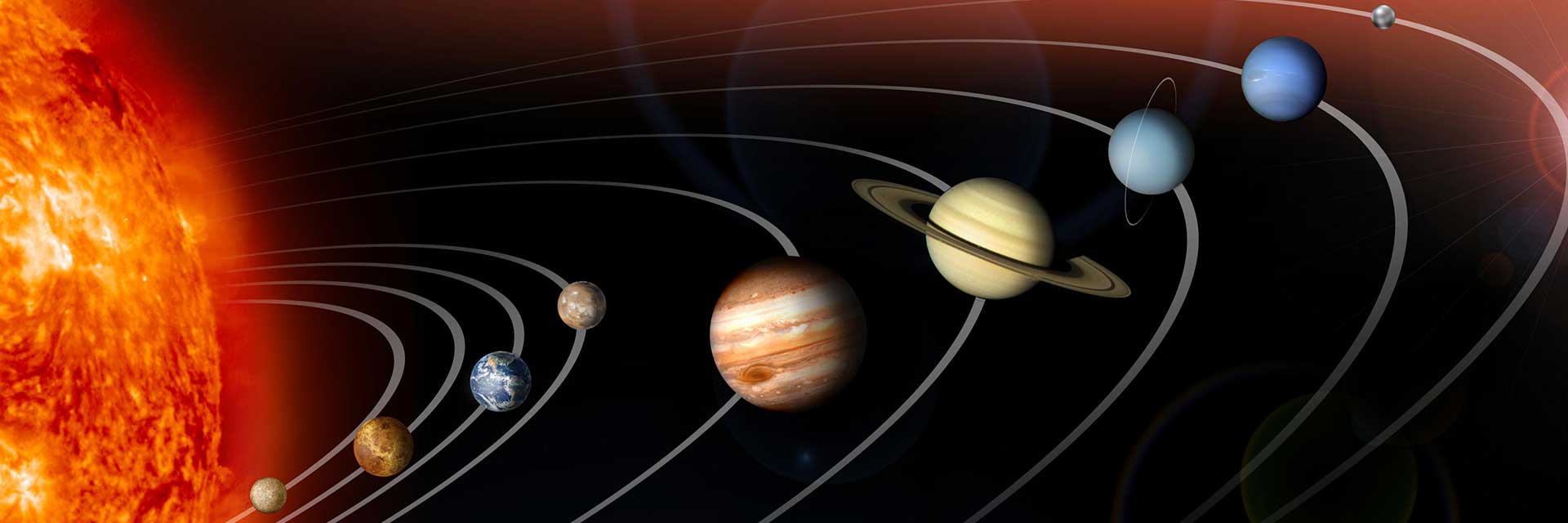

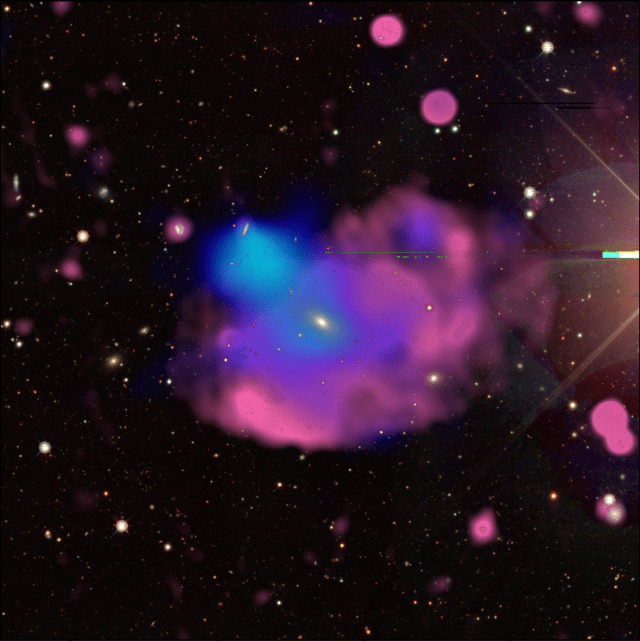

In a shared effort of advancing our scientific understanding of planets, stars, and galaxies, space agencies and astronomical centers have been building increasingly large telescopes. These observatories allow us to collect more light and extend angular resolution to detect fainter objects in the cosmos. While ground-based telescopes are fundamentally limited by atmospheric distortion and absorption, space-based telescopes avoid these disadvantages but introduce new challenges. The aperture size of a space-telescope is driven by scientific requirements for resolution and sensitivity, but it is constrained by the capabilities of launch vehicles. Segmented apertures relax some of the volume constraint, but a natural question is whether the primary should be a single large foldable mirror structure (like James Webb Space Telescope), or a modular structure suitable for in-space robotic assembly. The second option, which will be investigated in this research, overcomes volume and mass limitations of a single launch vehicle, allowing telescope components to be launched incrementally.

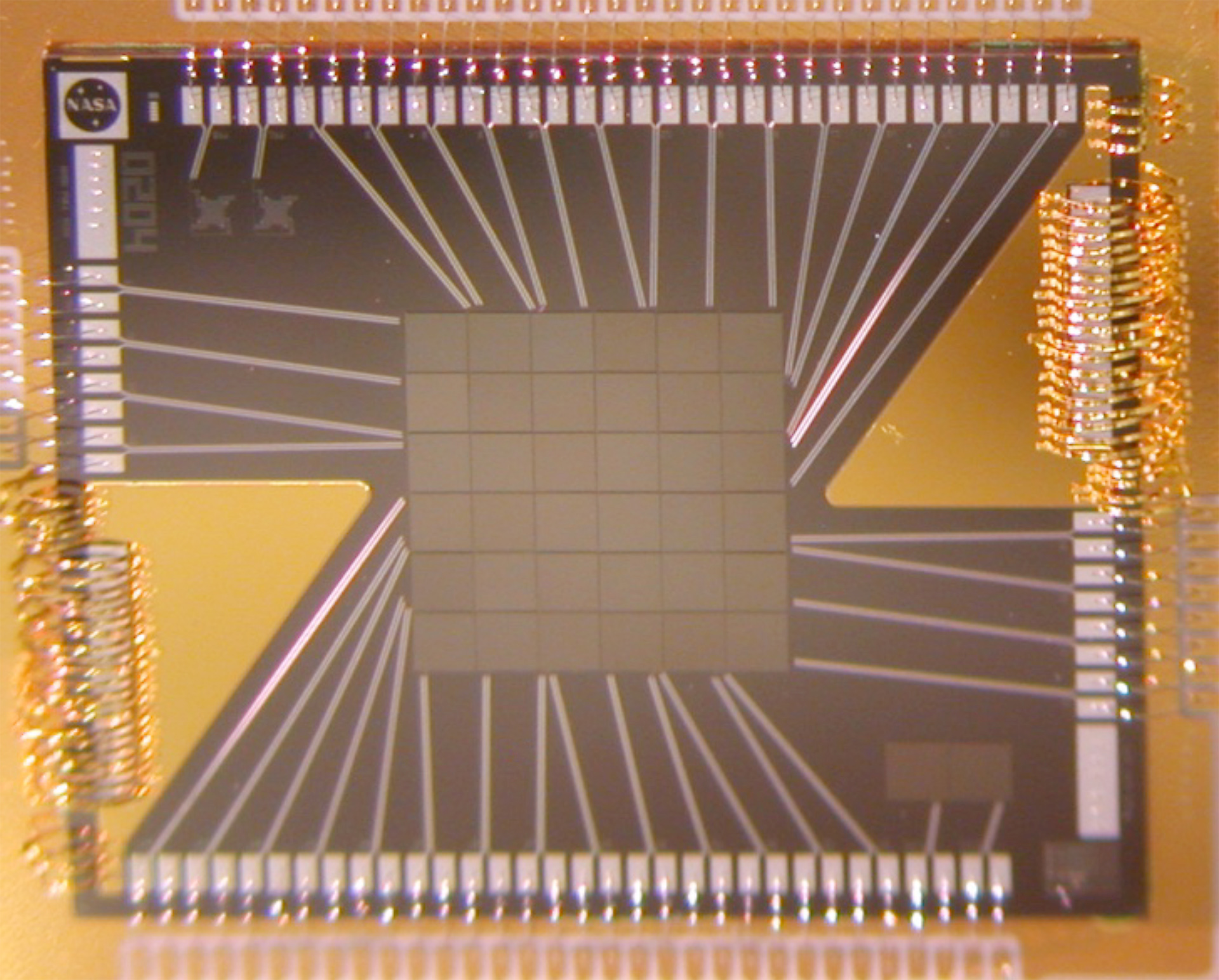

The goal of my research project is to provide ground-breaking designs for modular, ultra-light, and precision space structures, suitable for the development of extremely large optical reflectors (i.e. 10 m and above) that are robotically assembled in space. There are three main advantages related to this proposed approach: first, substantially reducing the cost of building large space optical reflectors by developing new and less expensive solutions, second, implementing a lightweight technology by utilizing ultra-thin composite materials, and third, increasing system redundancy by adopting an architecture that consists of separate modules that can be replaced.

There are many steps involved in the design of innovative structures. Here, I identify the four main tasks required to complete the proposed research: numerical simulations, material characterization, composite manufacturing, and testing and validation. Numerical simulations will help identify optimal design configurations and predict possible failure modes of the modular unit. Material characterization will be necessary to study the viscoelastic effects of long-term storage. Finally, manufacturing and testing of the modules will complete the design process and help find solutions.

The modular unit promises to meet NASA’s requirements for packaging-efficient, lightweight, low-cost, reliable, and precision structures, by incorporating established techniques and ground-breaking approaches. The success of this project will help in achieving NASA’s goals for future space exploration by developing low technology readiness concepts and enabling large space-based observatories.