Bryan Webler

Carnegie Mellon University

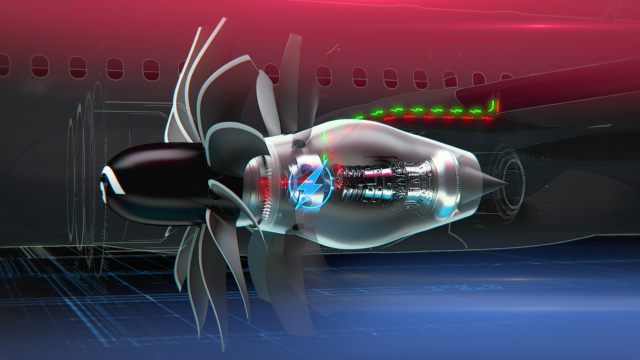

There are limited options for materials that can perform well at extremely high temperatures (above 2000°C). Alloys of refractory metals, e.g. tungsten, are candidates, but their properties at low temperatures make component fabrication and usage challenging. Additive manufacturing is a potential solution, but the process parameters needed to fabricate defect-free parts, as well as the effects of additive processing on material properties are not fully known. We will use computational thermodynamics calculations, machine-learning regression models, and heat transfer calculations to predict alloy behavior during processing and in-service. We will build test structures using additive manufacturing methods to assess and optimize the model predictions. The objective of this work is to develop a new refractory alloy with excellent properties at extremely high temperatures that can be successfully produced by additive manufacturing methods.