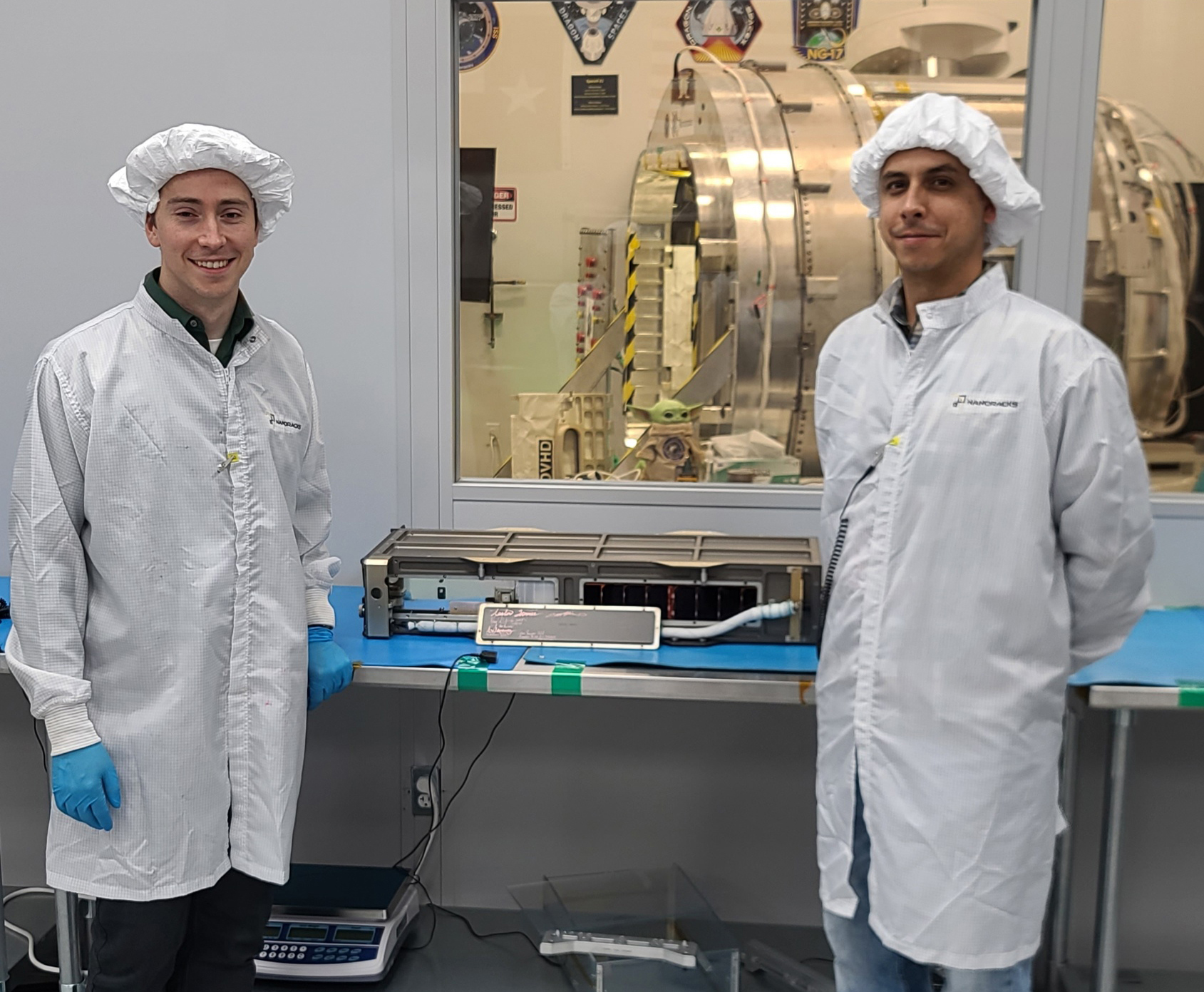

Darren Tinker

Vanderbilt University

Consistent and reliable rocket engine ignition has yet to be proven through an additively manufactured torch igniter for liquid propellants. The coupling of additive manufacturing and liquid fuel propulsion systems is the next great advancement for space technology and will ensure that spaceflight remains safe, affordable, and sustainable for our nation. It is hypothesized that a 3D printed torch igniter would act as a suitable replacement for torch igniters machined out of wrought metal stock.

3D printed injectors and thrusters have recently been built by NASA and undergone testing, but to date, they have either been ignited with a hypergolic propellant or a traditionally-machined torch igniter. An additively manufactured igniter could be printed directly into the injector system, further reducing the part quantity and complexity. Validation of a printed device provides a low-cost, quickly-manufactured device using state-of-the-art manufacturing capabilities without diminishing overall engine performance. Explicitly, the ability to additively manufacture the igniter reduces part counts, manufacturing time, and weld joints. The part and welding reduction would inherently raise device reliability. This is critical for main engine ignition and offers the ability for multiple ignition events.

The proposed research is directly aligned with objectives listed in NASA’s Space Technology Roadmap for liquid propellants, 1.2 Liquid Rocket Propulsion Systems. The sub-goal of which states, Improve the production and manufacturability of large booster engines to reduce cost without sacrificing performance or reliability. A 3D printed igniter would be applicable for liquid hydrogen and liquid methane fuels. Currently, liquid hydrogen is used for NASA’s RS-25 and J-2X engines. However, there has been growing interest in research and development of liquid methane systems due to in-situ resource utilization during space flight. Consequently, creation of an additively manufactured igniter, capable of handling both fuels, is necessary to maintain a competitive stance and to reduce research required to implement an upcoming fuel.

Combining the technology advances of manufacturing and liquid fuels will offer benefits beyond spaceflight. Aerospace applications alone range from small in-space thrusters to torch igniters used in core-stage engines that have thrust capabilities similar to the space shuttle main engine. Auxiliary uses for this technology includes scramjets, gas-turbines, and other terrestrial ignition needs. The proposed work will address both current and future needs for reliable ignition systems in terrestrial and space systems. Should the hypothesis be disproven, it will be known that state-of-the-art manufacturing techniques are not yet capable of advancing flame torch ignition systems. A successful proof-of-concept would provide a foundation of knowledge to build upon and design simplifications, reducing both the cost and complexity of propulsion systems for years to follow.