A fresh approach to designing and manufacturing heat-thwarting thermal protection systems (TPS) for spacecraft is being developed and tested, offering the promise of fabricating larger tile sizes while reducing labor, cost and waste.

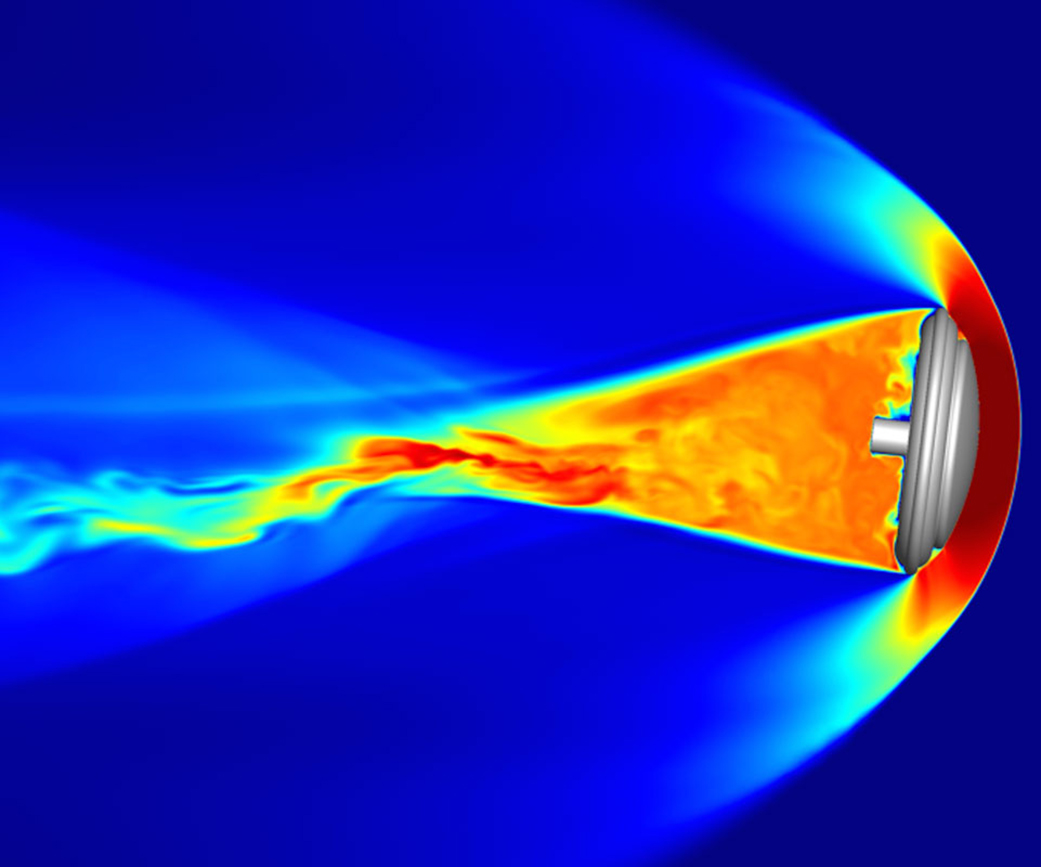

TPS, or heatshields, form the outer surface of spacecraft – called the aeroshell – and provide protection as the vehicle plunges through planetary atmospheres. This technology is critical to assuring mission success. Due to the nature of conventional TPS materials and the large size of the newer spacecraft, recent heatshield designs have consisted of a large number of size-limited tiles that are individually installed, some with strain isolation layers and with gaps between tiles carefully filled. That’s a burdensome and time-consuming procedure.

Streamlining idea

Conformal ablators are a type of flexible TPS. They form a protective barrier that can be shaped during processing, taking the form of a spacecraft, which makes for easy integration. These barriers dissipate heat as the spacecraft enters the atmosphere.

A new and streamlining idea is to produce conformal ablators by way of closed Vacuum Infusion Processing. Conformal TPS can be formed in large segments and directly bonded to an aeroshell without an intermediate strain layer between the TPS tile and the aeroshell structure. Doing so has the potential to lessen the burden on a spacecraft’s development schedule, assembly and budget.

This ongoing work is being spearheaded by Adam Sidor of the Georgia Institute of Technology, a member of the 2014 class of NASA Space Technology Research Fellows.

The NASA Space Technology Research Fellowship (NSTRF) program is funded by the agency’s Space Technology Mission Directorate (STMD). The fellowships allow students to carry out inventive, space technology research at their respective campuses and at NASA Centers and/or at nonprofit U.S. research and development laboratories.

Sidor is working with specialists at NASA Ames Research Center, drawing upon their expertise in conformal ablative materials and the current processing approach for these materials that make use of molding and immersion – but a method that can result in large amounts of wasted resins and solvents.

VIP process

“These conformal ablators improve upon previous ablative materials,” Sidor says, and are easier to install, reduce processing waste and labor at relatively low costs. “They address many difficulties inherent in more traditional ablator materials,” he adds.

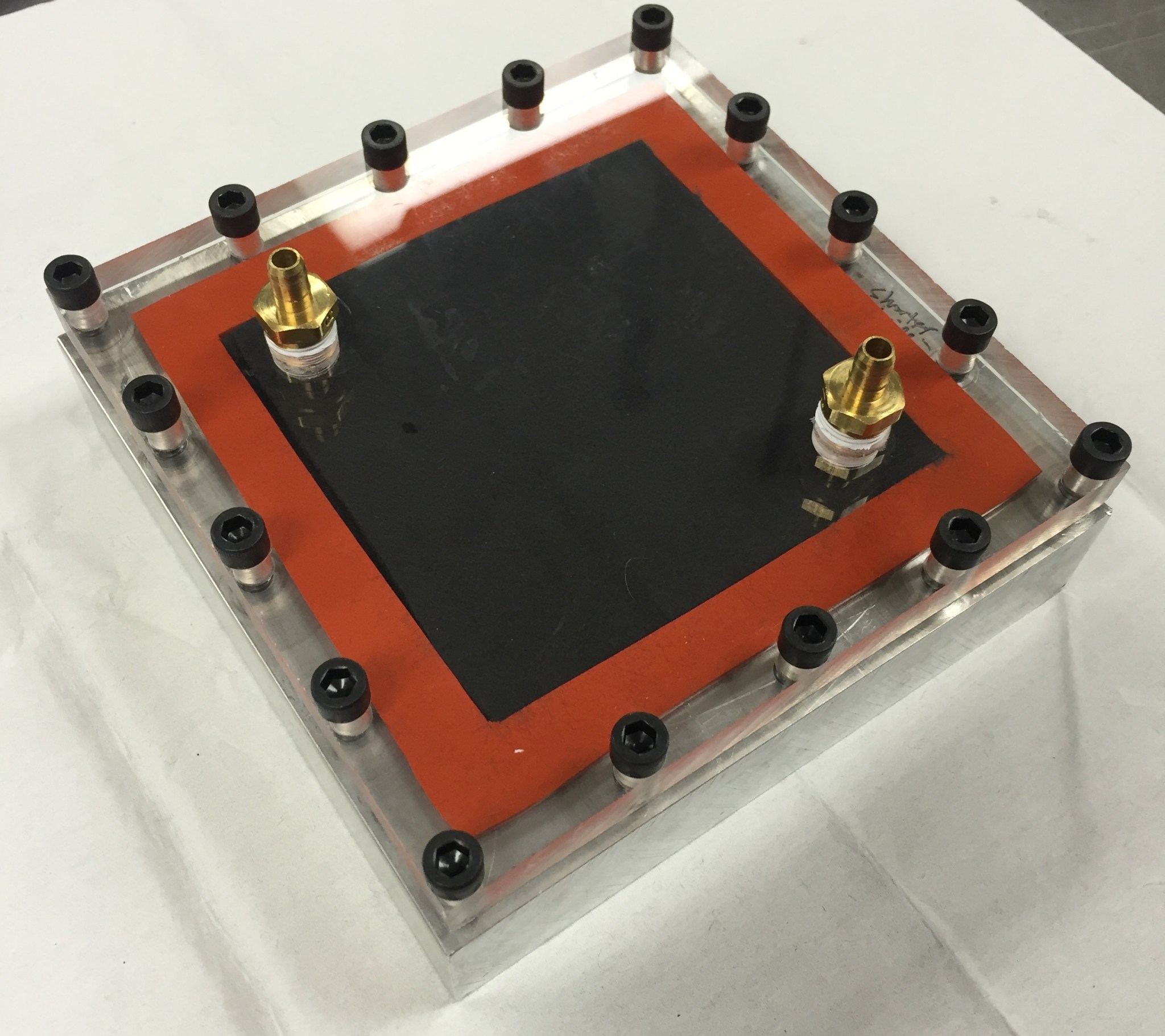

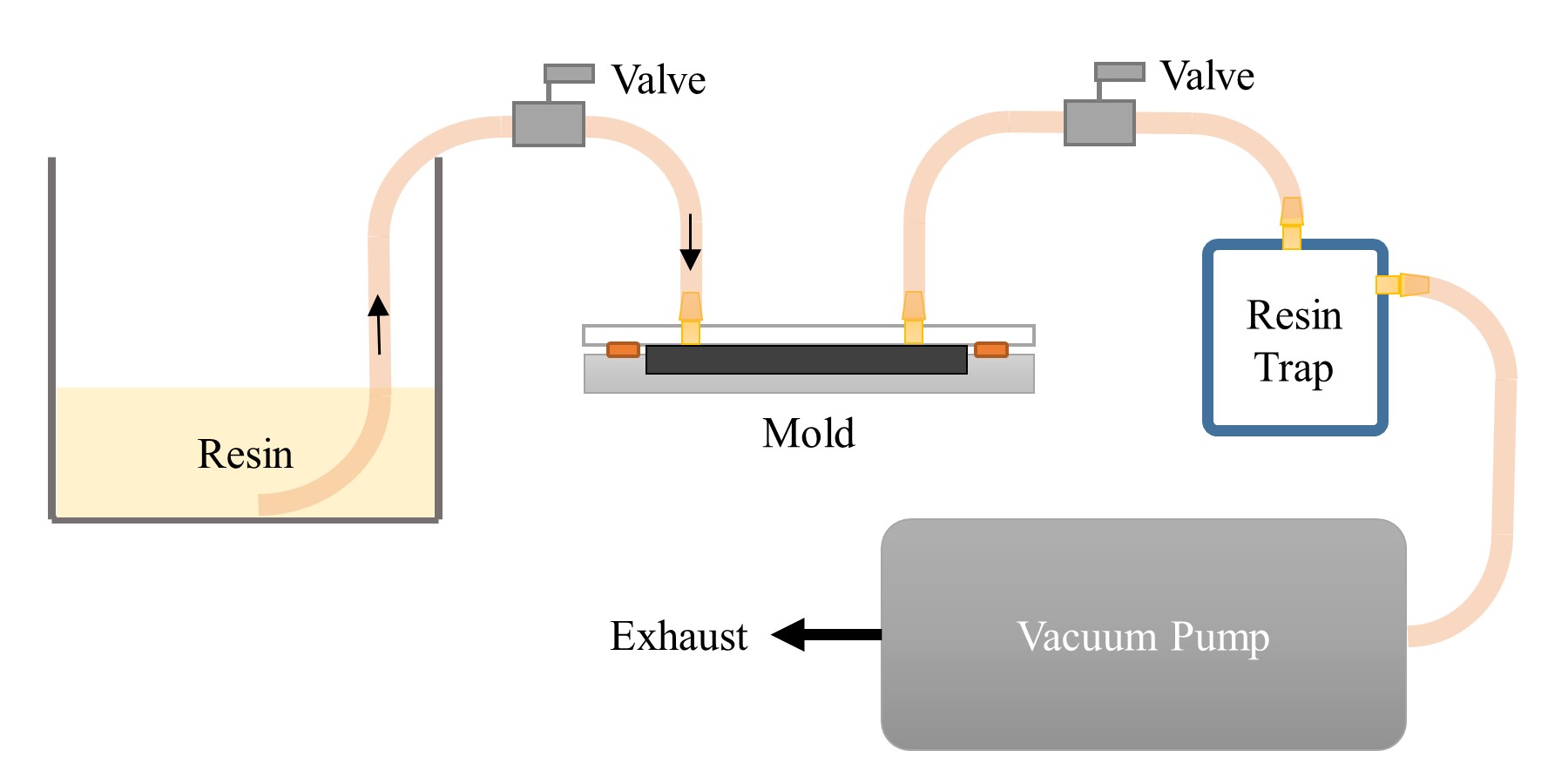

Vacuum Infusion Processing (VIP) was chosen as a candidate manufacturing process for conformal ablators. Closed molding utilizes sealed — rather than open tooling — to improve resin penetration and control volatile compounds.

Proof of concept work

The VIP approach uses vacuum pressure to draw resin into a fiber substrate. Closed molding processes like VIP have been in use for years within the composite industry. But modifying this technique and applying it for conformal ablators is a novel application, Sidor explains. “My VIP research improves upon the state-of-the-art in terms of reducing waste and cost. It’s a very efficient and easy to implement process,” he says.

Working with TPS experts at NASA’s Ames Research Center, Sidor has demonstrated the VIP technique on a small scale. Next, the process will be scaled up to produce larger TPS segments, he says.

That proof of concept work at Ames on the VIP process has yielded encouraging results, Sidor notes. “My plan is to scale up the TPS size and do more complex geometries that are actually like real heatshield tiles.”

Automated methodology

Thanks to his NSTRF-funded effort, Sidor’s investigations at Georgia Tech are also focused on computational work to develop an automated methodology to design conformal heatshields.

“Putting that methodology into computer code to model a very complex process, then you can sort of spit out the manufacturing design to actually make your heatshield,” Sidor says.

Sidor says he hopes that the work is general enough and broad enough to apply to a lot of different TPS materials and space missions. He considers his research being applied to future Mars landers, as well as robotic spacecraft that deep dive into the atmosphere of Jupiter’s moon, Europa, as well as those that probe Titan, an enigmatic moon of Saturn.

“I really love the experimental aspect of this NSTRF work. Graduate students in my area don’t always get to do this. I’m fortunate to do hands-on experimentation and get my hands dirty. So that’s fun,” Sidor concludes.

For more information about NASA’s Space Technology Research Grants, visit: