The Space Technology Mission Directorate (STMD) is building and testing critical, transformative technologies to make the Artemis missions to the Moon possible, all with an eye on how we can further what we learn and charge onward to Mars and beyond.

So today, NASA scientists, engineers, and technologists are working with universities and companies across the nation to build the hardware and advance the capabilities we need to land astronauts and equipment on the Moon, live and work on the lunar surface, and safely return to Earth.

Although our #NASAMoonKit won’t fit into one picture, here are just a few of the innovations we’re planning to take to the Moon. These technologies will help humans explore more of the lunar surface than ever before.

![]() About the size of two stacked cereal boxes, our Lunar Flashlight mission will search for ice on the Moon – especially at the bottom of shadowy craters – using special lasers. This mission will seek to achieve many technological firsts, including being the first mission to look for ice on the Moon using lasers. It will also be the first planetary spacecraft to use a “green” propellant, a new kind of fuel that is safer to transport and store than the commonly used spacecraft propellant hydrazine.

About the size of two stacked cereal boxes, our Lunar Flashlight mission will search for ice on the Moon – especially at the bottom of shadowy craters – using special lasers. This mission will seek to achieve many technological firsts, including being the first mission to look for ice on the Moon using lasers. It will also be the first planetary spacecraft to use a “green” propellant, a new kind of fuel that is safer to transport and store than the commonly used spacecraft propellant hydrazine.

![]() CAPSTONE is a microwave oven–sized CubeSat that will help reduce risk for future lunar spacecraft by validating innovative navigation technologies and verifying the dynamics of a unique, elliptical lunar orbit.

CAPSTONE is a microwave oven–sized CubeSat that will help reduce risk for future lunar spacecraft by validating innovative navigation technologies and verifying the dynamics of a unique, elliptical lunar orbit.

![]() Like we use electricity to charge our devices on Earth, astronauts will need a reliable power supply to explore both the Moon and Mars. The system will need to be lightweight and capable of running regardless of its location, the weather, or available sunlight and other natural resources. NASA and the U.S. Department of Energy are collaborating with industry to design, fabricate, and test a 10-kilowatt class fission surface power system. A single 10-kilowatt system could provide all the power needed for astronauts to stay on Mars for up to 50 days.

Like we use electricity to charge our devices on Earth, astronauts will need a reliable power supply to explore both the Moon and Mars. The system will need to be lightweight and capable of running regardless of its location, the weather, or available sunlight and other natural resources. NASA and the U.S. Department of Energy are collaborating with industry to design, fabricate, and test a 10-kilowatt class fission surface power system. A single 10-kilowatt system could provide all the power needed for astronauts to stay on Mars for up to 50 days.

![]() Robotic scouts like the Autonomous Pop-Up Flat Folding Explorer Robots (A-PUFFERs) are shoe-box-sized robots that could help astronauts explore locations that may be difficult for them to investigate on foot, like hard-to-reach craters and narrow caves.

Robotic scouts like the Autonomous Pop-Up Flat Folding Explorer Robots (A-PUFFERs) are shoe-box-sized robots that could help astronauts explore locations that may be difficult for them to investigate on foot, like hard-to-reach craters and narrow caves.

![]() The Polar Resources Ice Mining Experiment-1 (PRIME-1) consists of a lunar drill, which can core out a hole roughly three feet deep on the lunar surface. The second part of the PRIME-1 technology suite is the modified mass spectrometer. Mass spectrometers are used to measure the composition or concentration of various elements in the atmosphere. Together, these technologies will help NASA search for ice at the Moon’s South Pole and, for the first time, harvest ice from below the surface.

The Polar Resources Ice Mining Experiment-1 (PRIME-1) consists of a lunar drill, which can core out a hole roughly three feet deep on the lunar surface. The second part of the PRIME-1 technology suite is the modified mass spectrometer. Mass spectrometers are used to measure the composition or concentration of various elements in the atmosphere. Together, these technologies will help NASA search for ice at the Moon’s South Pole and, for the first time, harvest ice from below the surface.

![]() Our SPLICE project is working to make lunar landings more precise. It is made up of a combination of sensors, a camera, a high-speed computer, and sophisticated algorithms that will give spacecraft the artificial eyes and analytical capability to find a designated landing area, identify potential hazards, and adjust course to the safest touchdown site. SPLICE will eventually make it possible for spacecraft to avoid boulders, craters, and more within landing areas half the size of a football field already targeted as relatively safe.

Our SPLICE project is working to make lunar landings more precise. It is made up of a combination of sensors, a camera, a high-speed computer, and sophisticated algorithms that will give spacecraft the artificial eyes and analytical capability to find a designated landing area, identify potential hazards, and adjust course to the safest touchdown site. SPLICE will eventually make it possible for spacecraft to avoid boulders, craters, and more within landing areas half the size of a football field already targeted as relatively safe.

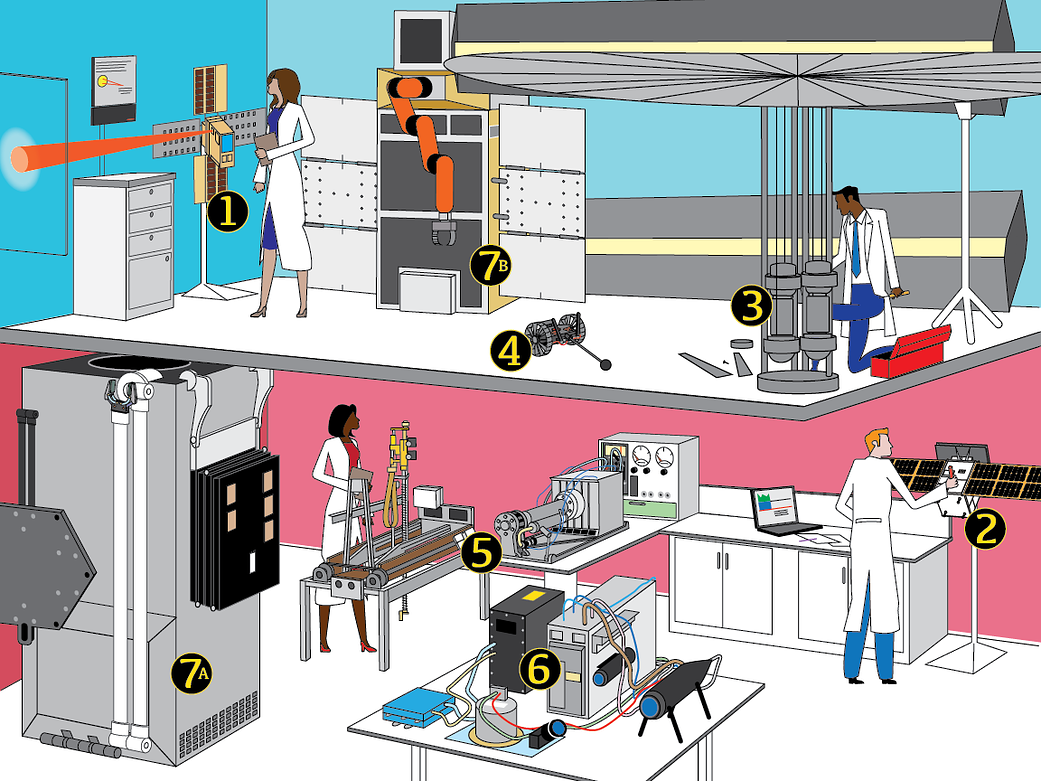

![]() On-orbit Servicing, Assembly, and Manufacturing (OSAM) technologies are developing robotic technologies to rapidly, efficiently, and autonomously manufacture and assemble hardware, components, and tools in space. OSAM-2 consists of a small spacecraft, roughly the size of a refrigerator, which will 3D print two beams, build hardware, and unfurl solar arrays that can generate up to five times more power than traditional solar panels on similar-sized spacecraft.

On-orbit Servicing, Assembly, and Manufacturing (OSAM) technologies are developing robotic technologies to rapidly, efficiently, and autonomously manufacture and assemble hardware, components, and tools in space. OSAM-2 consists of a small spacecraft, roughly the size of a refrigerator, which will 3D print two beams, build hardware, and unfurl solar arrays that can generate up to five times more power than traditional solar panels on similar-sized spacecraft.

![]() Building on NASA’s history of upgrading and maintaining assets in space, OSAM-1 is a robotic spacecraft equipped with the tools, technologies and techniques needed to extend satellites’ lifespans – even those not originally designed to be serviced. Its secondary payload will demonstrate robotic assembly of a functional communications antenna as well as in-space manufacturing.

Building on NASA’s history of upgrading and maintaining assets in space, OSAM-1 is a robotic spacecraft equipped with the tools, technologies and techniques needed to extend satellites’ lifespans – even those not originally designed to be serviced. Its secondary payload will demonstrate robotic assembly of a functional communications antenna as well as in-space manufacturing.