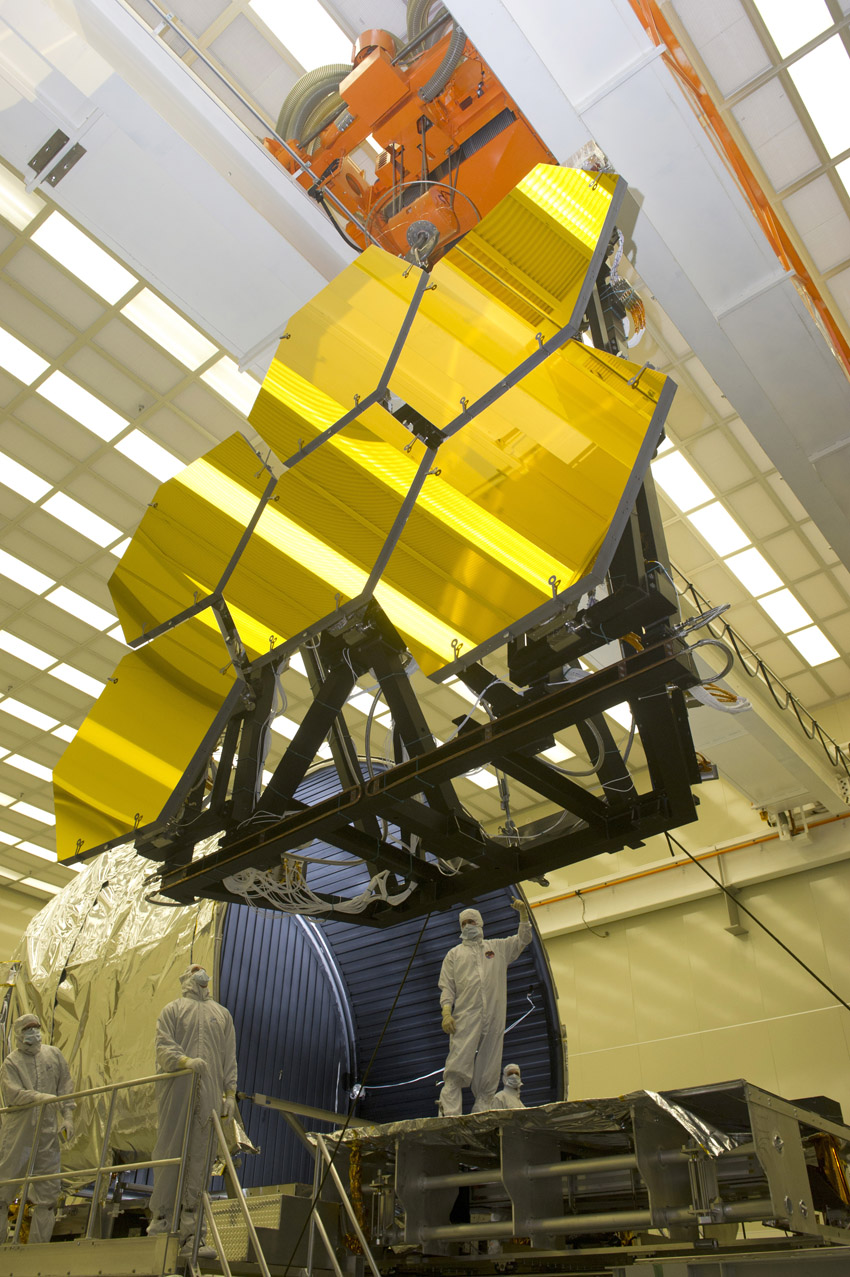

When handling a multi-billion-dollar space telescope, you want to be pretty careful not to jostle it — unless it’s your job to shake it with 100,000 pounds of force, that is.

In order to ensure the James Webb Space Telescope can survive its rocket launch — before it gets to its destination a million miles away, where it would be nearly impossible to fix — engineers strapped the telescope to vibration tables and shook it in every direction. Hard.

It’s a process every spacecraft and satellite has gone through since the space agency first began sending satellites into orbit in the 1950s. And that same technology has since been adapted to test everything from nuclear weapons to minivans, making safer and sturdier products for everyone.

To test the 14,300-pound Webb, NASA once again turned to a company that has been instrumental in the agency’s vibration testing since the beginning: Burlington, Washington-based Team Corporation.

Team specializes in high-end custom equipment. Its vibration machines can be found in just about every Department of Defense and Department of Energy lab and are used by companies like Boeing, Lockheed Martin and Northrup Grumman to test equipment ranging from tanks and airplanes to nuclear warheads. In other applications, the machines also test a variety of more everyday objects, from cars to yogurt containers.

But first they were built for NASA.

Shake It Up

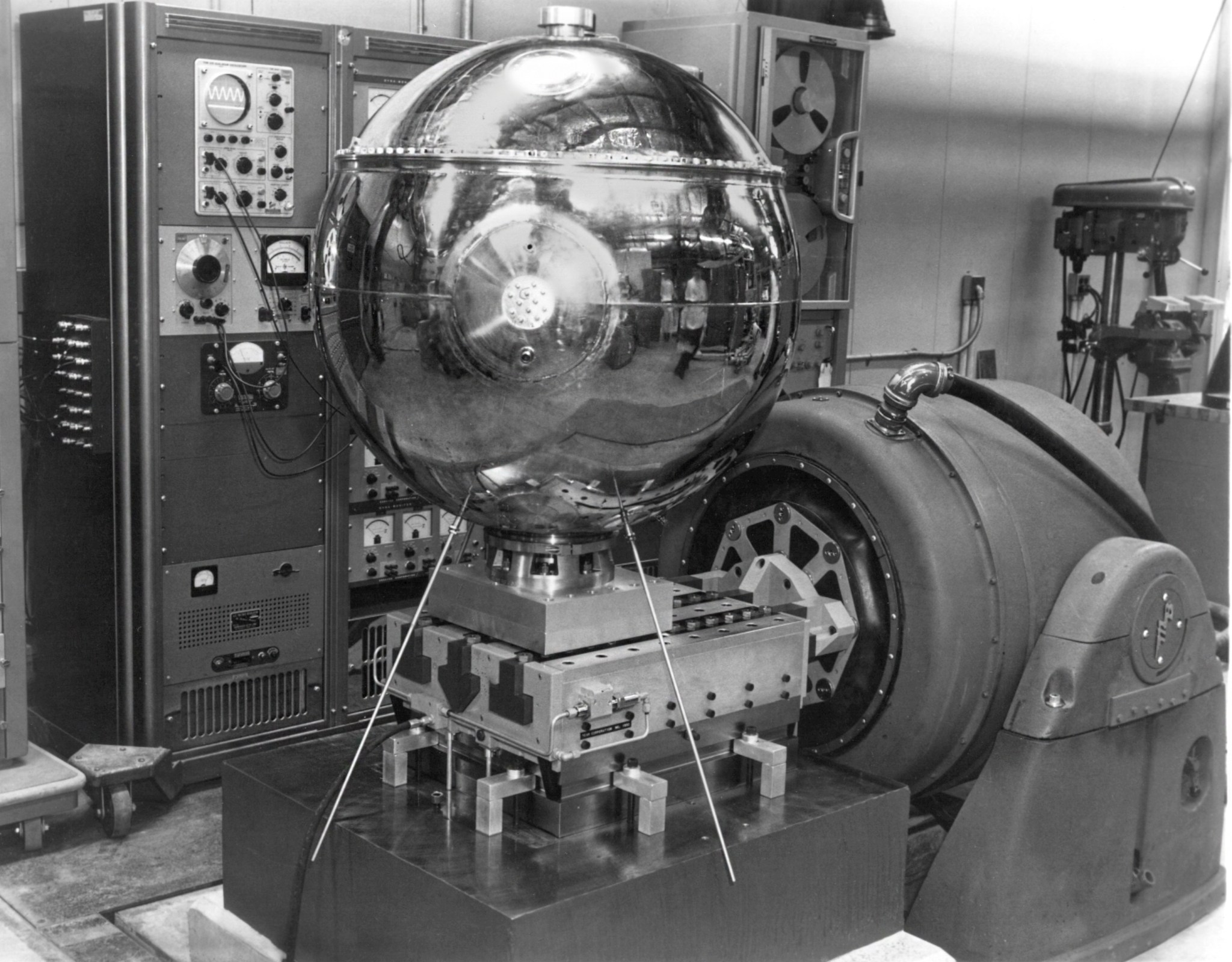

Team, which stands for Tauscher Engineering and Manufacturing, was founded in 1954. The company’s first clients were in the military aviation industry, but when NASA started testing spacecraft, it also turned to Team.

The company needed better equipment to meet the demands for spacecraft testing, so under a NASA contract it invented what it calls Model 1830 T and V bearings, which are stiff and frictionless and can carry both tension and compression.

The first shaker using these bearings was delivered to NASA and was used to test the Vanguard 1 satellite, one of the first U.S. satellites ever launched into orbit. Today thousands of these T and V bearings are used around the world in vibration testing equipment.

The bearings help Team recreate the forces of a rocket launch, an improvement over the earliest days of human flight, when the testing procedure was fairly primitive.

In addition to a rocket launch, Team’s vibration devices can recreate conditions of a bouncing road or a massive earthquake. It’s all aimed at determining just how well a structure will hold up in real life in a moment of extreme stress or over a lifetime of wear and tear.

Road Tested

Updates on those same bearings first designed for NASA in the 1950s can still be found in a number of the company’s vibration testers, including ones used by some of the world’s largest car companies. Team equipment tests individual components, from engine valves all the way up to passenger seats, as well as what’s called “end-of-the-line” testing, when the whole car is put together.

Using four small vertical shakers, one under each car wheel, automakers like Ford Motor Company test how well the fully assembled car or light truck will perform once it hits the road: Will it squeak and rattle? Will the parts hold up during tens of thousands of miles of highways and country roads?

In 2016, Team was working up a massive new proposal using these four-poster shakers for a company looking for “super high performance,” Nelson says, a project that could be worth $75 million if fully implemented. He is cautiously optimistic that the company will get the job, he says, a result he attributes in part to the expertise Team built in its work with NASA.

“We’ve evolved this in-house knowledge that NASA has been fundamental in helping us develop, and we bring that to bear on all our products.”

NASA has a long history of transferring technology to the private sector. Each year, the agency’s Spinoff publication profiles about 50 NASA technologies that have transformed into commercial products and services, demonstrating the wider benefits of America’s investment in its space program. Spinoff is a publication of the Technology Transfer Program in NASA’s Space Technology Mission Directorate.

To learn more about this NASA spinoff, read the original article from Spinoff 2017.

For more information on how NASA is bringing its technology down to Earth, visit

Naomi Seck

Goddard Space Flight Center