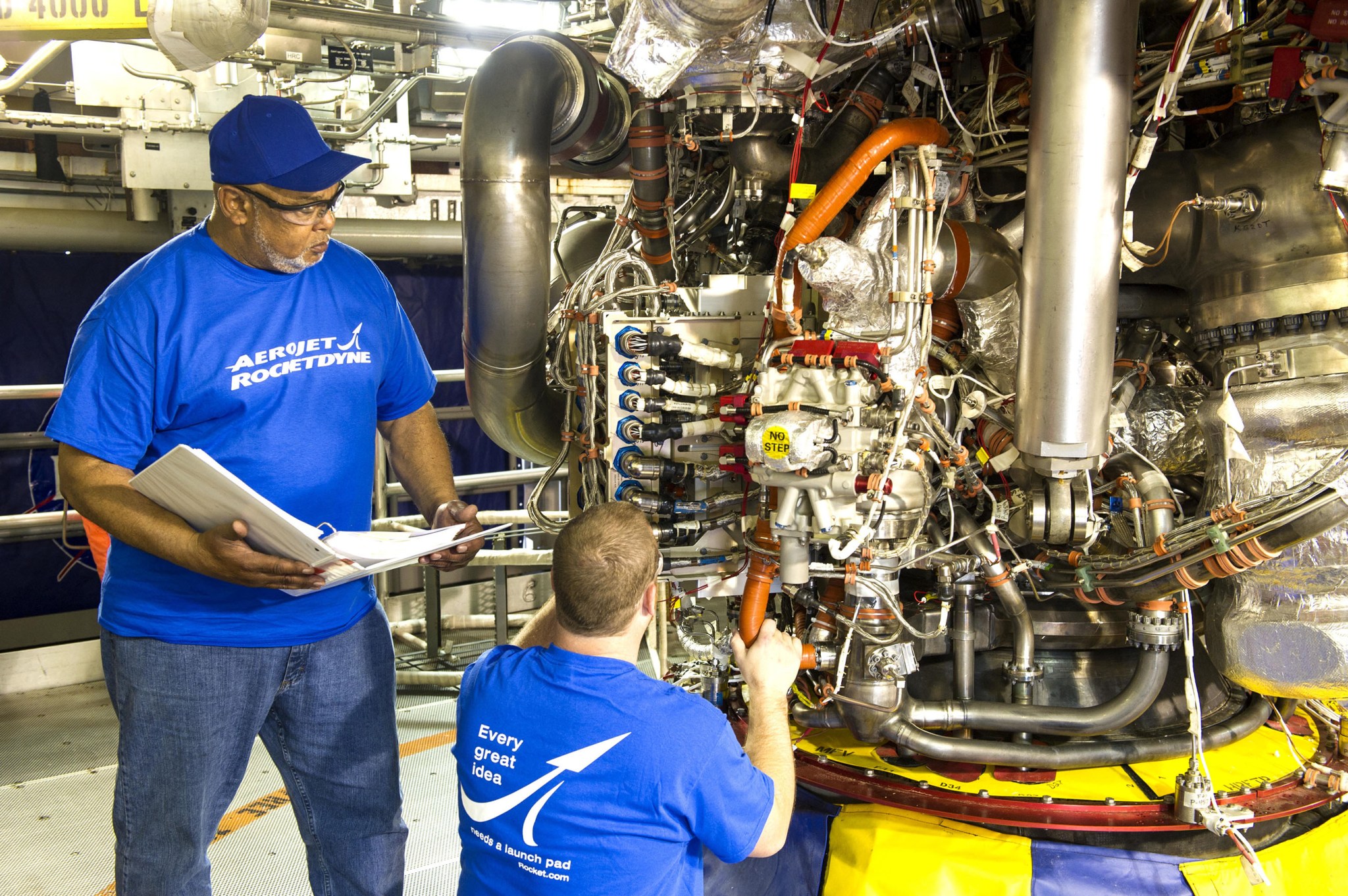

NASA marked a critical milestone March 23 with a test of the first RS-25 engine controller that will be used on the first flight of the new Space Launch System (SLS), the world’s most powerful rocket.

The new controller or “brain” has the electronics that operate the engine and communicate with the SLS vehicle. Engine Controller Unit-2 (ECU-2) was installed on RS-25 development engine No. 0528 and test fired for 500 seconds on the A-1 Test Stand at Stennis Space Center near Bay St. Louis, Mississippi. Once test data is certified, the engine controller will be removed and installed on one of four flight engines that will help power the first integrated flight of SLS and the Orion spacecraft.

This year, two more engine controllers for the first SLS mission will be tested on this development engine at Stennis, and then installed on flight engines. The fourth controller will be tested when NASA tests the entire core stage during a “green run” on the B-2 Test Stand at Stennis. That testing will involve installing the core stage on the stand and firing its four RS-25 flight engines simultaneously, as during a mission launch.

“This an important – and exciting – step in our return to deep space missions,” Stennis Director Rick Gilbrech said. “With every test of flight hardware, we get closer and closer to launching humans deeper into space than we ever have traveled before.”

The RS-25 engines that will help power the SLS vehicle on its first flights are former space shuttle main engines, built for NASA by Aerojet Rocketdyne. Four engines will fire simultaneously to provide 2 million pounds of thrust and operate in conjunction with a pair of solid rocket boosters to power the SLS launch.

Space shuttle main engines were tested extensively and used to power 135 missions from 1981 to 2011. For SLS, the engines have been upgraded to operate at a higher level and under different conditions, and the flight controller was one of the critical new parts of the engine to enable performance under these new conditions.

Prior to a flight, performance specifications, such as the percentage of thrust needed, are programmed into the controller. The controller then communicates the specifications and monitors engine conditions to ensure they are being met, controlling such factors as propellant mixture ratio and thrust level.

Testing for the upgraded engines and new controllers is vital to ensure they will perform as needed within the operating parameters. For instance, space shuttle main engines operated at a maximum of 104.5 percent of power level capability. For SLS flights, the RS-25 engines must fire at 109 percent of capability. The engines also will operate with colder liquid oxygen and engine compartment temperatures, higher propellant pressure and greater exhaust nozzle heating.

“The importance of this testing cannot be overemphasized,” A-1 Test Director Jeff Henderson said. “Each test has specific objectives to determine how the engine will respond. The goal is to learn as much as we can about the performance of the engine.”

RS-25 testing at Stennis is conducted by a team of NASA, Aerojet Rocketdyne and Syncom Space Services engineers and operators. Aerojet Rocketdyne is the prime contractor for RS-25 engines. Syncom Space Services is the prime contractor for Stennis facilities and operations.

For more about the SLS rocket, visit:

For more information about Stennis Space Center, visit:

www.nasa.gov/centers/stennis/.

Valerie Buckingham

Stennis Space Center

228-688-3898

valerie.d.buckingham@nasa.gov

Kim Henry

Marshall Space Flight Center, Huntsville, Ala.

256-544-0034

kimberly.m.henry@nasa.gov