By Tee Quillin

Jason Hyder helps ensure the valves, lines, and ducts on launch vehicles are ready for NASA’s SpaceX human spaceflight missions.

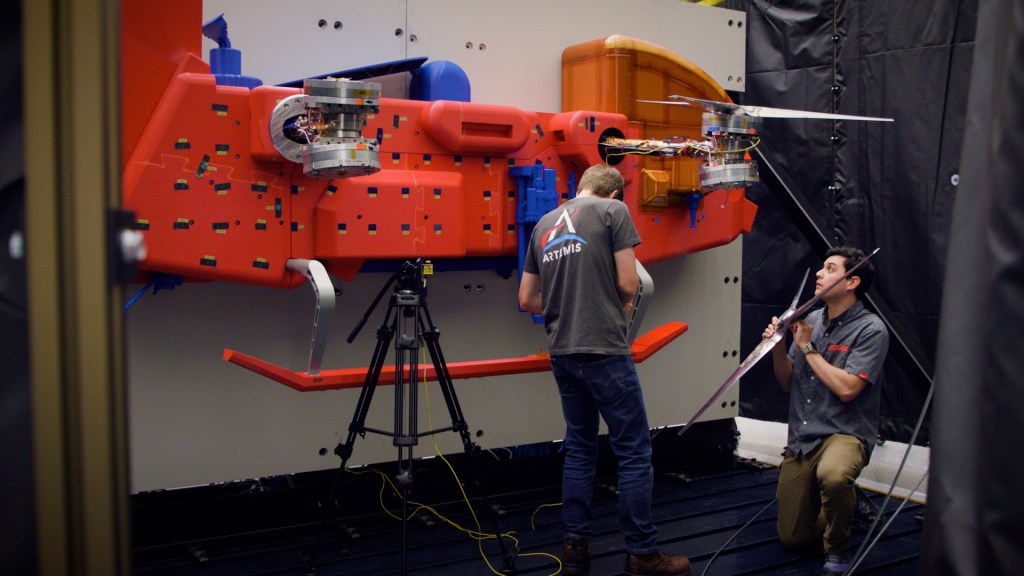

Hyder is a design and development engineer with Jacobs Space Exploration Group, working on the Engineering Services and Sciences Capability Augmentation contract in the Engineering Directorate at NASA’s Marshall Space Flight Center in Huntsville, Alabama. He supports the Commercial Crew Program’s Launch Vehicle Propulsion Engineering team as the subsystem manager for the Valves, Lines, and Ducts branch.

Each component of the valve, lines, and ducts has its own unique operating environment, method of operation, and type of wear it experiences. Verifying that these parts are up to the task is critical to mission success.

Hyder provides engineering insight to the Commercial Crew Program, ensuring valves are designed in compliance with program requirements and operate at peak efficiency from testing through launch – and all over again for each booster stage’s reuse that’s assigned to a commercial crew mission. He and his team of seven engineers work with SpaceX teams to ensure all 80 design units – made up over 700 valve, line, and duct sites on the SpaceX Falcon 9 rocket – are cleared for safe launch of commercial crew missions to the International Space Station – including the Crew-4 mission that launched April 27.

“With the high level of insight and cooperation between our team and SpaceX, there is an immense sense of pride that comes with supporting the mission on console during launch,” Hyder said. “That sense of pride brings with it a personal responsibility for the crew’s safety. The focus and concentration quickly turn to pure joy once the second stage shuts down and you hear the crew has reached orbit.

“Seeing NASA astronaut Bob Hines toss around the stuffed animal zero-gravity indicator marked the culmination of our team’s hard work leading up to launch, which was especially sweet given the large effort that went into certifying the first stage booster for four flights.”

Crew-4 marked the first time that a Falcon 9 first-stage booster planned for a crew flight was certified for a fourth flight. Previously, the program had only certified boosters for reuse on up to two flights. The fourth-flight booster was assigned to Crew-4 in January, and the commercial crew launch vehicle team demonstrated its flexibility to perform within a tight time window.

Hyder was part of a group – which included NASA team members from Marshall and Kennedy Space Center in Florida, and SpaceX team members – that established an effective approach to certify the Falcon 9 first stage for multiple reuses.

“Jason brings a great energy to the team and helps ensure our astronauts have a safe ride,” said Lisa McCollum, manager of Marshall’s Commercial Crew Program support team. “For example, he set up scripts that allowed him to analyze pressure data in real time during the countdown. At the Huntsville Operations Support Center, Jason was able to quickly interpret critical data on the health of the hardware while he was on console for the launch.”

In addition to the Crew-4 mission, Hyder and his team concurrently assisted with preparations for NASA’s Boeing Orbital Flight Test-2, which launched the CST-100 Starliner spacecraft on the United Launch Alliance Atlas V rocket on May 19 from Space Launch Complex 41 at Cape Canaveral Space Force Station in Florida – about three weeks after Crew-4.

Born and raised in Johnson City, Tennessee, Hyder earned his bachelor’s degree in mechanical engineering and Master of Business Administration from Tennessee Tech University in Cookeville. In between pursuing those degrees, he worked for MAHLE Engine Components in Morristown, Tennessee, as an engineer responsible for steel machining and automated optical inspection processes. The job took him to a sister plant in Nanjing, China, for two years on assignment as a technical advisor for the ramp-up of new piston manufacturing lines. He returned to the U.S. in 2020 to begin his current position at Marshall, supporting commercial crew.

The Commercial Crew Program was formed to facilitate the development of a U.S. commercial crew space transportation capability with the goal of achieving safe, reliable, cost-effective access to and from the space station and low-Earth orbit. The program is jointly led by Kennedy and NASA’s Johnson Space Center in Houston, with support from Marshall.

The support team at Marshall consists of about 80 people supporting the commercial crew office, engineering, and mission safety. Marshall provides management support as well as engineering expertise in propulsion valves and pyrotechnics, natural environments, and vehicle structures, among others.

For more information on NASA’s Commercial Crew Program, visit:

https://www.nasa.gov/exploration/commercial/crew/index.html

Lance D. Davis

NASA’s Marshall Space Flight Center

256-544-0034

lance.d.davis@nasa.gov