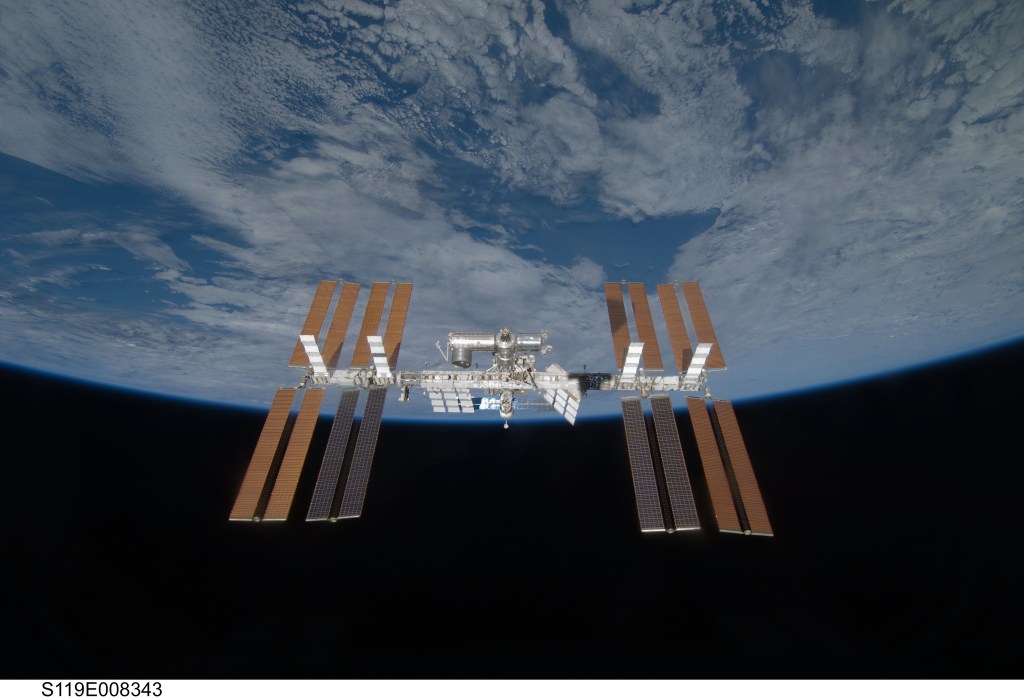

Wherever humans explore, they must essentially replicate the life support system provided naturally on Earth. People living on the International Space Station continuously for the last 15 years are helping NASA learn how to create life support systems for the journey to Mars.

“This has been a challenge from the start,” said Rex Graves, chief of the Flight Systems Integration and Test Branch at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “We pulled together a great team here at Marshall to look at ways to recover water and oxygen on orbit to reduce the need for resupply missions to the space station. Now more than 200 crewmembers have lived on the station continuously for 15 years, and this has taught us not only about the hardware but also about how people living in space affect the life support system’s operations.”

The Environmental Control and Life Support System, or ECLSS, built for the station is serving as the basis for a similar system that may one day enable astronauts to drink water on the surface of Mars. One of the most valuable lessons learned is that recycling makes spaceflight more affordable. When the first life support system was developed, one of the key aspects designers considered was how to reuse all the water produced on the station—even human urine and sweat. As anyone knows who has ever hauled gallon jugs of water on a camping trip, carrying enough water for all 220 crew members who have lived on the station for the past 15 years would mean transporting a lot of water to space. Since the activation of the ECLSS urine processor assembly in November 2008, more than 22,500 pounds of drinkable water have been recycled from crew members’ urine.

“If this amount of water had been resupplied from Earth, it would have cost more than $225 million to launch and deliver it to the station.” said Walt Schneider, project manager for the Life Support Project for Marshall’s Flight Programs and Partnerships Office. “This part of the life support system paid for itself pretty quickly.”

Another way NASA engineers are finding out what does and doesn’t work is to bring hardware back from the station, study it and refine it. The part of the station’s water recovery system that helps process urine, the distillation assembly, was recently returned to its designers at Marshall after the station crew replaced it. Before its return to Earth, the part helped provide the station with water by operating successfully for 1,014 hours beyond its expected service time of 4,380 hours — a feat with implications for further human exploration of our solar system where hardware must perform reliably for a long time under harsh conditions.

“Without air or water, humans simply can’t travel, live or work in space,” said Schneider. “Our team at Marshall is responsible for the design, construction and testing of the regenerative life support hardware, exploring new designs and getting new parts to the station and improving the efficiency of the system that provides clean air and water for crew members.”

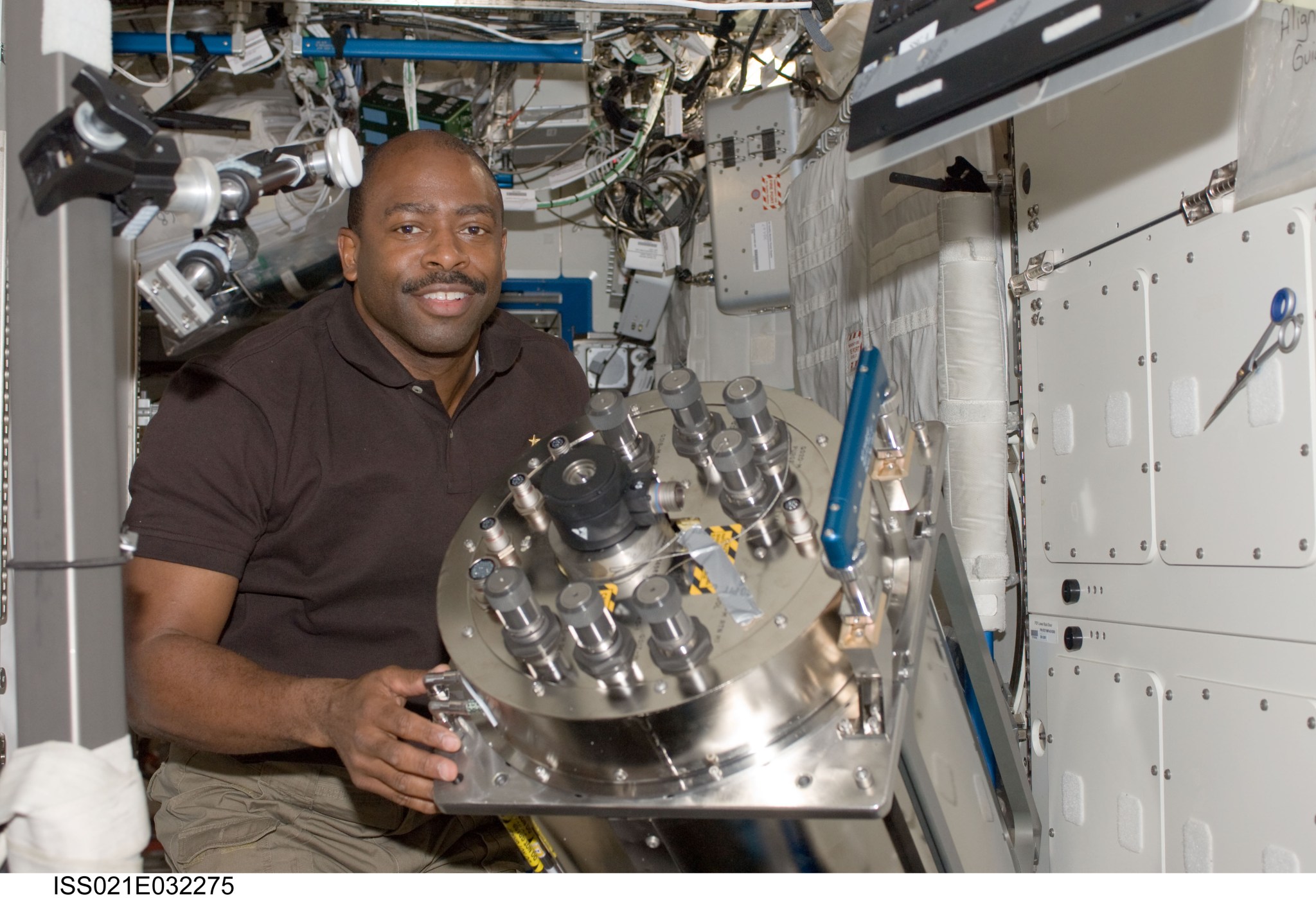

The Water Recovery System’s distillation assembly helps transform urine from crew members into usable water. When versions of the hardware were first installed nearly seven years ago, engineers noticed it wasn’t working as well as intended.

“We had some initial issues with calcium deposits,” said Larry Leopard, director of the Space Systems Department at Marshall. “We have since learned on the space station that astronauts suffer more bone loss than anticipated in a microgravity environment, and a lot of that calcium from bones ends up in their urine. The distillation assembly was having trouble filtering the extra calcium, and we had to change machines more frequently than anticipated.”

The calcium deposits meant the amount of water recovered from urine was reduced. While the crew was never in any danger, and the water recovery system still recovered 75 percent of the wastewater from urine, the team wanted it to be even more efficient. A new and improved distillation assembly — a cylindrical machine about the size of a kitchen garbage can — was delivered and installed in February 2010. An upcoming change in the pre-treatment chemicals will help prevent the calcium-related problems and allow a return to climb as high as a 85 percent recovery rate in 2016.

“The new distillation assembly performed exactly as we intended,” said Graves. “We had an expected life cycle of 4,380 hours. When it reached that, it showed no signs of a decline in performance, so we let it continue doing its job. The assembly finally started showing subtle signs of wear in April 2015 after 5,394 hours of operation, so the crew changed it out with the replacement assembly, and the used one was returned to us at Marshall for examination.”

The success of the hardware has a direct effect on NASA’s eventual mission to Mars. The ECLSS team is using information learned from this experience to improve the design and the overall chemical process, creating new hardware that is easier to get into space and uses less electricity.

“Several team members are finishing new designs for other fluid pumps on orbit now,” said Leopard. “We are also looking at concept studies for advanced ECLSS systems that could be smaller and more efficient for deep space and the long journey to Mars.”

The ECLSS team is celebrating the homecoming of the assembly by tearing it apart — disassembling it to learn what specific components wore out, what designs can be reused in the next version and maybe get even more time out of the machinery.

The space station’s life support system also benefits people on Earth by contributing to water purification systems used around the world.