Recent tests of a developmental rocket engine at NASA’s Marshall Space Flight Center in Huntsville, Alabama, produced all the performance data engineers were hoping for, along with the traditional fire and roar. But this engine is anything but traditional.

Marshall engineers are designing each of the components from scratch to ultimately be made entirely by additive manufacturing, or 3-D printing, methods. The series of 12 test firings in late fall brought them a big step closer to that goal, said Andrew Hanks, test lead for the project. The fuel turbopump, fuel injector, valves and other major engine components used in the tests were 3-D printed, with the exception of the main combustion chamber.

Previous testing of the engine parts used an ablative combustion chamber, which erodes during a burn, changing internal pressures and allowing only a 10-second firing time. The latest tests ran for 30 seconds and could have gone longer if needed, giving engineers a more realistic picture of what’s going on inside their developmental engine, which is designed to produce 35,000 pounds of thrust.

The regeneratively cooled main combustion chamber used in the tests was of the Marshall team’s new design, but was machined in a traditional way. That allowed engineers to proceed with testing nearly all the pieces of their demonstrator engine design in place, for the first time providing data about how the parts perform together under the extreme temperatures and pressures of a long-duration burn.

“With our new chamber and the longer firings, we are able to create a test environment that is much closer to our design point for this project,” Hanks said.

Validating the new combustion chamber’s performance with the other components was critical because it is the engine’s core, where super-cold fuel becomes the hot gases that ultimately provide thrust. In these tests, liquid oxygen and liquid hydrogen entered the chamber at approximately 400 degrees below zero Fahrenheit and exited at more than 6,000 degrees above zero.

Having the chamber in place allowed the team to obtain better data about each of the other components, said Nick Case, the project’s lead system analyst.

“A system is not just a sum of parts put together. It’s a product of the interaction of the parts. What we’re trying to do is understand and manage those interactions,” he said. “At the same time, we must understand the performance of the individual 3-D printed pieces. That’s what this test allowed us to do.”

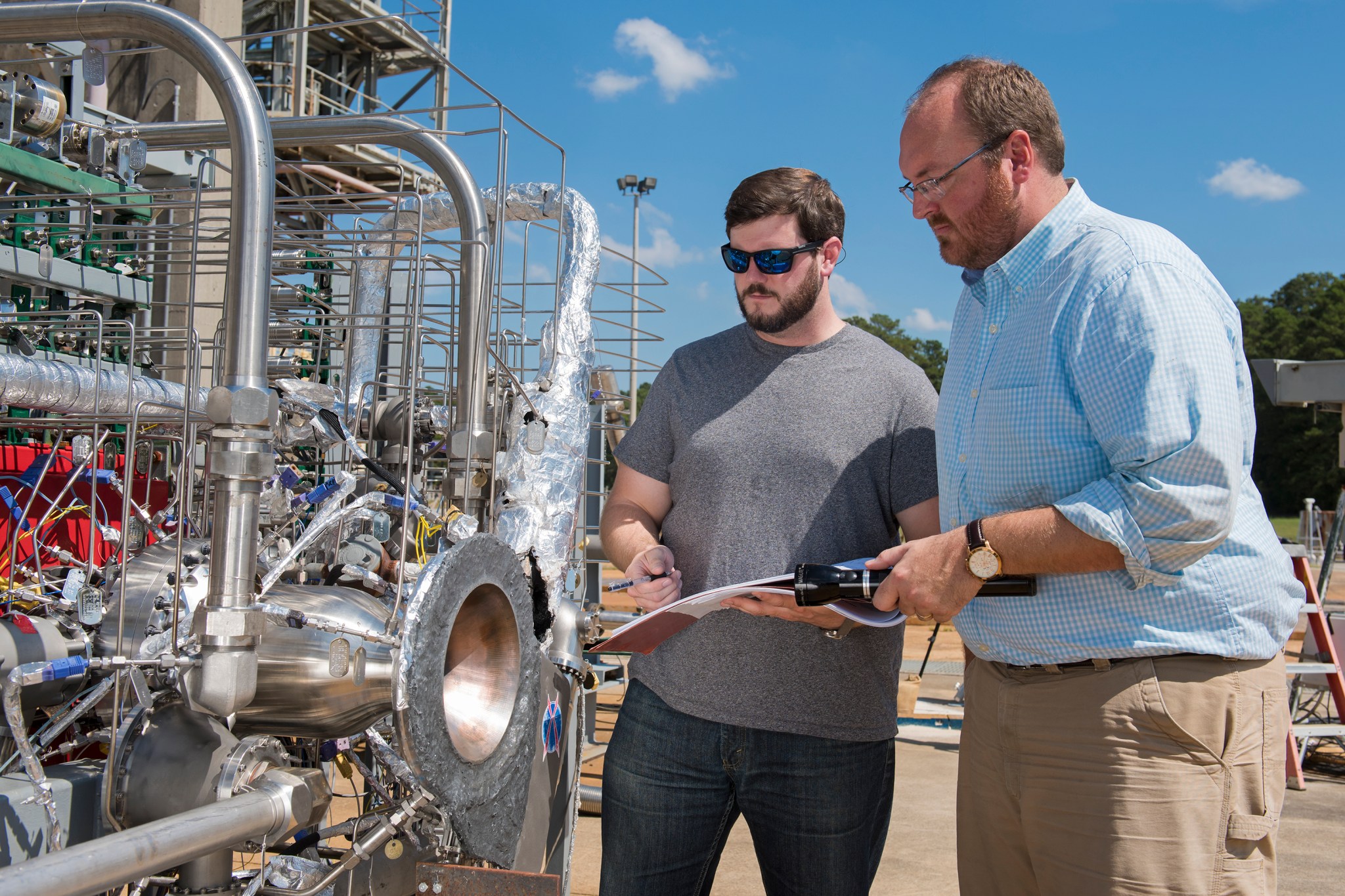

The project looks more like that sum of parts than any real rocket engine. The chamber, fuel turbopump, valves and other components are spread across a framework of tubing and wires in what engineers call a “breadboard” engine. They’re connected so they work together as they would if packaged for a spacecraft or flight, but the breadboard gives engineers the flexibility to easily make adjustments and changes during development, said Graham Nelson, project manager.

Using additive manufacturing allows the team to design and build complex parts that would ordinarily take workers many, many hours to machine and assemble. In many cases, some of the complex designs cannot even be built using traditional machining. As they make modifications to the chamber, injector and other components, the team can quickly build and test the new versions, greatly reducing development time and costs.

Data from the testing validates and enhances the team’s computer models and simulations. And the tests already show the benefits of designing for additive manufacturing can be realized in a high-performance propulsion environment, Nelson said. The team hopes to test a nearly 100-percent 3-D printed breadboard engine system next year.

The Marshall additive manufactured demonstrator engine project team isn’t working to become an engine manufacturer, but could produce a prototype that informs and influences commercial designs, Hanks said. For more than three years they’ve been working with vendors to manufacture some of the developmental engine’s parts, which is helping to grow a vendor base capable of producing rocket engine parts for industry.

The team continues to evolve the system as new components become available and new needs arise – providing more relevant hot-fire environments at each step. The next major step will be the addition of a 3-D printed oxidizer turbopump to the setup. It is being fabricated as part of a collaborative development with the NASA Space Technology Mission Directorate’s Game Changing Development program, which is also funding the development of a 3-D printed combustion chamber.

Marshall engineers hope to test that combustion chamber in the summer of 2017 and then add it to the engine system. In addition, the team is working to test the system with different propellant combinations, such as methane and oxygen — key propellants under consideration for landers and deep-space vehicles because it may be possible to produce the fuel on Mars.