NASA Prepares SLS Moon Rockets for First Crewed Artemis Missions

As teams continue to prepare NASA’s Space Launch System (SLS) rocket for its debut flight with the launch of Artemis I, NASA and its partners across the country have made great progress building the rocket for Artemis II, the first crewed Artemis mission. The team is also manufacturing and testing major parts for Artemis missions III, IV, and V.

“The Space Launch System team is not just building one rocket but manufacturing several rockets for exploration missions and future SLS flights beyond the initial Artemis launch,” said John Honeycutt, SLS program manager at NASA’s Marshall Space Flight Center. “The Artemis I mission is the first in a series of increasingly complex missions that will extend our presence on the Moon. The SLS rocket’s unprecedented power and capabilities will send missions farther and faster throughout the solar system.”

With its two solid rocket boosters and four RS-25 engines, SLS produces more than 8.8 million pounds of thrust to launch each Artemis mission beyond Earth’s orbit and onward to the Moon. The rocket features some of the largest, most advanced, and most reliable hardware elements ever built for space exploration.

To power the agency’s next-generation deep space missions, SLS delivers propulsion in phases. At liftoff, the core stage with its four RS-25 engines and the twin boosters fire to propel SLS off the launch pad into orbit. Once in orbit, the Interim Cryogenic Propulsion Stage provides the in-space propulsion to send NASA’s Orion spacecraft and its crew on a precise trajectory toward the Moon.

The first piece of rocket hardware – the Interim Cryogenic Propulsion Stage – for Artemis II arrived in Florida on July 28, 2021. It is undergoing final preparations at lead contractors Boeing and United Launch Alliance’s facilities and will soon be delivered nearby to NASA’s Kennedy Space Center. The Interim Cryogenic Propulsion Stage fires its RL10 engine, provided by Aerojet Rocketdyne, to send Orion toward the Moon. United Launch Alliance is already building the Artemis III Interim Cryogenic Propulsion Stage in its factory in Decatur, Alabama.

“The Space Launch System is a highly capable launch vehicle purposely designed and rigorously tested to safely transport people, large cargo, and flagship science missions to deep space destinations,” said John Blevins, SLS chief engineer at Marshall. “From the beginning, the SLS rocket was built to first safely send astronauts to space, and at the same time, to evolve to an even more powerful configuration that can support a variety of missions.”

Every NASA center and more than 1,000 different companies across America helped build the Artemis I SLS rocket as well as the SLS rockets that will launch future missions. The boosters and RS-25 engines – the main propulsion elements of the rocket — for the Artemis II and Artemis III missions are in the final stages of assembly. In Utah, crews with Northrop Grumman, the lead contractor for the boosters, have completed casting all the booster motor segments for both Artemis II and Artemis III and began casting segments for Artemis IV. The five-segment solid rocket booster is the largest and most powerful booster ever built for spaceflight.

Aerojet Rocketdyne, the RS-25 lead contractor, is readying the RS-25 engines for the next three SLS flights after Artemis I. The engines have been tested and will be integrated with their respective core stages closer to final assembly. The engines for Artemis II are ready to go to NASA’s Michoud Assembly Facility, where they’ll be integrated with the SLS core stage. The Artemis III engines are being prepared for flight at Aerojet Rocketdyne’s facility at NASA’s Stennis Space Center and the company is already manufacturing engines for missions beyond Artemis IV.

Each 212-foot-tall core stage is produced by Boeing at Michoud. The factory’s 2.2-million-square-feet of manufacturing space and its cutting-edge manufacturing equipment allow teams to build multiple rocket stages at once. Currently, NASA and Boeing, the lead contractor for the SLS core stage, are building core stages for Artemis II, Artemis III, and Artemis IV at Michoud. In addition to the core stage, manufacturing at Michoud has started on test articles for the Exploration Upper Stage that will power the Block IB configuration of the rocket starting with the Artemis IV mission.

“New tooling has been installed at Michoud to build the Exploration Upper Stage at the same time core stages are produced,” said Steve Wofford, NASA’s manager for the SLS Block IB effort. The Exploration Upper Stage will send 83,000 pounds to the Moon, which is 40% more payload to orbit than the ICPS used on early Artemis missions, and 70% more than any existing rocket.”

Crews from Teledyne Brown Engineering in Huntsville and Marshall are manufacturing the cone-shaped launch vehicle stage adapters and Orion stage adapters for Artemis II and Artemis III. The adapters serve as vital connection points for the core and Interim Cryogenic Propulsion Stage and Orion. For missions beyond Artemis III, the universal stage adapter will connect the Exploration Upper Stage to Orion and act as a payload storage compartment, accommodating large payloads, such as logistics modules or other exploration spacecraft. Engineers at RUAG Space USA completed panels for a universal stage adapter test article and delivered the panels to Dynetics in Huntsville, the lead contractor for the adapter, that is assembling the test article in preparation for tests later in 2022.

With Artemis, NASA will land the first woman and the first person of color on the lunar surface and establish long-term exploration at the Moon in preparation for human missions to Mars. SLS and Orion, along with the human landing system and the Gateway in orbit around the Moon, are NASA’s foundation for deep space exploration.

Artemis I Core Stage Engineering Testing Complete

Last week, engineers and technicians successfully completed an engineering test series of the Space Launch System (SLS) rocket core stage inside the Vehicle Assembly Building at NASA’s Kennedy Space Center as part of the integrated testing before launch.

After replacing and testing one of four RS-25 engine controllers, the team conducted several tests to ensure the massive core stage is ready to roll to the launch pad for the wet dress rehearsal ahead of the Artemis I launch. Engineers and technicians tested communication between the flight computers and other core stage systems and slightly moved the engines to practice the gimbaling they will experience during flight.

All four engine controllers were powered up and performed as expected as part of the Artemis I core stage engineering tests. Following the power up, engineers successfully performed diagnostic tests on each controller.

Next, the team will conduct a second countdown sequencing test to demonstrate the ground launch software and ground launch sequencer, which checks for health and status of the vehicle while at the pad. The simulated launch countdown tests the responses from SLS and the Orion spacecraft, ensuring the sequencer can run without any issues. After the countdown test and final closeouts are complete, SLS and Orion will head to the launch pad for the first time to complete the wet dress rehearsal test.

Four Inducted as AIAA Associate Fellows

The American Institute of Aeronautics and Astronautics inducted four team members from NASA’s Marshall Space Flight Center as associate fellows during a ceremony Jan. 3 in San Diego.

The grade of associate fellow recognizes individuals who have accomplished or been in charge of important engineering or scientific work, or who have done original work of outstanding merit, or who have otherwise made outstanding contributions to the arts, sciences, or technology of aeronautics or astronautics.

The Marshall honorees were:

Jody Singer, center director: For significant leadership and vision in enabling America’s space exploration and science missions, and for an inspirational career including serving as Marshall’s 14th director.

John Vickers, senior leader for Advanced and In-Space Manufacturing Capabilities in the Materials and Processes Laboratory: For sustained, significant contributions to the development of the body of knowledge in astronautics engineering, especially impacting nationwide advancement, deployment, and practice of advanced manufacturing.

George Story, solid propulsion engineer: For noteworthy contributions to chemical propulsion systems and processes, rocket failure investigations, contract management, and hybrid rocket developments.

Naveen Vetcha: An ERC Inc. employee who supports the Engineering Services and Science Capability Augmentation contract as a challenge manager and task lead for Centennial Challenges: In recognition of professional standing and outstanding contributions to major NASA missions and efforts as an engineering and public outreach educator.

Former Marshall Chief Technologist Andrew Keys was also inducted.

To be selected, an individual must be an American Institute of Aeronautics and Astronautics senior member in good standing, with at least 12 years of professional experience, and be recommended by three current associate fellows.

“This distinguished group of individuals exemplify passion and dedication to advancing the aerospace profession,” said Basil Hassan, president of the American Institute of Aeronautics and Astronautics. “Each of them was selected because of their significant and lasting contributions to the field. They are truly shaping the future of aerospace.”

I am Artemis: Gwen Artis

Although she was born and raised in the Rocket City of Huntsville, Alabama, math, science, and space exploration weren’t the usual topics of conversation around Gwen Artis’ family dinner table.

“I grew up on a farm before moving into the city at the age of 12. My first two years of education were spent in segregated schools,” Artis said. “During that time a little girl who looked like me wasn’t encouraged to pursue math and science. But thankfully, things changed. By the time I got to high school, I had excelled in math and science, and realized space exploration was amazing.”

Today, Artis is a senior systems engineer with Jacobs Space Exploration Group who assists with management and oversight of the production of the Space Launch System rocket’s launch vehicle stage adapter.

The adapter, manufactured in the Advanced Weld Facility at NASA’s Marshall Space Flight Center, plays an integral role in connecting the rocket’s core stage with the Interim Cryogenic Propulsion Stage that will help propel the Orion spacecraft to the Moon. Artis’ team makes this piece of hardware with a modern manufacturing technique called self-reacting friction stir welding. The 30-foot-tall, cone-shaped adapter helps protect the avionics during launch and ascent and houses the RL10 engine that powers the Interim Cryogenic Propulsion Stage. On the ground, it allows crews to access the upper stage during launch preparations at NASA’s Kennedy Space Center.

Artis started her career at NASA as one of the first high school summer interns at Marshall. Her mentor and valuable hands-on experience inspired her to earn a bachelor of science in engineering at the University Alabama in Huntsville, while working as a co-op student at Marshall. Over the course of her 34-year career at NASA, Artis has worked on a variety of programs including Spacelab, the Chandra X-Ray Observatory, In-Space Propulsion, and SERVIR, a joint endeavor with the United States Agency for International Development that delivers tremendous benefits by working with other countries to help them use data from NASA’s Earth observations satellites.

“Not everyone who works at NASA gets to work on hardware that will fly to space,” Artis said. “I feel extremely fortunate to be a part of this remarkable endeavor of sending astronauts to the Moon. In fact, I feel like the launch vehicle stage adapter is my baby! And I can’t wait to see my baby fly!”

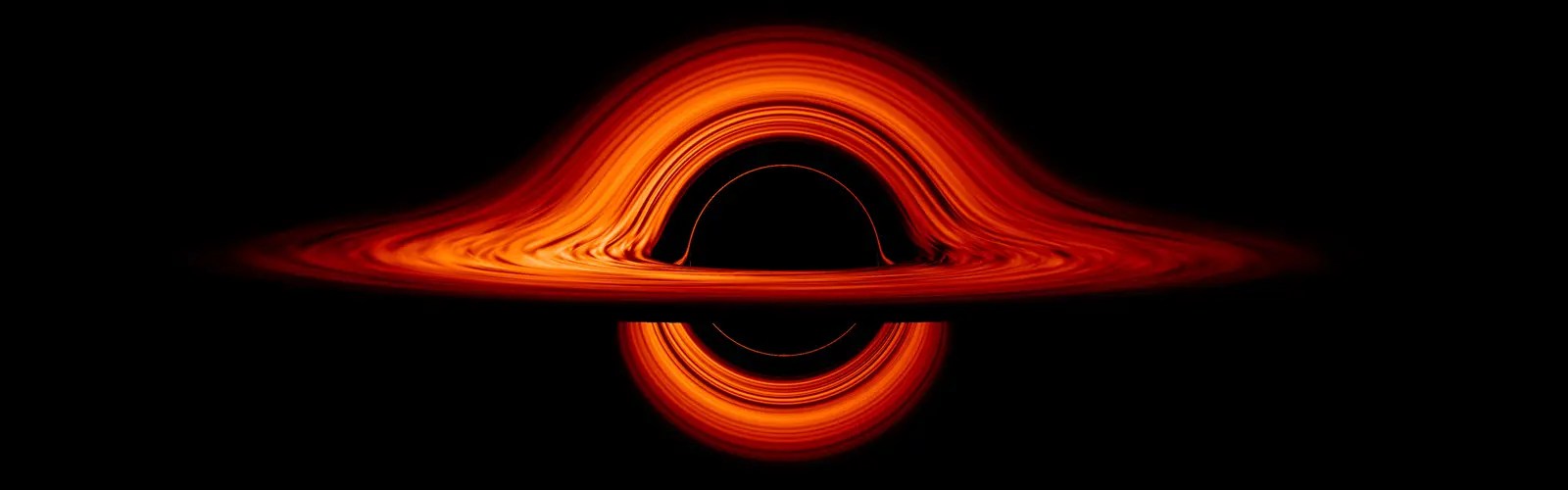

‘Mini’ Monster Black Hole Could Hold Clues to Giant’s Growth

The discovery of a supermassive black hole in a relatively small galaxy could help astronomers unravel the mystery surrounding how the very biggest black holes grow.

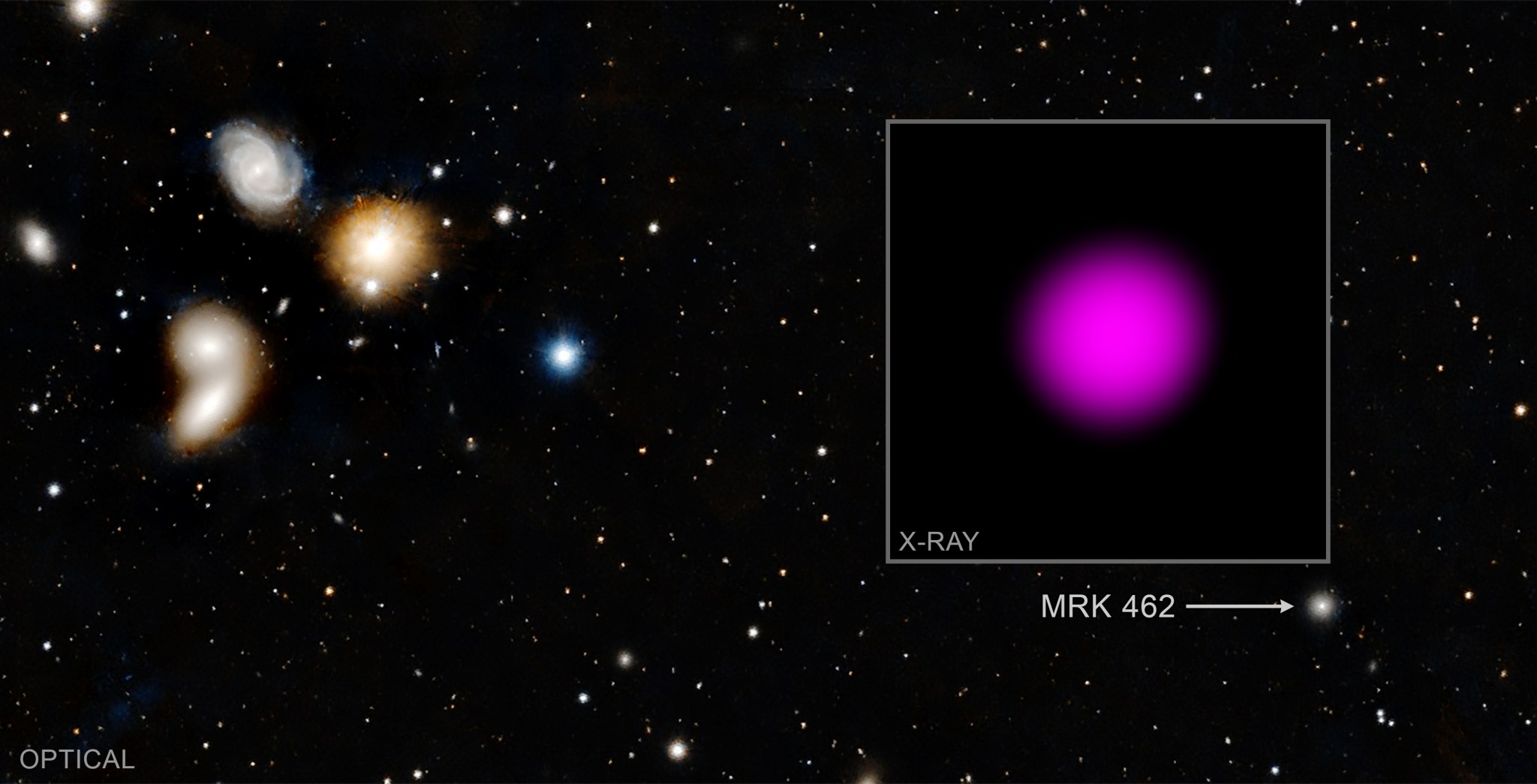

Researchers used NASA’s Chandra X-ray Observatory to identify a black hole – containing about 200,000 times the mass of the Sun – buried in gas and dust in the galaxy Mrk 462.

Mrk 462 contains only several hundred million stars, making it a dwarf galaxy. By contrast, the Milky Way is home to a few hundred billion stars. This is one of the first times that a heavily buried, or “obscured,” supermassive black hole has been found in a dwarf galaxy.

“This black hole in Mrk 462 is among the smallest of the supermassive, or monster, black holes,” said Jack Parker of Dartmouth College in New Hampshire, who led the study with Dartmouth colleague Ryan Hickox. “Black holes like this are notoriously hard to find.”

In larger galaxies, astronomers often find black holes by looking for the rapid motions of stars in the centers of galaxies. However, dwarf galaxies are too small and dim for most current instruments to detect this. Another technique is to search for the signatures of growing black holes, such as gas being heated up to millions of degrees and glowing in X-rays as it falls toward a black hole.

The researchers in this study used Chandra to look at eight dwarf galaxies that had previously shown hints of black hole growth from optical data gathered by the Sloan Digital Sky Survey. Of those eight, only Mrk 462 showed the X-ray signature of a growing black hole.

The unusually large intensity of high-energy X-rays compared to low-energy X-rays, along with comparisons to data at other wavelengths, indicates that the Mrk 462 black hole is heavily obscured by gas.

“Because buried black holes are even harder to detect than exposed ones, finding this example might mean there are a lot more dwarf galaxies out there with similar black holes,” Hickox said. “This is important because it could help address a major question in astrophysics: How did black holes get so big so early in the universe?”

Previous research has shown that black holes can grow to a billion solar masses by the time the universe is less than a billion years old, a small fraction of its current age. One idea is that these huge objects were created when massive stars collapsed to form black holes that weighed only about 100 times the mass of the Sun. Theoretical work, however, struggles to explain how they could pack on weight quickly enough to reach the sizes seen in the early universe.

An alternative explanation is that the early universe was seeded with black holes containing tens of thousands of solar masses when they were created – perhaps from the collapse of gigantic clouds of gas and dust.

A large fraction of dwarf galaxies with supermassive black holes favors the idea that small black hole seeds from the earliest generation of stars grew astonishingly quickly to form the billion solar mass objects in the early universe. A smaller fraction would tip the scales to favor the idea that black holes began life weighing tens of thousands of Suns.

These expectations apply because the conditions necessary for the direct collapse from a giant cloud to a medium-sized black hole should be rare, so it is not expected that a large fraction of dwarf galaxies would contain supermassive black holes. Stellar-mass black holes, on the other hand, are expected in every galaxy.

“We can’t make strong conclusions from one example, but this result should encourage much more extensive searches for buried black holes in dwarf galaxies,” Parker said. “We’re excited about what we might learn.”

These results were scheduled to be presented at the 239th meeting of the American Astronomical Society meeting in Salt Lake City and were part of a virtual press briefing held Jan. 10.

The latest Chandra discovery was featured in “This Week at NASA,” a weekly video program broadcast on NASA-TV and posted online.

NASA’s Marshall Space Flight Center manages the Chandra program. The Smithsonian Astrophysical Observatory’s Chandra X-ray Center controls science operations from Cambridge, Massachusetts, and flight operations from Burlington, Massachusetts.

Rockabilly in the Rocket City

By Brian Odom

The diverse workforce at NASA’s Marshall Space Flight Center possesses a wide range of talents. While math and science skills are prerequisites for many roles, developing, building, testing, and flying complex space hardware is sometimes as much an art as a science. The ability to “listen” to resonance within a propulsion system is a critical factor for validation. An ear for “music” traveling throughout the spacecraft – valves, fuel lines, and structures – is an essential proficiency. It is not surprising then that musicians make great engineers.

One such person from the Apollo years at Marshall was mathematician Jerry Huffman. Born in Belmont, Mississippi, Huffman started his education at Northeast Mississippi Community College in Booneville before earning a degree in mathematics from Memphis State University. His pursuit of an education and eventual work as a computer operator and programmer at the Air Force Depot placed the talented guitarist and songwriter at the birthplace of rock and roll – Memphis, Tennessee.

From 1955-1959, Huffman played guitar for several bands, even working with notable artists like Carl Perkins, Elvis Presley, Johnny Cash, Jerry Lee Lewis, Howlin’ Wolf, and Roy Orbison. But it was his relationship with the “King of Rockabilly” Charlie Feathers that really sparked his musical career. Together with Jody Chastain on bass and Jimmy Swords on drums, their band, The Musical Warriors, pioneered the unique bluegrass rock style that became characteristic of the sound.

In 1956, after finding little success with legendary producer Sam Phillip’s Sun Records, the group moved to Les Biharis’ Meteor record label and struck out from Memphis, travelling to RCA in Nashville and Sid Nathan’s King Records in Cincinnati. Along the way they recorded “Tongue Tied Jill,” “Get With It,” “One Hand Loose,” “I Can’t Hardly Stand It,” and “Bottle to the Baby” – songs that are today recognized as classics of the genre. The group’s standing in pop culture has endured, with covers by notable artists including The Cramps (1980), and cameos like “I Can’t Hardly Stand It” turning up in Quentin Tarantino’s 2004 film “Kill Bill: Vol. 2” and the video game Grand Theft Auto V (2013).

Experiencing little musical success by 1961, Huffman brought his mathematical talents to Marshall, where he eventually came to lead the Program Evaluation and Review Technique computer applications group in the Computation Lab. The group was a central component of NASA’s Program Management System, which the agency leaned upon to ensure discipline and standards were consistent across the vast, complex Apollo program. Huffman’s work at the center ensured the Saturn V made it from the drawing board to Launch Complex 39A in Florida by President John F. Kennedy’s deadline.

Huffman’s duties in the Computation Lab did not prevent him from pursuing his musical ambitions. In 1965, he finally hit it big when Kitty Wells took his song “You Don’t Hear” to the top of the country music charts. Huffman first wrote the song while in Memphis but was unhappy with the arrangement. Coming back to his earlier work, he recast the piece, produced a demonstration tape, and made the short drive from the Rocket City to the Music City.

In Nashville, Huffman gave the demo tape to Johnny Cash’s brother Tommy, who played it for Wells, and the group closed the deal over the phone. During the summer of 1965, “You Don’t Hear” was rated the No. 2 hit country song for five weeks straight, and in Huntsville, topped WBHP radio’s May country and western chart. That year, Wells performed the song in various appearances (including Huntsville on Dec. 16), television shows, and in the movie “Second Fiddle to a Steel Guitar.”

Huffman would not be the last musician to try and hack it in the rocket business. A present-day example is former engineer and program manager Danny Davis, who followed his 30-year career at NASA by crafting custom acoustic guitars and mandolins at his shop at Lowe Mill Arts & Entertainment in Huntsville. After a day of listening for the “music” throughout the complex workings of the Space Launch System, one can always head over and test the resonance of Davis’ handiwork and maybe even “hear” what Huffman was trying to say.

Odom is Marshall’s historian and the acting NASA chief historian.