In This Week’s Star

- COVID-19 and Mission Readiness: NASA Strives to Protect Team, Continue Nation’s Work in Space

- Marshall Medical Center a Resource for All Redstone Employees

- Roger Baird Appointed Associate Director for Operations of Marshall’s Engineering Directorate

- Marshall Environmental Control, Life Support System Team Completes Hardware Upgrades for Space Station Resupply

- I Am Building SLS: Hansel Gill

- Huntsville Plays Role in Naming of NASA’s Next Mars Rover

- Chandra Spots Record-breaking Black Hole Explosion

- Women Lead the Way for NASA’s Space Launch System Rocket Program

- Chief of Wallops Flight Facility’s Safety Office to Speak at Marshall

- OSIRIS-REx Sees Black Hole, Highlighted on ‘This Week @NASA’

- This Week in NASA History: Apollo 9 Splashes Down – March 13, 1969

COVID-19 and Mission Readiness: NASA Strives to Protect Team, Continue Nation’s Work in Space

By Rick Smith

Just as International Space Station crews in orbit 250 miles overhead are able to work flexible hours and communicate with coworkers anywhere on the globe, the NASA workforce is ready to seamlessly conduct its business via telework.

As the nation and the world confront the COVID-19 viral outbreak, NASA and Marshall Space Flight Center leaders held a town hall March 10 to respond to the situation and reassure team members they’re working to keep all personnel safe and enable them to continue the work of the nation’s multifaceted space mission.

NASA Associate Administrator Steve Jurczyk said the agency is “evaluating the situation locally, at the state level, nationally and internationally,” and guided by a 2018 directive from the U.S. Office of Personnel Management that facilitates government work from anywhere policy.

“As always, the protection and care of our NASA team is the top priority and critical to the success of our mission,” Jurczyk wrote previously in an email to the NASA team.

NASA leaders emphasized that health crises such as the COVID-19 outbreak are just one eventuality for which the agency prepares. NASA is ready to respond, whether remote network access is needed due to Flex Friday requirements, personal leave, weather-related safety precautions or base closure events intended to protect health and public safety.

On March 6, NASA verified its agencywide preparedness for large-scale teleworking by hosting a voluntary telework day. Telework is remote access that enables workers to perform their regular, paid duties at approved alternative worksites, such as their homes or a designated telework facility. Hundreds of Marshall civil service employees and on-site contractors — and thousands more at NASA centers around the country — took part, testing the agency’s capabilities, resources and work-readiness, said Marshall Associate Director Steve Miley.

“Our team successfully helped NASA determine that we have the tools and technology to continue the work of the nation, even when circumstances force us to do so from alternate locations,” Miley said.

Jurczyk and Marshall leaders further assured workers that NASA’s executive leadership team, working with its Office of the Chief Health and Medical Officer, will continue to monitor official travel guidelines on a daily basis to determine risk, address issues as they arise and continue to share the latest travel guidelines and general health and safety updates as they are made available.

Currently, travel to NASA’s Ames Research Center is restricted, owing to a documented COVID-19 case among its onsite workforce, and that center remains on mandatory telework. International travel also is suspended to China, South Korea, Japan, Italy and Iran — countries hardest hit at this time by the virus. NASA leaders encourage workers to talk with their managers and supervisors to curtail general travel wherever possible.

Throughout the crisis, NASA will maintain direct communications with its workforce via its NASAPeople website. Team members also are encouraged to visit the Centers for Disease Control and Prevention website for more general information on COVID-19 and guidance about illness symptoms and precautions.

In the event of planned or emergency site closures, NASA employs an enterprise virtual private network service for secure remote access to its resources. The VPN enables access to the local area network and other authorized resources as if the user were sitting at a desk on-site, directly plugged into the network.

For a list of collaboration services and tools, and instructions on using the agency’s VPN, visit SharePoint. Those in need of VPN access can place a connectivity request here. Contractors are encouraged to familiarize themselves with telework guidance provided by their management. Additional IT access questions should be directed to the Enterprise Services Desk at the Shared Services Center at 877-677-2123 or https://esd.nasa.gov/.

Team members are encouraged to begin taking home their government-issued laptop computers, power cords and NASA badges as a matter of course each day, and to periodically check their home connectivity for adequate service. Such diligence will help Marshall prepare in advance for potential short-term facility closures or other eventualities.

“Should it become necessary for NASA to close facilities, workers will receive emailed guidance,” Miley said. “We are confident we are ready to meet the requirements of our mission in these circumstances, just as we continue to do every day.”

Marshall Director Jody Singer emphasized that readiness at the center’s March 10 town hall. “We are asking you to be agile and ready to respond” to a mandatory telework requirement, she said, noting that NASA and center leaders will provide as much advance notice as possible of such a move.

For those with additional questions on COVID-19 and other health issues, NASA’s Employee Assistance Program provides no-cost, confidential support. Center clinicians are available to discuss any concerns team members might have. Learn more here.

Learn more about the emergency notification system, and how to update your contact information, here. Marshall team members also are encouraged to bookmark Inside Marshall and visit regularly for news and updates.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Medical Center a Resource for All Redstone Employees

With flu season still here, and concerns about the new coronavirus growing, NASA’s Marshall Space Flight Center team members are encouraged to continue making their health and safety a priority.

The Marshall Medical Center offers walk-in adult health care services for all Redstone Arsenal contractors and civil servants. Visitors to the medical center can use their health insurance — Blue Cross Blue Shield, Medicare and Aetna are currently accepted. Co-payments will apply and the center accepts credit cards and checks.

The medical center is located at 4249 Morris Road. Services include treatment of acute illness, allergy injections, strep test, testing for flu, tuberculin skin tests, immunizations and physical exams. Walk-in hours are noon to 3:30 p.m. from Monday through Thursday, and noon to 2:30 p.m. on non-flex Fridays. Appointments for wellness exams can be made by calling 256-544-5731.

The medical center is staying up-to-date on the latest recommendations from the Centers for Disease Control and Prevention on preventing spread of the newest coronavirus — COVID-19 — for health care facilities. Currently there is not a “rapid” test for COVID-19. Individuals exhibiting symptoms, such as fever, shortness of breath and cough, should call the medical center at 256-544-2390 prior to arriving inside of the building and ask to speak with a nurse. Do not directly enter the reception area.

Employees are encouraged to use these basic tips from the CDC for preventing illness:

- Avoid close contact with people who are sick.

- Avoid touching your eyes, nose and mouth.

- Stay home when you are sick.

- Cover your cough or sneeze with a tissue, then throw the tissue in the trash.

- Clean and disinfect frequently touched objects and surfaces using a regular household cleaning spray or wipe.

- Wash your hands often with soap and water for at least 20 seconds. If soap and water are not readily available, use an alcohol-based hand sanitizer with at least 60% alcohol. Always wash your hands with soap and water if they are visibly dirty.

For more information on the Marshall Medical Center, visit ExplorNet.

For more information on COVID-19, including Marshall, agency and CDC resources, visit here.

Roger Baird Appointed Associate Director for Operations of Marshall’s Engineering Directorate

Roger Baird has been appointed to the Senior Executive Service position of associate director for operations of the Engineering Directorate at NASA’s Marshall Space Flight Center. He has been detailed to the position since March 2019, providing senior management and expertise for the evaluation of spacecraft, payloads and rocket systems, and the integration of the associated budgets and resources authority for those efforts. The Senior Executive Service is the personnel system covering most of the top managerial positions in federal agencies.

Baird brings a wealth of expertise to the role, with almost 30 years of NASA experience in the areas of avionics systems design and integration, systems engineering and integration, space transportation, propulsion systems and resources management. He joined NASA in 1990 as an avionics engineer and later became lead for shuttle projects at Marshall. He has since led teams, branches and divisions within the Engineering Directorate’s Space Systems Department, Spacecraft and Vehicle Systems Department and Propulsion Systems Department.

Baird was previously manager of the Engineering Resource Management Office, where he was responsible for advising, coordinating, monitoring, directing and performing work associated with planning, programming, budgeting and managing the Engineering Directorate’s financial, human and infrastructure resources.

A native of Birmingham, Baird graduated from the University of Alabama in Birmingham with a bachelor’s degree in electrical engineering. He has received numerous NASA awards, including an Exceptional Achievement Medal and a Silver Snoopy.

Baird and his wife, Pam, have two children and live in Huntsville.

Marshall Environmental Control, Life Support System Team Completes Hardware Upgrades for Space Station Resupply

By Taylor Goodwin

NASA’s Marshall Space Flight Center delivered upgraded life support hardware to the International Space Station on March 9 aboard SpaceX’s 20th resupply mission.

Improving life support with reliable systems will help enable human exploration to the Moon and Mars. Building on experience gained at the space station over the last 20 years, NASA will land the first woman and next man on the Moon by 2024 through the Artemis Program and prepare to extend humanity farther into the solar system.

The station’s water recovery system provides clean water by reclaiming wastewater — including water from crew members’ urine, cabin humidity condensate and water from the hydration system inside crew members’ spacesuits. The redesigned urine distillation assembly — which boils astronauts’ urine to begin purification — will be installed into the space station’s urine processor assembly and tested to ensure the hardware functions as intended.

The recovered water must meet stringent purity standards before it can be used to support crew, spacewalk or payload activities. Water produced by the urine processor is combined with all other wastewaters and delivered to the water processor for treatment. The water processor sends the water through a series of filtering materials and chemical reactions for purification. The water purity is checked by electrical sensors in the systems, and unacceptable water is reprocessed until it meets purity standards. Clean water is sent to a storage tank — ready for the crew to use.

Observing the urine processor assembly in action since its installation in 2008 has revealed some weak points in the system — specifically concerning the long-term reliability of the hardware.

“One of the most important things we’ve learned in the last 12 years of the hardware’s orbital operation is that the hardware is vulnerable in its steam environment,” said Jennifer Pruitt, Environmental Control and Life Support System urine processor assembly project manager at Marshall. “We took those lessons learned and upgraded our urine distillation assembly to create a more reliable system equipped to travel to the Moon, Mars and beyond.”

These upgrades focus on internal redesigns — including a new toothed belt drive system, bearing seals, Teflon spacer and liquid level sensor — all of which will aid in controlling the hardware’s steam and fluid environment to provide the crew with the cleanest water possible.

The ECLSS team has spent the last two years updating components of the space station’s water recovery system. To conserve costs and manage size constraints, Marshall’s ECLSS team came together to think of creative ways to address known issues and improve the system’s reliability without entirely replacing the components. After several rounds of brainstorming, iterative design and testing, the team completed the hardware build two months ahead of schedule — landing the hardware on an early resupply mission for a technology demonstration aboard the space station.

“This team sees the importance of the project for Marshall, the space station, the astronauts and for furthering deep space exploration,” Pruitt said. “They embody what I love about working here: taking pride in your work, really caring about something and making it happen.”

Deep space missions in the future will rely heavily on efficient use of resources. The great distances traveled and the limited space on the vehicles will limit water resupply.

“Improving the efficiency and reliability of the current system will diminish the need for an excess of spare parts on board,” Pruitt said. “With less maintenance required, the crew can focus on the science at hand.”

Marshall and other NASA field centers will continue working to develop regenerative life support hardware to maximize recycling of water and oxygen to sustain life and allow humans to travel deeper into space than ever before.

Goodwin, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

I Am Building SLS: Hansel Gill

I started working at NASA as a summer intern just two weeks after I graduated from high school. By the end of that first summer, I knew I wanted my career to be with NASA, but I didn’t know then just what that career would entail. It’s hard to believe that the hardware I’ve helped build will enable America’s return to the Moon.

As the subsystem manager for manufacturing and production for the exploration upper stage of NASA’s Space Launch System Program, I am in the front row as blueprint designs transform into actual hardware for the rocket that will launch NASA’s Artemis missions — and astronauts — to the Moon.

The SLS rocket is a huge, complex piece of hardware that is designed to deliver propulsion in stages to send NASA’s Orion spacecraft and heavy cargo to the Moon for the Artemis missions. While the core stage and solid rocket boosters will launch the rocket and spacecraft into Earth’s orbit, the upper stage provides the in-space propulsion to send the spacecraft, its crew and its cargo farther into deep space.

The rocket’s core stage design will essentially remain the same for each of the Artemis missions. But, the rocket’s upper stage is designed to meet various mission requirements and goals to enable even larger cargos to the Moon and beyond.

My role bridges the gap between the design team at NASA’s Marshall Space Flight Center, where the SLS Program is managed, and the manufacturing team at NASA’s Michoud Assembly Facility, where the SLS rocket’s core stages and exploration upper stages are produced. My job is to ensure NASA and Boeing, the core stage lead contractor, are creating a technically sound rocket; and that the manufacturing and assembling teams are doing their work as efficiently as possible. It takes a lot of communication, teamwork and planning.

Because of this, I divide my time between Alabama and Louisiana. My time between Michoud and Marshall allows for face-to-face time that you can’t get from a distance. More importantly, I get to be on the floor with the hardware, which gives me a better understanding of the technical challenges because I can see it. It’s real.

My primary responsibilities revolve around the development and production of the upper stages for the SLS rocket. That requires a thorough understanding of the core stage, which is located just beneath the upper stage of the rocket that generates more than 2 million pounds of thrust to help launch SLS and Orion, and its production. My team and I tracked the production and assembly of the first core stage for Artemis I, so we could capture the lessons learned and apply those to the production of the upper stages for future rockets and Artemis missions.

I love hardware and being part of the build process. After earning my undergraduate degree in mathematics from Oakwood University in Huntsville and a graduate degree in industrial and systems engineering from the University of Alabama in Huntsville, I spent the first half of my career in metallic materials engineering, which has a production component. As I transitioned farther into the production side, my appetite for it only grew. I enjoy seeing these large systems being put together.

The Artemis missions are a source of inspiration for all of us. Being on the factory floor, interacting with and watching the steady hum of activity as men and women work on America’s rocket, makes me even more excited for the mission ahead and the new worlds that will be reached because of our work.

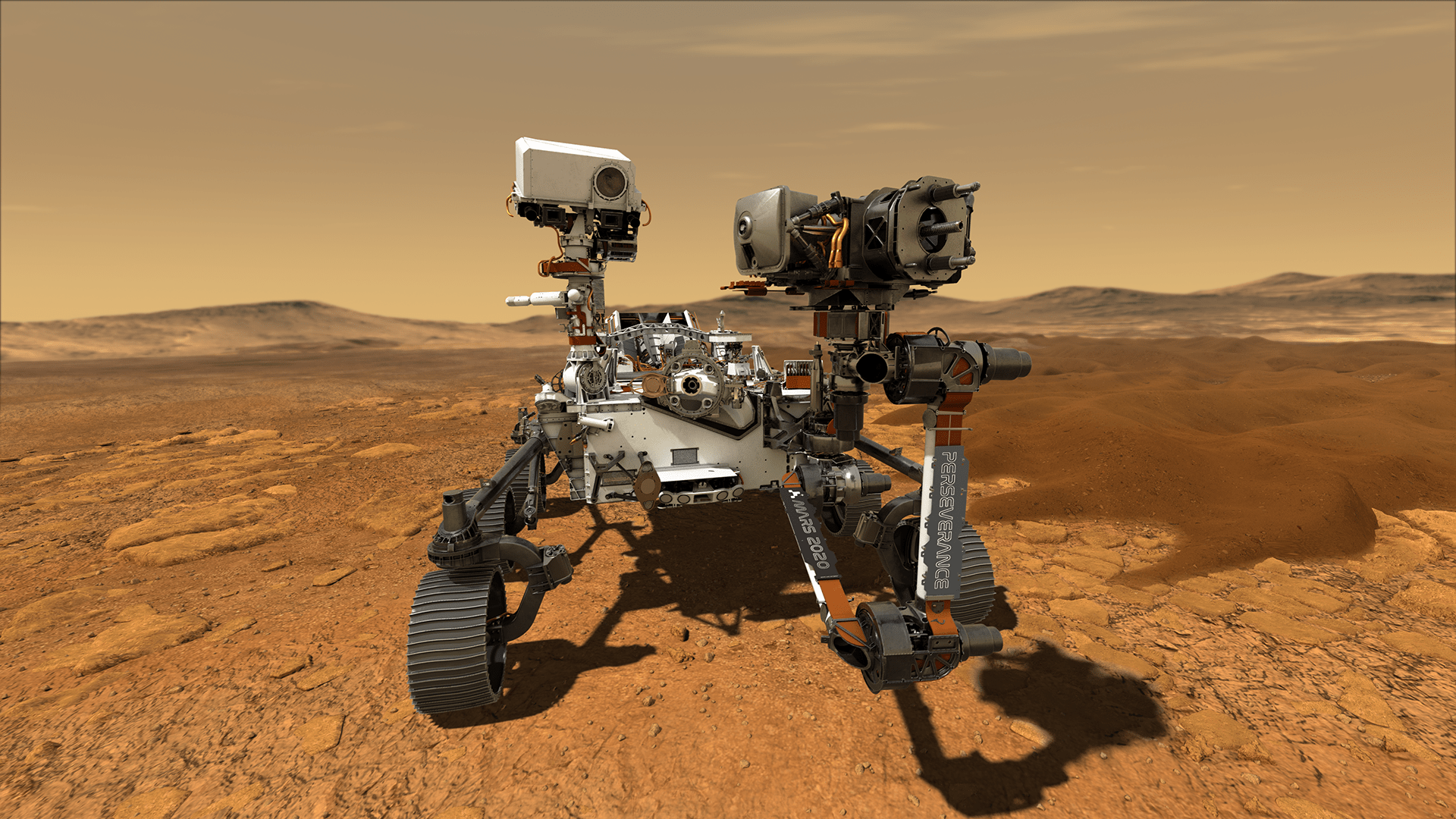

Huntsville Plays Role in Naming of NASA’s Next Mars Rover

NASA’s next Mars rover has a new name — Perseverance.

The name was announced March 5 by Thomas Zurbuchen, associate administrator of NASA’s Science Mission Directorate, during a celebration at Lake Braddock Secondary School in Burke, Virginia. Zurbuchen was at the school to congratulate seventh grader Alexander Mather, who submitted the winning entry to the agency’s “Name the Rover” essay contest — which received 28,000 entries from K-12 students from every U.S. state and territory.

Up until two years ago, Mather was more interested in video games than space. That all changed in the summer of 2018 when he visited Space Camp at the U.S. Space & Rocket Center. From his first glimpse of a Saturn V — the rocket that launched the Apollo astronauts to the Moon half a century ago — Mather became a bona fide space enthusiast, checking NASA.gov daily, consuming astronaut autobiographies and even 3D-printing flyable model rockets. When the call went out for students to propose a name for NASA’s new Mars rover, Mather knew he wanted to contribute.

“This was a chance to help the agency that put humans on the Moon and will soon do it again,” Mather said. “This Mars rover will help pave the way for human presence there and I wanted to try and help in any way I could. Refusal of the challenge was not an option.”

The contest that resulted in Alex’s winning entry of Perseverance began Aug. 28, 2019. Nearly 4,700 volunteer judges — educators, professionals and space enthusiasts from around the country — reviewed submissions to help narrow the pool down to 155 semifinalists. Once that group was whittled down to nine finalists, the public had five days to weigh in on their favorites, logging more than 770,000 votes online, with the results submitted to NASA for consideration. The nine finalists also talked with a panel of experts, including Lori Glaze, director of NASA’s Planetary Science Division; NASA astronaut Jessica Watkins; rover driver Nick Wiltsie at NASA’s Jet Propulsion Laboratory; and Clara Ma, who, as a sixth grade student in 2009, named Curiosity, another Mars rover.

“Alex’s entry captured the spirit of exploration,” Zurbuchen said. “Like every exploration mission before, our rover is going to face challenges, and it’s going to make amazing discoveries. It’s already surmounted many obstacles to get us to the point where we are today — processing for launch. Alex and his classmates are the Artemis Generation, and they’re going to be taking the next steps into space that lead to Mars. That inspiring work will always require perseverance. We can’t wait to see that nameplate on Mars.”

Along with forever being associated with the mission, Mather will also receive an invitation to travel with his family to Cape Canaveral Air Force Station in Florida to witness the rover begin its journey when it launches this summer. While Mather has received NASA’s grand prize in this competition, NASA also is acknowledging the valuable contributions of the semifinalists whose entries were among the top ones considered.

NASA’s Perseverance rover is a robotic scientist weighing just under 2,300 pounds. Managed for the agency by JPL, the rover’s astrobiology mission includes searching for signs of past microbial life. It also will characterize the planet’s climate and geology, and collect samples of Martian rocks and dust for a future Mars sample return mission to Earth, while paving the way for human exploration of the Red Planet.

“When word went out during the naming event here at JPL, I took a moment to look around the auditorium,” said John McNamee, project manager of the Mars 2020 Perseverance rover mission at JPL. “I saw all these dedicated men and women who for years have invested the full measure of their intellect and stamina into the most technologically advanced rover mission in history — and I saw a lot of smiling faces and high-fives. Perseverance? You bet, that is a worthy name that we can be proud of as the first leg of a sample return campaign.”

For more information about the mission, visit here. Follow Perseverance’s updates on Twitter and Facebook.

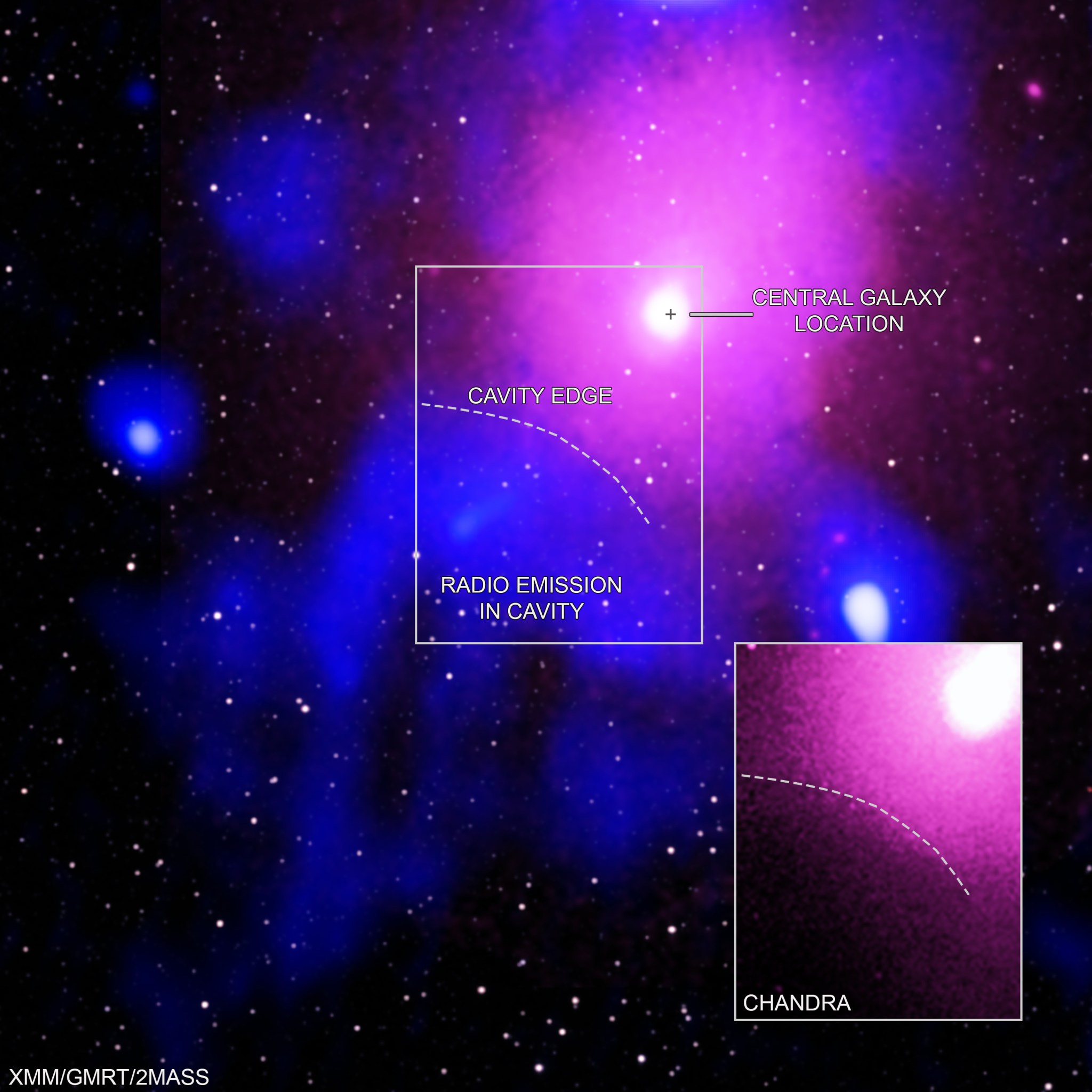

Chandra Spots Record-breaking Black Hole Explosion

NASA’s Chandra X-ray Observatory has detected the biggest explosion in the universe. Originating from a black hole that is hundreds of millions of light-years away, the record-breaking eruption was discovered using X-ray data from Chandra and the European Space Agency’s XMM-Newton observatory, as well as radio data from the Murchison Widefield Array in Australia and the Giant Metrewave Radio Telescope in India.

The unrivaled outburst was detected in the Ophiuchus galaxy cluster, which is approximately 390 million light-years from Earth. Galaxy clusters contain thousands of individual galaxies, dark matter and hot gases, and they are the largest structures in the universe held together by gravity.

“In some ways, this blast is similar to how the eruption of Mount St. Helens in 1980 ripped off the top of the mountain,” said Simona Giacintucci of the Naval Research Laboratory in Washington, D.C., and lead author of the study that found the explosion. “A key difference is that you could fit 15 Milky Way galaxies in a row into the crater this eruption punched into the cluster’s hot gas.”

Researchers believe the source of the explosion is a supermassive black hole at the center of the Ophiuchus cluster. Although black holes are famous for pulling material toward them, they often expel prodigious amounts of material and energy. This happens when matter falling toward the black hole is redirected into jets, or beams, that blast outward into space and slam into any surrounding material.

Chandra first revealed hints of the giant explosion in 2016, when Norbert Werner and colleagues reported the discovery of an unusual curved edge in the observatory’s image of the cluster. While researchers discounted the possibility at the time, the latest study by Giacintucci and her colleagues confirms that an enormous explosion did, in fact, occur.

Because the curved edge was also detected by XMM-Newton, they were able to confirm the Chandra observation. New radio data from the Murchison Widefield Array and data from the Giant Metrewave Radio Telescope archives showed the curved edge is indeed part of the wall of a cavity, because it borders a region filled with radio emission. This emission is from electrons accelerated to nearly the speed of light. The acceleration likely originated from the supermassive black hole.

“The radio data fit inside the X-rays like a hand in a glove,” said co-author Maxim Markevitch of NASA’s Goddard Space Flight Center. “This is the clincher that tells us an eruption of unprecedented size occurred here.”

The amount of energy required to create the cavity in Ophiuchus is approximately five times greater than the previous record holder, MS 0735+74, and hundreds and thousands of times greater than typical clusters.

Researchers believe the black hole eruption has finished due to the lack of evidence for current jets in the radio data. This shutdown can be explained by the Chandra data, which shows the densest and coolest gas seen is currently located at a different position from the central galaxy. If this gas shifted away from the galaxy, it would have deprived the black hole of fuel for its growth, turning off the jets.

This gas displacement is likely caused by gas around the middle of the cluster “sloshing” like wine in a glass. Usually the merger of two galaxy clusters triggers this behavior, however, in this case it could have been set off by the eruption.

Researchers are also trying to understand why only one giant region of radio emission is visible. Systems normally contain two emissions on opposite sides of the black hole, however, researchers believe it is possible that gas on the other side of the cluster from the cavity is less dense, causing the radio emissions in the area to fade quicker.

“As is often the case in astrophysics we really need multiwavelength observations to truly understand the physical processes at work,” said Melanie Johnston-Hollitt, a co-author from the International Centre for Radio Astronomy in Australia. “Having the combined information from X-ray and radio telescopes has revealed this extraordinary source, but more data will be needed to answer the many remaining questions this object poses.”

Managed by Marshall, Chandra allows scientists from around the world to obtain X-ray images of exotic environments to help understand the structure and evolution of the universe.

Women Lead the Way for NASA’s Space Launch System Rocket Program

The four women in charge of the effort to build and test the 212-foot-tall rocket stage that will enable NASA’s first Artemis mission to the Moon watch as the first completed core stage for NASA’s Space Launch System Program rolls out from the agency’s Michoud Assembly Facility on Jan. 8. These key leaders are, from left, Lisa Bates, NASA Stages element deputy manager; Jennifer Boland-Masterson, Boeing Michoud production/operations manager; Julie Bassler, NASA Stages element manager; and, Noelle Zietsman, Boeing chief engineer. Each of these women manage the entire scope of design, development, testing and production of the complex core stage that will power the super heavy-lift rocket and the agency’s Artemis lunar missions. Combined, the women have 90 years of experience in the aerospace and defense industries. Bassler and Bates previously held leadership positions within many NASA programs and projects, including International Space Station, space shuttle, microgravity experiments, robotic lunar landers and other launch vehicles. Manufacturing of the core stages for the SLS rocket is a multistep, collaborative process for NASA and Boeing, the core stage lead contractor. The first core stage for Artemis I is undergoing the core stage Green Run test series at NASA’s Stennis Space Center ahead of the program’s first launch. Michoud manufacturing teams are currently producing core stages for the second and third Artemis missions. (NASA/Jude Guidry)

Chief of Wallops Flight Facility’s Safety Office to Speak at Marshall

Glen Liebig, the chief of the Safety Office at NASA’s Wallops Flight Facility, will deliver the Mission Success is in Our Hands lecture March 19 at 11:30 a.m. in Room 1201 of Building 4203 at NASA’s Marshall Space Flight Center. He will present an overview of the failure response to the October 2014 Antares rocket failure. The rocket was carrying supplies to the International Space Station when it failed shortly after launch. Liebig will discuss the importance of planning for such an event and explain how the lessons learned can be applied to NASA’s future missions. In addition to Liebig’s talk, eight new Mission Success is in My Hands banners, each featuring a Marshall team member, will be unveiled. The banners spotlight employees making meaningful connections between their jobs and the safety and success of NASA and Marshall missions, and will be displayed throughout the center. These team members will be featured in a Marshall Star profile series beginning April 8. (NASA)

OSIRIS-REx Sees Black Hole, Highlighted on ‘This Week @NASA’

NASA’s OSIRIS-REx recently caught a glimpse of a newly discovered black hole and is featured in “This Week @NASA,” a weekly video program broadcast on NASA-TV and posted online.

While making observations off the edge of asteroid Bennu, a student-built spectrometer aboard OSIRIS-REx unexpectedly detected X-ray activity 30,000 light-years in the distance. It turned out to be a newly flaring black hole that was discovered a week earlier by a telescope on the International Space Station. The glimpse of the X-ray event by OSIRIS-REx marks the first time such an outburst has been detected from interplanetary space.

OSIRIS-REx is a project of the Science Mission Directorate’s New Horizons Program, managed by NASA’s Marshall Space Flight Center.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

This video is available for download from NASA’s Image and Video Library: https://images.nasa.gov/details-NHQ_2020_0307_A%20New%20Name%20for%20Our%20Next%20Mars%20Rover%20on%20This%20Week%20@NASA%20%E2%80%93%20March%207,%202020 Credits: NASA

This Week in NASA History: Apollo 9 Splashes Down – March 13, 1969

This week in 1969, Apollo 9 splashed down in the Atlantic Ocean following a successful 10-day mission. Here, the docked Apollo 9 command and service module and lunar module can be seen during astronaut David R. Scott’s stand-up spacewalk on the fourth flight day of the mission. The primary objective of Apollo 9 was an Earth-orbital engineering test of the first crewed lunar module. Other prime objectives included an overall checkout of rocket and spacecraft systems, the crew and procedures. The flight plan’s top priority was rendezvous and docking of the command and service module and the lunar module. All prime mission objectives were accomplished and all major spacecraft systems were successfully demonstrated. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)