In This Week’s Star

- Marshall to Recognize Outstanding Team Members at Annual Honor Awards Ceremonies July 8

- Selective Laser Melting Can Cut Time, Costs for SLS RS-25 Engine Parts

- Marshall Center Celebrates 55 Years of Turning Dreams Into Realities

- Longest SLS Engine Test Yet Heats Up Mississippi Sky

- Marshall Association Awards Scholarships to Five Students

- Marshall Center Hosts Small Business Supplier Conference

- Fourth RS-25 Engine Test Featured On ‘This Week @NASA’

Marshall to Recognize Outstanding Team Members at Annual Honor Awards Ceremonies July 8

By Brian C. Massey

NASA’s Marshall Space Flight Center will recognize more than 300 employees, contractors and teams during its Annual Honor Awards ceremonies in Morris Auditorium on July 8. All Marshall team members are invited to attend.

The theme for this year’s ceremonies is “Pushing the Boundaries — Unlimited Discovery,” which was inspired by a quote from President Barack Obama, “For pennies on the dollar, the space program has improved our lives, advanced our society, strengthened our economy and inspired generations of Americans.”

Award presentations will be made during two ceremonies — agency-level Honor Awards at 10 a.m. and center-level Honor Awards at 2 p.m. The morning ceremony will recognize those who have made significant achievements to NASA’s mission at an agency level. The afternoon ceremony will recognize those who have made outstanding mission contributions to Marshall.

NASA Administrator Charles Bolden will be the keynote speaker at both ceremonies. He and Marshall Center Director Patrick E. Scheuermann will present the awards to the honorees.

Announcing the agency-level awards will be Tereasa H. Washington, director of Marshall’s Office of Human Capital; Joe L. (Larry) Leopard, manager of the Space Systems Department in Marshall’s Engineering Directorate; and Lisa A. Watson-Morgan, manager of the Chief Engineers Office.

The center-level awards will be announced by Robin N. Henderson, Marshall Center associate director; Todd A. May, manager of the Space Launch System Program Office; and Audrey D. Robinson, Marshall’s chief counsel.

Steve Doering, manager of the Stages Office of the Space Launch System Program, will emcee.

For a list of the NASA Honor Awards recipients, click here.

For a list of the Marshall Honor Awards recipients, click here.

Massey, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

Selective Laser Melting Can Cut Time, Costs for SLS RS-25 Engine Parts

By Megan Davidson

Engine testing is firing forward for NASA’s new rocket, the Space Launch System, but it doesn’t stop on the test stand at the agency’s Stennis Space Center.

Some 400 miles away at NASA’s Marshall Space Flight Center, engineers are testing an additive manufacturing process — called selective laser melting. Selective laser melting is a 3-D printing process that can create complex rocket parts. The process is being used to make some of the parts more efficiently and affordably — without compromising performance and safety — for the engine and other components of the rocket.

“The opportunity for affordability extends well beyond manufacturing because these technologies give us the ability to reduce the entire development life cycle from design to flight,” said Chris Singer, director of the Engineering Directorate at the Marshall Center, where the SLS Program is managed for the agency.

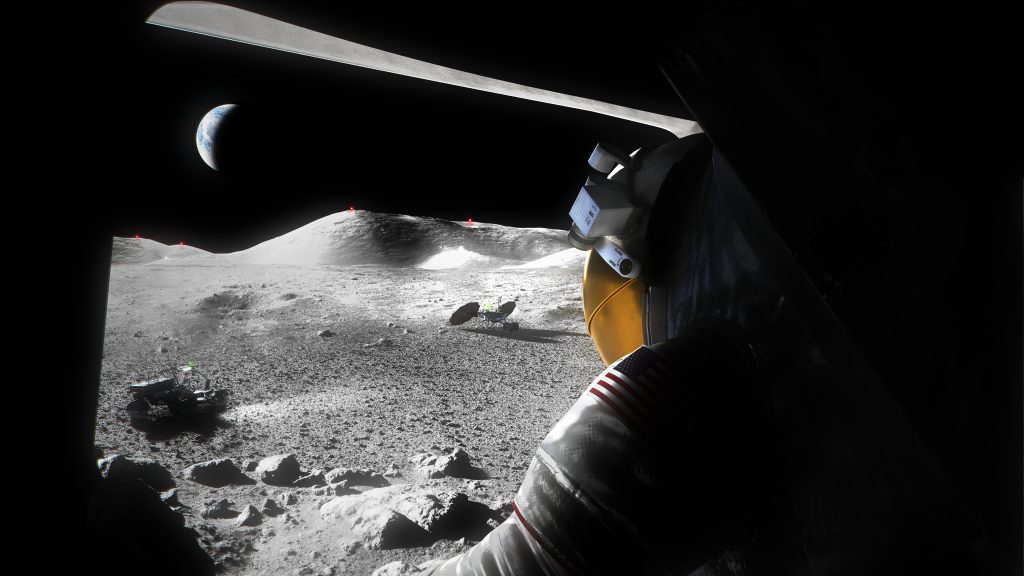

Four RS-25 engines, along with two, five-segment solid rocket boosters, will power the core stage of the SLS, which will provide an entirely new capability for science and human exploration beyond Earth’s orbit, including deep-space destinations, like an asteroid and Mars. The core stage, towering more than 200 feet tall with a diameter of 27.6 feet, will store cryogenic liquid hydrogen and liquid oxygen that will fuel the vehicle’s RS-25 engines.

The process for selective laser melting begins with a three-dimensional design created by a computer that is transmitted to a machine, and inside the machine, a high-energy laser melts metal powder and fuses the powder layer by layer to build the desired component. The process drastically reduces or eliminates the need for multiple welds common to traditional manufacturing methods.

“Selective laser melting is changing the way we think and do things in the manufacturing world,” said Andy Hardin, a subsystems manager in Marshall’s Liquid Engines Office. “We have conducted a lot of studies to see which RS-25 parts would benefit most from the selective-laser-melting process. Our initial estimates show, in some instances, this technology can reduce the RS-25 part cost by as much as 45 percent, and significantly shorten development and manufacturing time.”

Additive manufacturing would make parts for the brand-new RS-25 engines that will be built for future SLS missions after the first four SLS flights. The program has 16 RS-25s in inventory from the Space Shuttle Program that provide affordable propulsion for the first four SLS missions.

Marshall has three selective-laser-melting machines, adding its latest one — the X line 1000R — in February to the Advanced Manufacturing Lab. The X line 1000R is the largest of the machines and increases build capacity by more than 400 percent. It can create parts up to 24 inches long, 16 inches wide and 19 inches high — comparable to a large microwave oven.

“A lot of foundational work is being done right now,” said Ken Cooper, advanced manufacturing team lead in Marshall’s Engineering Directorate. “We are making samples and testing them. We have to demonstrate first that we can build these parts, which isn’t a simple process. A lot of work goes into how a part is printed. You can’t just push a button and have an intricate rocket engine part come out a minute later. We have to do a lot of development work, including analyzing and testing the strength of a material being used, how it reacts to environmental factors and other conditions that may affect how the material performs.”

Read the full story here.

Davidson, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

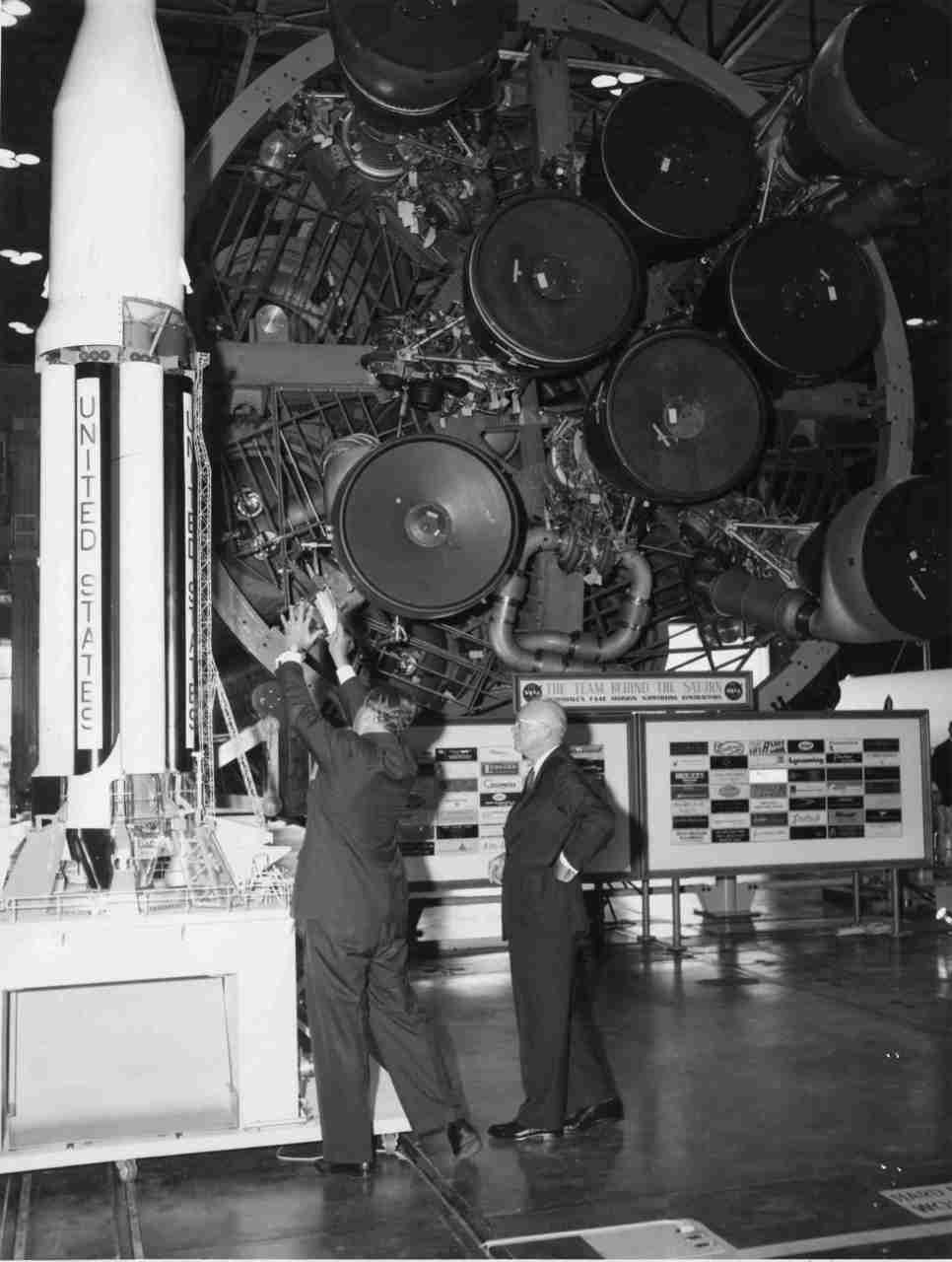

Marshall Center Celebrates 55 Years of Turning Dreams Into Realities

by Tracy McMahan

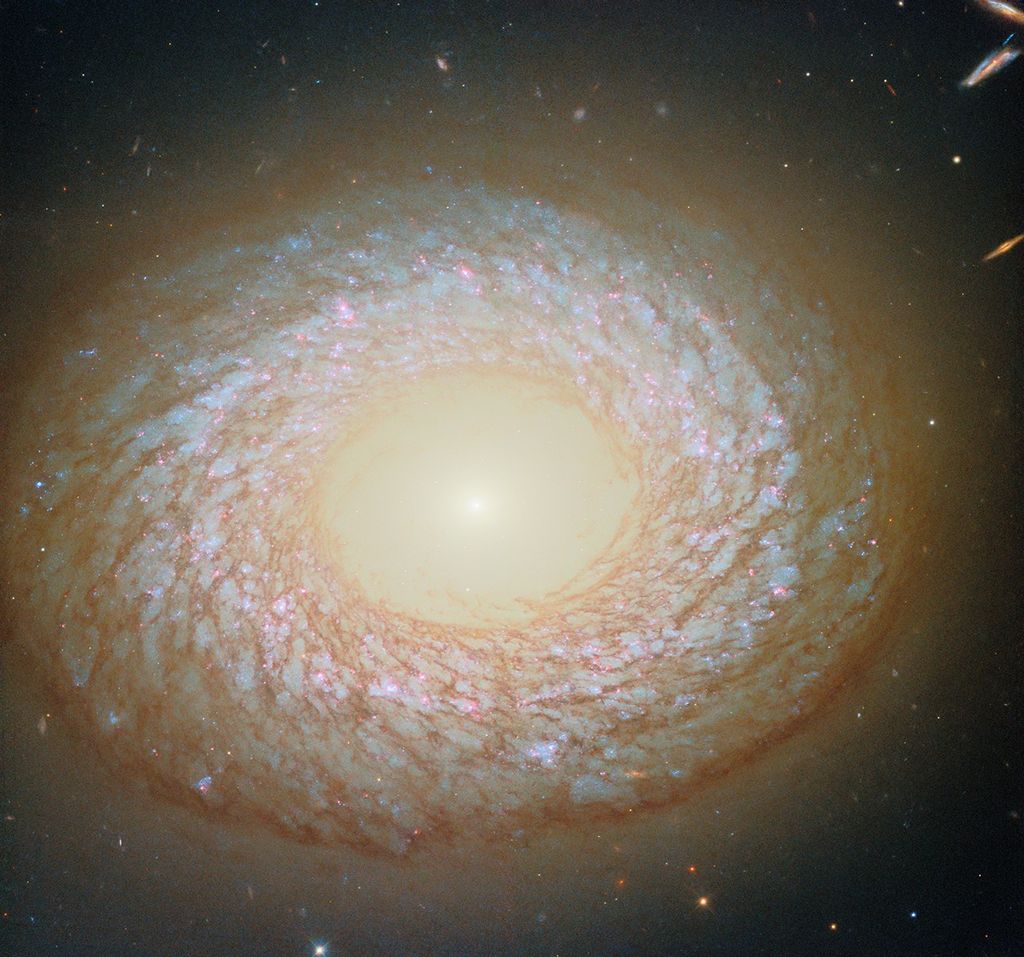

This year marks NASA Marshall Space Flight Center’s 55th anniversary. Marshall employees and their industry partners have achieved many milestones: sending the first American to space, landing the first people on the moon, building the first reusable launch vehicle, building great observatories that reveal the universe and helping to build and operate space stations.

These ideas were nothing more than science fiction in the years before Marshall was formed. Today, these historic milestones provide a foundation for NASA’s journey to Mars and beyond.

On Jan. 14, 1960, President Dwight D. Eisenhower directed the transfer of the Army Ballistic Missile Agency’s Development Operations Division and its space-related missions to form NASA’s Marshall Center Space Flight Center. Marshall was activated July 1, 1960, with the transfer of buildings, land, space projects, property and personnel from the U.S. Army to Marshall. The early center was made up of 4,670 civil service employees, 1,840 acres of Redstone Arsenal property and facilities worth $100 million. Dr. Wernher von Braun became Marshall’s first director.

Eisenhower named the center in honor of General George C. Marshall, the Army chief of staff during World War II, secretary of state and winner of the 1953 Nobel Peace Prize for his world-renowned “Marshall Plan” that helped get Europe back on its feet after the devastating effects for World War II. Fittingly, Eisenhower wrote in the executive order forming the Marshall Center: “These facilities are destined to play a major role in man’s conquest of outer space and its utilization for peaceful purposes for the benefit of all mankind.”

Marshall has lived up to that destiny and continues to push the boundaries of space exploration by building large spacecraft for human exploration as well as telescopes and other science instruments that reveal the universe’s splendor and operating a space station that benefits both future explorers and people on Earth. Today, Marshall employees are key to conducting science on the International Space Station built by a global partnership of 15 countries. Aboard the station, over 80 countries have conducted more than 1,600 investigations and student experiments. Marshall team members are building the next great spaceship — the Space Launch System — that will take us on journeys to asteroids and Mars and transport science probes to distant worlds.

A Marshall fact sheet written in 1960 proclaims, “The center, under the direction of Dr. Wernher von Braun, will have charge of developing and launching NASA’s space vehicles and conducting related research. It is the only self-contained organization in the nation which is capable of conducting the development of a space vehicle from the conception of the idea, through the production of hardware, testing and launching operations.”

The fact sheet goes on to list the specific facilities used by Marshall in those early days. Many of those facilities, including test stands, have been updated and are being used today for everything from operating the space station to developing the next-generation of aerospace materials to building new spacecraft that will help the world explore deep space. The people of Marshall, past and present, have truly created a foundation for NASA’s current exploration efforts.

To learn more about Marshall’s history, visit the Marshall History website and Flickr gallery of historic images.

Longest SLS Engine Test Yet Heats Up Mississippi Sky

Marshall Association Awards Scholarships to Five Students

By Zac Cameron

The Marshall Association at NASA’s Marshall Space Flight Center awarded college scholarships to five children of association members during a June 24 luncheon.

Rayna Burkard, Mary Crumbley, Olivia Hammond, Kayleigh Keith and Brandon Hicks each received $1,000 for a combined total of $5,000 in scholarships.

The Marshall Association is a professional, employee service organization, which includes Marshall team members and retirees. The association provides informal networking and community-building opportunities for members. In addition to the annual scholarship competition, it sponsors a speaker program addressing topics of interest to Marshall team members. Marshall Association scholarship awards are primarily funded from membership dues and donations.

The scholarship ceremony featured speakers from the Alabama State Department of Education.

The association selected recipients based on grade-point averages, honor awards, extracurricular activities, test scores and an essay on what they want to be doing 10 years from now.

“This is an extremely bright group of young people,” said Jonathan Pettus, president of the Marshall Association. “We congratulate these students, and we are delighted to provide these scholarships to help them continue their education.”

Rayna Burkard is a graduate of Huntsville High School and plans to attend Auburn University. She is the daughter of Tamara Burkard, a Jacobs Technology Inc. employee. Rayna plans to pursue a degree in biomedical sciences on a pre-med track while participating in the Auburn Band.

Mary Crumbley is a graduate of Bob Jones High School and the daughter of Robert Crumbley of the Office of the Chief Engineer. She plans to attend the University of Alabama in Tuscaloosa, study biology and join the STEM Master of Business Administration Program.

Olivia Hammond is a graduate of Madison Academy and the daughter of John Hammond, a flight systems engineer. She plans to attend Auburn University where she will study pre-pharmacy and pre-med.

Kayleigh Keith graduated from Bob Jones High School and plans to attend the University of Alabama in Tuscaloosa. The daughter of Amy Keith of the Environmental Engineering & Occupational Health Office, Kayleigh plans to pursue a degree in nursing and enter the field of radiology.

Brandon Hicks, son of the Facilities Management Office’s Roslin Hicks, graduated from Sparkman High School in May 2014 and is currently pursuing a degree in nursing at the University of Alabama in Tuscaloosa.

Cameron, a NASA intern, is supporting the Office of Strategic Analysis & Communications this summer.

Marshall Center Hosts Small Business Supplier Conference

Fourth RS-25 Engine Test Featured On ‘This Week @NASA’

The fourth test of an RS-25 engine was featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

Engineers at NASA’s Stennis Space Center conducted a 650-second test of an RS-25 developmental engine as part of preparation for deep-space missions aboard NASA’s new Space Launch System rocket. The SLS core stage will be powered by four RS-25 engines, former space shuttle main engines operated at slightly higher power levels to provide the additional thrust needed. This was the fourth test in the series to investigate how the RS-25 stands up to the rigors and specific requirements needed to boost the massive SLS core stage. Three additional tests are scheduled in July and August before the initial series is completed.

View this and previous episodes at “This Week @NASA” or at https://www.youtube.com/user/NASAtelevision.