In This Week’s Star

- Second SLS Test Stand Begins Rise at Marshall

- Marshall Team Moves Closer to Building a 3-D Printed Rocket Engine

- Todd May Discusses Human Space Exploration With Local Chapter of the National Space Society

- Ringing in the New Year with Robots and Rockets

- Quadrantid Meteor Lights Up the North Georgia Sky

- Marshall Team Members Featured in ‘Women @NASA’ Videos

- This Week in NASA History: STS-72 Launches to Recover Japanese Research Spacecraft — Jan. 11, 1996

- Obituaries

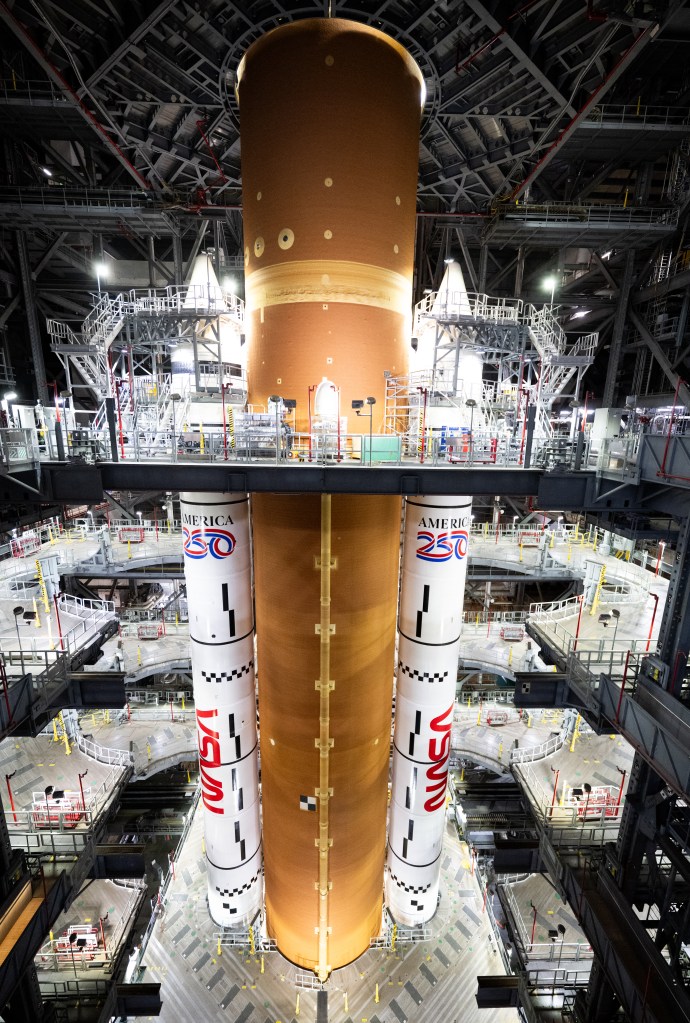

Second SLS Test Stand Begins Rise at Marshall

A crane moves the first steel tier to be bolted into place on Jan. 6, for welding of a second new structural test stand critical to development of the Space Launch System at NASA’s Marshall Space Flight Center. When completed this summer, the 85-foot-tall Test Stand 4697 will use hydraulic cylinders to subject the liquid oxygen tank and hardware of the massive SLS core stage to the same loads and stresses it will endure during a launch. The stand is rising in Marshall’s West Test Area, where work is also underway on the 215-foot-tall towers of Test Stand 4693, which will conduct similar structural tests on the SLS core stage’s liquid hydrogen tank. SLS, the most powerful rocket ever built, will carry astronauts in NASA’s Orion spacecraft on deep space missions, including the journey to Mars. (NASA/MSFC/Fred Deaton)

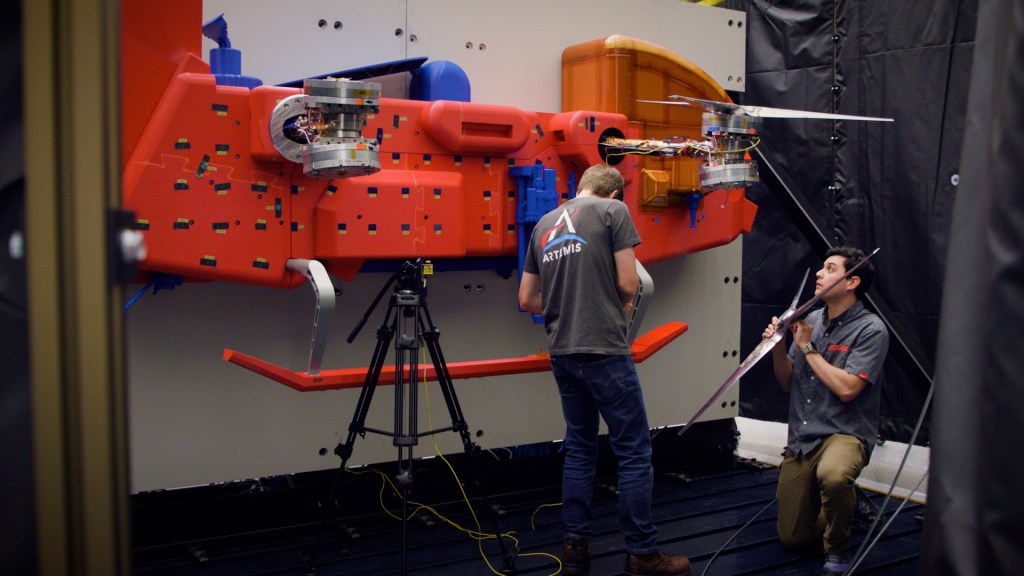

Marshall Team Moves Closer to Building a 3-D Printed Rocket Engine

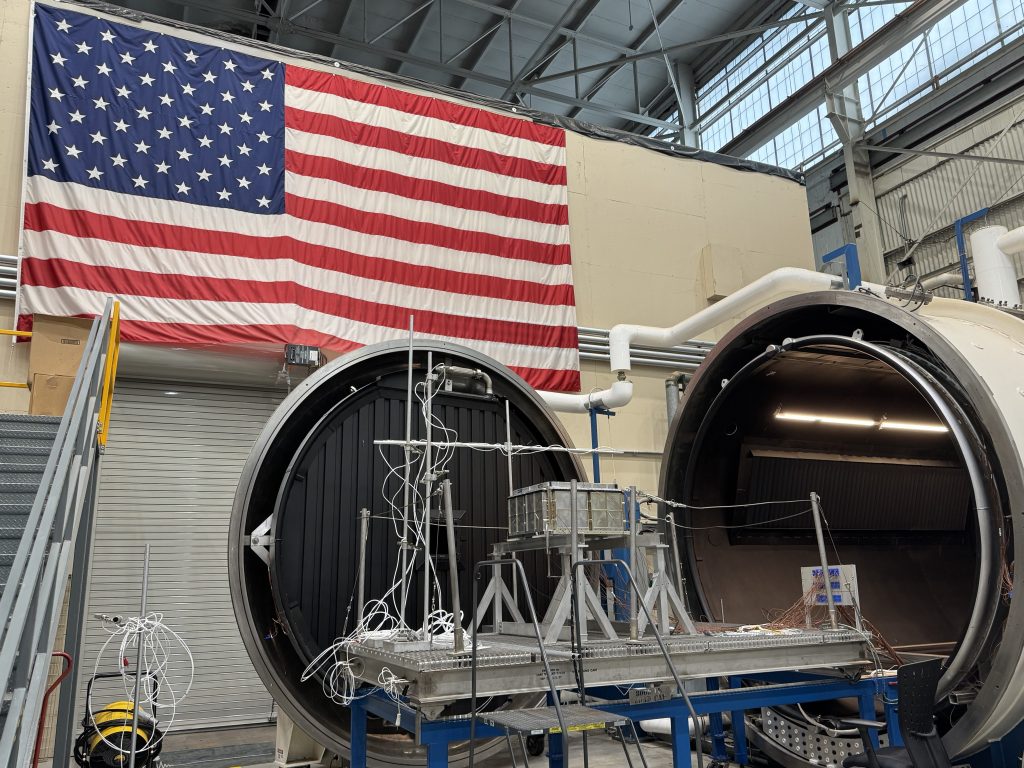

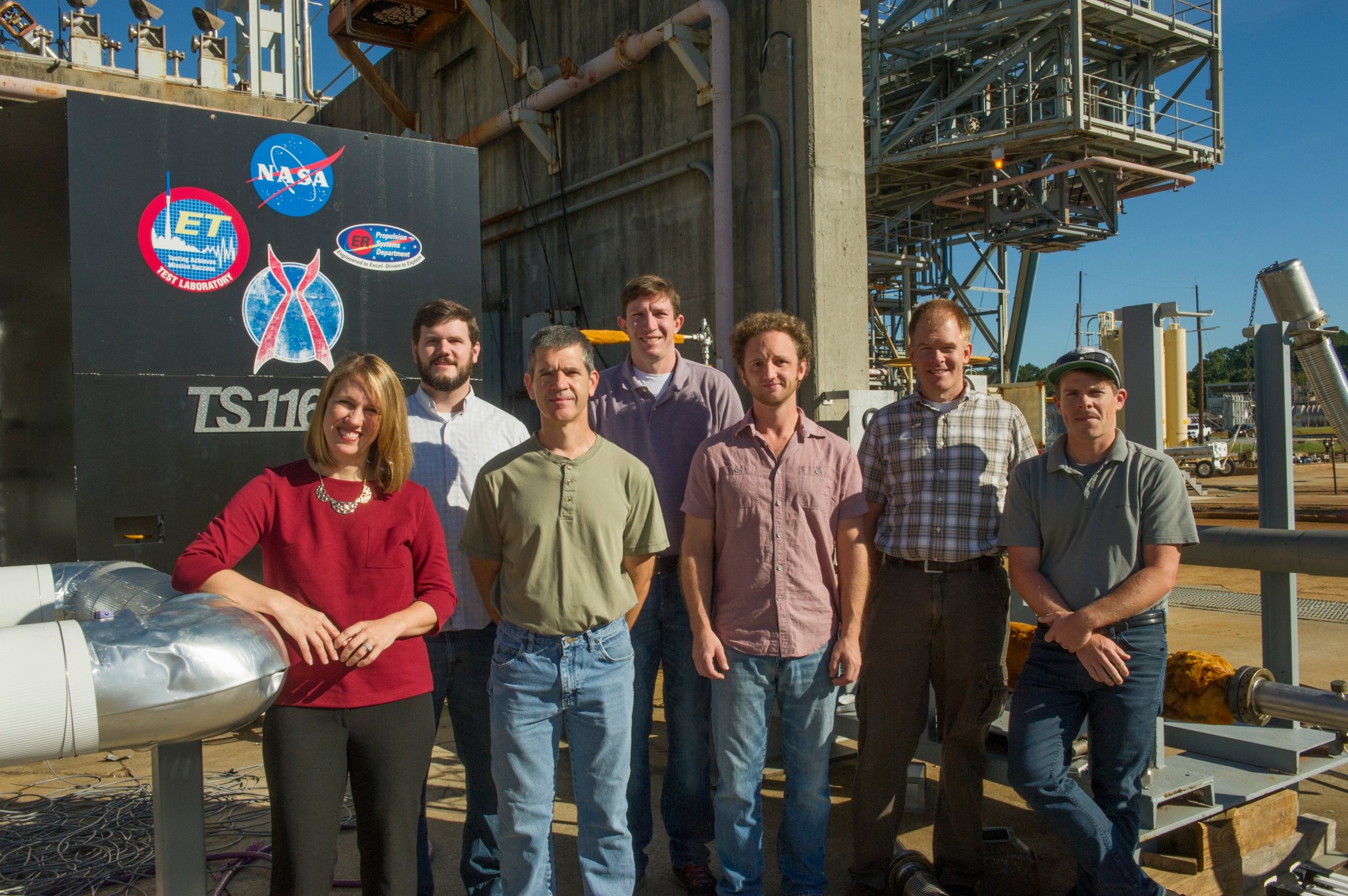

A NASA Marshall Space Flight Center team has moved a step closer to building a completely 3-D printed, high-performance rocket engine by manufacturing complex engine parts and test firing them together with cryogenic liquid hydrogen and oxygen to produce 20,000 pounds of thrust.

Additive manufacturing, or 3-D printing, is a key technology for enhancing space vehicle designs and manufacturing and enabling more affordable exploration missions. The technology has the potential to influence spacecraft built for leaving Earth, and spaceships and landers for visiting other destinations. Future plans include performing engine tests with liquid oxygen and methane — key propellants for Martian landers since methane and oxygen production might be possible on the Red Planet.

“We manufactured and then tested about 75 percent of the parts needed to build a 3-D printed rocket engine,” said Elizabeth Robertson, the Marshall project manager for the additively manufactured demonstrator engine. “By testing the turbopumps, injectors and valves together, we’ve shown that it would be possible to build a 3-D printed engine for multiple purposes such as landers, in-space propulsion or rocket engine upper stages.”

Over the last three years, the Marshall team has been working with various vendors to make 3-D printed parts, such as turbopumps and injectors, and test them individually. To test them together, they connected the parts so that they work the same as they do in a real engine. Only they are not packaged together in a configuration that looks like the typical engine you see on a test stand.

“In engineering lingo, this is called a breadboard engine,” explained Nick Case, the testing lead for the effort. “What matters is that the parts work the same way as they do in a conventional engine and perform under the extreme temperatures and pressures found inside a rocket engine. The turbopump got its ‘heartbeat’ racing at more than 90,000 revolutions per minute and the end result is the flame you see coming out of the thrust chamber to produce over 20,000 pounds of thrust, and an engine like this could produce enough power for an upper stage of a rocket or a Mars lander.”

Seven tests were performed, with the longest tests lasting 10 seconds. For the first time, a drone-mounted camera videotaped tests. During the tests, the 3-D printed demonstrator engine experienced all the extreme environments inside a flight rocket engine where fuel is burned at greater than 6,000 degrees Fahrenheit (3,315 degrees Celsius) to produce thrust. In addition to testing with methane, the team plans to add other key components to the demonstrator engine including a cooled combustion chamber and nozzle and a turbopump for liquid oxygen.

“These NASA tests drive down the costs and risks associated with using additive manufacturing, which is a relatively new process for making aerospace-quality parts,” said Robertson. “Vendors who had never worked with NASA learned how to make parts robust enough for rocket engines. What we’ve learned through this project can now be shared with American companies and our partners.”

Marshall engineers designed the fuel pump and its components and leveraged the expertise of five suppliers to build the parts using 3-D printing processes.

The 3-D printed turbopump, one of the more complex parts of the engine, had 45 percent fewer parts than similar pumps made with traditional welding and assembly techniques. The injector had over 200 fewer parts than traditionally manufactured injectors, and it incorporated features that have never been used before because they are only possible with additive manufacturing.

Todd May Discusses Human Space Exploration With Local Chapter of the National Space Society

Todd May, acting director of NASA’s Marshall Space Flight Center, discusses the next chapter of human exploration with the Huntsville Alabama L5 Society at the Huntsville-Madison County Public Library on Jan. 7. May updated HAL5 — a chapter of the National Space Society — on the status of NASA’s Space Launch System and discussed how and why SLS will open a new era of space exploration. SLS, now under development, is the most powerful rocket ever built, able to carry astronauts in NASA’s Orion spacecraft on deep space missions, including to an asteroid and ultimately to Mars. May was named Marshall’s acting center director in November 2015, shortly after being appointed as Marshall’s deputy director. Before the promotions, May had served as the SLS program manager since June 2008. During his time as program manager, May led SLS through a series of milestones, including engine tests and an in-depth critical design review. (NASA/MSFC/Emmett Given)

Ringing in the New Year with Robots and Rockets

By Christopher Blair

While school busses began shuffling kids back to class, dozens of students from Alabama, Tennessee and Mississippi were spotted in the Rocket City, eager and anxious to start tinkering away on a new science project.

They were participants in the annual FIRST Robotics kick-off event Jan. 9, hosted by NASA’s Marshall Space Flight Center and the U.S. Space & Rocket Center, held at the Davidson Center for Space Exploration.

The kickoff signified the beginning of the 2016 FIRST Robotics Competition season. FIRST – which stands for “For Inspiration and Recognition of Science and Technology” — is a national design challenge encouraging students to pursue careers in technology and engineering through robotic competition.

More than 200 students from schools across the Tennessee Valley and beyond attended the kick-off, including local teams such as the Mad Rockers of Bob Jones and James Clemens High Schools in Madison; Morgan County Mech Tech, of A.P. Brewer, Priceville, Danville and West Morgan High Schools; and Team G.R.E.A.T. from Grissom High School in Huntsville.

“It really is a most wonderful time of the year, as we greet these future scientists and engineers with a fun, real-world engineering project for the new year,” said Susan Currie of Marshall’s Academic Affairs Office. “From electronics, metal fabrication, engineering and more, we’re encouraging student interests in the STEM fields of science, technology, engineering and math.”

Ready to start the season, teams of students in grades 9-12 attended similar kick-off events all across the country. One of the exciting parts of each year’s kick-off event is the “big reveal” when the new year’s game and rules are announced.

Until that announcement this year, teams were left to guess what the new game would entail. Many kids took to social media to tweet, post and share their thoughts. “Is it a water challenge; I heard it was capture the flag,” was just some of the online chatter. To build anticipation and excitement, the FIRST Robotics staff produced a short video “hint,” which fueled much of the speculation.

Each year’s challenge includes some form of gameplay, making it a fun way for students to compete and learn at the same time. In years past, games have included variants of basketball, disc golf, stacking boxes and more. Because the game changes annually, teams must build new robots with different capabilities.

The new challenge for 2016 is called FIRST Stronghold, and has a medieval theme to the gameplay. Teams will use robots to storm their opponent’s castle by breaching defenses, launching foam boulders and attempting to capture the opposing tower.

Immediately following the challenge announcement, teams picked up their “Kit of Parts,” provided by FIRST and sponsors such as NASA. Students will use the kits to build their robots. Each kit is identical and consists of donated items worth tens of thousands of dollars. They are, however, missing one critical component – an instruction manual. This is not an accident, but a specific strategy to encourage student creativity and collaboration when designing their robots.

With the build season officially open for only the next six weeks, teams will work with adult mentors to build and test their robots. Once finished, they can compete in district and regional competitions in February and March, including two opportunities in Huntsville.

“Robots to Rocket City,” a demonstration event where teams can practice using their robot in a non-competitive environment, will be held at the Space & Rocket Center on Feb. 21. The second event, Alabama’s inaugural FIRST regional competition, the “FRC Rocket City Regional,” will be held at the Von Braun Center on March 23-26. Each district and regional competition across the nation gives teams a chance to qualify for a spot at the national competition, to be held in St. Louis on April 27-30.

Blair, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Quadrantid Meteor Lights Up the North Georgia Sky

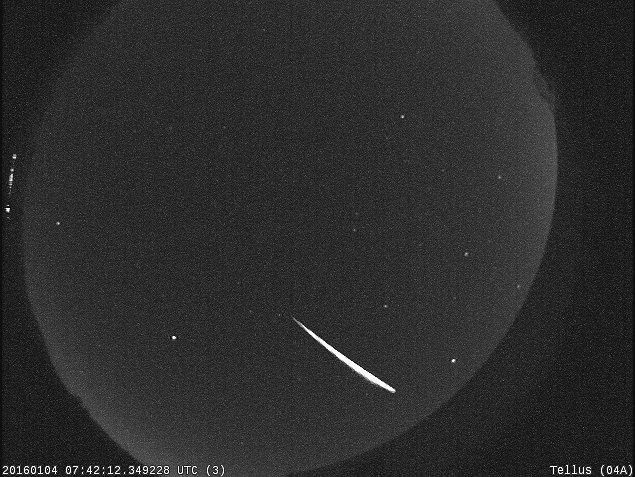

NASA’s All Sky cameras captured this image of a Quadrantid meteor Jan. 4. The meteor was moving at 93,000 miles per hour. This 1-inch-diameter member of the Quadrantid meteor shower left a brilliant streak in the north Georgia skies before burning up 44 miles above Earth’s surface. Located at NASA’s Marshall Space Flight Center, NASA’s Meteoroid Environment Office is responsible for meteoroid environments pertaining to spacecraft engineering and operations. The office leads NASA’s technical work on the meteoroid environment and coordinates the existing meteoroid expertise at NASA centers. (NASA)

Marshall Team Members Featured in ‘Women @NASA’ Videos

Three team members from NASA’s Marshall Space Flight Center were featured in video profiles on the Women@NASA Web page. The page includes videos and essays of women across the agency contributing to NASA’s mission.

Chosen were Rosalind Cylar, an attorney in Marshall’s Office of the Chief Counsel; Cindy Stemple, acting project manager for the SERVIR project; and Seunghee Lee, a program senior integration engineer in the Space Launch System Program Chief Safety Mission Assurance Office.

Cylar started working at Marshall in 2005, where she provides a variety of legal services designed to assure adequacy and propriety for activities and documentation. Born and raised in the Bronx, New York, she received a Bachelor of Arts from Duke University in Durham, North Carolina, and a Juris Doctorate from the Vanderbilt University School of Law in Nashville, Tennessee. To read Cylar’s official essay and bio, click here.

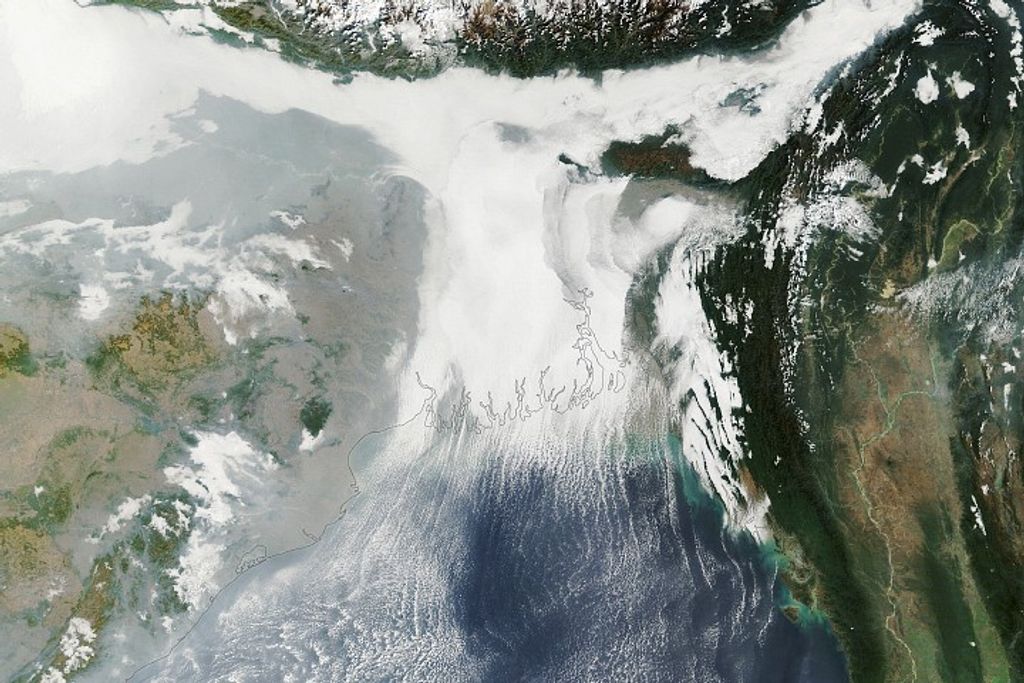

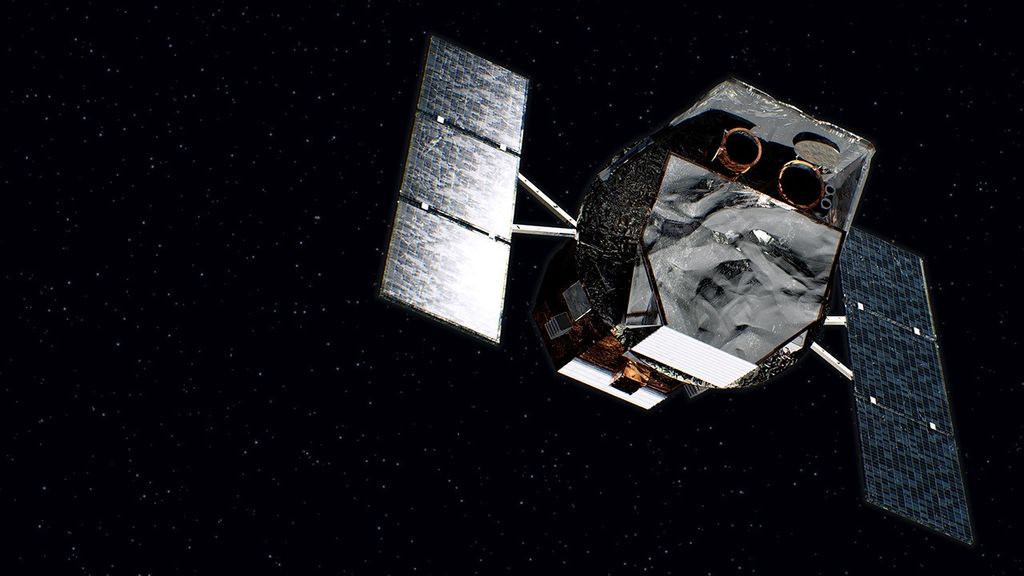

Stemple graduated cum laude in 1985 from Mississippi State University in Starkville and started her career at Marshall in 1989 as a software engineer. She designed and developed data systems for testing the Chandra X-ray Observatory, International Space Station Science facilities and Mighty Eagle, a robotic lander prototype. Currently, she is the acting project manager for the SERVIR project, a joint venture between NASA and the U.S. Agency for International Development in Washington. SERVIR provides satellite-based Earth monitoring to improve environmental decision-making among developing nations around the world. To read Stemple’s official essay and bio, click here.

Lee was born in South Korea and immigrated to America during her junior year in high school. She earned a Bachelor of Science in mechanical engineering from Southern Illinois University in Carbondale. In 1987, Lee started her NASA career as an Orbiter Hypergolic Systems engineer at NASA’s Kennedy Space Center. In 1996, she moved to the Armstrong Flight Research Center, where she worked as the project manager for the planning and implementation of the X-34 Test Flight Program. Currently, Lee is a program senior integration engineer in the SLS Chief Safety Mission Assurance Office. Also serving as Marshall’s range safety representative, she supports flight safety system development and provides range safety guidance to small rocket or unmanned aerial system flight programs at Marshall and at NASA’s Michoud Assembly Facility. To read Lee’s official essay and bio, click here.

This Week in NASA History: STS-72 Launches to Recover Japanese Research Spacecraft — Jan. 11, 1996

This week in 1996, STS-72, space shuttle Endeavor’s 10th mission, launched from NASA’s Kennedy Space Center. One of 34 night launches, STS-72’s launch window was planned to support the mission’s primary objective, the recovery of Space Flyer Unit, a Japanese microgravity research spacecraft. The NASA History Program documents and preserves NASA’s remarkable history through a variety of products — photos, press kits, press releases, mission transcripts and administrators’ speeches. For more pictures like this one and to connect to NASA’s history, visit the History Program’s Web page. (NASA)

Obituaries

Donald O. Worrell, 92, of Huntsville, died Dec. 16. He retired from the Marshall Center in 1981 as a public affairs specialist. He is survived by his wife, Noako Worrell.

Paul O. Hurst, 82, of Huntsville, died Dec. 18. He retired from the Marshall Center in 1995 as an aerospace engineer. He is survived by his wife, Carol Bostick Hurst.

William B. Chubb, 84, of Harvest, Alabama, died Dec. 22. He retired from the Marshall Center in 1994 as the director of the Systems Analysis and Integration Lab. He is survived by his wife, Carol Chubb.

Dewey L. Lusk, 93, of Huntsville, died Dec. 23. He retired from the Marshall Center in 1999 as an aerospace engineer.

Ellis T. Baggs, 92, of Decatur, Alabama, died Dec. 24. He retired from the Marshall Center in 1995 as an electrical engineer. He is survived by his wife, Jeflyn Landers Baggs.

T. Leroy Osborne, 87, of Huntsville, died Dec. 29. He retired from the Marshall Center in 1988 as an executive assistant. He is survived by his wife, Deloris Wells Osborne.

Ramon J. Samaniego, 89, of Huntsville, died Dec. 30. He retired from the Marshall Center in 1994 as an architect. He is survived by his wife, Mary F. Samaniego.

Lloyd B. Marks, 91, of Huntsville, died Jan. 2. He retired from the Marshall Center in 1979 as an aerospace engineer.

Clyde M. Hightower, 85, of Huntsville, died Jan. 4. He retired from the Marshall Center in 1989 as an employee relations specialist.