In This Week’s Star

- NASA’s Juno Successfully Completes Jupiter Flyby

- NASA’s OSIRIS-REx Set to Launch Sept. 8

- Taking a Test Drive: SLS Core Stage Transporters Rolling Down Historic Saturn Road at Michoud

- NASA Astronaut Jeff Williams Sets American Record For Most Time in Space

- Faces of SLS: Jonathan Looser

- Marshall Spinoffs Help You Reel In the Big One

- This Week in NASA History: Marshall Ships Skylab Mockup to California — Sept. 1, 1967

- SLS Fuel Tank’s Construction Featured on ‘This Week @NASA’

- Obituaries

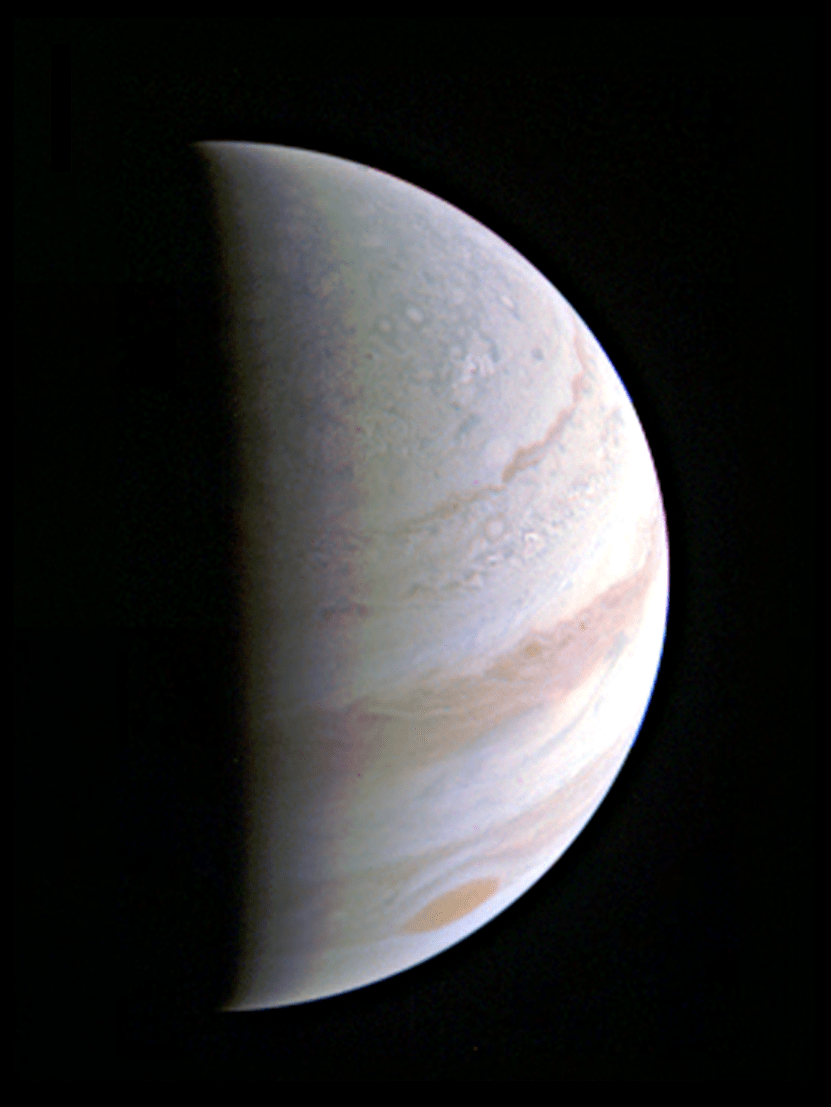

NASA’s Juno Successfully Completes Jupiter Flyby

NASA’s Juno mission successfully executed its first of 36 orbital flybys of Jupiter Aug. 27. The time of closest approach with the gas-giant world was 8:44 a.m. when Juno passed about 2,600 miles (4,200 kilometers) above Jupiter’s swirling clouds. At the time, Juno was traveling at 130,000 mph (208,000 kilometers per hour) with respect to the planet. This flyby was the closest Juno will get to Jupiter during its prime mission.

“Early post-flyby telemetry indicates that everything worked as planned and Juno is firing on all cylinders,” said Rick Nybakken, Juno project manager at NASA’s Jet Propulsion Laboratory.

There are 35 more close flybys of Jupiter planned during Juno’s mission (scheduled to end in February 2018). The Aug. 27 flyby was the first time Juno had its entire suite of science instruments activated and looking at the giant planet as the spacecraft zoomed past.

“We are getting some intriguing early data returns as we speak,” said Scott Bolton, principal investigator of Juno from the Southwest Research Institute in San Antonio. “It will take days for all the science data collected during the flyby to be downlinked and even more to begin to comprehend what Juno and Jupiter are trying to tell us.”

While results from the spacecraft’s suite of instruments will be released down the road, a handful of images from Juno’s visible light imager — JunoCam — are expected to be released the next couple of weeks. Those images will include the highest-resolution views of the Jovian atmosphere and the first glimpse of Jupiter’s north and south poles.

“We are in an orbit nobody has ever been in before, and these images give us a whole new perspective on this gas-giant world,” said Bolton.

The Juno spacecraft launched on Aug. 5, 2011, from Cape Canaveral and arrived at Jupiter on July 4, 2016. JPL manages the Juno mission for the principal investigator, Scott Bolton, of Southwest Research Institute. California Institute of Technology in Pasadena, California, manages JPL for NASA. Juno is part of NASA’s New Frontiers Program, which is managed at NASA’s Marshall Space Flight Center for NASA’s Science Mission Directorate. Lockheed Martin Space Systems, Denver, built the spacecraft.

For more information on NASA’s Juno mission, click here.

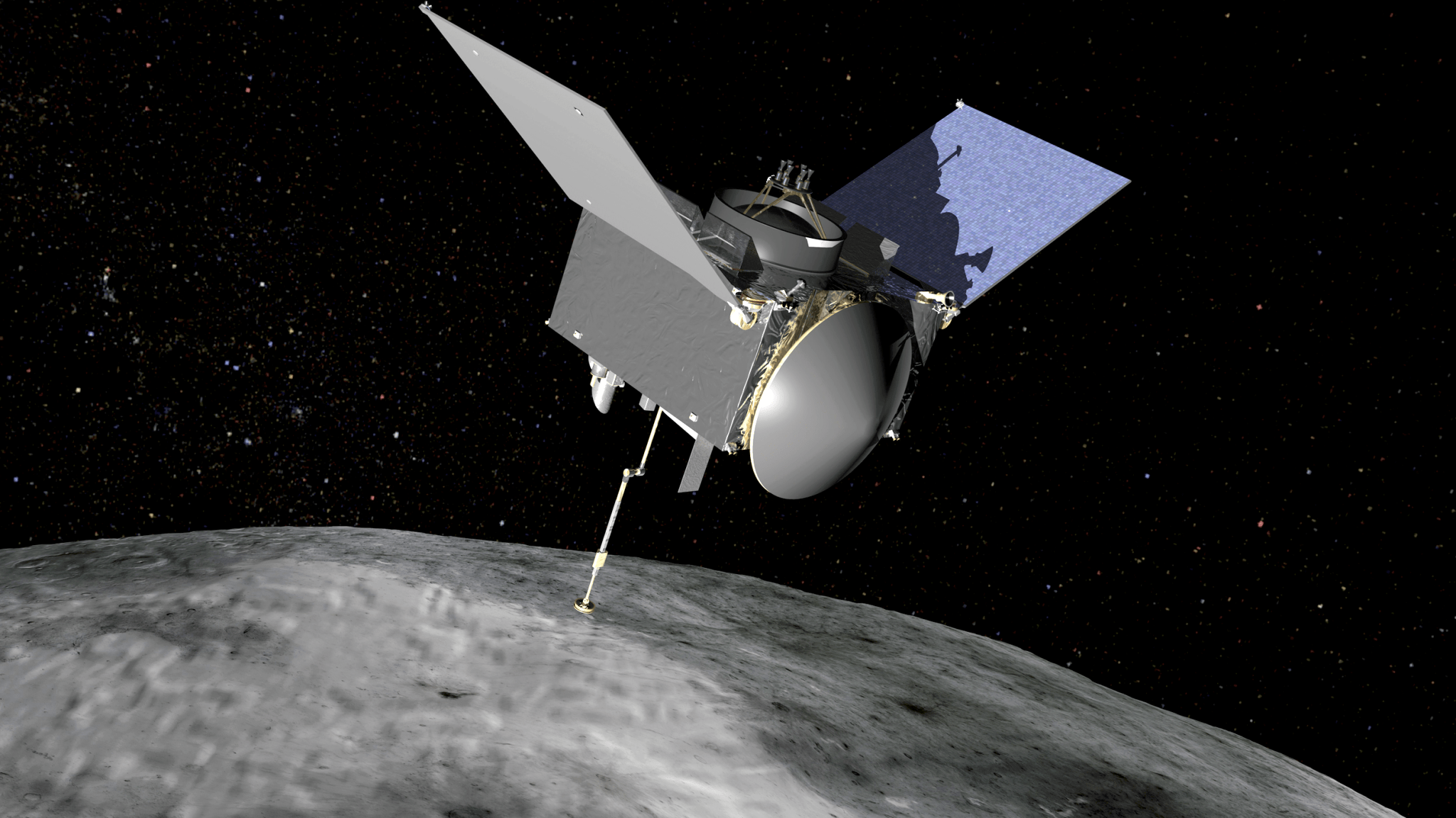

NASA’s OSIRIS-REx Set to Launch Sept. 8

The Origins, Spectral Interpretation, Resource Identification, Security-Regolith Explorer, OSIRIS-REx, spacecraft is set to launch from Kennedy Space Center Sept. 8 at 6:05 p.m. OSIRIS-REx will travel to the near-Earth asteroid Bennu and bring a sample back to Earth for intensive study. The mission will help scientists investigate how planets formed and how life began, and will improve our understanding of asteroids that could impact Earth.

“This is a really exciting mission,” said Allen S. Bacskay, manager of the Planetary Missions Program Office at NASA’s Marshall Space Flight Center. “The things we learn from Bennu will help us understand our universe’s origins, and help us prepare for further missions to deep space.”

OSIRIS-REx is the third mission in NASA’s New Frontiers Program, which is managed by Marshall under the Planetary Missions Program Office for the agency’s Science Mission Directorate. Goddard Space Flight Center provides overall mission management, systems engineering, and safety and mission assurance for OSIRIS-REx. Lockheed Martin Space Systems built the spacecraft and Dante Lauretta of the University of Arizona, Tucson, is the principal investigator.

“This in an incredible mission and I feel very fortunate to be part of it,” said Scott Bellamy, mission manager for OSIRIS-REx in Marshall’s Planetary Missions Program Office. “This is an amazing team to work with, and so many talented people have worked really hard to make this mission happen. We’re all looking forward to seeing what Bennu is going to tell us.”

The 4,650-pound (2,110-kilogram) fully fueled spacecraft will launch aboard an Atlas V 411 rocket during a 34-day launch window that begins Sept. 8, and will reach its asteroid target in 2018. After a careful survey of Bennu to characterize the asteroid and locate the most promising sample sites, OSIRIS-REx will collect between 2 and 70 ounces (about 60 to 2,000 grams) of surface material with its robotic arm and return the sample to Earth via a detachable capsule in 2023.

OSIRIS-REx contains five instruments to explore Bennu, and each will contribute a specific element to the mission. The suite of instruments will be used for remote sensing and scanning of the surface of the asteroid.

Asteroids are the remnants of the building blocks that formed the planets and enabled life. Scientists believe that by studying Bennu and its natural resources such as organics and metals, they will have a better understanding of the early solar system, as well as the hazards and resources of near-Earth space.

For more information on OSIRIS-REx, click here.

Taking a Test Drive: SLS Core Stage Transporters Rolling Down Historic Saturn Road at Michoud

Engineers at NASA’s Michoud Assembly Facility are testing the agency’s four new transporters for the Space Launch System’s core stage. The transporters will carry test and flight articles on and off the Pegasus barge and down roadways at Michoud, NASA’s Marshall Space Flight Center and the Kennedy Space Center. Two structures designed and developed at Marshall — the multiple purpose carrier and hardware interface system — serve as the interface between the transporters and the rocket’s hardware. The hardware interface system directly connects to the payloads and provides a cradle for the hardware to move in as the transporters turn corners, ascend inclines and navigate roadways. Engineers ensure the critical components are not bent or twisted during transit by closely monitoring the hardware’s movement with sensors. Developed and built by Wheelift in Waterloo, Iowa, each self-propelled modular transporter is over 33 feet long, 12 feet wide and can carry 75 tons — or the equivalent of 14 fully grown elephants. The four roadway transporters work together wirelessly to move the components with extreme precision and care and are operated by a driver walking alongside with a joystick and control unit called a “belly pack.” The SLS test articles will travel from Michoud to Marshall, and flight articles will travel to NASA’s Stennis Space Center. The first flight-ready core stage is expected to arrive at Kennedy in 2018. For more about NASA’s Space Launch System, click here. (NASA/MAF/Steven Seipel)

NASA Astronaut Jeff Williams Sets American Record For Most Time in Space

NASA astronaut Jeff Williams poses on the International Space Station with patches for the missions he has participated in on his way to breaking a new record for most time spent in space by an American astronaut. On Aug. 24, Williams surpassed 520 days living in space, breaking the previous record set by Scott Kelly during his Year in Space mission that ended in March 2016. By the time Williams returns home on Sept. 6, he’ll have a total record of 534 days. He won’t hold on to the position for long, however, as fellow NASA astronaut Peggy Whitson is scheduled to surpass him during her next mission, which will launch in November. (NASA)

Faces of SLS: Jonathan Looser

An interest in math and science led this NASA engineer to an exciting career of working on the powerful propulsion for NASA’s deep-space rocket, the Space Launch System. Meet Jonathan Looser, SLS core stage propulsion lead at NASA’s Marshall Space Flight Center.

It’s extremely rewarding to know that the product of your work plays such a critical part on the journey to putting humans on Mars. As SLS core stage propulsion lead at Marshall, I oversee the design, construction, test and performance of the SLS core stage propulsion systems. It’s a once-in-a-lifetime opportunity to work on a project of this magnitude from conception to flight. What I love most about my job is the amazing team I get to work with each and every day.

I think growing up in the “Rocket City” of Huntsville gave me a deep appreciation for the space program and the work happening in pursuit of NASA’s missions. My original path as a student at the University of Alabama in Huntsville was to get a degree in political science and go to law school. I took one political science class and decided it wasn’t for me. I had always enjoyed and done well in math and science classes, so I decided to give engineering a try. I’m glad I did.

My experience at NASA started while I was still in college. During my junior year, I took part in a cooperative education program supporting Marshall’s Space Shuttle Program Office. One of my early mentors was my manager, Alex McCool. His passion for the work, and care for the people around him, left a lasting impression on me that I hope I carry on to the team that I now lead.

It’s important for me to see SLS fly, and will be a testament to years of hard work by people across the nation to build this rocket. It’s a critical next step in the future of America’s space program.

Outside of work, I enjoy spending time with my family — especially watching and coaching my kids in sports. I want them to know that STEM — science, technology, engineering and math — education opens career paths that are almost limitless. The heart of STEM is problem solving, and problem solving is so important in life — no matter what career path you choose.

Meet more people building the world’s most powerful rocket here.

Marshall Spinoffs Help You Reel In the Big One

By Will Bryan

It’s no secret that fishermen sometimes exaggerate the size of the fish they caught or the battle it took to get the “thrashing monster” in the boat. What are not exaggerations are two tackle box technologies that owe their origins to NASA’s Marshall Space Flight Center. FishBytes, a forecasting tool used to tell you where your favorite aquatic bounty is likely hanging out, and the high-strength aluminum alloy MSFC-398, used to make pistons for Evinrude’s E-TEC outboard motors, may not guarantee success on the water, but they could help you get a new fishing story.

Whether you are an experienced fisherman or a new member of the rod-and-reel club, if you can’t cast your line where the fish are, your odds of catching anything decreases dramatically. Luckily there’s an app for that — sort of. Its name is FishBytes.

FishBytes was created in 2006 when Baron Services Inc. of Huntsville approached Marshall and Marshall partner, WorldWinds Inc. of Slidell, Louisiana, to create a way to predict favorable conditions for various fish populations.

Now available through SiriusXM Radio’s Marine package, the tool uses data collected by Marshall’s Short-term Prediction Research and Transition Center, SPoRT, from the Earth Observing System — a fleet of satellites that help scientists understand climate change on a global, long-term scale while making weather and oceanic observations — and fish species’ environmental preferences to predict where the fish are, accurate to within a 2 kilometer range of the actual location. The service also provides weather information to fishermen.

The keys to the system are the chlorophyll and temperature boundary predictions. Chlorophyll indicates the presence of phytoplankton, which is food for small fish, which in turn attract the larger fish that anglers search for. A proprietary algorithm predicts where these boundaries are and, thus, where the fish are most likely congregating.

Knowing where the fish are is only half of the battle, though. To reel in the catch of a lifetime, you have to get where the underwater master of the sea is. In short, you need a boat. In the early 2000s, Marshall engineer Jonathan Lee and PoShou Chen, a scientist with the Alabama-based Morgan Research Corp., developed a high-strength aluminum alloy dubbed MSFC-398. Developed through the Partnership for Next Generation Vehicles — a cooperative research program between the U.S. government and automobile corporations — the alloy was designed in an effort to increase automotive fuel efficiency.

The award-winning alloy is strong and reliable, even at high temperatures, and can be manufactured in high volumes at low cost.

A meeting between Canadian-based Bombardier Recreational Products Inc. and NASA led to the determination that the alloy could be used in the company’s high-performance outboard engine pistons. Just months after the first meeting, prototype production started in 2001 at the company’s Boats and Outboard Engines Division in Sturtevant, Wisconsin. Less than four years later, the alloy was on the commercial market as a key piston component in Bombardier’s new mid-power outboard motor.

The Evinrude E-TEC engines that use the pistons greatly benefit from the Marshall spinoff by being not only significantly more durable at high temperatures, but also cleaner, more efficient and quieter. Evinrude is a subsidiary of Bombardier.

When you’re out there on the boat, few things are as exciting as fighting a mighty fish, trying to both outlast and outsmart the beast. Helping you find and reach the right spot to reel in the big one are two technologies that owe their origins to the workforce and teams at Marshall.

If you believe a technology you’ve been working on has potential to reel in the next big one, submit a New Technology Report.

As Terry Taylor, manager of Marshall’s Technology Transfer Office explains, “Every year the agency develops thousands of technologies to improve the space program, and makes the them available to industry. These technologies generate revenue, create jobs, save lives and show a clear return on investment for the nation’s space program.”

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

This Week in NASA History: Marshall Ships Skylab Mockup to California — Sept. 1, 1967

This week in 1967, a mockup of the Skylab Orbital Workshop was shipped from Marshall Space Flight Center to McDonnell Douglas in Huntington, California, for design modifications. Skylab — America’s first space station — began as the Apollo Applications Program with an objective to develop science-based human space missions using hardware originally developed for the effort to land astronauts on the moon. Launched on May 14, 1973, Skylab orbited Earth from 1973 to 1979. The 169,950-pound space station included a workshop, solar observatory, docking adapter and systems to allow three crews to spend up to 84 days in space. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the History Program’s webpage. (NASA)

SLS Fuel Tank’s Construction Featured on ‘This Week @NASA’

Construction of one of the Space Launch System’s massive fuel tanks is featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

Final welding was recently completed on a liquid hydrogen tank test article for SLS at NASA’s Michoud Assembly Facility. The tank was moved from Michoud’s Vertical Assembly Center and will be outfitted with sensors to record important data during future structural loads testing in the new, twin-tower test stand currently under construction at the NASA’s Marshall Space Flight Center. Those tests are designed to ensure the tank can withstand the incredible stresses of a launch. When completed, SLS will have the power and payload capacity needed to carry crew and cargo on exploration missions to deep space, including Mars. Marshall manages SLS and Michoud for the agency.

View this and previous episodes at “This Week @NASA” or at https://www.youtube.com/user/NASAtelevision.

Obituaries

Wayne T. Harmon, 65, of Huntsville, died Aug. 27. He retired from the Marshall Center in 2011 as a contract specialist. He is survived by his wife, Lynn Marie Harmon.