In This Week’s Star

- NASA Marshall Missions Glimpse First Light from a Gravitational Wave Source

- First Four Space Launch System Flight Engines Ready to Rumble

- NASA Develops and Tests New Housing for In-Orbit Science Payloads

- Astronauts Peggy Whitson and Jack Fischer Visit Payload Operations Integration Center for Mission Debrief

- Cargo Craft Launches for Journey to International Space Station

- Essential to the Mission: Leonardo Barreda

- Mother’s Battle with Cancer Leads Marshall’s Dwight Pope to a Life of Advocacy

- Employee Registration Deadline Oct. 20 for Annual Wernher von Braun Memorial Symposium

- Michoud’s First On-site Gas Station Opens

- This Week in NASA History: US Microgravity Laboratory-2 Launches – Oct. 20, 1995

- Obituaries

NASA Marshall Missions Glimpse First Light from a Gravitational Wave Source

For the first time, NASA scientists — including a team of NASA Marshall Space Flight Center astrophysicists — have detected light tied to a gravitational-wave event, thanks to two merging neutron stars in the galaxy NGC 4993, located about 130 million light-years from Earth in the constellation Hydra. The first sign of the Aug. 17 neutron star merger was a short burst of gamma rays seen by the Marshall-managed Gamma-ray Burst Monitor instrument, GBM, on NASA’s Fermi Gamma-ray Space Telescope. Shortly after, Laser Interferometer Gravitational-wave Observatory scientists reported detecting gravitational waves that arrived 1.7 seconds before the GBM burst. Nine days later, scientists used NASA’s Chandra X-ray Observatory to study the X-ray afterglow emitted by the jet directed toward Earth after it had spread into our line of sight. Marshall manages the Chandra program for the NASA’s Science Mission Directorate in Washington. This animation captures phenomena observed over the course of nine days following the merger. They include gravitational waves (pale arcs), a near-light-speed jet that produced gamma rays (magenta), expanding debris from a kilonova that produced ultraviolet (violet), optical and infrared (blue-white to red) emission, and, once the jet directed toward us expanded into our view from Earth, X-rays (blue). Read more here. (NASA/Goddard Space Flight Center/CI Lab)

First Four Space Launch System Flight Engines Ready to Rumble

By Kaitlin Chappell

Flight preparations for the four engines that will power NASA’s Space Launch System on its first integrated flight with NASA’s Orion spacecraft are complete and the engines are assembled and ready to be joined to the deep-space rocket’s core stage. All five structures that form the massive core stage for the rocket have been built including the engine section where the RS-25 engines will be attached.

“NASA’s priority is to deliver hardware for the first flight,” said John Honeycutt, SLS program manager at NASA’s Marshall Space Flight Center. “This year, the SLS team has constructed major parts of the rocket, such as the in-space stage, which is already at NASA’s Kennedy Space Center, the four RS-25 engines, core stage structures and solid rocket booster segments.”

The backbone of the massive SLS rocket — the largest core stage ever built — will be powered by four RS-25 engines. After powering 135 flights of NASA’s Space Shuttle Program, the agency’s RS-25 fleet is being upgraded, tested and prepared for integration into SLS. The four engines scheduled to power the rocket’s first integrated flight with Orion, Exploration Mission-1, supported a total of 21 shuttle missions.

In total, NASA’s 16 flight-proven RS-25 engines and two development engines are being used as “workhorse” engines for testing. These engines have been used to test new controllers — the brains of the engine — which have now been installed on the flight engines. The flight engines will be attached to the core stage to prepare for green run testing — the final test for the flight engines and the core stage before the first mission.

“NASA has transformed these phenomenal engines that served so well in the past for a new bold mission — the first integrated flight of SLS and Orion,” said Steve Wofford, the SLS liquid engines manager at Marshall. “For engines needed beyond the first four flights, we are working with our industry partner Aerojet Rocketdyne to streamline manufacturing and make future engines more affordable.”

NASA is investing in new RS-25 engines for future launches built with modern manufacturing techniques. NASA’s prime contractor, Aerojet Rocketdyne, of Sacramento, California, has restarted RS-25 production and the agency has ordered six new RS-25 engines built to be expendable and more affordable to produce for future deep-space exploration missions.

In addition to progress made with the rocket’s RS-25 engine, major welding is complete on the liquid hydrogen tank for SLS — the last of five parts to be built for the rocket’s core stage. When it is assembled, the core stage will stand taller than a 20-story building and hold more than 700,000 gallons of propellant. The core stage is made up of the liquid hydrogen and liquid oxygen tanks, intertank, forward skirt and the engine section that will house the rocket’s RS-25 engines.

“To make these massive propellant tanks, NASA and our industry partner Boeing have used the largest robotic rocket welding tool to build the thickest pieces ever welded with self-reacting friction stir welding,” said Steve Doering, SLS stages manager at Marshall. “Now, we are moving from manufacturing major structures for the core stage to outfitting them to do their jobs and make the rocket fly.”

The liquid oxygen flight tank recently completed the first hydrostatic test for an SLS tank. The weld strength was tested by filling the tank with 200,000 gallons of water and subjecting it to pressures and forces similar to those it will experience during flight. The liquid hydrogen tank will soon undergo proof testing using gaseous nitrogen. The core stage pathfinder recently arrived at NASA’s Michoud Assembly Facility, and will be used to help develop and verify handling and transportation procedures before these processes are used on the valuable flight hardware.

“This rocket is happening now,” said Honeycutt. “The Space Launch System team has made great progress and has an exciting year ahead as NASA conducts crucial structural tests at Marshall, assembles the core stage and the four RS-25 engines at Michoud and delivers more hardware to the launch pad at Kennedy.”

Chappell, an ASRC Federal/Analytical Services employee supports the Office of Strategic Analysis & Communications.

NASA Develops and Tests New Housing for In-Orbit Science Payloads

By Amanda Adams

Imagine cramming 20 years’ worth of science experiments — each requiring resources such as water, electricity and data connections — into a few closets in your home. For the crew members aboard the International Space Station, this is a reality. Thanks to an increase in investigations coming in through the National Lab and more demand for exploration technology development payloads, the space station is going to have to make room for a whole new wardrobe.

“To solve this problem, engineers at NASA’s Marshall Space Flight Center are developing a new and simplified version of the racks that support these experiments that will add the needed space and resources to accommodate the growing need for science payloads,” said Sean Thompson, Payload Facilities team lead at Marshall.

Conducting science experiments in orbit provides the advantage of conducting the experiment with minimal interference from the force of gravity. As the demand for science payloads has grown, projections show that by the end of 2018 the eight existing racks will be at capacity.

“We’re excited about the opportunities these additional racks will bring by expanding our capacity for science payloads in orbit,” said Bobby Watkins, manager of the Human Exploration Development and Operations Office at Marshall. “By simplifying the EXPRESS rack and using the standard connectors, it will be easier for payload developers to design the experiments, opening the door to do more research in areas such as medicine, physical science, and Earth science.”

Science payloads are currently housed on the space station in eight shelving units called EXpedite the PRocessing of Experiments to Space Station Racks, or EXPRESS Racks. These high-tech units are outfitted with everything the astronauts need to maintain experiments in space, including water, electricity, cooling systems and data connections. The existing racks were transported to the space station over the course of several years, starting in 2001 with the most recent in 2011.

The experiments housed in these racks are managed and monitored 24/7 by the Payload Operations Integration Center at Marshall and can be controlled either from the ground or by the station crew. Each EXPRESS Rack — roughly the size of a refrigerator — is equipped with eight lockers and two drawers to house payloads. While the racks themselves remain on the station, the experiments are exchanged in and out of the racks as needed, depending on the experiment’s time requirements.

The new racks, developed at Marshall and built by Boeing in Huntsville, are called Basic Express Racks. These racks have been simplified to include only the most commonly required resources and feature more common connectors such as a standard ethernet cable. The first two Basic Express Racks are scheduled to make their journey to the space station in late 2018 aboard HTV7, a Japanese launch vehicle.

Prior to their launch, the Basic Express Racks will undergo a series of tests at Marshall including end-to-end testing where they will be connected via network to the Huntsville Operations Support Center to simulate the connection to the Payload Operations and Integration Center where the experiments are monitored while in orbit. After testing is complete, the racks will be packed with cargo and then travel to Tanegashima, Japan, for installation into the HTV7 launch vehicle.

For more information on Space Station Research Experiments click here or to learn more about EXPRESS racks, click here.

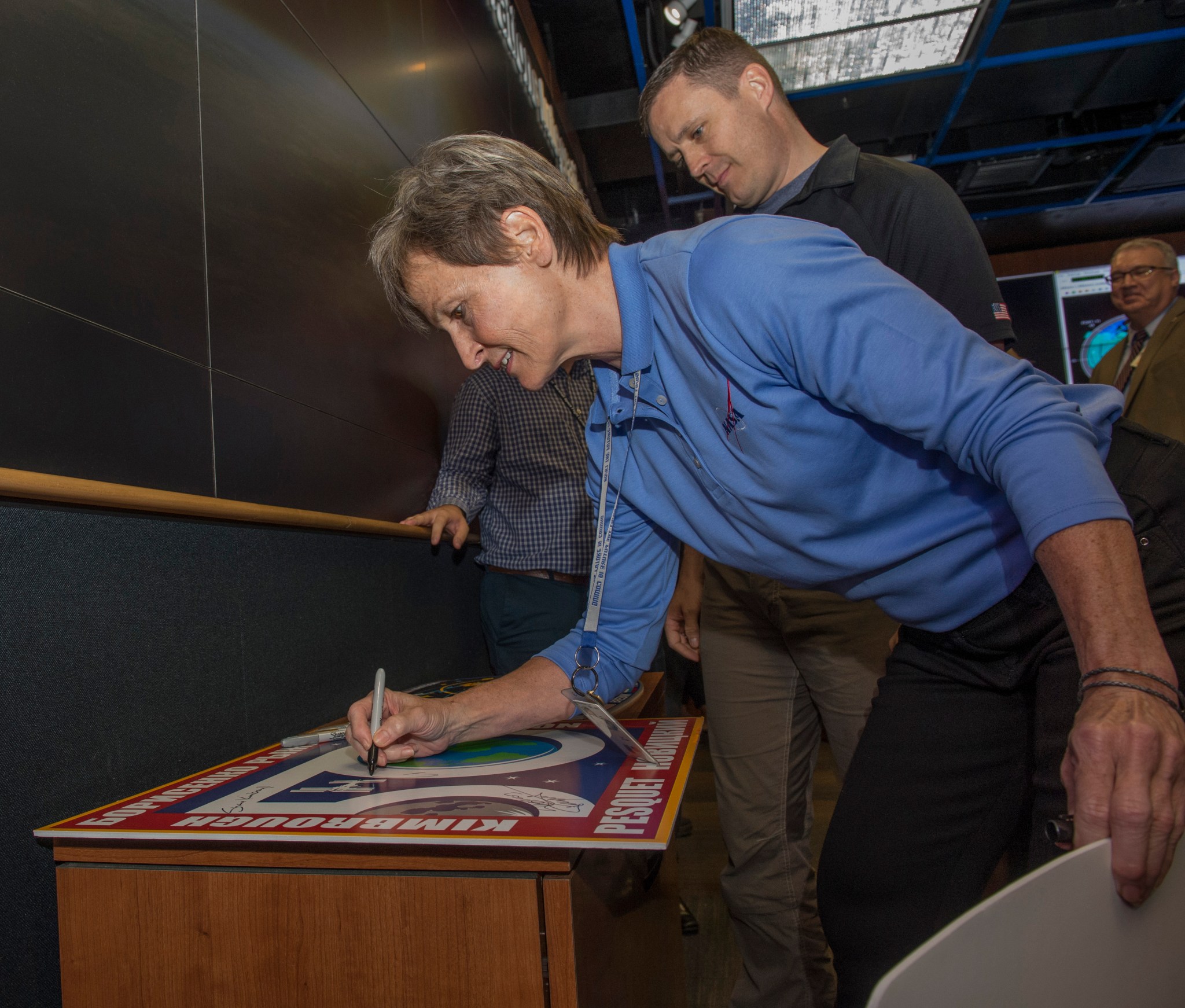

Astronauts Peggy Whitson and Jack Fischer Visit Payload Operations Integration Center for Mission Debrief

NASA astronauts Peggy Whitson, foreground, and Jack Fischer prepare to autograph the International Space Station Expedition 52 mission plaque before it is hung in the Payload Operations Integration Center control room. Whitson and Fischer, crew members on the Expedition 52 mission, visited NASA’s Marshall Space Flight Center Oct. 12 for a debrief meeting with the Marshall-based payload operations team that guides and supports science on the orbiting laboratory. (NASA/MSFC/Emmett Given)

NASA astronauts Peggy Whitson, left, and Jack Fischer speak with their former crew members on the International Space Station while visiting the Payload Operations Integration Center at NASA’s Marshall Space Flight Center Oct. 12. Whitson and Fischer returned to Earth from the station on Sept. 2. During her latest mission, Whitson performed four spacewalks, bringing her career total to 10. With a total of 665 days in space, Whitson holds the U.S. record and places eighth on the all-time space endurance list. Fischer, who launched to the space station in April, completed 136 days in space, during which he conducted the first and second spacewalks of his career. (NASA/MSFC/Emmett Given)

Cargo Craft Launches for Journey to International Space Station

The unpiloted Russian ISS Progress 68 cargo craft launched to the International Space Station Oct. 14 from the Baikonur Cosmodrome in Kazakhstan. The Progress carried almost 3 tons of food, fuel and supplies for the Expedition 53 crew on the station. The Progress 68 cargo ship docked at 6:04 a.m. CDT to the Pirs Docking Compartment of the space station. For more information about the current crew and the International Space Station, visit: https://www.nasa.gov/station. (NASA)

Essential to the Mission: Leonardo Barreda

By Jonathan Deal

Leonardo Barreda always wanted to work on complex engineering problems, so it’s no surprise that he ended up working on a key part of NASA’s new deep-space rocket, the Space Launch System. Barreda is a mechanical engineer in the Propulsion Systems Department in the Engineering Directorate of NASA’s Marshall Space Flight Center.

Working in the Thrust Vector Control Test Lab, Barreda and his team provide unique thrust vector control test capabilities for all elements of SLS. The lab enables significant risk reduction as well as cost and schedule efficiency by performing early integration and testing of core stage thrust vector control hardware.

“Thrust vector control steers the rocket on the right trajectory,” said Barreda. “During launch, forces on the vehicle can shift the vehicle’s direction, and the thrust vector control is tuned with a flight computer and flight software, so it automatically changes the path and vectors the nozzles for the engine to direct the vehicle on the right trajectory.”

Barreda’s team recently solved an issue that prevented a redesign of a core stage component. Conflicting analysis led engineering teams to be concerned about the structural strength of the core stage auxiliary power unit. His team delivered a detailed analysis that confirmed the part is structurally sound and even provided a way to redistribute those loads and help lower the stresses the component will endure during flight.

“Even if the analysis had called for a redesign, we had a parallel path ready to implement,” said Barreda. “So, we were not only helping with the analysis, but also with a cost-effective solution to a structural issue.”

After graduating from the University of Texas in El Paso in 2008, Barreda accepted a position with Marshall’s Engineering Directorate. He has worked in its Structural & Dynamics Analysis Department, the Main Propulsion Systems Department and in December 2016 joined its Thrust Vector Control Systems & Components Branch.

In the early part of his career, Barreda worked at NASA’s Kennedy Space Center, supporting the Marshall resident office. At Kennedy, he was able to see the end of the Space Shuttle Program firsthand. It was an experience that has stuck with him to this day.

“One of the most memorable times was going to the Vehicle Assembly Building at Kennedy and seeing the integrated space shuttle stack with boosters, the orbiter and the external tank,” Barreda recalled. “Looking at just how magnificent that vehicle was and then seeing it launch, it really brings back the focus of what it is that we do here. That was an experience I will never forget.”

Deal, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

Mother’s Battle with Cancer Leads Marshall’s Dwight Pope to a Life of Advocacy

By Morgan MacMillan

Every October, Breast Cancer Awareness Month brings on the thoughts of cancer survivors and those lost. We rally around those fighting the disease, buy pink items and donate to charities funding research.

Dwight Pope, a television film librarian at NASA’s Marshall Space Flight Center, learned about a different role in the fight when he became the caregiver of his mother, Clara Cartwright, as she fought breast cancer for the last three years of her life. His passion for honoring and advocating on behalf of women who need help started with his mother, but it didn’t end there.

Pope now volunteers and works with local groups to advocate for those fighting cancer and those taking care of them. He speaks to women of all ages to spread awareness, while also addressing the caregivers — those standing strong for a loved one.

“With my mother, I made sure that just as she had served us, she was given the same care and consideration,” Pope said. “As she grew weaker in her physical strength, I grew stronger in my spiritual resolve to see it through.”

By the time Cartwright let her family know she needed medical help, doctors discovered the Metastatic breast cancer — stage IV or advanced breast cancer — had spread to her lungs, chest wall, liver and hip.

“At that point, it was just a matter of just trying to make her as comfortable as possible,” Pope said. “Clearview Cancer Institute in Huntsville treated her to slow it down — but that was about the best they could do.”

On Aug. 10, 2009, Cartwright lost her battle to breast cancer at the age of 73 — but her son didn’t stop fighting.

He partnered with the Kimberly Fails Jones Foundation to help serve women in Madison County fighting breast cancer.

Kimberly Fails Jones, the foundation’s namesake, founded the charity before she passed away just one year and one month after Cartwright. “She knew she was sick and started the foundation to help other women in her hometown of Huntsville,” said Pope. “The foundation was the perfect fit for me. We had the same goals and desires to help, so her family and I partnered to reach out and help support ladies in need.”

One of the many projects and events Pope has worked on with the foundation is “In Her Name.” The original event, held in 2014, was hosted by men to honor women. The women, ranging in age from 21-80, were escorted to their seats and served dinner, while men read poetry and serenaded them throughout the evening.

“This event offers us the opportunity to show compassion for each other, to listen to each other and be willing to care and uplift each other,” Pope said. “‘In Her Name’ was our gift to the community – to those fighting cancer and to those helping.”

Pope and the foundation plan to host the second “In Her Name” event next spring. “We won’t stop giving,” he said. “Giving is what we do. It’s why we are here.”

For more information about the Kimberly Fails Jones Foundation, click here.

MacMillan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Employee Registration Deadline Oct. 20 for Annual Wernher von Braun Memorial Symposium

Employees wishing to attend the Wernher von Braun Memorial Symposium have until Oct. 20 to register. The 10th annual event will be held Oct. 25-26 at the University of Alabama in Huntsville with panel discussions taking place in the Charger Union Theater.

This year’s symposium theme, “Gateways in Space: Exploration, Security and Commerce,” will focus on benefits, challenges and opportunities in advancing space activities, and highlight recent progress in science, engineering and technology.

Marshall team members must register in advance at https://vonbraun.rostrum-cms.com/registration/.

Symposium registration must be directly related to an employee’s job and supervisors must approve attendance. Parking at the conference is limited to the W30, Executive Plaza parking area across Sparkman Drive and designated visitor spaces in the Intermodel parking facility. Shuttle service will be available from the Executive Parking area to the conference.

The event, hosted by the American Astronautical Society, will feature speakers and panelists from government, industry and academia. The symposium’s panel discussions and presentations, with the exception of the Oct. 25 and 26 luncheons, will be streamed live online at http://astronautical.org/live.

Michoud’s First On-site Gas Station Opens

NASA Marshall Space Flight Center Director Todd May addresses team members at NASA’s Michoud Assembly Facility during the ribbon cutting ceremony for the Coast Guard Exchange Gas Station. May was joined by Michoud Director Keith Hefner, NASA Stennis Space Center Deputy Director Randy Galloway and a host of officials from the U.S. Coast Guard, one of many tenants located on the 832-acre campus. The gas station is the first of its kind at Michoud and will serve the site’s more than 3,000 employees. Managed by Marshall, Michoud is a world-class manufacturing facility currently building hardware for NASA’s Space Launch System and Orion spacecraft. (NASA/Michoud/Jude Guidry)

This Week in NASA History: US Microgravity Laboratory-2 Launches – Oct. 20, 1995

This week in 1995, the space shuttle Columbia and STS-73 launched from NASA’s Kennedy Space Center carrying USML-2, the U.S. Microgravity Laboratory-2. Here, the lab is visible in the orbiter’s cargo bay. U.S. Microgravity Laboratory-2, managed by NASA’s Marshall Space Flight Center, conducted experiments on fluid physics and the effects of microgravity on combustion and the formation of semiconductor crystals. Today, the Payload Operations Integration Center at Marshall serves as “science central” for the space station, working 24/7, 365 days a year in support of the orbiting laboratory’s scientific experiments. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

Obituaries

Rondal C. Mize, 79, of Cullman, Alabama, died June 8. He retired from the Marshall Center in 2005 as a facility safety systems supervisor.

Fernander R. Kirby, 102, of Huntsville, died Sept. 17. He retired from the Marshall Center in 1984 as a program analyst.

James B. Herring, 80, of Owens Cross Roads, Alabama, died Sept. 22. He retired from the Marshall Center in 1994 as an aerospace engineer. He is survived by his wife, Clarissa Herring.

William G. Simpson, 96, of Ardmore, Alabama, died Oct. 8. He retired from the Marshall Center in 1988 as a flight systems engineer.

Claude K. Brown, 87, of Huntsville, died Oct. 8. He retired from the Marshall Center in 1987 as a printing specialist. He is survived by his wife, Nancy P. Brown.

Kenneth A. Hill, 87, of Huntsville, died Oct. 14. He retired from the Marshall Center in 1986 as an aerospace engineer. He is survived by his wife, Jane J. Hill.