In This Week’s Star

- Successful Orion Test Brings NASA Closer to Moon, Mars Missions

- Pegasus Barge Delivers Final SLS Structural Test Article to Marshall

- Maxar, Dynetics Team for Gateway Power and Propulsion Element Development

- Time to Celebrate: Marshall to Mark Apollo 50th Anniversary with Employee Event

- Federal Tenant Satisfaction Survey Now Open

- Suren Singhal Named Deputy Manager, Office of the Chief Engineer, Engineering Directorate

- Micro-Coil Springs Provide Suspension for Circuit Boards

- Marshall Helps Restore Mercury-Redstone Rocket

- 3, 2, 1… Lift-Off of the Artemis 1 Mission to the Moon

- X-rays Spot Spinning Black Holes Across Cosmic Sea

- This Week in NASA History: 1st S-IVB Test Hardware Delivered to Marshall – July 11, 1964

Successful Orion Test Brings NASA Closer to Moon, Mars Missions

On July 2, NASA successfully demonstrated the Orion spacecraft’s launch abort system can outrun a speeding rocket and pull astronauts to safety during a launch emergency. The test is another milestone in the agency’s preparation for Artemis missions to the Moon that will lead to astronaut missions to Mars.

During the approximately three-minute test, called Ascent Abort-2, a test version of the Orion crew module launched at 6 a.m. CDT from Cape Canaveral Air Force Station on a modified Peacekeeper missile procured through the U.S. Air Force and built by Northrop Grumman Corp.

The Orion test spacecraft traveled to an altitude of about 6 miles, at which point it experienced maximum high-stress aerodynamic loading conditions expected during ascent. The abort sequence triggered and, within milliseconds, the abort motor fired to pull the crew module away from the rocket. Its attitude control motor flipped the capsule end-over-end to properly orient it, and then its jettison motor ignited, releasing the crew module for splashdown in the Atlantic Ocean.

NASA next will analyze data captured by 12 onboard data recorders ejected during the test capsule’s descent, gaining additional insight into the abort system’s performance.

“We’re building the most powerful rocket in the world to send astronauts to the Moon in the Orion spacecraft for Artemis missions,” said Bill Hill, deputy associate administrator for Exploration Systems Development at NASA Headquarters. “We’ll also have an equally powerful launch abort system that will pull the crew away if there is a problem with the rocket during the early portion of ascent.”

Engineers at NASA’s Marshall Space Flight Center oversaw preliminary motor testing in late 2018 at the U.S. Army Redstone Test Center on Redstone Arsenal, as well as qualification tests for both the attitude control and abort motors at motor vendor facilities in Utah and Maryland.

“We’re extremely proud of the successful AA-2 motor test,” said Tom Zoladz, Solid Propulsion Systems manager in Marshall’s Engineering Directorate. “The motor performed well under simulated dynamic loads reflecting those Orion and her crew will experience during ascent, and every test success such as this one helps ensure they’ll fly safely — making history every step of the way.”

The tower-like abort structure consists of two parts: the fairing assembly, which is a shell composed of a lightweight composite material that protects the capsule from the heat, air flow and acoustics of the launch, ascent, and abort environments; and the launch abort tower, which includes the abort motor, attitude control motor and jettison motor. The system is built specifically for deep space missions and to ride on NASA’s powerful Space Launch System rocket.

“Launching into space is one of the most difficult and dangerous parts of going to the Moon,” said Mark Kirasich, Orion program manager at Johnson Space Center. “[We’re] one huge step closer to the first Artemis flight carrying people to the Moon.”

NASA was able to accelerate the test schedule and lower costs by simplifying the test spacecraft and eliminating parachutes and related systems. NASA already qualified the parachute system for crewed flights through extensive developmental and qualification tests in 2018.

Engineers are building and testing the Orion spacecraft for Artemis 1, the first uncrewed mission with the SLS rocket — an integrated system traveling thousands of miles beyond the Moon — and for Artemis 2, the first mission with astronauts.

Orion, along with the SLS and Gateway, is part of NASA’s backbone for deep space exploration, set to land the first woman and next man on the Moon by 2024. Through the Artemis program, the next American Moon walkers will depart Earth aboard Orion to begin a new era of space exploration.

Pegasus Barge Delivers Final SLS Structural Test Article to Marshall

The fourth and final structural test article for NASA’s Space Launch System core stage was unloaded from NASA’s barge Pegasus at NASA’s Marshall Space Flight Center on July 9. The nearly 70-foot-long liquid oxygen tank structural test article, manufactured at NASA’s Michoud Assembly Facility, is structurally identical to the flight version. Next, crews will load it into a test stand at Marshall for critical testing. The liquid oxygen tank is one of two propellant tanks in the rocket’s core stage that will produce more than 2 million pounds of thrust to help launch Artemis 1, the first flight of NASA’s Orion spacecraft and SLS, to the Moon. (NASA/Fred Deaton)

Maxar, Dynetics Team for Gateway Power and Propulsion Element Development

Huntsville, Alabama-based Dynetics will support Maxar Technologies of Westminster, Colorado, in building and demonstrating the power and propulsion element for NASA’s lunar Gateway. The companies announced the signing of a teaming agreement during a press conference July 9 at Dynetics.

Maxar was selected in May to build and perform spaceflight demonstrations of the power and propulsion element, a 50-kilowatt solar electric propulsion spacecraft and the first element for Gateway. The element is targeted for launch by the end of 2022 and will provide power, maneuvering, attitude control, communications systems and initial docking capabilities for the Gateway.

The Gateway will provide a communications relay for human and robotic expeditions to the lunar surface, starting at the Moon’s south pole. The Gateway will play a critical role in ensuring that NASA astronauts can land on the surface of the Moon by 2024 while serving as a vital platform to support future missions to Mars and beyond.

“Dynetics has decades of expertise in human space exploration,” said Mike Gold, Maxar’s vice president of Civil Space, “and will play a critical role in executing the Artemis mission, landing the first woman on the surface of the Moon, and establishing the sustainable space infrastructure that is necessary to explore Mars.”

The agreement enables Dynetics to collaborate with Maxar in the design, manufacturing and operations of the power and propulsion element.

“The partnership between Maxar and Dynetics is a key step in NASA moving forward to the Moon,” said Bobby Watkins, director of the Human Exploration Development Office at NASA’s Marshall Space Flight Center. “The power and propulsion element is the Gateway’s core, and the commitment of these companies will help ensure that we lay a successful foundation upon which the remainder of the outpost is built.”

Time to Celebrate: Marshall to Mark Apollo 50th Anniversary with Employee Event

By Will Bryan

On July 16, NASA’s Marshall Space Flight Center and the Marshall Exchange will celebrate the 50th anniversary of the historic Apollo 11 mission with “Summer Blast: The Apollo Edition,” a social event celebrating the contributions made by the Marshall workforce toward the Apollo program.

The free event — open to all NASA employees, contractors and their families – will be from 2:30 to 5:30 p.m. at the walking trails behind the Wellness Center, Building 4315, on Digney Road. It kicks off with model rocket launches of both Saturn V and Space Launch System rockets. There will be a variety of food, exhibits and activities for all ages, including live music, inflatables for kids, a balloon artist and a moonwalking contest. Beer and wine will be available for purchase. Moon Pie of Chattanooga, Tennessee, will bring a 4-foot-diameter Moon Pie emblazoned with the Apollo 50th logo.

In the event of inclement weather, festivities will be held in the Activities Building, 4316.

On July 19, the eve of the first Moon landing, Downtown Huntsville Inc. will host the free community event “Dancing in the Streets” from 5 to 9 p.m. at the Courthouse Square in downtown Huntsville. Each side of the square will feature NASA exhibits highlighting different eras of space exploration — Apollo, the space shuttle, International Space Station and the SLS, and each will feature live music and dancing from the respective era. Food and refreshments will be available for purchase.

The Exchange is a nonappropriated-fund activity that aims to contribute to the welfare, efficiency and morale of Marshall team members, other government personnel, retired NASA employees and their families.

More information about activities and events during the celebration week will be updated on ExplorNet.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Federal Tenant Satisfaction Survey Now Open

The 2019 Tenant Satisfaction Survey administered by the General Services Administration is now open to all federal government and civil service employees. The survey opened July 9 and will close August 22. All federal government employees should receive an email unique for them within a week of the start date with instructions on how to complete the survey.

“The TSS is a very useful tool in helping us identify how we can improve our buildings and facilities,” said Jeff Brown, manager of the Facilities Management Office at NASA’s Marshall Space Flight Center. “As a result of responses from previous surveys, we’ve included an extra day of cleaning restrooms, added a summertime crew for maintaining the grass in the test area and hired a customer support person.”

The survey is for government employees in federally owned and leased buildings to provide feedback on their building, security, building management staff and overall satisfaction. The results help assess performance, identify areas of improvement and help government agencies provide effective and sustainable workplace solutions at the best value of the American taxpayer. The survey takes about 10 minutes to complete, and helps to ensure productive and safe workspaces at Marshall.

For more information on the survey, visit the GSA TSS website or can send an email to TSScustomerservice@research.gsa.gov.

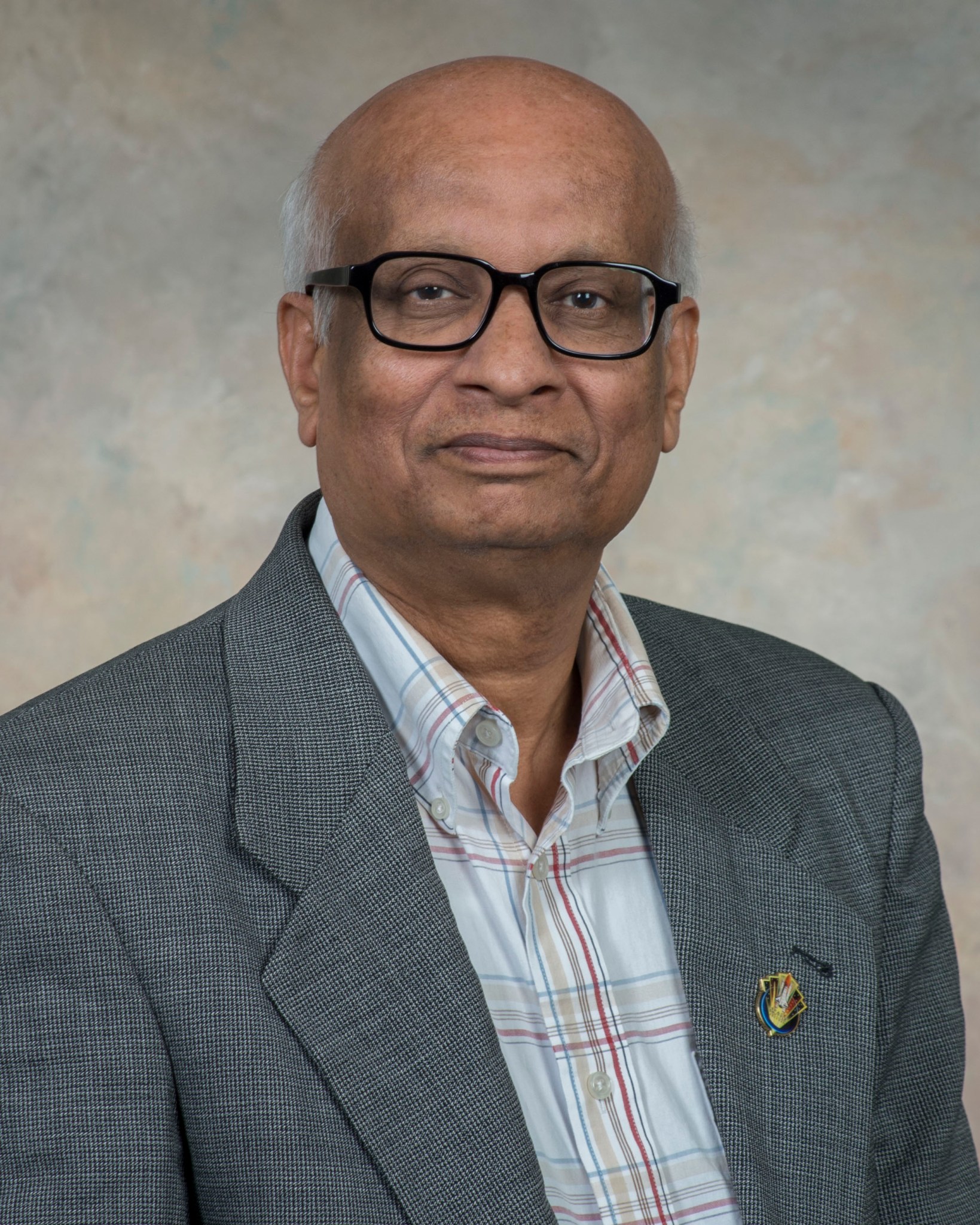

Suren Singhal Named Deputy Manager, Office of the Chief Engineer, Engineering Directorate

Suren Singhal has been appointed to the position of deputy manager of the Office of the Chief Engineer in the Engineering Directorate at NASA’s Marshall Space Flight Center.

With the chief engineer, Singhal will be responsible for technical leadership in planning, directing and executing research, technology, design, development, production, integration and sustaining engineering for the Space Launch System program, the Human Exploration Development and Operations Office and the Science and Technology Office.

Singhal has nearly 30 years of experience in materials research and development, and manufacturing for propulsion and space vehicle applications. His work and leadership have impacted nearly every major NASA program, including the space shuttle, International Space Station, Ares, SLS and aeronautics research.

He began his NASA career in 1989 at Glenn Research Center as a contractor for various corporations, serving as director of propulsion, director of structures and materials, director of test facilities, and deputy general manager of Glenn’s $180 million engineering contract.

In 2002, Singhal transferred to Marshall to become technical manager of the Materials, Processes and Manufacturing Department. Concurrent with those duties, he served for one year as acting chief of the Non-destructive Evaluation and Damage Tolerance Branch. In 2006, he became assistant manager of the Materials and Processes Laboratory, where he led NASA-wide teams in developing integrated roadmaps for space science and technology, as well as agency materials and engineering processes and manufacturing programs. He served as deputy director of the Materials and Processes Laboratory from 2011 until 2014, when he was appointed to the Senior Executive Service as director of the organization.

Prior to his NASA career, Singhal was a senior research engineer for Amoco Exploration and Production and a research engineer for Shell Research/Shell Oil, where he coordinated national and international projects, negotiated crucial testing for a $2 billion energy program that led to a competitive edge for the United States, and identified gaps between research and operations.

Singhal earned a bachelor’s degree in mechanical engineering from the Indian Institute of Technology in Kanpur, India, followed by a master’s degree in fluid, thermal and aerospace sciences from Case Western Reserve University in Cleveland. He earned a master’s degree in business administration from the University of Houston and a master’s degree and doctorate in mechanical engineering from the University of Wisconsin in Madison.

Micro-Coil Springs Provide Suspension for Circuit Boards

By Will Bryan

The constant bumping and jarring of driving down a rough gravel road in an old pickup truck is enough to rattle anyone’s brains. A good suspension, though, will make that ride smooth and comfortable.

In space, the electronics and elements on a circuit board also need a suspension system. Instead of a pocket-filled road, the brains of computers contend with high levels of vibration and extreme temperature swings that cause expansion and contraction on levels almost imperceptible to the human eye.

A novel type of spring developed by engineers at NASA’s Marshall Space Flight Center is just the suspension system needed for space and industry. Called the micro-coil spring, it is licensed by Milledgeville, Georgia’s Topline Corp. and is used in multiple industries, including down-hole drilling in oilfields.

Circuit boards are comprised of many different pieces made of various materials attached to a main substrate — the board itself — typically with solder. Different materials expand and contract at different rates, making it difficult for even the state-of-the-art solder attachment to hold everything together when the component undergoes extreme temperature swings or high levels of vibration.

A better solution was needed.

Marshall engineers Jim Hester and Mark Strickland studied different ideas and ultimately selected the micro-coil spring as the best. The springs are approximately the size of one number in the year on a U.S. penny. The engineers solved the challenge of attaching the springs to the circuit board and tested the integrated spring-circuit boards in extreme temperatures, from minus 70 degrees to more than 250 degrees Fahrenheit. The spring attachments lasted twice as long as solder on ceramic boards and five times longer than solder on plastic boards in the extreme thermal environments and sustained vibrations of 10 Gs — 10 times the force of gravity on Earth.

In 2014, the innovation won the Tech Briefs’ Design the Future award in the electronics category, catching the eye Marshall’s Technology Transfer Office. Tech Briefs is an online resource and print magazine covering the latest technologies applicable to the spaceflight industry, including those developed by NASA.

Sammy Nabors, the licensing manager in the office, contacted Topline and its CEO, Martin Hart. Hart saw great value in the small spring, and his company was granted an exclusive license to produce and sell the devices. Today, the company sells the micro-coil springs for components used in a multitude of industries and applications including aerospace and automobile electronics and avionics technologies.

As NASA engineers, scientists and team members continue to push the bounds of space exploration and aim to put the next humans on the Moon in 2024, the technologies developed are brought into the commercial market to improve life on Earth.

If you have a technology that could make a difference, submit a New Technology Report.

“The agency holds more than 1,400 patents and makes them available to industry through its patent licensing program,” said Terry Taylor, manager of Marshall’s Technology Transfer Office. “These inventions generate revenue, create jobs, save lives and show a clear return on investment for the nation’s space program.”

To read more about this spinoff, visit here.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Helps Restore Mercury-Redstone Rocket

In the summer of 1961, Project Mercury took the first American astronauts to space. The U.S. Space & Rocket Center recently partnered with NASA Marshall Space Flight Center contractor Aerie Aerospace to restore one of the first Mercury-Redstone rockets. To show the progress of the restoration, the rocket was displayed June 14 at Marshall’s Building 4705, where the restoration is in process. The U.S. Space & Rocket Center’s Education Foundation launched the Rocket Protector Restoration initiative to restore the historic rockets at the museum’s Rocket Row. (U.S. Space & Rocket Center/James Jordan)

The restoration team included, front, from left, Aerie’s David Stancil, Pat Hand and Charles Hardy, Michelle Gudgen of the U.S. Space & Rocket Center, and Aerie’s Cody Eudy and Alvin Hodge; and back, from left, Aerie’s Cliff Plaxco, Chris McCain, Brad Sullivan, Wayne Ellenburg, Mark Beutjer and Bryan Whaley. Not pictured are Aerie’s David Osborne, Jeffery Holt, Troy Parker, Richard Caldwell, Philip White, Kenny Webster and Johnny Lebrun. (U.S. Space & Rocket Center/James Jordan)

3, 2, 1… Lift-Off of the Artemis 1 Mission to the Moon

Hear the countdown and see how NASA’s Space Launch System, the world’s most powerful rocket, will send the Orion spacecraft to the Moon on the Artemis 1 Mission. This video takes you through the pre-launch sequence at NASA’s Kennedy Space Center and through all the flight operations as SLS launches Orion and sends it on to lunar orbit.

X-rays Spot Spinning Black Holes Across Cosmic Sea

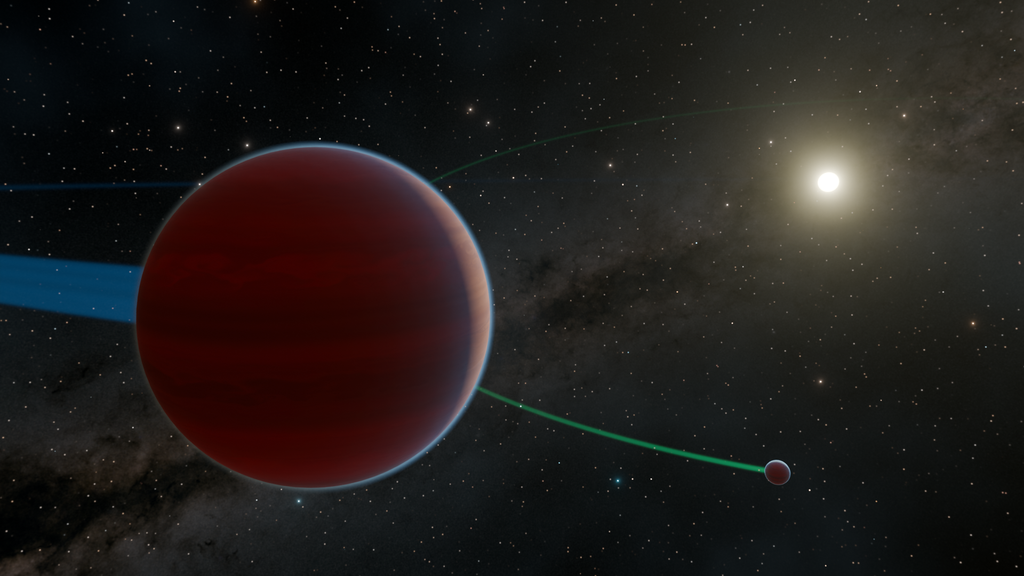

Like whirlpools in the ocean, spinning black holes in space create a swirling torrent around them. However, black holes do not create eddies of wind or water. Rather, they generate disks of gas and dust heated to hundreds of millions of degrees that glow in X-ray light.

Using data from NASA’s Chandra X-ray Observatory — a program managed by NASA’s Marshall Space Flight Center for the Science Mission Directorate — and chance alignments across billions of light years, astronomers have deployed a new technique to measure the spin of five supermassive black holes. The matter in one of these cosmic vortices is swirling around its black hole at greater than about 70% of the speed of light.

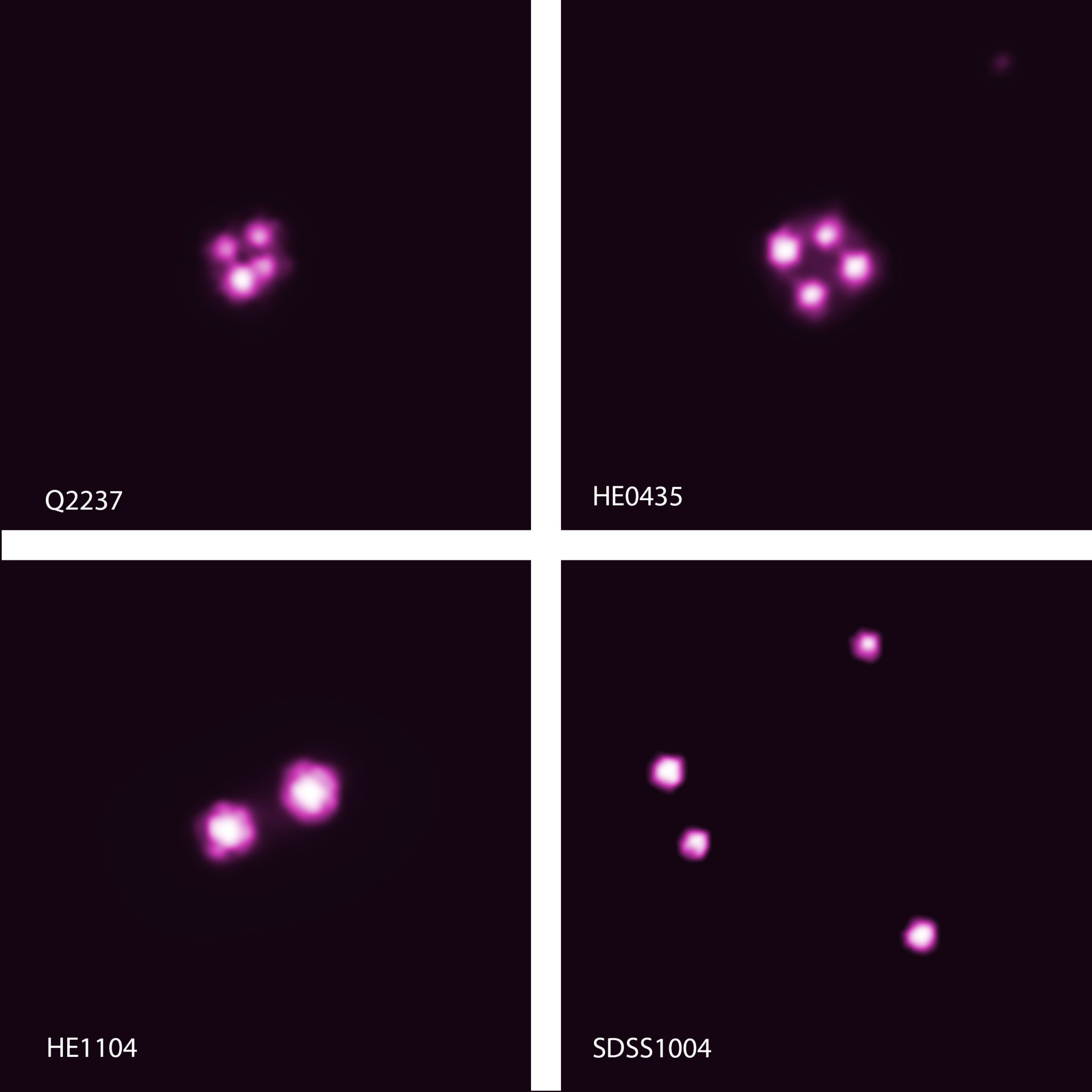

The astronomers took advantage of a natural phenomenon called a gravitational lens. With just the right alignment, the bending of space-time by a massive object, such as a large galaxy, can magnify and produce multiple images of a distant object, as predicted by Albert Einstein.

In this latest research, astronomers used Chandra and gravitational lensing to study six quasars, each consisting of a supermassive black hole rapidly consuming matter from a surrounding accretion disk. Gravitational lensing of the light from each of these quasars by an intervening galaxy has created multiple images of each quasar, as shown by the above Chandra images of four of the targets. The sharp imaging ability of Chandra is needed to separate the multiple, lensed images of each quasar.

The key advance made by researchers in this study was that they took advantage of “microlensing,” where individual stars in the intervening, lensing galaxy provided additional magnification of the light from the quasar. A higher magnification means a smaller region is producing the X-ray emission.

The researchers then used the property that a spinning black hole is dragging space around with it and allows matter to orbit closer to the black hole than is possible for a non-spinning black hole. Therefore, a smaller emitting region corresponding to a tight orbit generally implies a more rapidly spinning black hole. The authors concluded from their microlensing analysis that the X-rays come from such a small region that the black holes must be spinning rapidly.

The results showed that one of the black holes, in the lensed quasar called the “Einstein Cross,” is spinning at, or almost at, the maximum rate possible. This corresponds to the event horizon, the black hole’s point of no return, spinning at the speed of light, which is about 670 million miles per hour. Four other black holes in the sample are spinning, on average, at about half this maximum rate. (The sixth did not enable an estimate of spin.)

For the Einstein Cross the X-ray emission is from a part of the disk that is less than about 2.5 times the size of the event horizon, and for the other four quasars the X-rays come from a region four to five times the size of the event horizon.

How can these black holes spin so quickly? Researchers think that these supermassive black holes likely grew by accumulating most of their material over billions of years from an accretion disk spinning with a similar orientation and direction of spin, rather than from random directions. Like a merry-go-round that keeps getting pushed in the same direction, the black holes kept picking up speed.

The quasars are located at distances ranging from 8.8 billion to 10.9 billion light years from Earth, and the black holes have masses between 160 and 500 million times that of the sun. These observations were the longest ever made with Chandra of gravitationally lensed quasars, with total exposure times ranging between 1.7 and 5.4 days.

A paper describing these results is published in the July 2 issue of The Astrophysical Journal, and is available online.

The Smithsonian Astrophysical Observatory in Cambridge, Massachusetts, controls Chandra’s science and flight operations.

Read more about Chandra. View more Chandra images, multimedia and related materials.

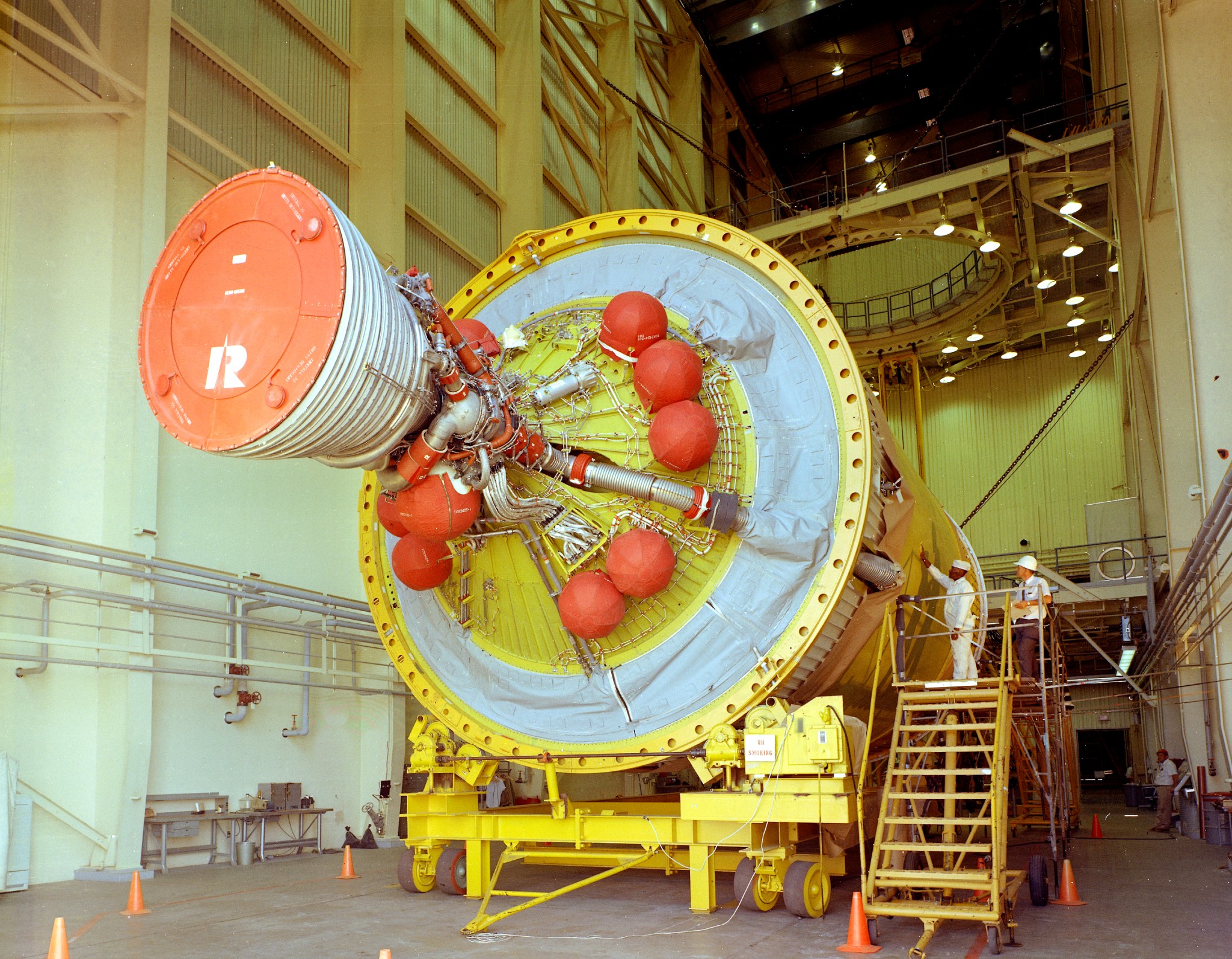

This Week in NASA History: 1st S-IVB Test Hardware Delivered to Marshall – July 11, 1964

This week in 1964, the first Saturn V S-IVB, or third stage test hardware was delivered to NASA’s Marshall Space Flight Center from Long Beach, California. The S-IVB stage forward skirt would connect the top of the stage to the vehicle’s instrument unit. Developed and manufactured by Douglas Aircraft Co., the S-IVB measured about 21 1/2 feet in diameter, was about 58 feet in length and was powered by one J-2 engine capable of producing 225,000 pounds of thrust. Here, the fully assembled S-IVB for the SA-503 rocket, the Apollo 8 mission, is in Douglas’ vertical checkout building. This July, in a series of special events, NASA is marking the 50th anniversary of the Apollo Program — the historic effort that sent the first U.S. astronauts into orbit around the Moon in 1968, and landed a dozen astronauts on the lunar surface between 1969 and 1972. For more pictures, and to connect to NASA’s remarkable history, visit the Marshall History Program’s webpage. (NASA)