In This Week’s Star

- NASA Hosts Artemis Day Events at Michoud, Stennis

- Space Launch System’s Core Stage Comes Together in New Video

- NASA Engineers at Marshall Push SLS Tank to Test Extreme Limits

- NASA Motor Test Part of Next-Generation Booster Development

- Weber Selected as Marshall Science and Technology Office’s Senior Scientist

- Marks Appointed Deputy Director of Marshall’s Office of Center Operations

- Cargo Vehicles Arrive at Space Station in Back-to-Back Days

- ‘Innovation is Not Optional’ Says NASA Chief Technologist

- Marshall’s Zachary Jones to Deliver Tech Talk Dec. 12

- Marshall Team, Family Members Usher in Season With Holiday Tree Lighting

- This Week in NASA History: 1st Hot Fire Test of RS-25 with Large 3D Printed Part – Dec. 13, 2017

NASA Hosts Artemis Day Events at Michoud, Stennis

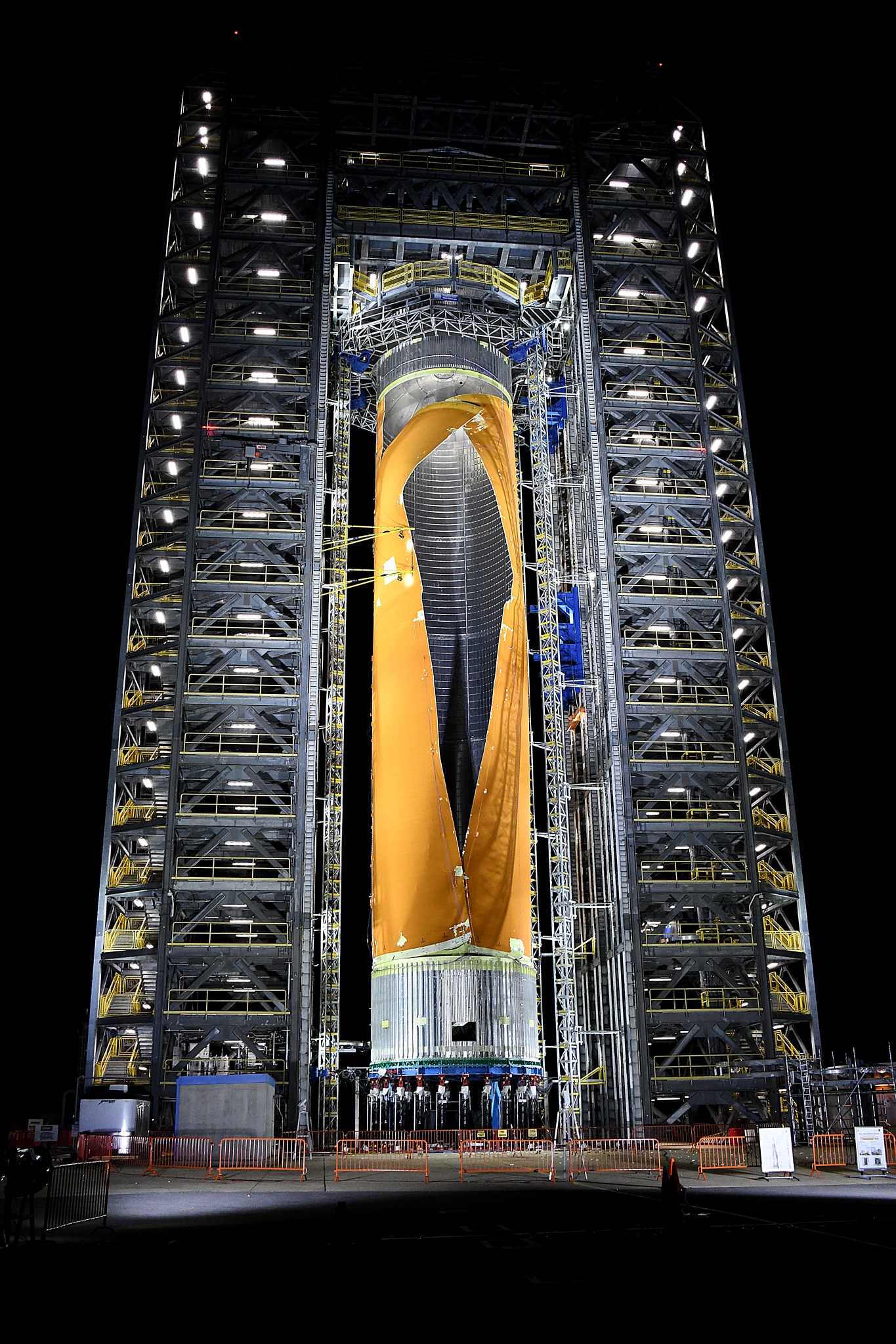

NASA Administrator Jim Bridenstine welcomes members of the news media and social media influencers to the agency’s Artemis Day program at NASA’s Michoud Assembly Facility on Dec. 9. Visitors to Michoud and NASA’s Stennis Space Center on Dec. 9-10 toured manufacturing and test facilities for an up-close look at the core stage of the Space Launch System rocket, which is set to power the first Artemis lunar mission. “The completion of the SLS core stage is a major milestone and a testament to American enterprise and ingenuity,” Bridenstine said at Michoud. “With more than 1,100 large and small businesses in 44 states contributing to the design and assembly, the SLS rocket will empower America to achieve the Artemis program’s goal of landing the first woman and next man on the Moon by 2024.” SLS is the only rocket that can send the Orion crew spacecraft, astronauts and supplies to the Moon on a single mission. (NASA/Bill Ingalls)

Space Launch System’s Core Stage Comes Together in New Video

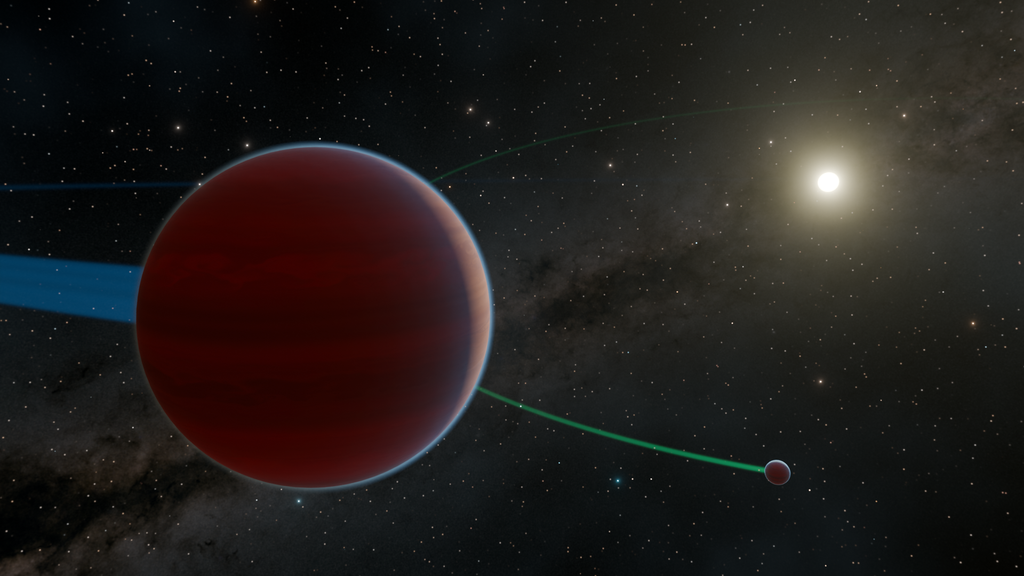

The core stage that will help launch NASA’s Space Launch System rocket to the Moon for NASA’s first Artemis mission is fully assembled, and you can see how teams at NASA’s Michoud Assembly Facility made it happen in this video. With four RS-25 engines and two giant tanks holding a combined 733,000 gallons of propellant, the core stage is the powerhouse of the rocket. Technicians attached the five structures in three phases, or joins, before individually adding each of the four RS-25 engines to the stage. Once the stage passes final check-outs, NASA’s Pegasus barge will ferry it to NASA’s Stennis Space Center for the Green Run test series. Read more about SLS here. (NASA)

NASA Engineers at Marshall Push SLS Tank to Test Extreme Limits

On Dec. 5, engineers at NASA’s Marshall Space Flight Center deliberately pushed the world’s largest rocket fuel tank beyond its design limits to really understand its breaking point. The test version of the Space Launch System rocket’s liquid hydrogen tank withstood more than 260% of expected flight loads over five hours before it ruptured.

“We purposely took this tank to its extreme limits and broke it because pushing systems to the point of failure gives us additional data to help us build rockets intelligently,” said Neil Otte, chief engineer of Marshall’s SLS Stages Office. “We will be flying the Space Launch System for decades to come, and breaking the propellant tank will help us safely and efficiently evolve the SLS rocket as our desired missions evolve.”

The test version of the tank aced earlier tests, withstanding forces expected at engine thrust levels planned for Artemis lunar missions, showing no signs of cracks, buckling or breaking. The test on Dec. 5 — conducted using a combination of gaseous nitrogen for pressurization and hydraulics for loads — pushed the tank to the limits by exposing it to higher forces that caused it to break as engineers predicted.

Earlier tests at Marshall certified the tank for both the current version of the SLS — called Block 1, which will use an upper stage called the Interim Cryogenic Propulsion Stage — and the Block 1B version that will replace the ICPS with the more powerful Exploration Upper Stage.

“This final tank test marks the largest controlled test-to-failure of a NASA rocket stage pressurized tank,” said Mike Nichols, Marshall’s lead test engineer for the tank. This data will benefit all aerospace companies designing rocket tanks.”

For all the tests, NASA and Boeing engineers simulated liftoff and flight stresses on a test version of the SLS liquid hydrogen tank that is structurally identical to the flight tank. For each test, conducted in Marshall’s 215-foot-tall test stand, they used large hydraulic pistons to deliver millions of pounds of punishing compression, tension and bending forces on the robust test tank.

The test tank was fitted with thousands of sensors to measure stress, pressure and temperature, while high-speed cameras and microphones captured every moment to identify buckling or cracking in the cylindrical tank wall.

“The initial tank buckling failure occurred at the same relative location as predicted by the Boeing analysis team and initiated within 3% of the predicted failure load,” said Luke Denney, qualification test manager for Boeing’s Test & Evaluation Group. “The accuracy of these predictions against real life testing validates our structural models and provides high confidence in the tank design.”

Teams at NASA’s Michoud Assembly Facility are wrapping up functional testing of the assembled SLS core stage for the Artemis I mission and already are building the core stage for the Artemis II mission. The 212-foot-tall core stage is the largest, most complex rocket stage NASA has built since the Saturn V stages that powered the Apollo missions to the Moon.

“We are happy that NASA’s tests with the core stage structural test article will contribute not only to Space Launch System flights but also to the design of future rocket propellant tanks,” said Julie Bassler, manager of the SLS Stages Office.

Success! Engineers @NASA_Marshall tested the @NASA_SLS liquid hydrogen test article tank to failure – the tank withstood more than 260% of expected flight loads before buckling and rupturing! #Artemis MORE: https://t.co/xznmov26FP pic.twitter.com/qAIyapEJA5

— Jim Bridenstine (@JimBridenstine) December 9, 2019

NASA Motor Test Part of Next-Generation Booster Development

Teams at NASA’s Marshall Space Flight Center tested a small solid rocket motor Dec. 5 that will help the agency build next-generation solid rocket boosters for future Space Launch System flights.

The 20-second hot fire test — conducted on a 24-inch-diameter, 20-foot-long subscale test motor at Marshall’s East Test area — produced 56,000 pounds of thrust and temperatures of more than 5,000 degrees Fahrenheit.

The 20-second hot fire, conducted on a 24-inch-diameter, 20-foot-long subscale test motor at Marshall’s East Test area, produced 56,000 pounds of thrust and temperatures of more than 5,000 degrees Fahrenheit. The test will help NASA and prime contractor Northrop Grumman evaluate the effect the new propellant has on the performance of materials used in the motor’s insulation and nozzle. NASA is phasing out the current propellant. The solid rocket motor industry has moved to a new propellant that provides better performance. For more, visit https://www.nasa.gov/exploration/systems/sls/news.html. Credits: NASA

The test will help NASA and prime contractor Northrop Grumman evaluate the effect a new propellant has on the performance of materials used in the motor’s insulation and nozzle. NASA is phasing out the current propellant, as the solid rocket motor industry has moved to a new propellant that provides better performance.

SLS flight boosters are 177 feet tall and 12 feet in diameter. Using a scaled-down rocket motor designed to mimic a full SLS booster provides an affordable and efficient way to evaluate new components and materials. For the insulation materials analysis, three types of insulation were placed into the motor’s aft dome — the last portion of the motor, which is dome-shaped and part of the aft assembly containing the nozzles. The three types include insulation currently used in SLS boosters and two variations of a new insulation, one with a variant that reduces the risk of static discharge and one without.

“All three insulation materials were tested at the same time,” said Sarah Howse, materials and processes lead for the solid rocket test motor. “The team will compare the effect of the new propellant on the material with the historical propellant.”

NASA is focusing its analysis on the insulation in the large acreage areas of the motor.

“That part of the motor interfaces with the new propellant and historical materials are obsolete,” said Tim Lawrence, motor assembly system manager.

“In the forward end of the motor, engineers collected data to measure the thermal aspects of the motor during the test. This will help refine the accuracy of existing thermal models,” Lawrence said.

The SLS booster is the largest, most powerful solid propellant booster ever built for flight. Standing 177 feet tall, each booster generates a maximum thrust of 3.6 million pounds, providing more than 75% of the total thrust at launch.

NASA’s SLS booster is based on three decades of knowledge and experience gained with the space shuttle boosters and has been updated with the latest technology. The agency is working to design, develop and test next-generation boosters that will power SLS flights after all available shuttle-era hardware is expended. NASA has cast segments for the Artemis I and Artemis II lunar missions and the first two SLS flights. The agency has also begun casting the third flight set of motor segments.

SLS and the Orion spacecraft — along with the Gateway in orbit around the Moon — are NASA’s backbone for deep space exploration and the Artemis program, which will send the first woman and next man to the lunar surface by 2024. SLS is the only rocket that can send Orion, astronauts and supplies to the Moon on a single mission.

Weber Selected as Marshall Science and Technology Office’s Senior Scientist

Renee Weber has been selected to the senior technical position of senior scientist of the Science and Technology Office at NASA’s Marshall Space Flight Center.

Weber will provide strategic leadership to a multidisciplined technical organization with responsibility for oversight of the formulation, maturation, design, development and operation of research and technology projects. Additionally, she will represent Marshall science to the external community, including NASA Headquarters and NASA field centers, academia, other government agencies and private industry for the purpose of growing successful partnerships.

Weber came to NASA in 2010 in support of the Constellation Program for human exploration, leading a diverse portfolio of lunar and planetary science research focusing on terrestrial planet interiors. Since 2016, she has served as manager of the Science and Technology Office Heliophysics and Planetary Science Branch, providing technical, administrative and supervisory direction in managing the proposal and execution of research, instrumentation and flight programs. She was acting senior scientist for Marshall in 2018.

Weber received a bachelor’s degree in physics with a focus on geophysics from the University of California, Berkeley in 2000, and a doctorate in earth sciences with a concentration in planetary geophysics from the University of California, San Diego in 2007. Following graduate school, she was awarded a Chateaubriand Postdoctoral Fellowship at l’Insitut de Physique du Globe de Paris in 2008, where she conducted independent research in planetary seismology in partnership with the French seismometer instrument team for the current Mars InSight mission. As a Shoemaker Postdoctoral Fellow at the U.S. Geological Survey’s Astrogeology Science Center in 2009, she performed formative research which established the first direct seismic constraint on the size of the Moon’s core.

Weber was born in Rochester, New York, and raised in Redding, California. She and her husband Peter, an electrical engineer in Marshall’s Space Systems Department, have two sons and reside in Huntsville.

Marks Appointed Deputy Director of Marshall’s Office of Center Operations

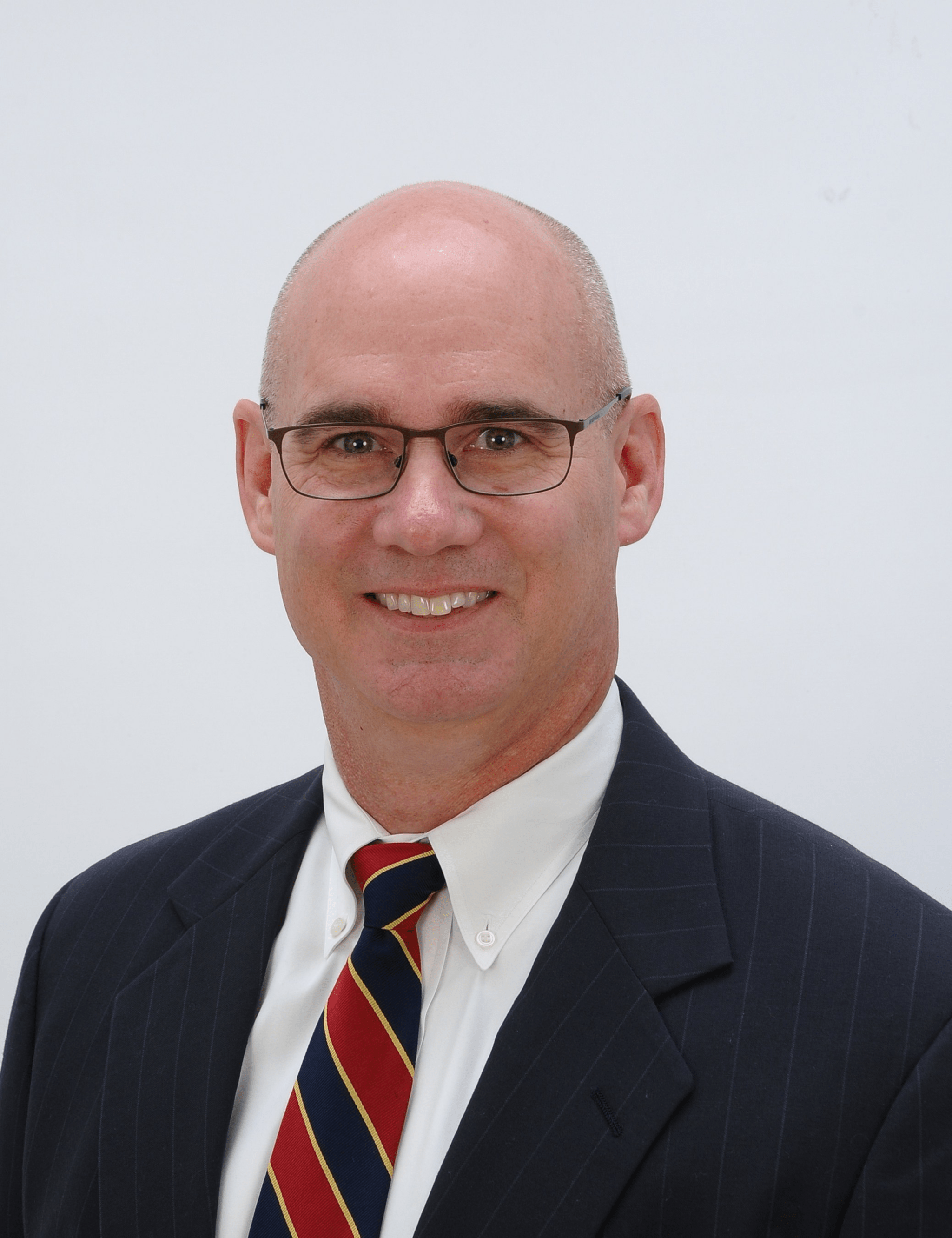

Bill Marks has been appointed to the Senior Executive Service position of deputy director of Office of Center Operations at NASA’s Marshall Space Flight Center.

The Senior Executive Service is the personnel system covering most of the top managerial positions in federal agencies.

The Office of Center Operations, with an annual budget of approximately $100 million, includes 127 engineers and specialized civil servants and 700 contractors. The organization’s services include industrial labor relations, environmental engineering, occupational health, facility management, logistics and transportation, protective services, emergency management and subordinate site operations.

Marks has served in numerous staff and leadership roles throughout his career. In the U.S. Army, his unit leadership roles included serving as a rifle platoon leader in the 25th Infantry Division (Light); company commander of a maintenance company in the 3rd Infantry Division (Mechanized); battalion commander in the 3rd Infantry Division; and garrison commander of Redstone Arsenal, where he retired as a colonel in 2016.

Marks was commissioned as a second lieutenant in the U.S. Army Ordnance Corps and detailed to the infantry in 1990. He served twice in Iraq during Operation Iraqi Freedom. He served from 2005 to 2006 as the battalion executive officer, and from 2009 to 2010 as the battalion commander of 203rd Brigade Support Battalion, 3rd Heavy Brigade Combat Team, 3rd Infantry Division. He most recently was an executive director of Geocent LLC, an information technology and engineering firm based in New Orleans.

Marks earned a bachelor’s degree in finance from the University of South Alabama in Mobile. He holds a master’s degree in public administration from Webster University in St. Louis and a master’s degree in strategic studies from the Air University at Maxwell Air Force Base in Montgomery. He is also a graduate of the Air War College at Maxwell.

Marks’ awards include the Legion of Merit, two Bronze Star Medals, the Defense Meritorious Service Medal, five Meritorious Service Medals, three Army Commendation Medals, a Joint Service Achievement Medal, three Army Achievement Medals, the Ranger Tab, Parachutist Badge and the Air Assault Badge. He currently serves on the boards of directors for The Schools Foundation and the Association of the United States Army–Redstone Chapter. He is a member of the Downtown Huntsville Chapter of the Rotary Club International, a member of the Huntsville Committee of 100 and serves as chairman of Launch 2035, a regional partnership between Alabama’s Limestone, Madison and Morgan counties dedicated to fostering economic growth in the area.

Cargo Vehicles Arrive at Space Station in Back-to-Back Days

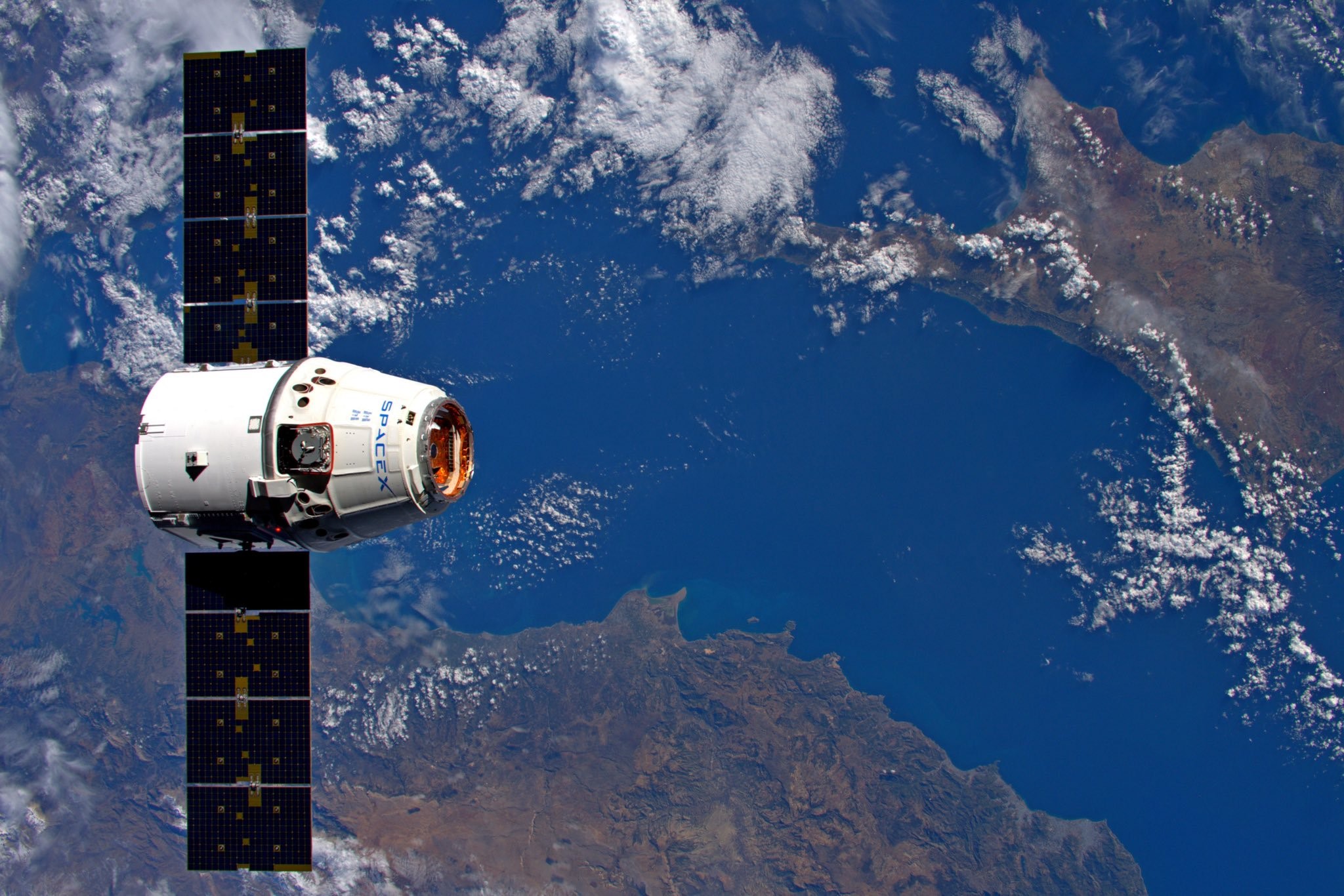

The Expedition 61 crew had busy days Dec. 8-9 on the International Space Station, as two cargo vehicles — a SpaceX Dragon and a Russian Progress spacecraft — arrived and docked at the orbiting outpost. Each vehicle delivered thousands of pounds of experiments, cargo and supplies.

Three days after its launch from Cape Canaveral Air Force Station in Florida on Dec. 5, the SpaceX Dragon cargo spacecraft was installed on the Earth-facing side of the space station’s Harmony module on Dec. 8 at 6:47 a.m. CST. The 19th contracted commercial resupply mission from SpaceX delivered more than 5,700 pounds of research, crew supplies and hardware to the orbiting laboratory.

One experiment is the Rodent Research-19 experiment, which investigates myostatin and activin — molecular signaling pathways that influence muscle degradation — as possible targets for preventing muscle and bone loss during spaceflight and enhancing recovery following return to Earth. This study also could support the development of therapies for a wide range of conditions that cause muscle and bone loss on Earth.

Another important piece of cargo is the Robotic Tool Stowage, a docking station that allows Robotic External Leak Locator units to be stored on the outside of the space station, making it quicker and simpler to deploy the instruments. The leak locator is a remote-controlled tool that helps mission operators detect the location of an external leak and rapidly confirm a successful repair. These capabilities can be applied to any place that humans live in space, including NASA’s lunar Gateway and eventually habitats on the Moon, Mars and beyond.

Dragon will spend approximately one month attached to the space station before returning to Earth with cargo and research.

On Dec. 9, while traveling approximately 260 miles over the Yellow Sea east of Shanghai, the automated Russian Progress 74 cargo resupply spacecraft docked to the space station’s Pirs docking compartment. The spacecraft carried nearly three tons of food, fuel and supplies to the crew.

The International Space Station is a stepping stone for NASA’s Artemis program that will land the first woman and next man on the Moon. As the only place for conducting long-duration research on how living in microgravity affects living organisms, as well as testing technologies to allow humans to work at the Moon, the space station serves as a unique asset in the effort to establish a sustainable presence on the lunar service and prepare for missions to Mars.

‘Innovation is Not Optional’ Says NASA Chief Technologist

“Innovation is not optional,” says Douglas Terrier, NASA chief technologist, during a talk about innovation at the agency Dec. 3 in Morris Auditorium at NASA’s Marshall Space Flight Center. Terrier said that NASA must continue to be innovative to achieve the agency’s missions and goals for the next 5-10 years, including the 2024 Artemis II Moon landing. He spoke about the importance of innovation for accomplishing NASA missions, fostering economies and improving life around the world. Terrier serves as NASA’s principal advisor and advocate on technology policy and programs, helping plot the strategic direction of the agency’s space technology program. The talk was hosted by the Marshall Center Chief Technologist’s Office. (NASA/Emmett Given)

John Dankanich, Marshall’s center chief technologist, also gave a presentation about NASA innovation. Dankanich discussed types of innovation, barriers and how to overcome the challenges. He emphasized the importance of looking for solutions outside one’s current industry, citing multiple examples, including how a violinist helped a potato chip company produce better chips. As center chief technologist, Dankanich helps prioritize NASA investments in technologies to support future needs of NASA and the U.S. space sector. (NASA/Emmett Given)

Marshall’s Zachary Jones to Deliver Tech Talk Dec. 12

Zachary Jones, left, who works in NASA’s Additive Manufacturing Lab at NASA’s Marshall Space Flight Center, will deliver a combined Tech Talk and “Did You Know Marshall Did That?” presentation Dec. 12 in Building 4203, Room 1201. Jones will discuss the current state-of-the-art additive manufacturing, or 3D printing, capabilities at Marshall and NASA, and how the tools and technologies are being used for future aerospace projects. Both lecture series are hosted by Marshall’s Center Chief Technologist’s Office. Above, Jones and fellow engineer Chris Protz examine the first full-scale 3D-printed copper engine part in the Additive Manufacturing Laboratory in 2015. (NASA/Emmett Given)

Marshall Team, Family Members Usher in Season With Holiday Tree Lighting

NASA’s Marshall Space Flight Center team members usher in the season Dec. 9 with the lighting of the Marshall holiday tree, seen here flanked by the powerful Saturn-era F1 rocket engine in front of Building 4200. The festive crowd, led by David Burns, manager of Marshall’s Science and Technology Office, sipped hot cocoa and enjoyed music by children from the Marshall Child Development Center. (NASA/Daniel Boyette)

At the Marshall holiday tree lighting Dec. 9, Bentley Deemer — the granddaughter of Betty Grisham, a program support specialist in Marshall’s Office of Strategic Analysis and Communications — bends the ear of a certain jolly old elf. St. Nick stopped by for a break from preparing for his Dec. 25 rounds to greet Marshall revelers — many of whom also were taking a break from prepping for Artemis-generation flight tests and other exciting new NASA activities set for next year. (NASA/Emmett Given)

This Week in NASA History: 1st Hot Fire Test of RS-25 with Large 3D Printed Part – Dec. 13, 2017

This week in 2017, NASA engineers completed the eighth and final RS-25 rocket engine hot fire test at NASA’s Stennis Space Center. The engine tested included a large 3D-printed part scheduled for use on future RS-25 flight engines that will power the core stage of NASA’S Space Launch System. The part was a beach ball-sized pogo accumulator assembly that acts as a shock absorber to dampen vibrations, or oscillations, caused by propellants as they flow between the vehicle and the engine. The hardware performed as expected, opening the door for more components scheduled for future tests. Today, NASA’s Marshall Space Flight Center is playing a vital role in the Artemis program by developing the SLS, the backbone of NASA’s exploration plans and the only rocket capable of sending humans to the Moon and Mars. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)