By Jessica Barnett

NASA’s Mars Ascent Vehicle (MAV) recently reached some major milestones in support of the Mars Sample Return program. The Mars Ascent Vehicle would be the first launch of a rocket from the surface of another planet. The team developing MAV conducted successful tests of the first and second stage solid rocket motors needed for the launch.

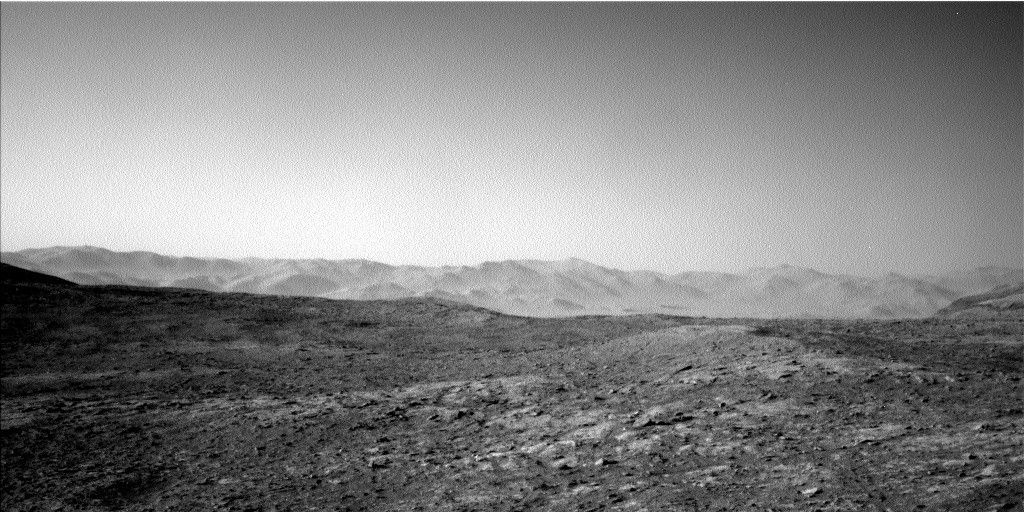

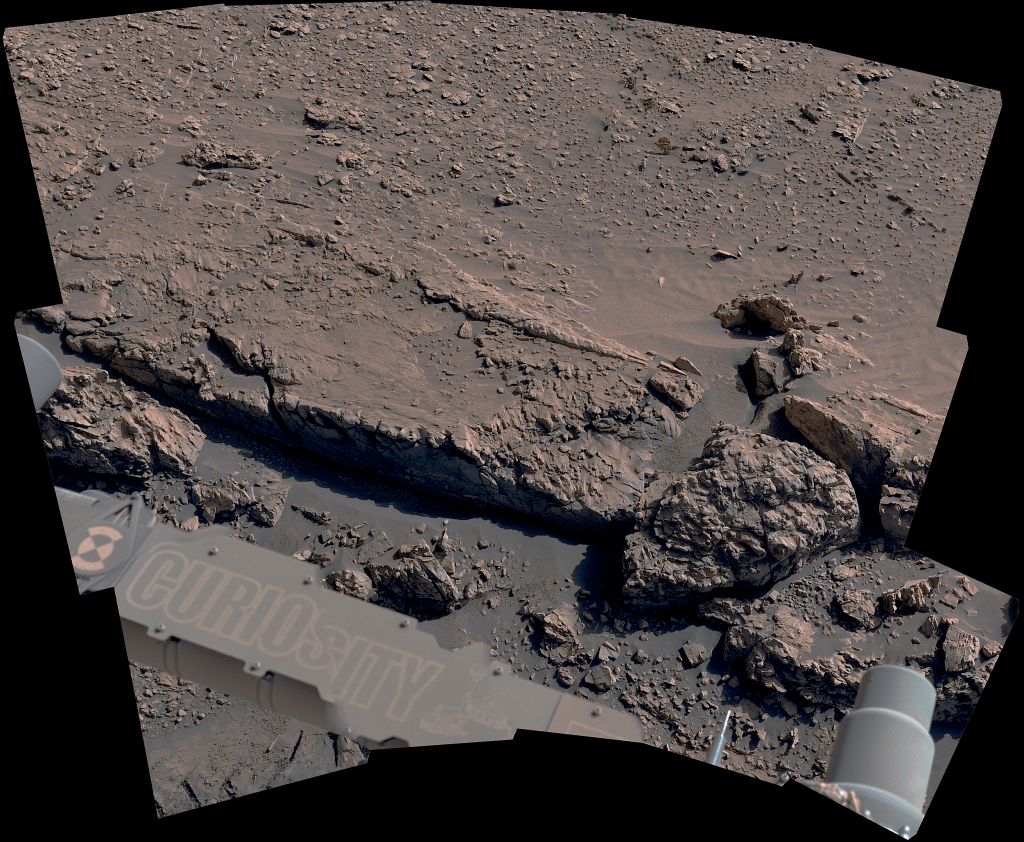

Mars Sample Return will bring scientifically selected samples to Earth for study using the most sophisticated instrumentation around the world. This strategic partnership with ESA (European Space Agency) features the first mission to return samples from another planet. The samples currently being collected by NASA’s Perseverance Rover during its exploration of an ancient river delta have the potential to reveal the early evolution of Mars, including the potential for ancient life.

Managed at NASA’s Marshall Space Flight Center in Huntsville, Alabama, MAV is currently set to launch in June 2028, with the samples set to arrive on Earth in the early 2030s. The Mars Sample Return Program is managed by NASA’s Jet Propulsion Laboratory (JPL) in Southern California.

For the MAV to be successful, the team performs extensive testing, analysis, and review of MAV’s design and components. The vehicle will travel aboard the Sample Retrieval Lander during launch from Earth, a two-year journey to Mars, and nearly a year of receiving samples collected by Perseverance.

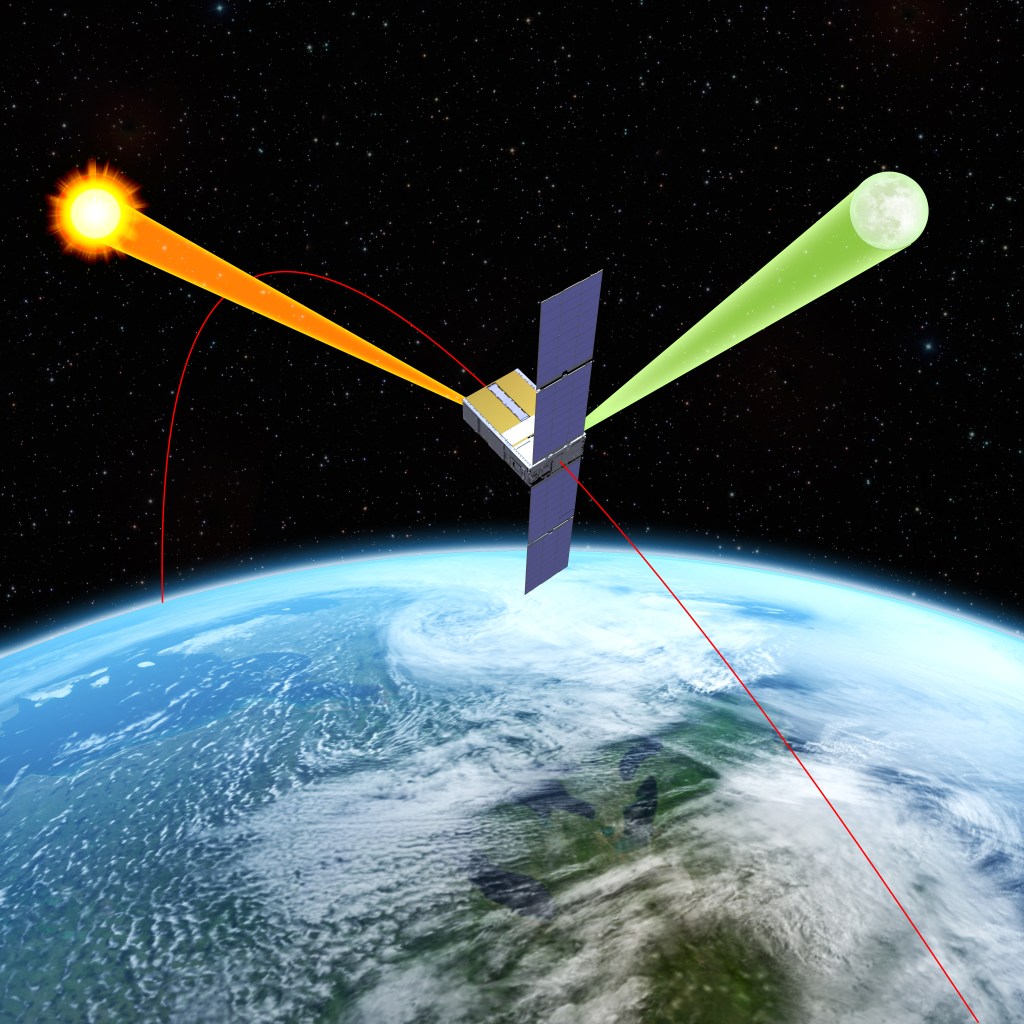

After the Sample Transfer Arm on the lander loads the samples from Perseverance into a sample container in the nose of the rocket, the MAV will launch from Mars into orbit around the planet, releasing the sample container for the Earth Return Orbiter to capture.

The MAV launch will be accomplished using two solid rocket motors – SRM1 and SRM2. SRM1 will propel MAV away from the Red Planet’s surface, while SRM2 will spin MAV’s second stage to place the sample container in the correct Mars orbit, allowing the Earth Return Orbiter to find it.

To test the solid rocket motor designs, the MAV team prepared development motors. This allowed the team to see how the motors will perform and if any adjustments should be made before they are built for the mission. The SRM2 development motor was tested on March 29, 2023, at the Northrop Grumman facility in Elkton, Maryland. Then, SRM1’s development motor was tested on April 7 at Edwards Air Force Base in California.

SRM1’s test was conducted in a vacuum chamber that was cooled to minus-20 degrees Celsius (minus-4 degrees Fahrenheit) and allowed the team to also test a supersonic splitline nozzle, part of SRM1’s thrust vector control system. Most gimballing solid rocket motor nozzles are designed in a way that can’t handle the extreme cold MAV will experience, so the Northrop Grumman team had to come up with something that could: a state-of-the-art trapped ball nozzle featuring a supersonic split line.

After testing and disassembling the SRM1 development motor, analysis showed the team’s ingenuity proved successful.

“This test demonstrates our nation has the capacity to develop a launch vehicle that can successfully be lightweight enough to get to Mars and robust enough to put a set of samples into orbit to bring back to Earth,” said MAV Propulsion Manager Benjamin Davis at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “The hardware is telling us that our technology is ready to proceed with development.”

In fact, the supersonic splitline nozzle has achieved the sixth of nine technology readiness levels – known as TRL-6 — developed by NASA. TRL-1 is the starting point at which there is just an idea for a new technology, while TRL-9 means the technology has been developed, tested, and successfully used for an in-space mission.

Davis said the supersonic splitline nozzle achieved TRL-6 through vacuum bench testing and full-scale hot fire testing in April. Results are being independently evaluated and will be confirmed in August.

The supersonic splitline nozzle will also undergo qualification testing to make sure it can handle the intense shaking and vibration of launch, the near vacuum of space, and the extreme heat and cold expected during MAV’s trip.

In addition to motor testing, the MAV team recently conducted its Preliminary Design Review, which was a four-day, in-depth review of MAV’s overall design. Mars Ascent Vehicle Project Manager Stephen Gaddis said MAV passed that review, which means the team can now focus on continuing to improve MAV before its Critical Design Review next summer.

NASA Marshall is designing, building, and testing MAV along with the project’s two primary contractors, Lockheed Martin Space and Northrop Grumman. Lockheed Martin Space is the overall system integrator and provides multiple subsystems, and Northrop Grumman provides the first stage and second stage main propulsion systems. The Mars Sample Return Program is managed by NASA’s Jet Propulsion Laboratory (JPL) in Southern California.

Learn more about the Mars Sample Return campaign.

Jonathan Deal

Marshall Space Flight Center

jonathan.e.deal@nasa.gov

256-544-0034