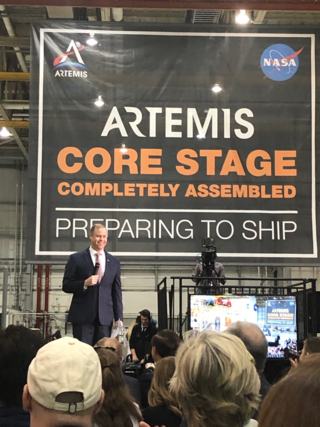

NASA recently celebrated progress towards a future Moon landing with Artemis Day, held Dec. 9, at the Michoud Assembly Facility (MAF) in New Orleans. The 212-ft. Artemis I core stage—now with four RS-25 engines mounted—acted as the backdrop for the main stage event where NASA Administrator Jim Bridenstine declared it “core complete.”

By January, the core stage will be moved by the Pegasus barge over to Stennis Space Center in Mississippi where a “green run” at its B2 test stand will occur mid-2020. This test will verify the core stage components with an 8-minute test fire of the engines. It will then be moved to Kennedy Space Center in Florida to be readied for launch, now projected for 2021. Artemis I is the first uncrewed launch of the Space Launch System and Orion capsule with a planned 25-day mission to orbit the Moon and return. The following mission, Artemis II, will send humans to orbit the Moon.

During the Artemis Day celebration, roughly 800 NASA stakeholders, media and social media toured the facility and viewed exhibits from NASA Centers, commercial companies and universities. NASA Langley showcased several Artemis-themed research and technology areas.

Darlene Pokora, Associate Director for Exploration Systems and Space Operations in the Space Technology and Exploration Directorate (STED) at NASA Langley sums up the experience.

“Being able to participate in Artemis Day at the Michoud Assembly Facility was a fantastic way to showcase Langley’s contributions to the Artemis Program,” said Pokora. “We highlighted wind tunnel testing for SLS, water impact testing for Orion, the Ascent Abort II test for the Orion Launch Abort System, and technologies like Navigation Doppler Lidar, radiation protection, and autonomous in-space assembly capabilities.”

Associate Administrator (AA) for Human Explorations and Operations, Doug Loverro, visited with Langley staffers at length during the event. “Being able to showcase the variety of things we do at Langley,” said Pokora, “all to the NASA Administrator, the HEOMD AA, other NASA Centers and support contractors, as well as social media, while supporting a significant achievement in the Artemis Program – the completion of the SLS Core Stage – made for an exciting day.”

Debi Tomek, Acting Director, Space Technology Exploration Directorate at NASA Langley, participated in an afternoon panel session moderated by Administrator Jim Bridenstine geared towards social media titled, “Artemis in 280 Characters or Less.” When asked what first inspired her to think about NASA as a career path, Tomek answered, “For me, it was seeing my first Space Shuttle launch.”

Technologies Showcased

Invested in Space Radiation Protection

Radiation protection is an enabling technology for future missions. The radiation protection vest is one strategy against secondary radiation as particles pass through the walls of the space structure (vehicle, lander, habitat) and also with the regolith on the surface of the Moon. One element blocks both fast-moving protons and neutrons well—hydrogen. Hydrogen-rich materials, like those used in space radiation vests, will help protect astronauts during the space weather events possibly extending the duration of space missions in the future.

On-Orbit Servicing, Assembly and Manufacturing

Specialized joints and a video showcased Langley’s On-Orbit Servicing, Assembly and Manufacturing research. Building structures in space using autonomous robotic assembly means vehicles and hardware designs are no longer restricted to the size of the rocket launching the payload. Larger truss systems can be assembled on-orbit. Satellites can share infrastructure and resources such as data downlink systems and power from solar panels. Structures on the Moon can be built faster and cheaper by robots, in advance of human missions.

Pinpoint Moon Landings

During the Apollo 11 mission, astronauts Neil Armstrong and Buzz Aldrin realized the lander had overshot its intended landing area by four miles. Navigating a new landing site amid the boulder fields, used more fuel than intended. The famous Moon landing mission was actually only seconds away from a possible abort of the mission entirely. With Navigation Doppler Lidar (NDL), Artemis astronauts will no longer have to worry about that scenario. NDL is a laser-based sensor mounted to the underside of a lunar lander that transmits three laser beams in fixed directions in order to determine velocity and range for the lander. The lidar data is used by an autonomous Guidance, Navigation and Control system to precisely navigate and execute a gentle touchdown on the Moon while providing additional fuel savings.

Orion Water Drop Testing

Langley’s 20-foot-deep Hydro Impact Basin is used for water drop testing to produce necessary data for testing different scenarios for Orion’s parachute-assisted landings, wind conditions, velocities and wave heights that the spacecraft may experience when upon splashdown in the ocean.

Orion Launch Abort System

The Orion Launch Abort System is a safety mechanism for the Orion capsule that will launch atop the Space Launch System. The launch abort system will safely lift the Orion Crew Module away from the launch vehicle in the event of an emergency on the launch pad or during ascent. The launch abort system weighs 16,000 lbs. and houses an abort motor capable of producing 400,000 pounds of thrust.

Space Launch System Wind Tunnel Testing

Wind tunnel testing of the NASA Space Launch System is a cross-agency effort. NASA Langley Jeremy Pinier showcased the Ground Wind Loads 1.75%-scale test model and 3D-printed launch tower model during the event. Pressure data across the model helps refine the rocket’s guidance and control systems during launch.

Meghan Guethe

NASA’s Langley Research Center