By Danielle Sempsrott

NASA’s Kennedy Space Center

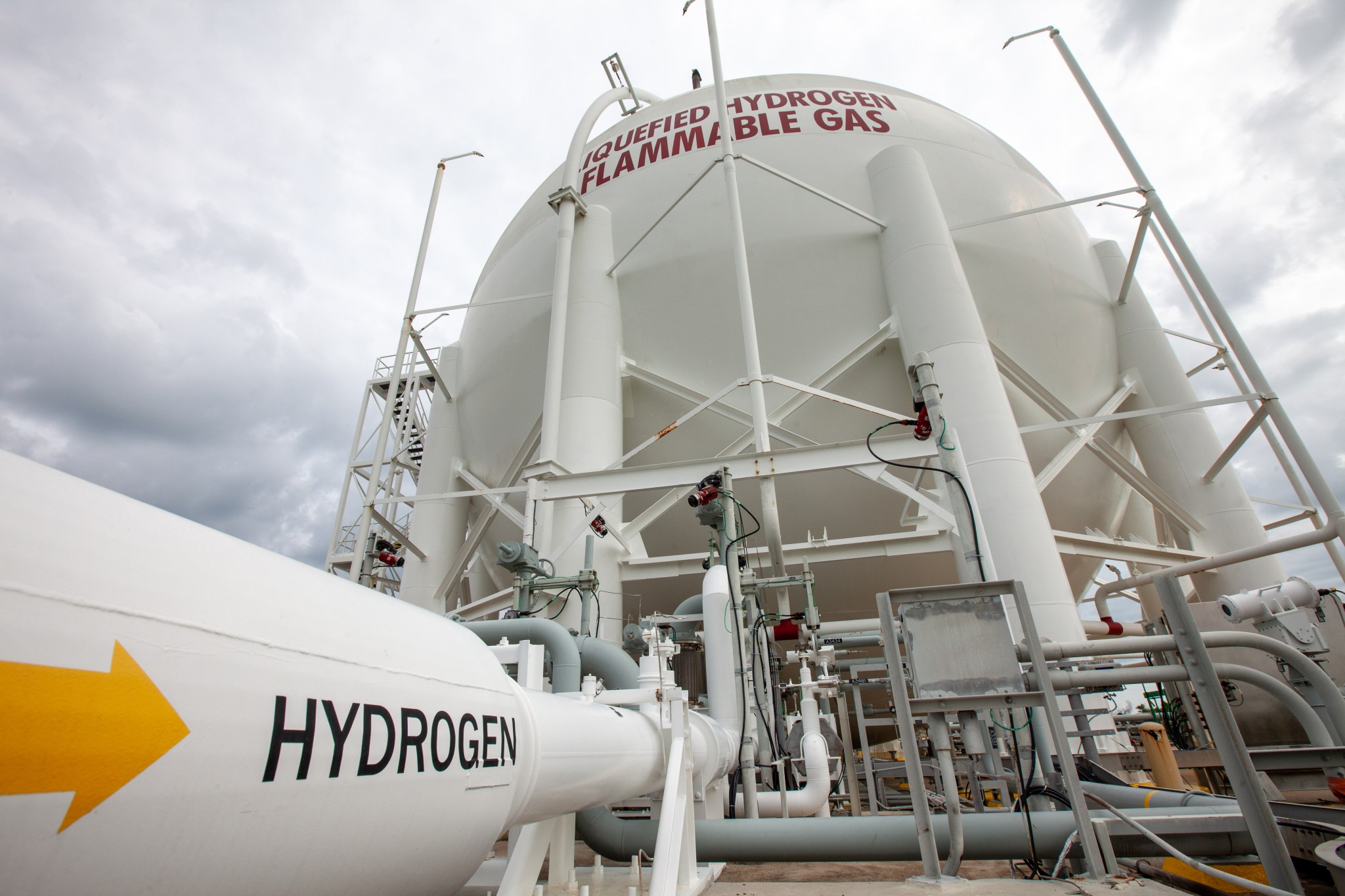

With NASA’s mobile launcher at Launch Pad 39B for final verification and testing, the agency’s Exploration Ground Systems (EGS) team has completed another critical set of tests, bringing the agency even closer to the first integrated launch of the Space Launch System (SLS) rocket and Orion spacecraft for the Artemis I mission. Over the course of two weekends, teams tested the flow of cryogenic fluids through the pad’s infrastructure – those systems that will send liquid hydrogen (LH2) and liquid oxygen (LOX) to the rocket at the time of launch.

“This is the first time that we’ve flown LOX and LH2 through the pad’s systems with the mobile launcher at the pad and with all the interfaces connected,” said Melissa Batis, NASA operations project engineer and EGS integration lead. “Everything worked perfectly. This test was huge in validating and verifying that the ground systems at the pad function with the mobile launcher as they were designed and will be able to support the SLS rocket.”

During launch, LH2 and LOX will flow from storage tanks near the pad – each of which can hold more than 800,000 gallons of propellant – to the mobile launcher’s Tail Service Mast Umbilicals. The umbilicals will connect to the SLS core stage, considered the backbone of the rocket, and contain all of the fluid lines for propellant loading. The cryogenic fluids will travel about 1,800 feet from the storage tanks to the umbilicals via piping referred to as cross-country lines.

The LOX and LH2 storage areas include hardware that was developed for the Apollo program and the Space Shuttle Program, as well as brand-new hardware elements, such as the mobile launcher. These tests demonstrated that the newer and older systems could successfully work together to support fueling of the rocket.

“It was important to couple the two together as one unit – one large LOX unit and one large LH2 unit – and validate that we could provide cryogenic propellant to the umbilicals,” said Kody Smitherman, a LOX system engineer on the Test Operations and Support Contract. “And that’s exactly what we’ve done. We can say we would’ve successfully loaded the rocket if it were present at the pad.”

While LOX and LH2 share some similarities, such as the storage areas they come from and the lines and systems they’ll flow through, they also have major differences. LOX is much heavier than LH2 – around nine-and-a-half pounds per gallon as opposed to half-a-pound per gallon – requiring the need for a pump to create the necessary pressure to push it from the tank to the rocket. The lighter LH2 will make its way up to the pad using gaseous hydrogen to pressurize the tank to begin the flow.

One other difference is how excess LOX and LH2 are handled. Any LOX left over from testing, or any that doesn’t end up going into the rocket, flows to a basin and gets reabsorbed into the atmosphere. LH2 is very flammable and would ignite if released. Any excess LH2 travels to a new 60,000-gallon tank and then out to a flare stack to burn it off.

The test verified the disposal methods for excess fluids, checked for leaks, confirmed that the LOX pumps could perform appropriately and validated that piping on the mobile launcher could handle the extremely cold temperatures of LOX and LH2. The next time these systems are used will be about two months before launch for the wet dress rehearsal, during which the SLS rocket rolls out to the pad completely fueled and drained.

“Proving the ground systems work as expected under cryogenic conditions is critical, and completing this test continues our progress toward the Artemis I launch,” said Charlie Blackwell-Thompson, EGS launch director.

The first in a series of complex missions, Artemis I will demonstrate the agency’s ability to extend human presence to the Moon, paving the way for future missions to Mars. This test was a vital step in validating the infrastructure at Kennedy that will support those launches.