Capabilities

Ames is always looking to further technologies in wind tunnel force transducer science with the goals of improving accuracy, repeatability, and flexibility. We collaborate with our NASA, Government, and Industry colleagues in research, testing, and production to meet these goals.

Single Component Check Loads

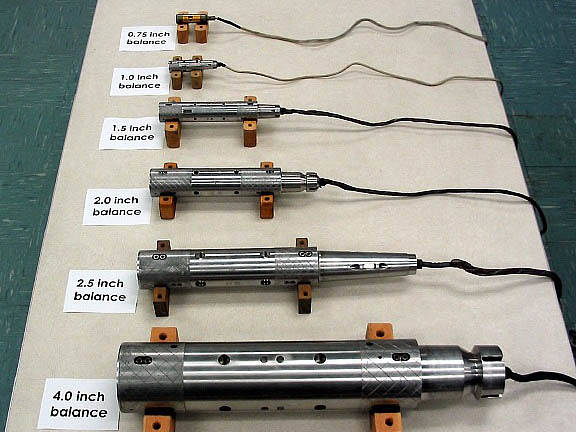

NASA Ames Balance Calibration Laboratory (Bal Cal) is setup to perform single component check loads of internal strain gage balances, from 0.75 to 4.00-inches in diameter. The lab has limited capability to calibrate single element load cells, flow through balances, and custom configurations.

Balance Electrical Checks

The Balance Calibration Lab conducts electrical checks to determine the health of a balance before and after every use. We record the no-load balance output and bridge resistance for each gage.

Calibrated Weights

The lab has an inventory of weights, ranging from 0.5-lbs. to 1000-lbs. The weights are calibrated to 0.03% of quoted value.

Data Acquisition Instrumentation and Computing Analysis

The lab uses National Instruments PXI series of equipment for data acquisition, analysis, and database storage. The data acquisition and control systems can provide accurate, flexible, multi-channel, and continuous acquisition of voltages and temperatures. The systems also have real-time balance monitoring to ensure a balance is always operating under design limits.

Data reduction of strain gage balance calibrations uses the BALFIT analysis software package that was developed at NASA Ames Research Center. The lab performs calibration analysis using industry-wide accepted load iteration procedures (AIAA Recommended Practice R-091-2003) in combination with a recently developed automatic math model selection algorithm. The BALFIT calibration software also performs load envelope analysis of strain-gage balance data.

The BALFIT software package computes a data reduction matrix for a given balance calibration data set. During a wind tunnel test this data reduction matrix is used in combination with a load iteration scheme to compute loads from measured electrical responses.

Force Transducers

The lab also uses calibrated uniaxial load cells with 0.03% full-scale accuracy, with cells varying in range from 1,000-lbs. to 10,000-lbs.

Balance Support Rigs

There are two sting support rigs that can accommodate taper mounted balances from 0.75 to 4.0 inches.

Loading and Balance Hardware

The lab maintains an inventory of roll arms, calibration bodies, axial loading plates, flexures, knife edges, and weight pans for many balance sizes. Also maintained are a number of dummy balance gages and master taper gages.

Position and Angle Sensors

To generate an accurate calibration, both the applied load and its vector must be known accurately. To insure that applied loads are positioned accurately, we enlist an variety of devices depending on the situation. The devices include: 2-axis quartz-flexure (inertial navigation) accelerometer levels with 0.0001 degree resolution, bubble levels with 3 arc second resolution, optical transits with a 2 arc second level line of sight reference and optical grade mirrors and prisms.