In This Week’s Star

- › Some Assembly Required: The Newest RS-25 Joins the Space Launch System Family

- › Steamy Summer Begins for SLS with RS-25 Test

- › High Waves Prompt NASA to Postpone LDSD Launch Until June 4

- › Orion Heat Shield Analysis Work Nears Conclusion at Marshall

- › Marshall Deputy Director Keynotes Tennessee Valley Corridor National Summit

- › X-rays, Blood and Needles: Bobby Hall’s Unique Perspective on 44 Years at Marshall

- › Marshall to Host ‘Take Our Children to Work Day’ June 18

- › Exchange to Host Great Summer Blast June 4

- › SLS Engine Test, Upcoming LDSD Launch Featured On ‘This Week @NASA’

Some Assembly Required: The Newest RS-25 Joins the Space Launch System Family

By Martin Burkey

NASA’s Space Launch System, America’s new deep-space exploration rocket, has a new addition to the family with the completed assembly of RS-25 Engine 2063. The RS-25 engine will power the core stage of the SLS, the launch vehicle that will take humans and cargo on deep space missions, including to an asteroid and ultimately to Mars.

Engine maker Aerojet Rocketdyne completed assembly of RS-25 Engine 2063 at NASA’s Stennis Space Center after approximately three months of work. The new engine becomes the 16th assembled RS-25 flight engine in inventory for SLS flights. It will be one of four RS-25s used to power Exploration Mission 2, the second SLS launch targeted for the 2021 time frame. Testing of these four engines will begin later this year as work accelerates on NASA’s newest launch vehicle.

While SLS is designed for deep-space exploration far beyond Earth, it’s also designed to take advantage of the investments the nation has already made in space exploration, including the RS-25.

Fourteen of the 16 RS-25 engines in the SLS inventory are veterans of numerous space shuttle missions, where they were commonly referred to as space shuttle main engines, or SSMEs. Engine 2063 is one of two additional “rookie” engines without previous shuttle flight experience. Engine 2063 will undergo acceptance testing to verify it is acceptable for flight, checking out the completed system. It does include some previously flown hardware, including the four turbopumps which have flown on several shuttle missions.

“Assembly of this new engine is part of a very busy year for the RS-25 team,” said Steve Wofford, manager of the SLS Liquid Engines Office at NASA’s Marshall Space Flight Center, where the SLS Program is managed for the agency. “We’re testing one engine, developing a new controller and planning to manufacture new engines in the future.”

Engine 2063 joins a famous family with a proud tradition. The RS-25 is one of the most tested large rocket engines in history, with more than 3,000 starts and over a million seconds of total ground test and flight firing time over 135 missions.

Four RS-25 liquid propellant engines will power the SLS for the eight-minute climb to orbit with the help of two solid propellant boosters — both flight-qualified components of the Space Shuttle Program and now essential to SLS’s unmatched payload capability.

Read the full story, and watch a time-lapse video of the engine assembly here.

Burkey, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Steamy Summer Begins for SLS with RS-25 Test

A billowing plume of steam signals a successful, 450-second test of the RS-25 rocket engine May 28 at NASA’s Stennis Space Center. The hotfire test was conducted on the historic A-1 test stand, where Apollo Program rocket stages and Space Shuttle Program main engines also were tested. RS-25 engines tested on the stand will power the core stage of NASA’s new rocket, the Space Launch System, which is being developed to carry humans deeper into space than ever before, including to an asteroid and ultimately to Mars. NASA’s Marshall Space Flight Center manages the SLS Program for the agency. RS-25 testing is set to continue through the summer. For more information on the test, click here. (NASA/Stennis)

High Waves Prompt NASA to Postpone LDSD Launch Until June 4

By Kim Newton

Mission managers postponed the second launch attempt, scheduled for June 3, of a high-altitude balloon carrying NASA’s Low Density Supersonic Decelerator test vehicle due to unfavorable ocean conditions. The next launch opportunity is June 4, no earlier than 12:30 p.m.

The ocean wave height continues to be an issue for the crew that would recover the vehicle and its data after splashdown. The first test, scheduled for June 1, was also postponed due to similar concerns.

LDSD test success requires an intricate set of events, including use of a high-altitude balloon, rocket engines, an aeroshell and multiple supersonic decelerators. The LDSD crosscutting technology demonstration mission will test breakthrough technologies that will enable larger payloads to be landed safely on the surface of Mars or other planetary bodies with atmospheres, including Earth.

The project is led by NASA’s Jet Propulsion Laboratory. It’s supported by NASA’s Marshall Space Flight Center, which manages the project as part of the Technology Demonstration Missions program for NASA’s Space Technology Mission Directorate.

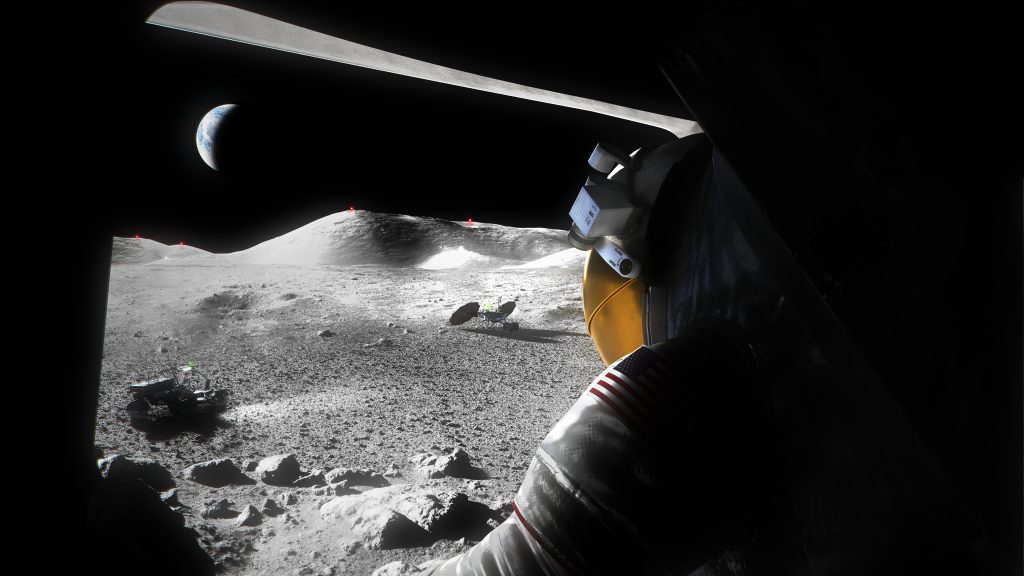

Orion Heat Shield Analysis Work Nears Conclusion at Marshall

By Rick Smith

The harsh buzz of powered cutting tools reverberates in the close air of Building 4705 at NASA’s Marshall Space Flight Center as a dozen or so technicians and engineers work to remove burnt ablative material — the incinerated outer layer of a spacecraft’s heat shield — from the massive, dish-shaped structure at the center of the facility.

The team includes researchers from three NASA field centers — Marshall, Ames Research Center and Johnson Space Center — and prime contractor Lockheed Martin, all of which support development of the Orion crew module, which will carry future astronauts on missions to an asteroid and on toward Mars. Lockheed Martin built Orion and its heat shield for the agency.

Since May 4, the workers have clustered in this expansive Marshall test space to remove for analysis the last 180 or so small squares of an ablative material called Avcoat. That’s the outer coating of Orion’s 16.5-foot-diameter heat shield, charred during the successful Exploration Flight Test-1 in late 2014. Many of the squares contain sophisticated sensors, designed and fabricated at Ames and used to collect critical entry environment and thermal protection performance data as Orion made its fiery reentry and splashed into the Pacific Ocean.

The delicate nature of those sensors is a key reason this facility was tapped to conduct the Avcoat removal work, said Marshall engineer Matthew Pruitt, who leads the milling effort.

State-of-the-art capabilities

Upon arrival at Marshall March 9, the heat shield was delivered to Building 4705, which houses the state-of-the-art, seven-axis milling and machining facility. The seven-axis machine, built for NASA by Ingersoll Machine Tools, uses precision, computer-aided tools able to fluidly maneuver in a variety of ways to manufacture parts and cut large metal or composite materials or structures. It is the largest such machine in the world — other than its twin, which currently supports next-generation aerospace work at NASA’s Michoud Assembly Facility.

The seven-axis machine boasts a fixed, rotating “table,” Pruitt said, which enables researchers to easily inspect and conduct work on large-scale structures such as the 5,000-pound heat shield. Also in use is a heavy piece of Lockheed Martin Ground Support Equipment which enables the heat shield to be suspended at any angle for ease of access — and helps minimize impacts to the vehicle that might have been caused in the past by large-scale loaders or lifting clamps.

Improved handling techniques help minimize the analysts’ need to separate actual material ablation and other effects of atmospheric entry and descent from damage caused after its return to Earth. “That’s essential for this kind of work, where the physical condition of the heat shield is crucial to understanding the impact of reentry on the material,” Pruitt said.

The integrity of the data is vital to researchers studying high-speed flow and burn characteristics, agreed Dr. Deepak Bose, senior scientist in Ames’ Space Technology Division. His team, which leads the analysis effort, must be able to trust and properly interpret the empirical data provided by the heat shield to accurately compare those findings to NASA’s ablation models, validating or refining them for future missions.

How much of the ablative material burned off? Where? Why? These are questions Bose and his team ask during analysis, he said, “to refine our ability to deliver state-of-the-art thermal protection systems that will keep our astronauts and spacecraft safe on their journeys.”

He points to one of the charred Avcoat squares being cut free by workers in protective white suits. “The answers start there,” he said.

Once the team removes the final pieces by hand, all those sensors and chunks of ablated material will be secured for shipping to Ames and other NASA facilities for study over the next six months or so, Bose said. The findings then will be presented to the wider Orion program team, helping guide development of the next flight test vehicle.

Meanwhile, the stripped heat shield will be readied for transfer to NASA’s Langley Research Center for water-impact testing.

Pruitt is proud of the team, as it carries on developing Orion for human explorers. “This has been an example of world-class machining work by an expert team,” he said.

Orion will launch atop the Space Launch System, the nation’s heavy-lift rocket now in development. Visit NASA on the Web for more information about Orion, its flight test and NASA’s journey to Mars.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Deputy Director Keynotes Tennessee Valley Corridor National Summit

Teresa Vanhooser, deputy director of NASA’s Marshall Space Flight Center, keynotes the Tennessee Valley Corridor National Summit May 27 at East Tennessee State University in her hometown of Johnson City, Tennessee. The Tennessee Valley Corridor Inc. is a science and technology collaborative fostering partnerships between major universities, the Department of Energy, NASA, NOAA, the Tennessee Valley Authority, various DOD research and engineering facilities, major corporate partners and the South’s highest concentration of scientists, engineers and Ph.D.s in North Carolina, Virginia, Tennessee, Kentucky and Alabama. Marshall has been a sponsor for the annual National Summit since 2000. The summit brings together science and technology stakeholders from different backgrounds and provides an opportunity for collaboration.

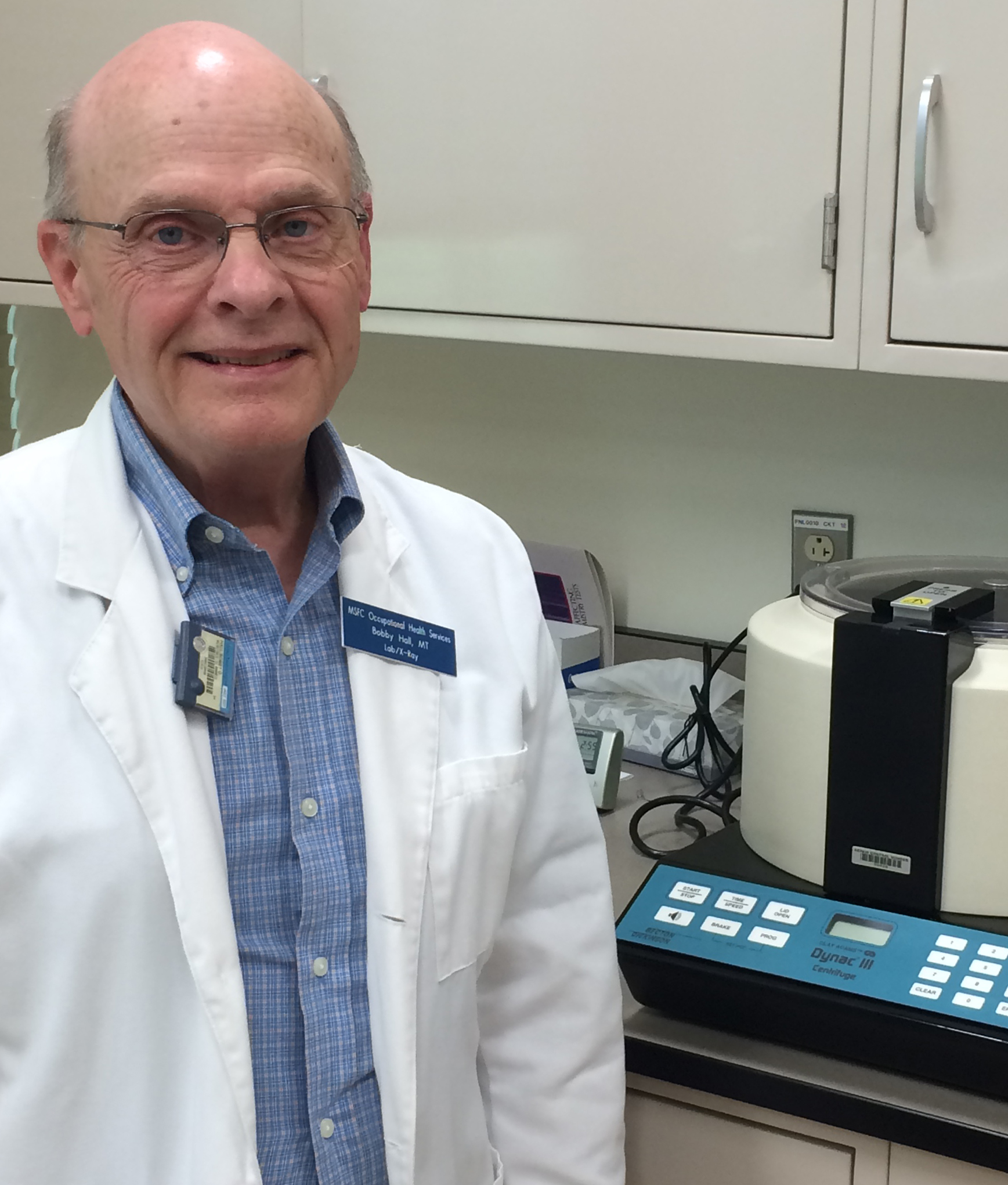

X-rays, Blood and Needles: Bobby Hall’s Unique Perspective on 44 Years at Marshall

By Brian C. Massey

For most people, a trip to the doctor’s office is filled with anxiety and fear. Most of these fears revolve around needles and the perceived pain of giving blood.

For NASA’s Marshall Space Flight Center team members, Bobby Hall has been helping calm those fears for the last 44 years. Hall is the X-ray/lab technologist at Marshall’s Medical Center and has one of the most unique reputations at Marshall — Bobby Hall is the man who can painlessly draw blood.

Hall himself admits that it’s not the same for everybody. “I’ve had people say it hurts, but most say they didn’t even feel the needle,” he said.

Just walking into Hall’s lab puts his patients at ease. With his calm, gentle demeanor, he takes pride in being the technologist that Marshall team members can feel comfortable with. “I try to treat every patient the way I would want to be treated,” he said. “I don’t ‘stab’ people or use my elbow to insert the needle. I just use my fingers with a delicate touch. I do it quickly.”

Since coming to Marshall in March 1971, Hall has spent every day in the same lab, and he has seen a lot. “When I first started here, it was the tail end of the Apollo program,” he said. “A lot has changed since then.”

From the Apollo missions through today, Hall has had a front-row seat to spaceflight history from a very unique perspective. From his lab, he’s seen it all. On average, 18-20 Marshall team members visit Hall and the Medical Center everyday. He has been part of every Marshall program for over four decades.

In addition to his busy workload, he has also drawn blood from volunteers for Skylab and Spacelab experiments, and even examined an injured astronaut and a visiting Miss USA in his time at Marshall.

In 1992, NASA presented Hall with the Space Flight Awareness Honoree Award — one of the highest awards presented to NASA and industry employees. He and his wife, Glenda, travelled to Kennedy Space Center where they were honored as special guests at the launch of STS-50.

Born in Huntsville, Hall was raised on a farm in Farley, Alabama. Before his junior year in high school, his family moved to Boonshill, Tennessee. After many doctor and hospital visits with his ill father, Hall, who had always received very good grades in biology and chemistry, first began to consider a career in healthcare.

After graduating from Mid-State College of Medical Arts in Nashville, Tennessee, he spent a year working in Tennessee before returning to Huntsville to be closer to his father, who had since sold the family dairy farm. Three years later, Hall accepted a position at Marshall, where he’s been ever since.

“It’s been a good career here. I think I’ve done a lot of things that have been helpful to the Marshall family over the years,” Hall said.

He has done just that. Hall’s reach at Marshall goes much farther than his calming presence and painless blood draws. The lab work and X-rays he has performed have helped keep Marshall team members healthy. The routine, yearly exams of team members have helped diagnose cases of leukemia, cancer and diabetes before symptoms presented. This early detection is something the quiet Hall is very proud of, but he’s not one to brag.

“That’s just my job,” he said. “I’ve always had a good relationship with the doctors and medical directors here at Marshall. They trust my ability to turn out good results. I just want to make sure that to the best of my ability I do a good job.”

This month will be Hall’s last at Marshall. July will bring a new chapter for him and his family as he plans to retire. If you ask Hall about his post-Marshall plans, his ever-present smile will only grow as he talks about his five grandchildren and his and his wife’s possible travel destinations. It’s an exciting time for Hall.

“I have really enjoyed it,” he reflects. “I’ve enjoyed being part of this great family that does so many amazing things.”

Massey, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall to Host ‘Take Our Children to Work Day’ June 18

NASA’s Marshall Space Flight Center will host “Take Our Children to Work Day” June 18. Registration opens June 3.

Marshall civil service employees and contractors are encouraged to bring their children, grades 3-12, to the center to participate in a series of fun, hands-on, educational activities and to learn more about the interesting and exciting work accomplished here.

To register, click here. A complete agenda will be posted to ExplorNet soon.

The theme this year is “#MPOWR — Knowledge + Choice = Strength.” The annual, centerwide event is designed to inspire and empower the next generation of young people, raising their interest in studies and careers in the STEM fields: science, technology, engineering and mathematics.

For more information, contact Abbie Johnson in Marshall’s Office of Diversity and Equal Opportunity, at 256-544-0014 or abbie.j.johnson@nasa.gov.

Exchange to Host Great Summer Blast June 4

On June 4, NASA Marshall Space Flight Center’s Exchange will host the Great Summer Kickoff Blast at the Wellness Walking Trail from 2:30-6 p.m.

Free food and drinks will be provided, including hamburgers, hotdogs, ice cream and funnel cakes. There will also be vegan hamburger options, beer and wine, while supplies last.

Planned as a relaxed afternoon full of fun and food, the Great Summer Kickoff will be highlighted by bingo, an all-star softball game, corn hole, volleyball and a homemade ice cream contest.

There will be two, one-hour bingo sessions, beginning at 3 p.m. and 4:30 p.m. The entry fee for each session is $5 per person and each session should include seven to eight games per session.

Also, there will be a homemade ice cream contest. For more information about the contest and to sign up, click here.

The event will be held under the shade trees and tents in the walking area behind the wellness center. In the event of inclement weather, the activities center will be used as a rain location.

SLS Engine Test, Upcoming LDSD Launch Featured On ‘This Week @NASA’

The testing of an RS-25 engine and the upcoming launch of NASA’s Low-Density Supersonic Decelerator project were featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

Engineers at NASA’s Stennis Space Center conducted a 450 second test of an RS-25 engine on the A-1 test stand. Four RS-25 engines will power the Space Launch System rocket. This was the second in the current series of test firings to investigate how the RS-25 stands up to the rigors and specific requirements needed to boost the massive SLS core stage. Six more tests are planned for the current cycle of development.

Also featured was the second flight test of NASA’s Low-Density Supersonic Decelerator project, scheduled for no earlier than June 4 from the U.S. Navy’s Pacific Missile Range Facility in Hawaii. The test, which simulates a supersonic entry and descent through the Martian atmosphere, is helping researchers investigate breakthrough technologies for landing future robotic and human Mars missions and safely returning large payloads to Earth.

View this and previous episodes at “This Week @NASA” or at https://www.youtube.com/user/NASAtelevision.