In This Week’s Star

- FY 2018 Budget All-Hands Meeting Set May 23 with NASA Acting Administrator Robert Lightfoot and Marshall Center Director Todd May

- First SLS Core Stage Structural Test Article Arrives from Michoud, Team Members Invited to View Hardware

- NASA Affirms Plan for First Mission of SLS, Orion

- Astronauts Complete 200th Space Station Spacewalk

- Marshall Engineers Successfully Test Major Part of Orion Launch Abort System

- NASA Continues Testing, Manufacturing World’s Most Powerful Rocket

- Marshall’s World-class Metrology and Calibration Laboratory to Host Open House May 19

- Astronomers Pursue Renegade Supermassive Black Hole

- Winners Announced for NASA, Orbital ATK Rocketry Challenge

- This Week in NASA History: Skylab Launches — May 14, 1973

- Obituaries

FY 2018 Budget All-Hands Meeting Set May 23 with NASA Acting Administrator Robert Lightfoot and Marshall Center Director Todd May

By Brian C. Massey

NASA’s Marshall Space Flight Center team members are encouraged to attend a viewing of NASA Acting Administrator Robert Lightfoot’s televised agency budget address at 11:30 a.m. and participate in an all-hands meeting with Marshall Center Director Todd May at 11:45 a.m. on May 23 in Morris Auditorium, Building 4200.

Following Lightfoot’s address, May will discuss Marshall’s fiscal year 2018 budget and how it will advance space science and exploration and enable NASA’s Journey to Mars.

Marshall team members unable to attend can watch both Lightfoot’s address and the all-hands meeting live on Marshall Desktop TV. Lightfoot’s address will also be carried live on NASA TV. May will answer questions from the audience and questions submitted by email at the all-hands. To submit a question by email, click here.

Following the all-hands meeting, NASA will host a number of Facebook Live streaming videos from each NASA center discussing the work enabled by the budget. More information about the live streaming videos will be posted on NASA and Marshall’s Facebook pages.

Massey, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

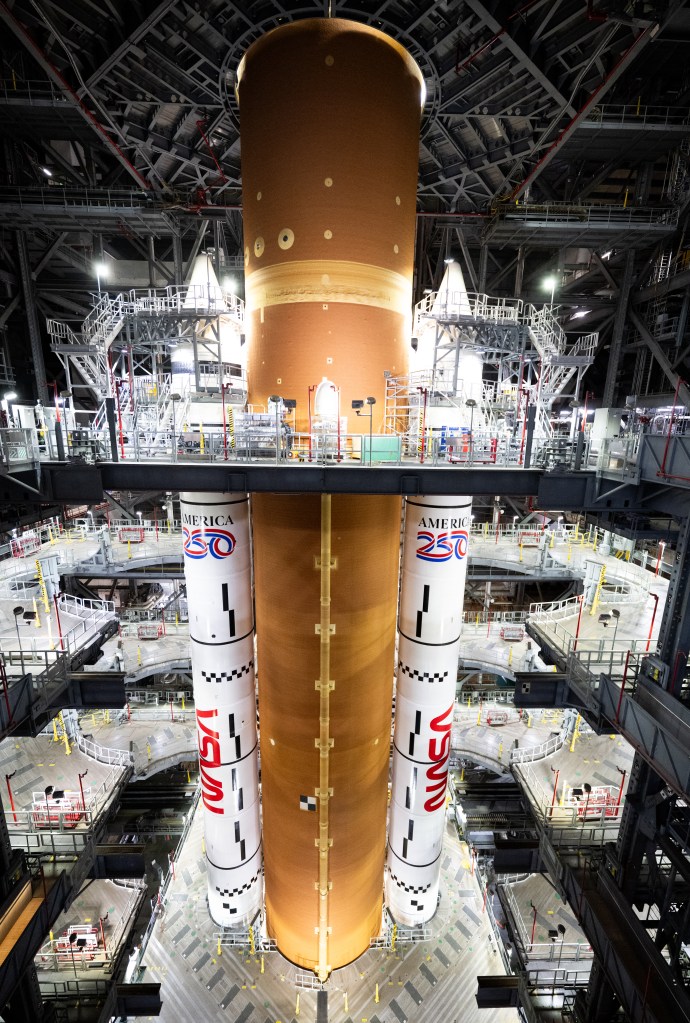

First SLS Core Stage Structural Test Article Arrives from Michoud, Team Members Invited to View Hardware

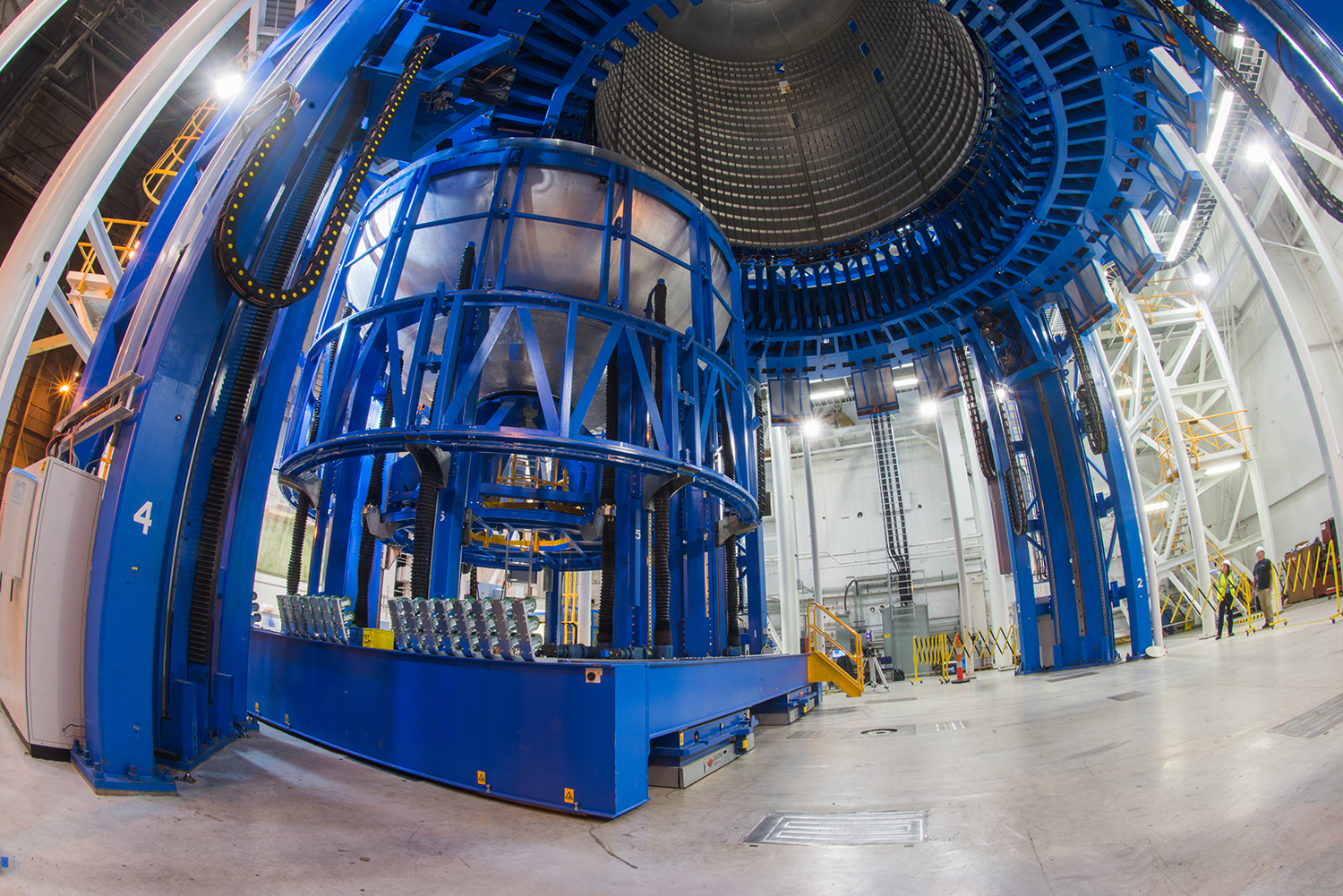

The core stage engine section structural test article for NASA’s new heavy-lift rocket, the Space Launch System, arrived May 15 at NASA’s Marshall Space Flight Center from NASA’s Michoud Assembly Facility after an 18-day voyage aboard the barge Pegasus. The engine section, located at the bottom of the rocket’s core stage, will house the four RS-25 engines and be an attachment point for the two solid rocket boosters. The test article is the first of four core stage test articles manufactured at Michoud that will be delivered to Marshall for testing. Marshall team members are invited to view the engine section structural test article at 9:30 a.m. May 19 in Building 4619, located at the corner of Rideout and Fowler roads. For more information about the employee event, visit the SLS group page on ExplorNet. (NASA/MSFC)

NASA Affirms Plan for First Mission of SLS, Orion

In February, NASA began an effort looking at the feasibility of putting crew aboard the first integrated flight of the Space Launch System rocket and Orion spacecraft — Exploration Mission-1, or EM-1. After weighing the data and assessing all implications, the agency will continue pursuing the original plan for the first launch, as a rigorous flight test of the integrated systems without crew. However, engineers will apply insights gained from the effort to the first flight test and the integrated systems to strengthen the long-term push to extend human presence deeper into the solar system.

NASA determined it is technically capable of launching crew on EM-1, but after evaluating cost, risk and technical factors in a project of this magnitude, it would be difficult to accommodate changes needed to add crew at this point in mission planning. The effort confirmed that the baseline plan to fly EM-1 without crew is still the best approach to enable humans to move sustainably beyond low Earth orbit.

“We appreciate the opportunity to evaluate the possibility of this crewed flight,” said NASA acting Administrator Robert Lightfoot. “The bi-partisan support of Congress and the President for our efforts to send astronauts deeper into the solar system than we have ever gone before is valued and does not go unnoticed. Presidential support for space has been strong.”

Exploration Mission-1 is the first in a broad series of exploration missions that will take humans to deep space, and eventually to Mars. It is designed to be a flight test of our entire system — one that is challenging in itself and will offer the opportunity to better understand our capabilities and limitations and ultimately build confidence in our ability to safely send crew into deep space.

“We’re considering additional ground testing of the heat shield prior to EM-1 as well as the possibility of advancing the ascent abort test for the Orion launch abort system based on findings from the study,” said William Gerstenmaier, associate administrator for NASA’s Human Exploration and Operations Mission Directorate. “Conducting these tests in advance of EM-1 would provide additional data that will advance our systems knowledge faster and possibly improve the robustness of the overall plan for sending humans into deep space.”

As part of the assessment, NASA also reviewed the schedule for EM-1, including production schedules across the enterprise, anticipated budgets and appropriations, projected delivery of the European Service Module, first time production issues related to the core stage that is at the leading edge of new manufacturing, and the ongoing impact of the February tornado that directly affected the Michoud Assembly Facility. As a result of these factors, NASA will adjust the target launch date for the EM-1 mission to 2019, and will execute its normal process in the coming weeks to determine an official revised launch date.

NASA continues to keep each part of the enterprise — Orion, SLS, and ground systems — moving at their best possible pace toward the first integrated test mission. While components for EM-1 are being delivered, contractors can turn to the next phase of their work for the second flight, Exploration Mission-2, which will carry crew beyond the moon.

Flight hardware for SLS and Orion is currently in production for both the first and second missions, and progress continues across the country. The SLS engine section structural test hardware has arrived by barge at NASA’s Marshall Space Flight Center for testing, a series of engine tests is taking place in Mississippi, and the Orion abort attitude control system was tested in Maryland. An abort motor for the launch abort system will soon be tested in Utah, and avionics systems for the Orion European Service Module have been integrated into the Orion testing laboratory near Denver. Meanwhile at the Kennedy Space Center, Orion’s heat shield is being installed, and ground systems and software continue development. In addition, deep-space habitation and propulsion system development activities also are underway and life support and related technologies are being tested 250 miles above the Earth aboard the International Space Station now.

“We are building both systems and supporting infrastructure to ensure a sustained cadence of missions beginning with EM-1 and continuing thereafter,” said Lightfoot. “NASA will continue to work with the Administration and Congress as we move toward a crewed flight test on EM-2 and, right now, we are very focused on accomplishing the EM-1 flight test.”

NASA continues to lead the way in sending humans into deep space beyond the moon through building a flexible, reusable and sustainable capability and infrastructure that will last multiple decades and support missions of increasing complexity. This infrastructure will be available for use by others both domestic and international as they want to join in the effort to advance human presence into the solar system. These systems create an incredible capability from which future generations will continue to benefit.

Astronauts Complete 200th Space Station Spacewalk

NASA astronauts Peggy Whitson and Jack Fischer completed a four-hour spacewalk on May 12, replacing a large avionics box that supplies electricity and data connections to science experiments. The astronauts also completed additional tasks to install a connector that will route data to the Alpha Magnetic Spectrometer, repaired insulation at the connecting point of the Japanese robotic arm and installed a protective shield on the Pressurized Mating Adapter-3. This adapter will host a new international docking port for the arrival of commercial crew spacecraft. Spacewalkers have now spent a total of more than 1,247 hours working outside the station during 200 spacewalks in support of assembly and maintenance of the orbiting laboratory. The first space station spacewalk was conducted Dec. 7, 1998, by NASA astronauts Jerry Ross and Jim Newman during space shuttle Endeavour’s STS-88 mission. (NASA)

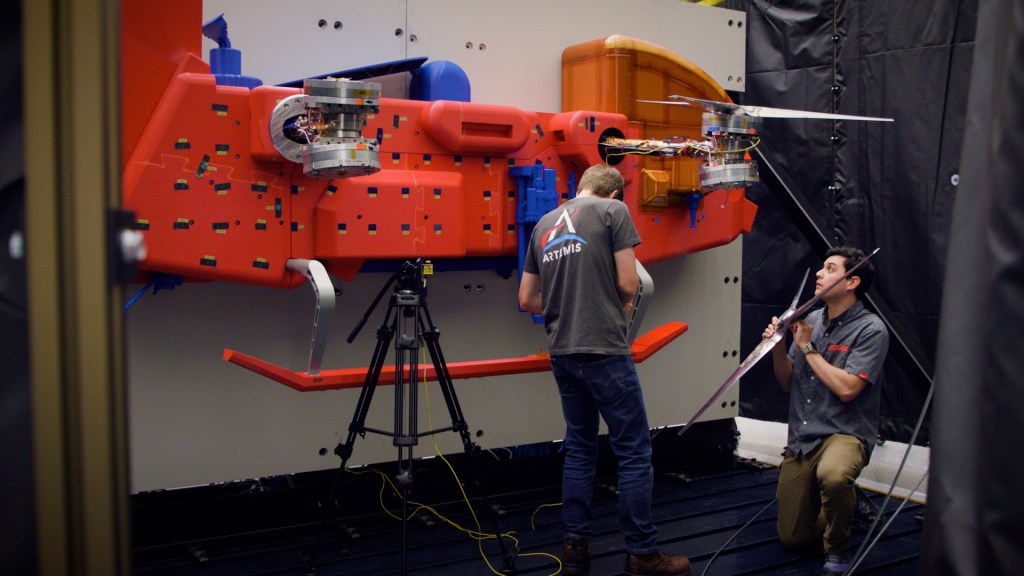

Marshall Engineers Successfully Test Major Part of Orion Launch Abort System

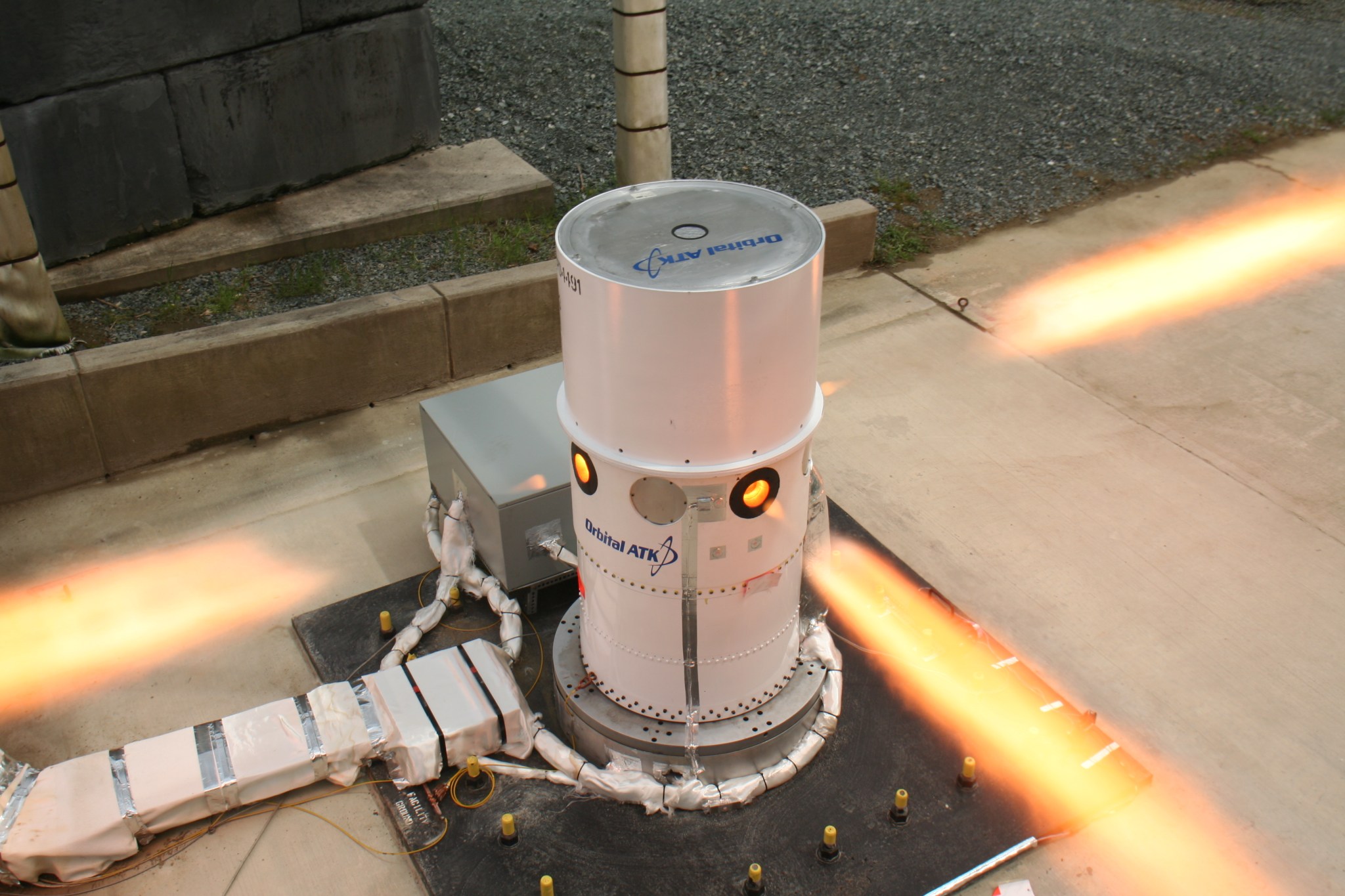

Engineers with NASA’s Marshall Space Flight Center; the Lockheed Martin Corp., of Bethesda, Maryland; and Orbital ATK of Dulles, Virginia, helped take a step forward when it comes to the safety of astronauts that will fly on NASA’s Space Launch System.

A motor designed for the Launch Abort System on the Orion spacecraft was successfully tested at Orbital ATK’s facility in Elkton, Maryland, on April 27.

“The Launch Abort System provides an important capability,” said Ben Davis, acting Launch Abort System propulsion lead at Marshall. “It provides an abort capability to safely transport the Orion crew module away from the launch vehicle stack in the event of an emergency on the launch pad or during ascent.”

Marshall engineers provided propulsion expertise for the Launch Abort System project office at NASA’s Langley Research Center, and were involved in the planning and execution of the test.

The motor tested was a subscale version of the attitude control motor, consisting of a solid propellant gas generator with three valves around the outside of the 3-foot diameter motor. The flight configuration of the attitude control motor will feature eight valves. Together, the valves can exert up to 7,000 pounds of force to steer the vehicle in any direction as commanded by the Orion spacecraft.

This is a critical safety enhancement of Orion for NASA’s mission to explore deep space. This motor, along with the crew capsule, will launch on the second integrated flight of Orion and the SLS rocket, which is managed at Marshall.

NASA Continues Testing, Manufacturing World’s Most Powerful Rocket

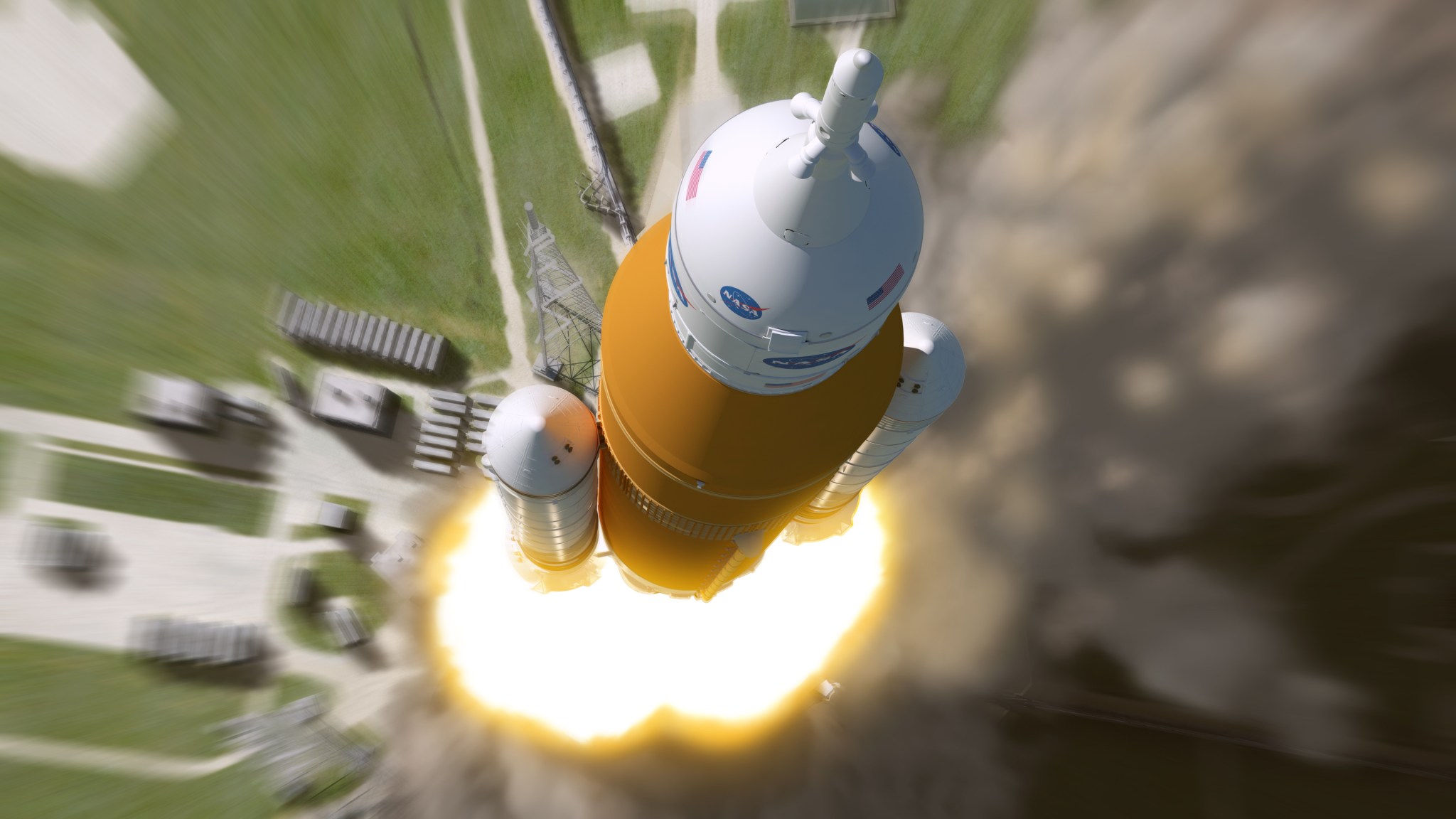

NASA’s Space Launch System rocket will launch crew and massive amounts of cargo to deep space including missions to Mars. Before launching the world’s most powerful rocket the first time, each part of SLS must undergo numerous tests to ensure the rocket and its components have been designed, manufactured and integrated to withstand the stresses of launch.

The heavy-lift rocket for the first integrated flight with the agency’s Orion spacecraft is a foundation for all future SLS configurations. NASA recently completed a major test series on hardware for the upper part of the rocket. A test article of the rocket’s core stage engine section arrived recently by barge at NASA’s Marshall Space Flight Center, for a qualification test series. The engine section is the first of four core stage test articles manufactured and is designed to the specifications needed for launch.

“Completing these SLS structural tests puts NASA one step closer to the launch pad,” said John Honeycutt, the SLS Program manager at Marshall. “Our upcoming core stage testing will continue the largest testing campaign for a NASA rocket since the space shuttle.”

Building new hardware

In addition to shipping the completed engine structural test article this month, the liquid hydrogen tank structural test article manufacturing is also complete. It is being equipped before heading to Marshall for testing later this year. Finally, the flight intertank structural assembly is also nearly finished and will soon undergo application of thermal protection systems.

While NASA is making significant progress overall with SLS to prepare for deep-space exploration, the agency is overcoming production delays at the Michoud Assembly Facility due to tornado damage and the learning curve for first-time operations. As schedules are adjusted to account for tornado recovery, the processes for friction stir welding are also under evaluation to validate performance of the weld process over time. This assessment will help engineers to duplicate their process for long-term production, and will ensure flight hardware made-to-date is consistent with requirements.

During recent manufacturing of the liquid oxygen tank test article in Michoud’s Vertical Assembly Center, the rear or aft dome was inadvertently damaged during pre-weld preparations. This occurred before the dome was welded to the rest of the test article. NASA and the Boeing Co. of Chicago formed independent mishap investigation teams to evaluate the incident. No personnel were injured, and assessments are ongoing to ensure this doesn’t happen again.

“Small things from the tiniest screws to each weld matter,” said Honeycutt. “Our engineers are learning as we work with Boeing to tackle challenges from aligning robotic weld machines off by as little as the width of a paperclip to addressing the fact that tiny threads on welding pins affect weld strength. We’re working together to ensure critical flight hardware is handled safely in the factory and as it is moved thousands of miles by ships, trains and planes.”

New tools and techniques

Making a world-class evolvable rocket for the first time is challenging, Honeycutt added. The 212-foot-tall core stage uses four RS-25 engines to power SLS, and is the largest rocket stage NASA has ever manufactured and it will power all SLS rocket configurations. The agency is using innovative tools and new techniques and processes not only to build SLS, but also to transport it inside and outside the factory at Michoud Assembly.

“We are advancing U.S. leadership in manufacturing while building and testing a powerful rocket that meets the quality and safety criteria needed to take humans farther in space than we’ve ever traveled before,” said Honeycutt.

NASA and Boeing, the agency’s prime contractor for SLS, have done extensive work to develop weld parameters and processes for making the first-of-their-kind large fuel tanks.

“Production of the fuel tank pushes the state-of-the-art for self-reacting friction stir welding of thicker materials,” said Steve Doering, the SLS stages manager at Marshall. “This is the first time robotic self-reacting friction stir weld technology has built such large rocket parts with thicker joints. We’ve learned a lot as we work through processes to get weld parameters for the large fuel tanks adjusted to produce high-quality welds that can withstand the extreme forces of launch and spaceflight.”

By establishing repeatable manufacturing processes now, NASA will evolve SLS to meet a variety of mission needs as America moves deeper into the solar system. All the work done across the country now will support for the agency’s series of planned missions beyond the moon in the future.

Marshall’s World-class Metrology and Calibration Laboratory to Host Open House May 19

By Rick Smith

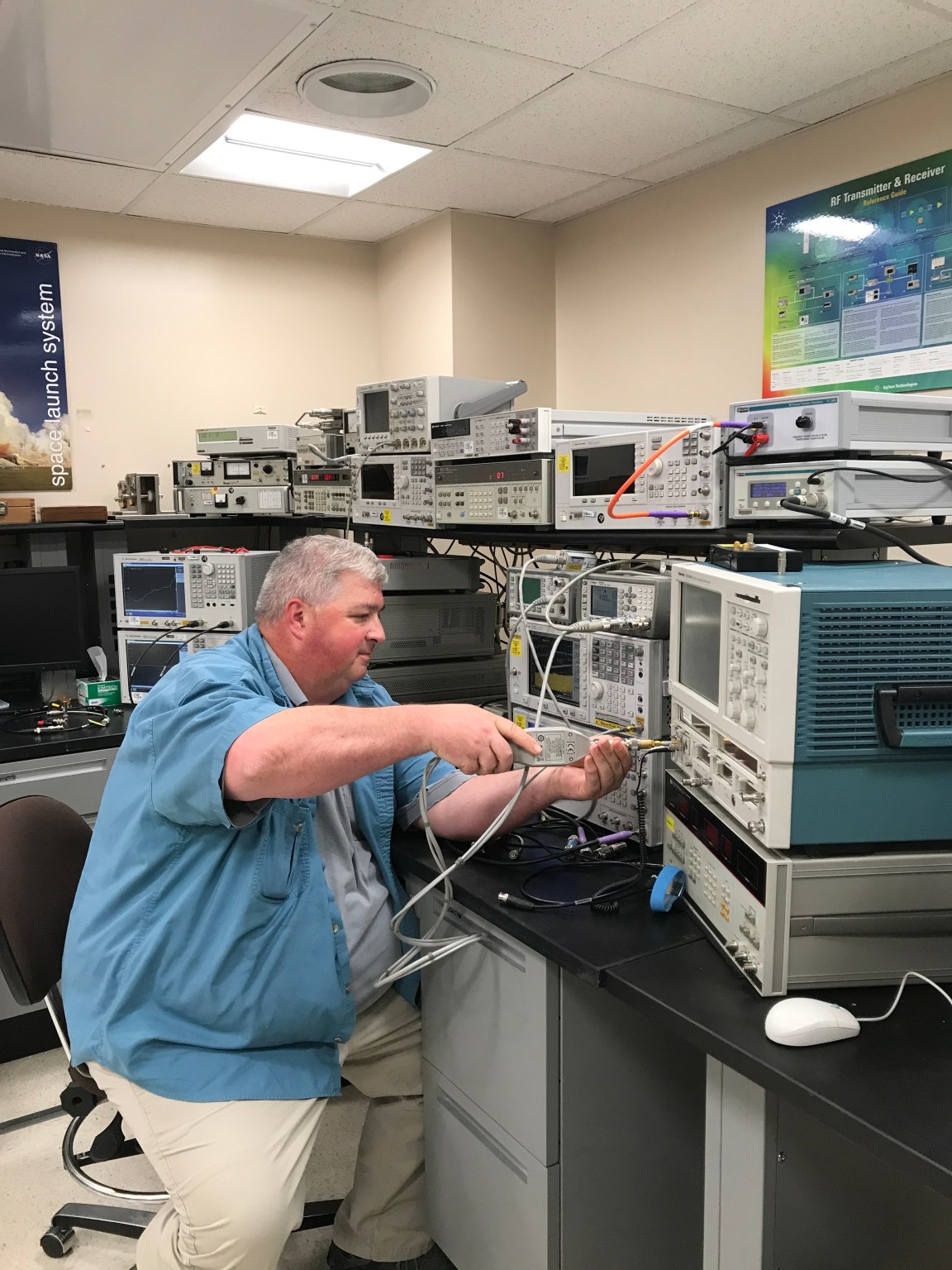

The state-of-the-art Metrology and Calibration Laboratory at NASA’s Marshall Space Flight Center will host an open house for team members from 10 a.m. to noon May 19.

It’s the facility’s second annual open house, intended to showcase the precision work of Marshall’s team of metrology specialists and raise awareness for World Metrology Day, to be celebrated globally May 20. Marshall team members are invited to the lab for a tour, a chance to meet the team and a free lunch of hot dogs, chips and other refreshments.

The Metrology and Calibration Laboratory, managed by Marshall’s Engineering Directorate Test Laboratory, is situated in Building 4650, on the corner of Dodd and Fowler roads on Redstone Arsenal.

Metrology is the scientific study of measurement in all its forms, from simple calculations such as dimension, mass and volume to more complex interpretations of motion, pressure, force, flow and more. Calibration is the accurate configuration of tools, instruments and hardware to accurately deliver repeatable results within known or desired parameters.

In the lab at Marshall, technicians conduct more than 1,500 different test processes. The team executes approximately 14,000 unique calibration and measurement actions annually. Each piece of test equipment is thoroughly checked at the end of its calibration interval to ensure it is within specification and, if needed, readjusted and fine-tuned for the next calibration period. Every measurement result is performed to strict NASA requirements, and reflects what program manager Gary Kennedy calls “traceability,” or a well-documented test history that may be traced back, via an unbroken chain of precision calibration, to the National Institute of Standards and Technology or a NIST-recognized institution.

Traceability doesn’t end there. “Every quantitative measurement made at Marshall is in some way traceable through this laboratory,” Kennedy said. Precise, reproducible measurements are always critical, but in the business of spaceflight they regularly help protect lives, as well as millions of dollars’ worth of hardware, vehicles and instrumentation, he noted.

“We’re here to protect our Marshall customers,” he said. “That requires focus, dedication and accountability — all reasons why I take great pride in this laboratory and our team.”

The laboratory also conducts calibration and measurement testing for other NASA centers, government agencies and military organizations nationwide.

Led by the Office of Safety and Mission Assurance at NASA Headquarters, the agency’s Metrology and Calibration Program strives to ensure the accuracy and reliability of measurements essential to NASA’s twin goals of safety and mission success.

More about World Metrology Day

World Metrology Day is the annual industry celebration of the signing of the Metre Convention — the worldwide uniformity of measurement — on May 20, 1875. Representatives of 17 nations signed the document, which set the standard for global collaboration in scientific measurements and applications throughout industry and commerce. The theme for 2017 is “Measurements for Transport,” reflecting the importance of safe, efficient transportation of foods, goods and materials to nearly every aspect of modern life.

The global occasion is jointly sponsored by the International Organization of Legal Metrology and the Bureau International des Poids et Mesures, leading intergovernmental organizations whose member nations work together on matters related to the science and standards of measurement.

Smith, an ASRC Federal/Analytical Services employee, supports Marshall’s Office of Strategic Analysis & Communications.

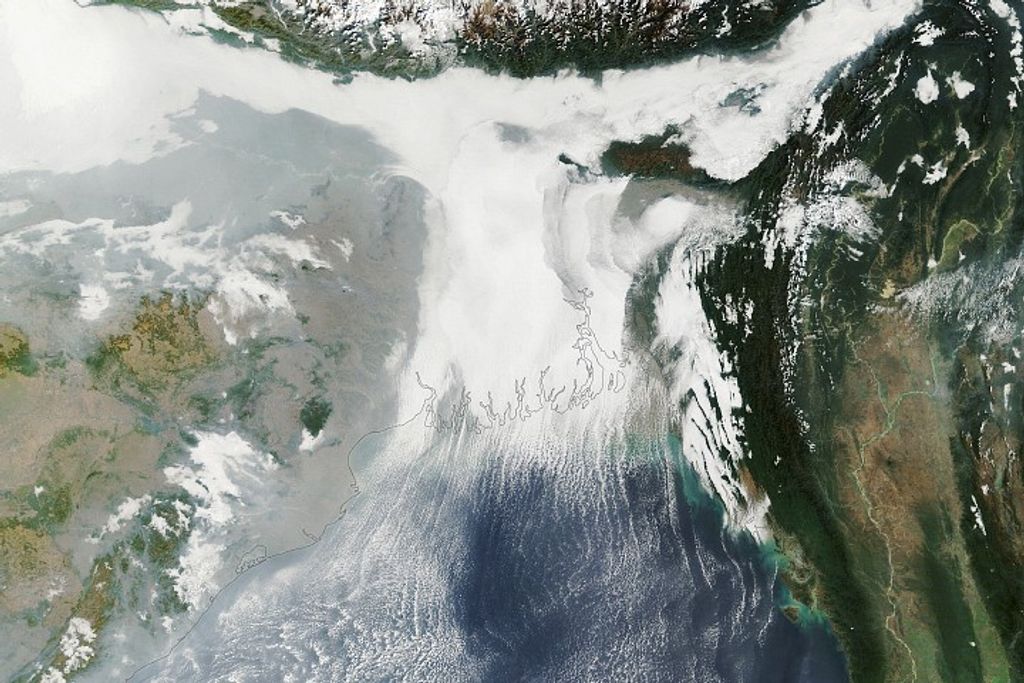

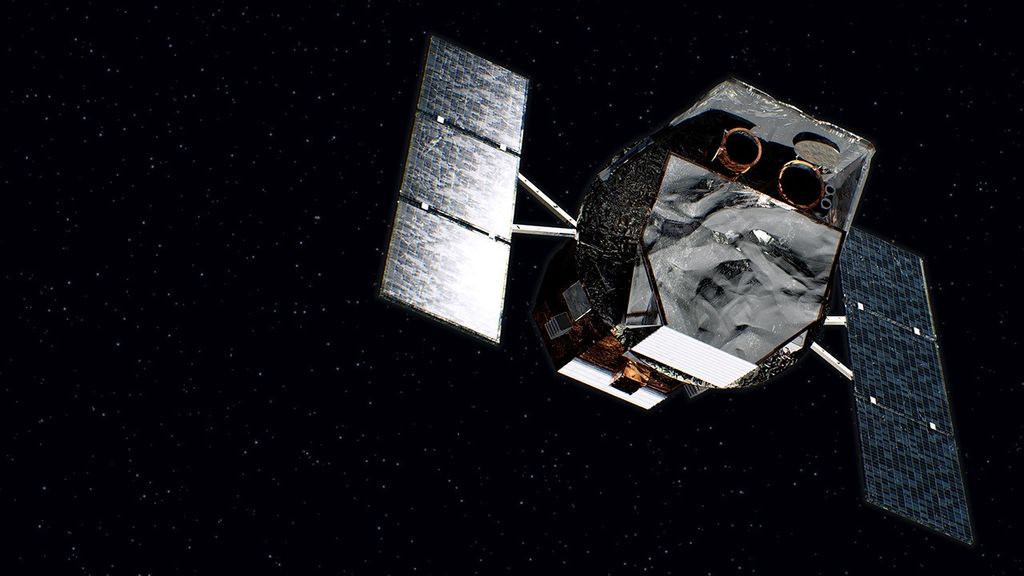

Astronomers Pursue Renegade Supermassive Black Hole

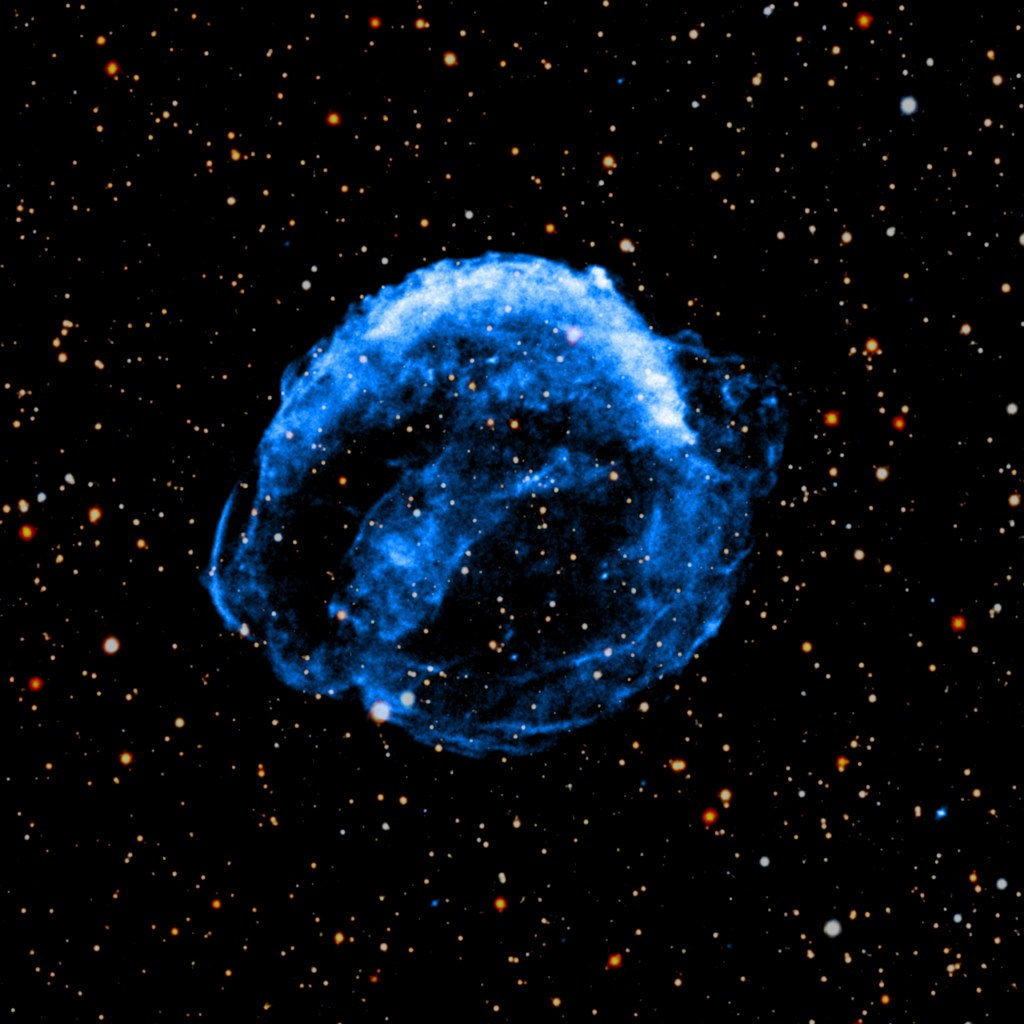

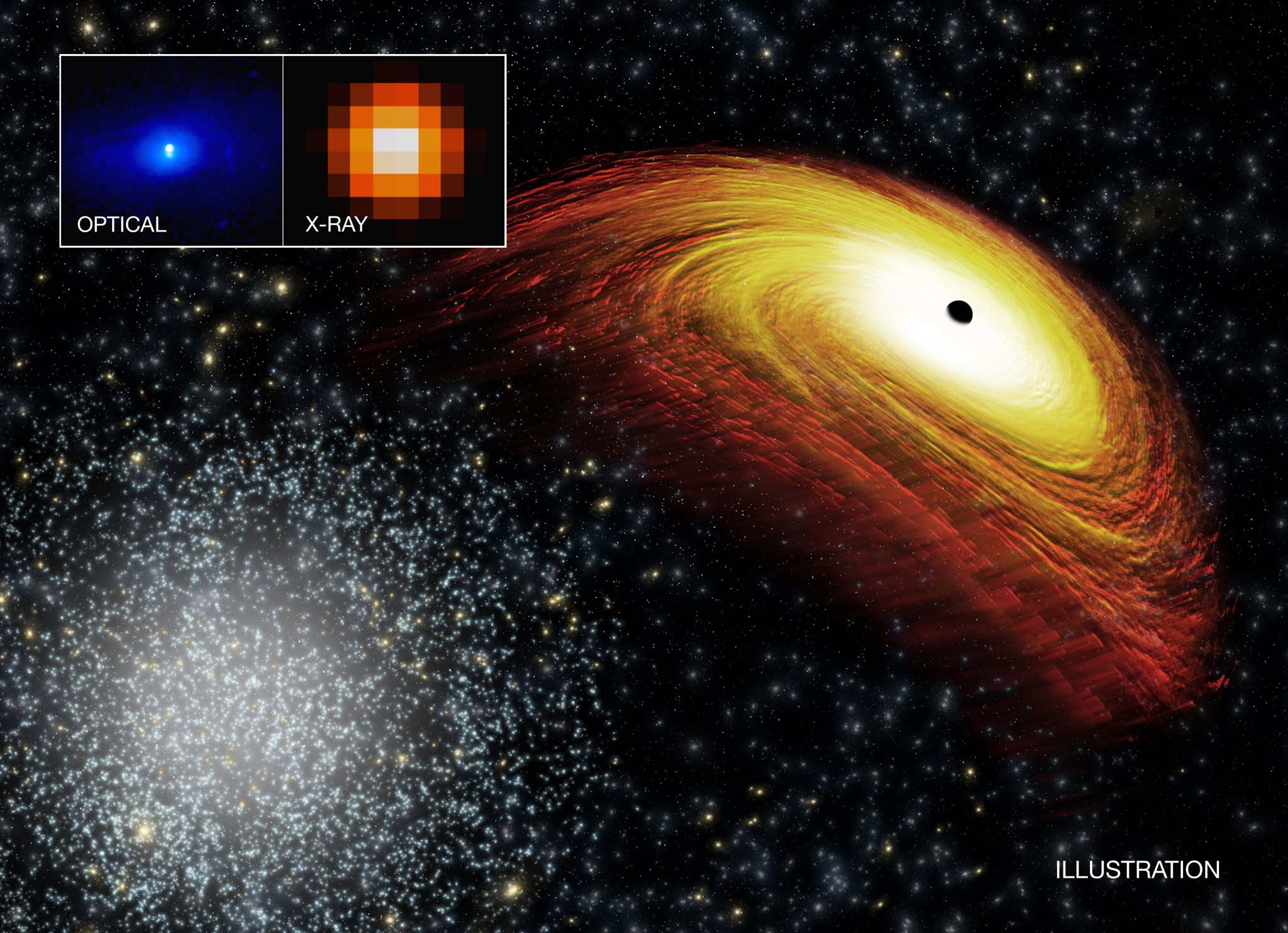

Supermassive black holes are generally stationary objects, sitting at the centers of most galaxies. However, using data from NASA’s Chandra X-ray Observatory and other telescopes, astronomers recently hunted down what could be a supermassive black hole that may be on the move.

This possible renegade black hole, which contains about 160 million times the mass of our sun, is located in an elliptical galaxy about 3.9 billion light years from Earth. Astronomers are interested in these moving supermassive black holes because they may reveal more about the properties of these enigmatic objects.

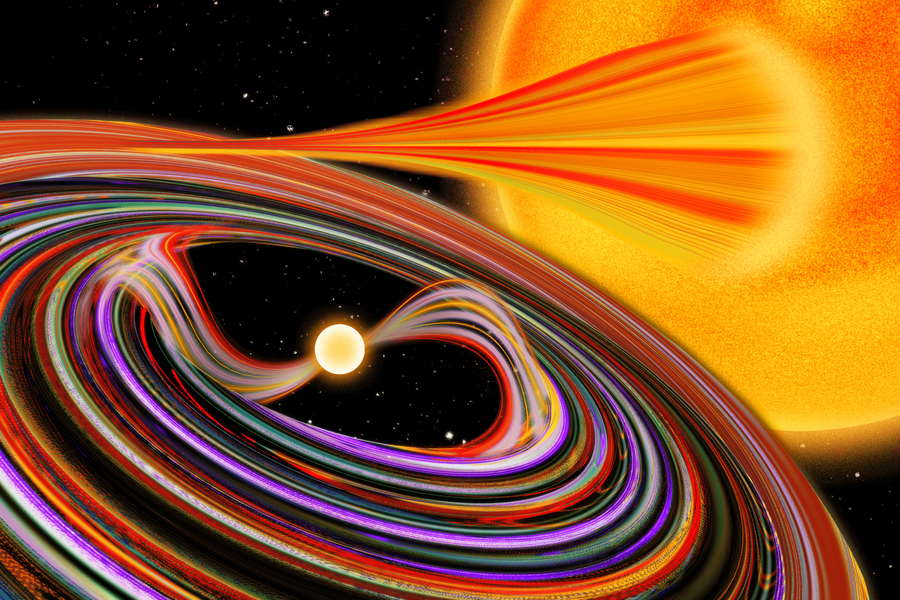

This black hole may have “recoiled,” in the terminology used by scientists, when two smaller supermassive black holes collided and merged to form an even larger one. At the same time, this collision would have generated gravitational waves that emitted more strongly in one direction than others. This newly formed black hole could have received a kick in the opposite direction of those stronger gravitational waves. This kick would have pushed the black hole out of the galaxy’s center, as depicted in the artist’s illustration.

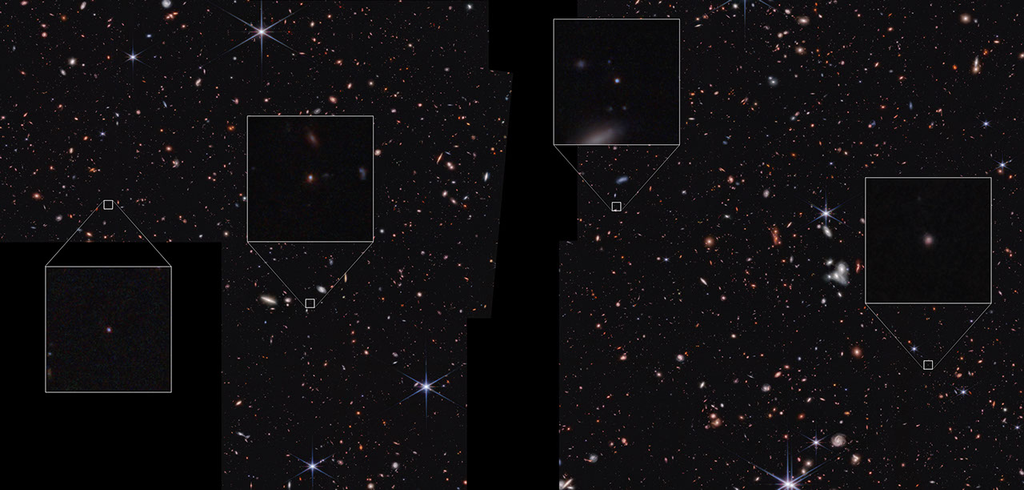

The left image in the inset is from data from the Hubble Space Telescope, which shows two bright points near the middle of the galaxy. One of them is located at the center of the galaxy and the other is located about 3,000 light years away from the center. The latter source shows the properties of a growing supermassive black hole and its position matches that of a bright X-ray source detected with Chandra — shown in the right inset. Using data from the Sloan Digital Sky Survey and the Keck telescope in Hawaii, the team determined that the growing black hole located near, but visibly offset from, the center of the galaxy has a velocity that is different from the galaxy. These properties suggest that this source may be a recoiling supermassive black hole.

A paper describing these results was recently accepted for publication in The Astrophysical Journal and is available online. The first author is Dongchan Kim from the National Radio Astronomy Observatory in Charlottesville, Virginia.

NASA’s Marshall Space Flight Center manages the Chandra program for NASA’s Science Mission Directorate. The Smithsonian Astrophysical Observatory in Cambridge, Massachusetts, controls Chandra’s science and flight operations.

Winners Announced for NASA, Orbital ATK Rocketry Challenge

By Christopher Blair

For the first time in four years, a new team won NASA’s Student Launch, a high-powered rocketry challenge, hosted by and held near NASA’s Marshall Space Flight Center, April 5-8. After weeks reviewing post-flight data and analysis reports from all teams, NASA and Orbital ATK, longtime corporate sponsor for this event, announced this year’s overall winner, as well as the top five finishers, and the rookie of the year award.

Last month, preliminary awards such as best vehicle design, best website and others were announced and can be viewed here.

The University of Louisville in Kentucky captured top honors, taking home a cash prize of $5,000, offered by Orbital ATK, longtime corporate sponsor of the challenge. Since 2011, this team from the bluegrass state has earned more than 10 awards, including Best Vehicle Design, Safety Award, Project Award and more.

In second place, after a record-setting “four-peat” as champions, is Vanderbilt University in Nashville, Tennessee. They earned a cash prize of $2,500, offered by new sponsor, Huntsville Chapter of the National Space Club. For 10 straight years, Vanderbilt soared to success with innovative rocket designs and payloads, and this year was no exception. Having earned more than 20 awards the past decade, Vanderbilt added the 2017 Payload Design, Rocket Fair Display and Education Engagement awards.

Rounding out the top five is Cornell University of Ithaca, in New York; the University of Alabama in Huntsville; and the University of North Carolina, in Charlotte, in third through fifth place, respectively. The 2017 Rookie of the Year award goes to the University of Evansville, in Indiana.

Nearly 50 teams from middle and high schools, colleges and universities in 22 states demonstrated advanced rocketry and engineering skills. Teams spent eight months building and testing rockets designed to fly to an altitude of one mile, deploy an automated parachute system, and safely land for reuse, each carrying a scientific payload for data collection during flight.

While veteran teams prove consistent participation helps, the novice and rookie teams continue to excel. For example, the University of Huntsville in Alabama team was made up of all-rookie members, yet launched their way to fourth place.

Finishing first may be fun, but it’s not the most important aspect. Student Launch is a real-world outlet for young people to apply lessons learned in class toward relevant and cost-effective research into propulsion and recovery systems.

“It’s exciting to see team designs and enable them to conduct meaningful research into NASA’s Journey to Mars and beyond,” said Katie Wallace of Marshall’s Academic Affairs Office. “Working through the NASA design process, students gain a broader understanding of current projects, like the Space Launch System, NASA’s next deep-space exploration rocket.”

As the high-pitched whistle of rocket launches have faded, next year’s teams are on deck, ready to solve thrust-to-weight ratios and kinetic energy predictions. After all, it is rocket science.

To view behind-the-scene photos of this year’s Student Launch, visit the Marshall’s education album on Flickr.

Archived launch-day footage is available on the Marshall’s Ustream page.

Blair, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

This Week in NASA History: Skylab Launches — May 14, 1973

This week in 1973, the uncrewed Skylab was launched aboard a modified Saturn V launch vehicle from NASA’s Kennedy Space Center. The initial concept for the United States’ first space station was devised at NASA’s Marshall Space Flight Center. Marshall managed the development of Skylab hardware, provided the Saturn launch vehicles for the four Skylab missions and directed many of the space station’s experiments. Over the course of its human occupation from May 25, 1973, to February 8, 1974, three crews visited Skylab, carried out 270 scientific and technical investigations and logged a combined 171 days on orbit. Today, Marshall’s Payload Operations Integration Center serves as “science central” for the International Space Station, working 24/7, 365 days a year in support of the orbiting laboratory’s scientific experiments. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

Obituaries

Clynton T. Ratliff, 89, of Huntsville died May 7. He retired from the Marshall Center in 1989 as an aerospace engineer.