In This Week’s Star

- ‘State of NASA’ to Broadcast Live from Marshall Feb. 12, Followed by Center All-Hands Meeting with Marshall Director Todd May

- Structural Testing Complete on SLS Core Stage Powerhouse

- NASA Completes Green Run Testing for RS-25 Engines Set for First Crewed SLS Flight

- Need Help Cleaning Your Air or Doing Laundry? There’s a Marshall Spinoff for That!

- Essential to the Mission: Stanley McCaulley

- Marshall Team Members Make an Impact on Young Girls at STEM Event

- This Week in NASA History: STS-98 Launches to Space Station – Feb. 7, 2001

- Obituaries

‘State of NASA’ to Broadcast Live from Marshall Feb. 12, Followed by Center All-Hands Meeting with Marshall Director Todd May

By Brian C. Massey

NASA Acting Administrator Robert Lightfoot will deliver the annual “State of NASA” address live from NASA’s Marshall Space Flight Center at noon, Feb. 12. Marshall team members are encouraged to watch the address on Marshall Desktop TV or NASA TV.

With hardware for NASA’s Space Launch System serving as a backdrop, Lightfoot’s address will highlight the progress made and work ahead on NASA’s exploration initiative that secures America’s leadership in space.

At 1 p.m., Lightfoot will join Marshall Center Director Todd May in Morris Auditorium, Building 4200, for a center all-hands meeting. Team members are encouraged to attend.

May will reflect on Marshall’s achievements in 2017 and discuss how the center will continue to make human space exploration possible in 2018 and beyond. He will also talk about the fiscal year 2019 NASA President’s Budget Request and how it will impact Marshall.

The all-hands meeting will be streamed live on Desktop TV, for team members who are unable to attend.

After May’s remarks, he will answer questions during a Q&A session. To submit questions before the meeting, click here.

Massey, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Structural Testing Complete on SLS Core Stage Powerhouse

By Brian C. Massey

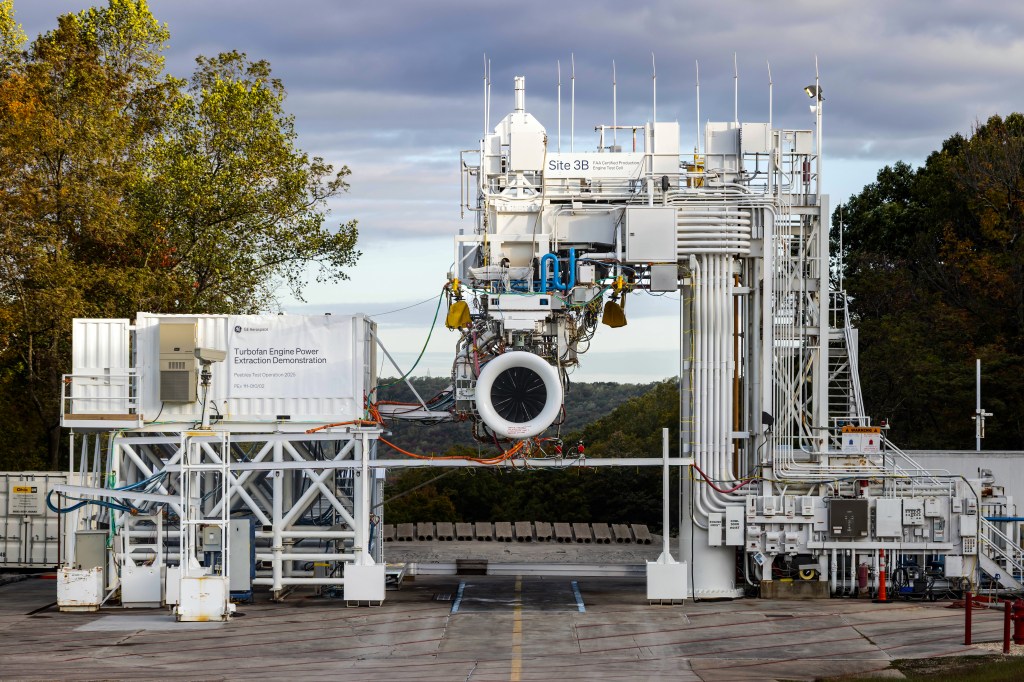

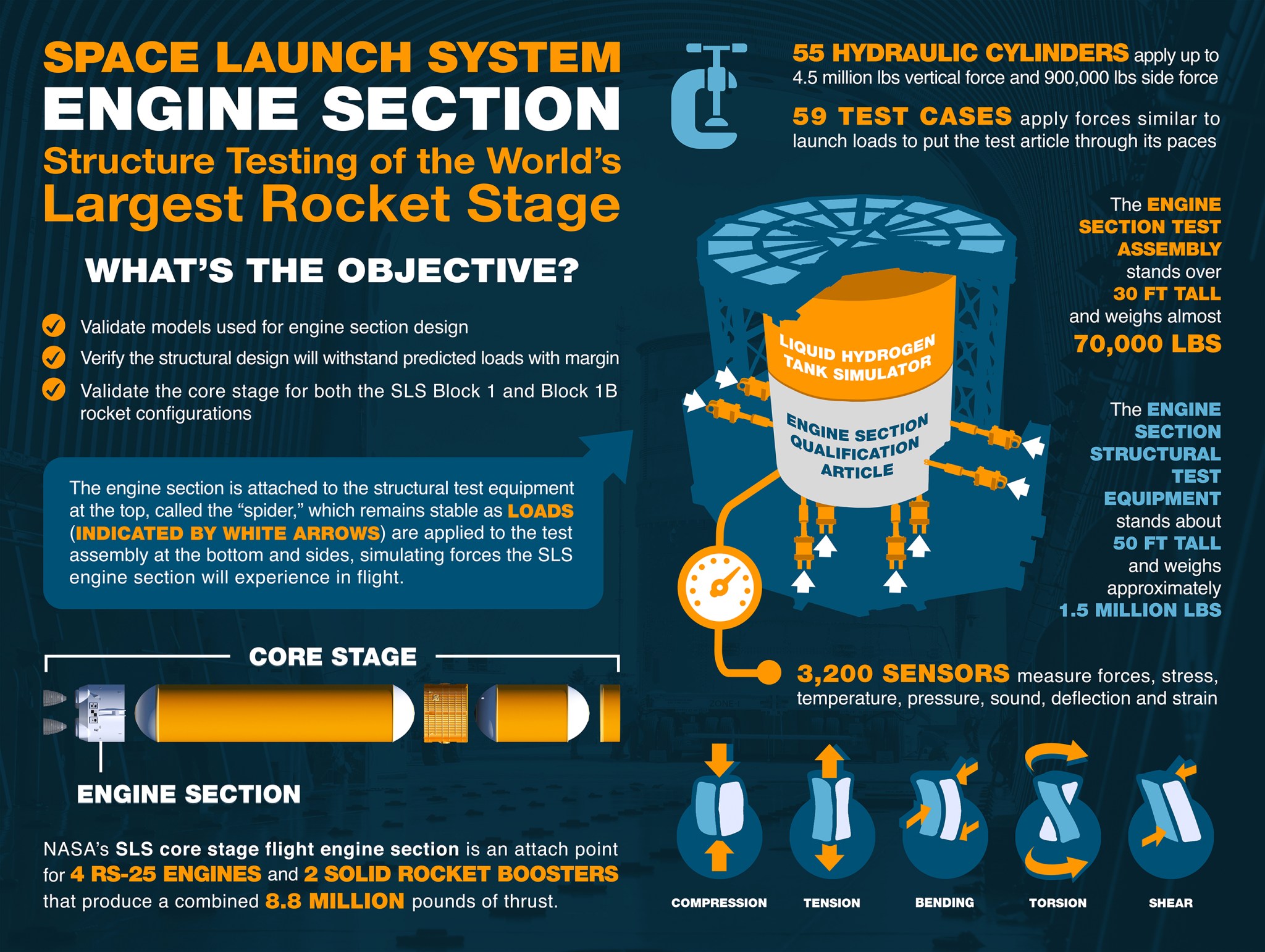

After numerous tests using millions of pounds of force, engineers have successfully completed structural qualification testing on the engine section for NASA’s new deep-space rocket, the Space Launch System.

A true powerhouse, with four RS-25 engines and side attachment points for two solid rocket boosters, the engine section is located at the bottom of the rocket’s massive core stage. The 212-foot-tall core stage will be the backbone of all SLS configurations, making the tests critically important for upcoming missions sending crews to the Moon, Mars and beyond.

During launch, the engines and boosters will produce more than 8 million pounds of thrust, requiring the engine section to be incredibly strong.

“These tests mark significant progress to the pad for the first flight of SLS,” said Mark White, lead test engineer for the engine section at NASA’s Marshall Space Flight Center. “The tests performed by NASA with core stage prime contractor Boeing prove the hardware is strong enough to withstand the stresses and loads of launch and ascent.”

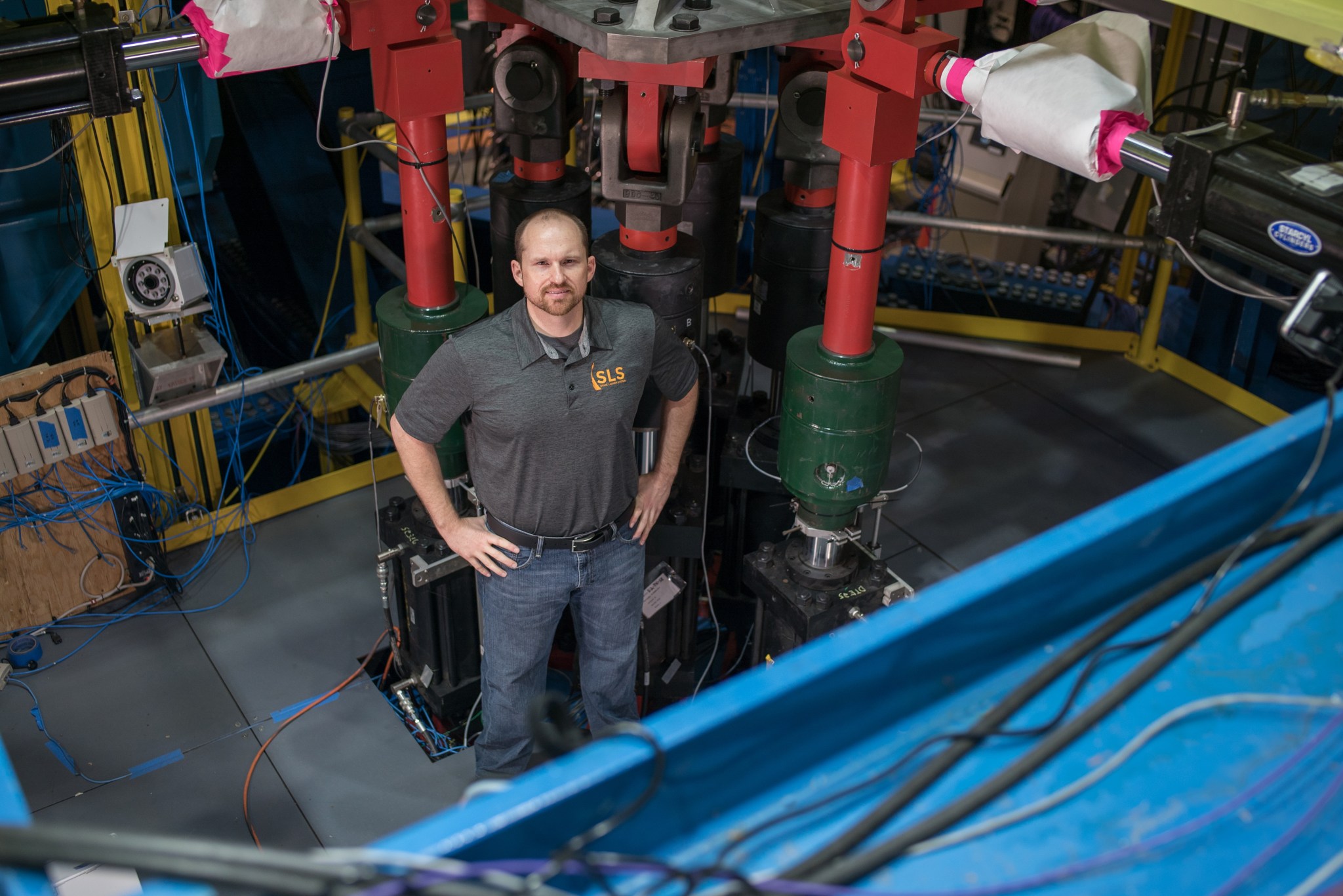

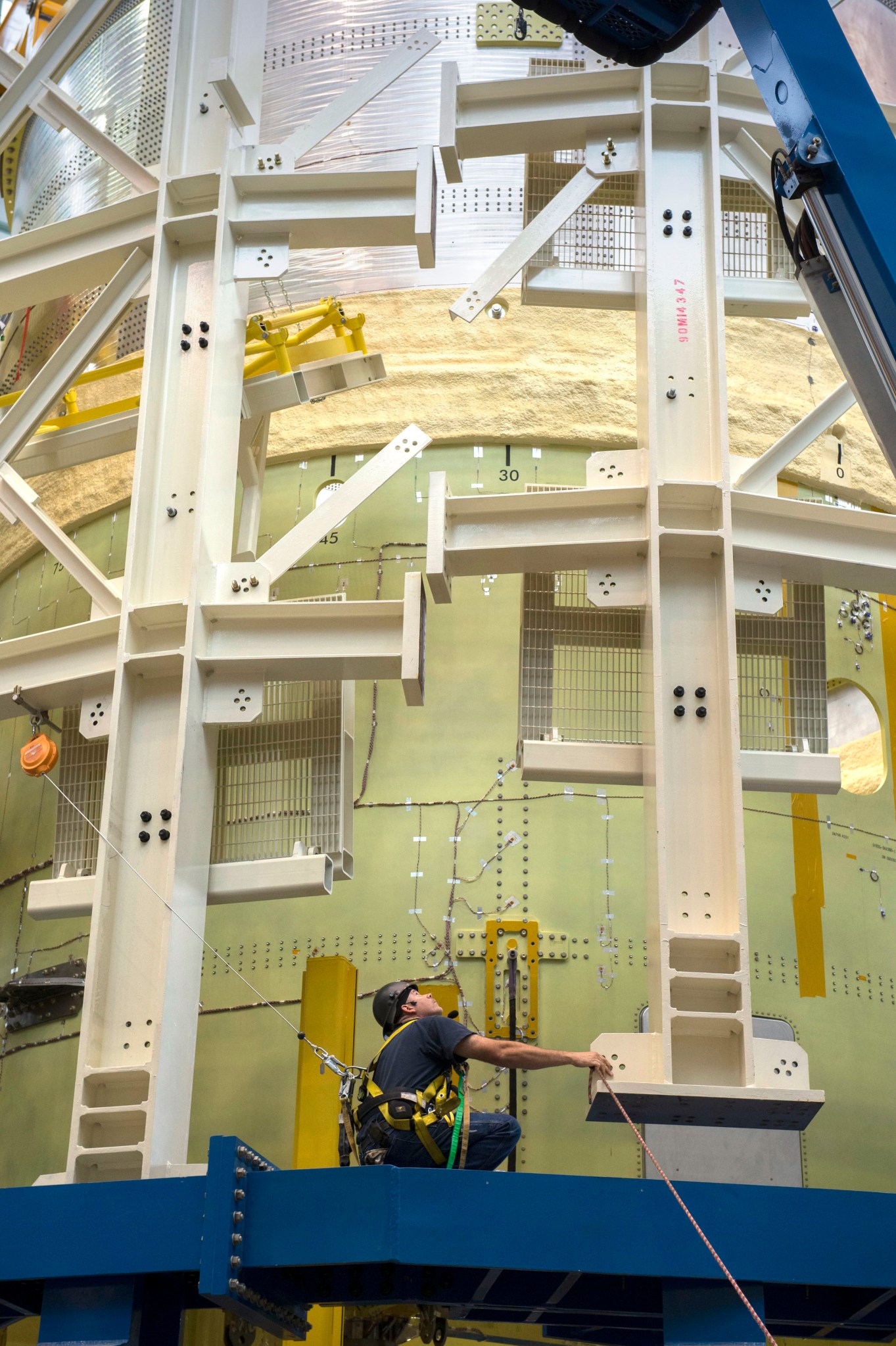

The engine section structural test article was built at NASA’s Michoud Assembly Facility and shipped to Marshall for testing. The hardware was installed into a unique 50-foot test stand where electronically controlled hydraulic cylinders pushed, pulled and bent the test article with millions of pounds of force.

“SLS will be the most powerful rocket in the world and to simulate the incredible loads it will produce, NASA and Boeing had to be innovative when designing the stand,” said White. “A traditional test stand, reacting onto the concrete, would have filled the entire test bay, leaving no room to maneuver and install the hardware.”

Traditional structural test stands are bolted to deep concrete foundations to absorb the force from the test back the ground. The Marshall test stand — which looks much like a bird cage built around the test article — is completely self-reacting, meaning the test stand itself is designed to be both strong enough and flexible enough to withstand the energy of the test. It sits on only four concrete pads, each roughly the size of a pizza box, allowing the stand to be more compact and flexible.

Inside the 1.7 million-pound test stand, the engine section test article hangs with a cryogenic supply system simulating the frigid temperatures created by the rocket’s liquid hydrogen tank. Using more than 16,000 fasteners, the test article is connected to the stand and the more than 50 actuators used to simulate the expected flight loads.

During tests, the actuators simulated more than 3 million pounds of upward RS-25 engine thrust loads and up to 750,000 pounds of loads on each side for the outward forces created by the solid rocket boosters. A series of tests also validated brackets designed to hold feedlines from the liquid oxygen tank.

Located near the top of the rocket’s core stage, the liquid oxygen tank will supply the oxidizer needed to power the four RS-25 engines. The liquid oxygen will travel more than 150 feet to the engines down the outside of the core stage, past the intertank and liquid hydrogen tank, via a large feedline known as the “downcomer.” The tests verified that the engine section feedline brackets would perform as expected when the heavy liquid makes the turn toward the engines in flight.

Engineers recorded and analyzed over 3,000 channels of data for each test case to verify the capabilities of the engine section and downcomer. Teams compared the data to design and analysis models to validate the accuracy of the predicted loads.

“The core stage structural qualification test campaign is NASA’s largest such effort since the Space Shuttle Program,” said Heather Haney, SLS core stage dry structures test lead at Marshall. “Next, we’ll test the intertank and then the rocket’s two colossal fuel tanks. It’s an exciting time for the future of deep-space exploration, and these tests move SLS closer to its first launch.”

SLS, which is managed at Marshall, will enable a new era of exploration beyond Earth’s orbit, launching astronauts in NASA’s Orion spacecraft on deep-space exploration missions to the Moon and eventually to Mars.

Major welding on all five parts of the core stage, including the engine section, for the first flight has been completed and the components are being outfitted for flight. The four RS-25 engines and engine controllers for the first mission have been certified and are ready to be joined to the engine section.

Massey, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA Completes Green Run Testing for RS-25 Engines Set for First Crewed SLS Flight

A Feb. 1 RS-25 engine test marked the completion of green run testing for all four flight controllers needed for the second flight of NASA’s Space Launch System rocket, which will be the first flight to send astronauts to space. Green run testing for the controllers means this is the first time they have been tested outside of a lab and actually controlled an engine. The flight controllers are new, modern avionic systems that serve as the RS-25 “brain” to help the engine communicate with the SLS rocket and to help control engine operation and internal health diagnostics.

NASA has completed testing of the flight controllers for Exploration Mission-1, the first SLS flight, and assembled the four engines in preparation for installing them on the SLS core stage at NASA’s Michoud Assembly Facility in New Orleans. With this test, SLS has met a major milestone for Exploration Mission-2, which will be the first crewed flight of the Orion spacecraft. The full-duration, 365-second certification test of another RS-25 engine flight controller on the A-1 Test Stand at NASA’s Stennis Space Center comes 16 days after a Jan. 16 hot fire.

In addition to the flight controller, the Feb. 1 hot fire at Stennis also marked the third test of a 3-D printed pogo accumulator assembly for the RS-25 engine. Testing of the 3-D printed component is part of an ongoing effort to use advanced manufacturing techniques and processes as a means of reducing engine construction costs on future SLS missions. NASA plans to test a number of 3-D printed components for the RS-25 engine.

For the recent test, flight controller ECU 11 was installed on RS-25 developmental engine E0528 and fired under conditions akin to an actual launch. Each RS-25 hot fire is designed to test and evaluate the performance of the engine and its components in specific scenarios. Typically, an engine is cycled through various thrust levels that may be needed during flights to help engineers gather as much performance data as possible. Once certified, tested flight controllers are removed for installation on flight engines for the SLS rocket.

All RS-25 engines and flight controllers for SLS missions are being tested at Stennis, as is the flight core stage for the first SLS mission. SLS core stage testing will involve installing the stage on the B-2 stand at Stennis and firing all four of the RS-25 engines simultaneously. At launch, the four RS-25 engines will generate 2 million pounds of thrust and work in conjunction with a pair of solid rocket boosters to produce more than 8 million pounds of thrust. RS-25 engines for initial SLS flights are former space shuttle main engines, modified to provide additional power to launch the larger SLS rocket.

Aerojet Rocketdyne, of Sacramento, California, is the RS-25 prime contractor.

Need Help Cleaning Your Air or Doing Laundry? There’s a Marshall Spinoff for That!

By Will Bryan

As rockets roar off launch pads and spacecraft beam data back from distant planets, the technologies enabling those mighty feats are being put in your hands every day as products and technologies called spinoffs. They are the result of NASA’s innovation being put in the hands of the public where new tools and goods to improve life on Earth are born.

“For over 50 years, the Technology Transfer Office at NASA’s Marshall Space Flight Center has worked with center innovators to identify technologies with commercial potential and license those technologies to companies that have created new commercial products that have improved life here on Earth,” said Terry Taylor, manager of Marshall’s Technology Transfer Program. “If you had to develop a new technology or software tool in your NASA work, we’d love to hear about it.”

In January, the 2018 edition of NASA’s annual Spinoff publication was released, detailing 49 new spinoffs of NASA technologies that have been commercialized and are making a difference in the world.

Four of those technologies — to be highlighted in the Marshall Star in the coming weeks — owe their origins to Marshall, a long-time leader in propulsion, life support systems and innovation.

One spinoff — the ActivePure cleaning tools — impacts everything from a gas leak in California to baseball parks across the country.

When a natural gas leak in Los Angeles in late 2015, stretching into early 2016 forced thousands of people to temporarily relocate, thousands more were able to remain in their homes thanks to a Marshall spinoff. Aerus Holdings — headquartered in Dallas — employed its ActivePure line of air purification products to cleanse the air in homes around Los Angeles.

The Marshall technology used commercially by ActivePure was initially developed by NASA to purify air for crews in space by reacting ultraviolet light and metal oxides to purge the air of harmful contaminants.

The ActivePure devices cleanse air in buildings — from homes and businesses to locker rooms and restaurants — eliminating bacteria and fungus on surfaces. One of its product can even be hooked up to any washing machine to eliminate the need for detergent, bleach and hot water.

For nearly 60 years, Marshall has enabled crewed missions into space, facilitating science and discoveries once thought only to be science fiction. Those efforts in space exploration have transferred into the commercial sector where Marshall has once again made its mark — helping improve life on Earth for generations to come.

To report new technologies or software tools, visit NASA’s Technology Transfer Program website.

To learn more about Marshall’s Technology Transfer Program, click here.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Essential to the Mission: Stanley McCaulley

By Jonathan Deal

Stanley McCaulley has always wanted to work at NASA’s Marshall Space Flight Center. As a Huntsville native, McCaulley has been visiting Redstone Arsenal since he was 7 years old with his grandfather, who taught electronics to U.S. Army soldiers.

Now McCaulley is a 10-year veteran of Marshall, and it’s his own daughter who wants to follow in his footsteps.

“I get a sense of joy when I drive by the U.S. Space & Rocket Center and my daughter points to the rocket and says, ‘Daddy, that’s your rocket,’” he said. “She’s just simply letting me know that I’m part of something great and maybe one day she’ll want to follow in my footsteps.”

McCaulley works in the Engineering Cost Office in Marshall’s Office of Strategic Analysis and Communications. As a senior cost engineer, his primary focus is serving as a cost lead for NASA’s Space Launch System. McCaulley and his team provide support to all SLS subsystem elements.

The Engineering Cost Office, also known as CS50, performs life cycle cost estimates, cost risk analyses, joint cost/schedule risk analyses, engineering economic analyses, cost/benefit analyses and financial case analyses for programs and projects across the center and agency. The office also provides programmatic assessment capabilities for agency-level independent assessments, supports concept development and develops and maintains cost models and historical project cost data for NASA.

“Part of my role at Marshall is helping educate the decision makers on what the architecture, hardware or concept will cost. You never want to fail. And you definitely don’t want the reason it fails to be because of cost or schedule,” said McCaulley. “I believe that’s where our work in the Engineering Cost Office helps our customers understand the cost challenges based on the proposed design. To do this, we use historical data, perform cost analysis or simply talk to the engineers to gather a better understanding of the hardware.”

On his journey to fulfilling his lifelong dream of working for NASA, McCaulley earned an industrial engineering degree from the University of Alabama in Tuscaloosa. He joined Marshall straight out of college and has been a member of CS50 ever since.

“Being part of this office for the past 10 years, I’ve been able to work on multiple projects with various customers across the agency,” he said. “The excitement that comes with being on a team to do something that educates the world in science is simply cool.”

Deal, an ASRC Federal/Analytical Services employee and Marshall Star Editor, supports the Office of Strategic Analysis & Communications.

Marshall Team Members Make an Impact on Young Girls at STEM Event

Lisa Waddell, supporting Marshall Space Flight Center as a mechanical engineering team lead at Jacobs Engineering of Huntsville, teaches young girls about the Life Sciences Glovebox at the Celebration of STEM event at the U.S. Space & Rocket Center on Feb. 4. Marshall supported the event aimed to encourage young girls to pursue careers in science, technology, engineering and mathematics by providing hands-on demonstrations and highlighting women working in these fields. (NASA/MSFC/Amanda Adams)

This Week in NASA History: STS-98 Launches to Space Station – Feb. 7, 2001

This week in 2001, STS-98 launched aboard the space shuttle Atlantis from NASA’s Kennedy Space Center. The primary mission objective was to deliver the Destiny module to the International Space Station. Here, the newly attached Destiny module can be seen at the lower right of the station. Destiny, developed and constructed at NASA’s Marshall Space Flight Center, is the primary research laboratory for U.S. payloads, supporting a wide range of experiments and studies contributing to health, safety and quality of life for people all over the world. Today, the Payload Operations Integration Center at Marshall serves as “science central” for the space station, working 24/7, 365 days a year in support of the orbiting laboratory’s scientific experiments. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

Obituaries

Victor I. Richard, 82, of Huntsville, died Jan. 31. He retired from the Marshall Center in 2004 as an engineer. He is survived by his wife, Gladys W. Richard.

James L. Etheredge, 86, of Woodville, Alabama, died Jan. 31. He retired from the Marshall Center in 1981 as an engineer.