In This Week’s Star

- NASA Advances Additive Manufacturing for Rocket Propulsion

- NASA’s Mars InSight Lander Successfully Launches

- I am Building SLS: Beth St. Peter

- Doing It for the Science: SpaceX Dragon Capsule Departs ISS

- NASA Day in Baton Rouge Honors Louisiana’s Contributions to Space Exploration; Engages Over 1,800 Students in Outreach Events

- Marshall Showcases Work of Spring Interns at ‘Poster Day’ Event May 2

- This Week in NASA History: STS-125 Launches on Final Hubble Servicing Mission – May 11, 2009

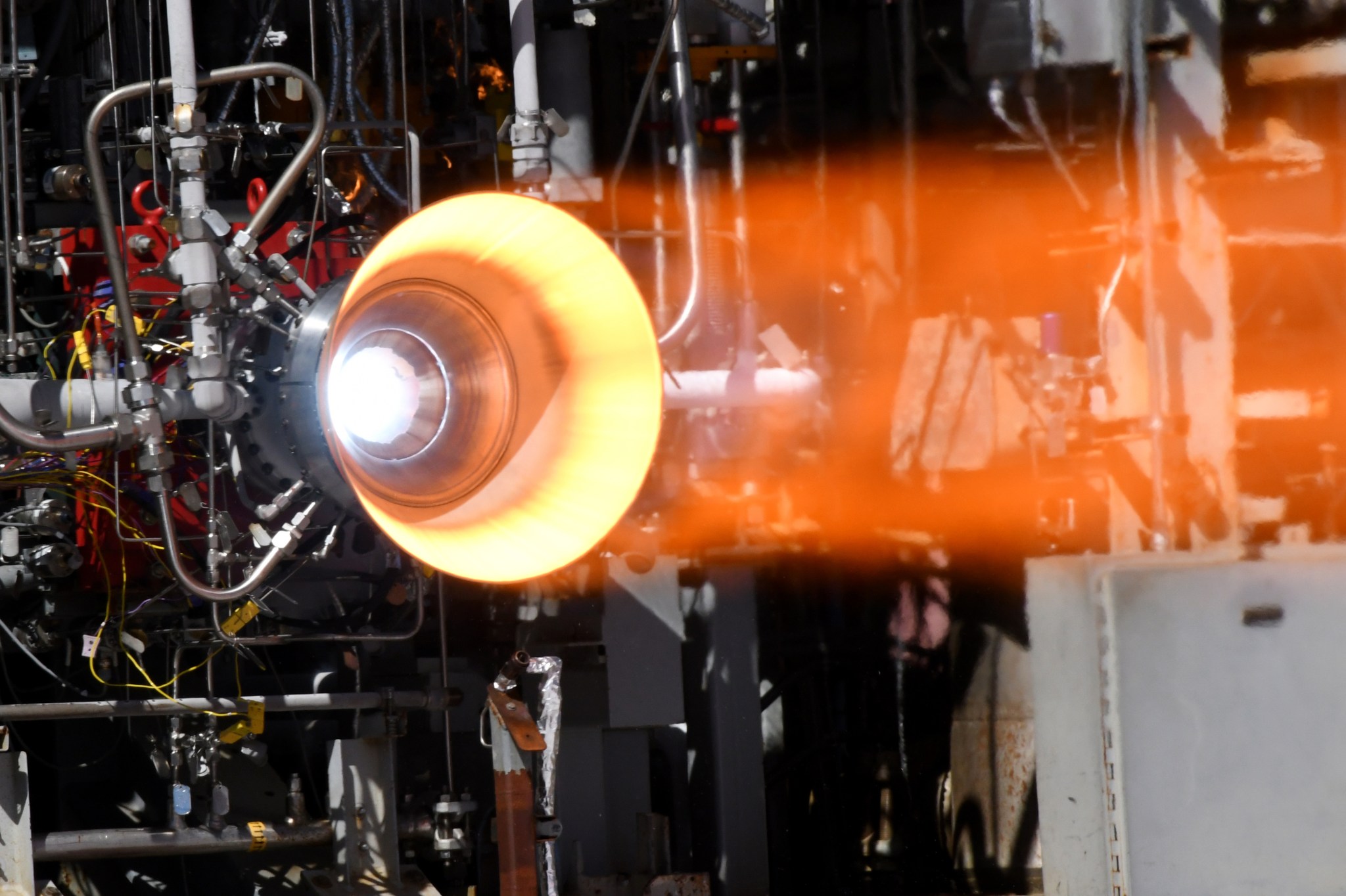

NASA Advances Additive Manufacturing for Rocket Propulsion

By Amanda M. Adams

NASA is breaking ground in the world of additive manufacturing with the Low Cost Upper Stage-Class Propulsion project. Recently, the agency successfully hot-fire tested a combustion chamber at NASA’s Marshall Space Flight Center made using a new combination of 3-D printing techniques.

“NASA continues to break barriers in advanced manufacturing by reducing time and costs involved in building rocket engine parts through additive manufacturing,“ said John Fikes, project manager for the Low Cost Upper Stage-Class Propulsion Project. “We are excited about the progress of this project. We demonstrated that the E-Beam Free Form Fabrication-produced combustion chamber jacket can protect the chamber liner from the pressures found in the combustion chamber.”

The project is a joint effort by three NASA centers — Glenn Research Center, Langley Research and Marshall. The agency successfully printed the first, full-scale 3-D printed copper combustion chamber liner in 2015 at Marshall using a powdered copper alloy created by material scientists at Glenn. The liner was then sent to Langley where E-Beam Free Form Fabrication Technology, a layer-additive process that uses an electron beam and wire to fabricate metallic structures, was used to deposit a nickel-alloy onto the liner to form the chamber jacket.

While the copper lining is good for thermal conductivity, it is not very strong, therefore it is covered in a nickel-alloy jacket to provide a strong structure that can withstand the stress from the pressure contained in the chamber. This additive manufacturing process eliminates traditional techniques including brazing which enabled the jacket to be made in hours, rather than days or weeks. Additionally, this process produces a single article with increased durability by reducing the multiple parts with welded joints found in traditional manufacturing.

For the just-completed series of tests, the chamber, composed of the liner and the newly added jacket was shipped back to Marshall and installed in a test stand to be fired at various power levels for durations ranging from 2 to 30 seconds under conditions akin to an actual launch. The final test went the full duration of 25 seconds at 100 percent power. The post-test data shows the hardware remained in great shape.

“Testing the chamber in flight-like conditions helps us continue to prove these revolutionary technologies,” said Chris Protz, engineering and design lead for the propulsion project. “We are proud of the way the chamber preformed during this test and the capabilities here at Marshall that allow us to continue paving the way for advancements in additive manufacturing.”

The technology for the liner and jacket will be incorporated into a new project called Rapid Analysis and Manufacturing Propulsion Technology. This project aims to further improve production time and costs for thrust chamber assemblies.

The Low Cost Upper Stage-Class Propulsion Project is funded by NASA’s Space Technology Mission Directorate’s Game Changing Development Program, which seeks to identify and rapidly mature innovative technologies that may lead to entirely new approaches for future space missions.

Adams, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

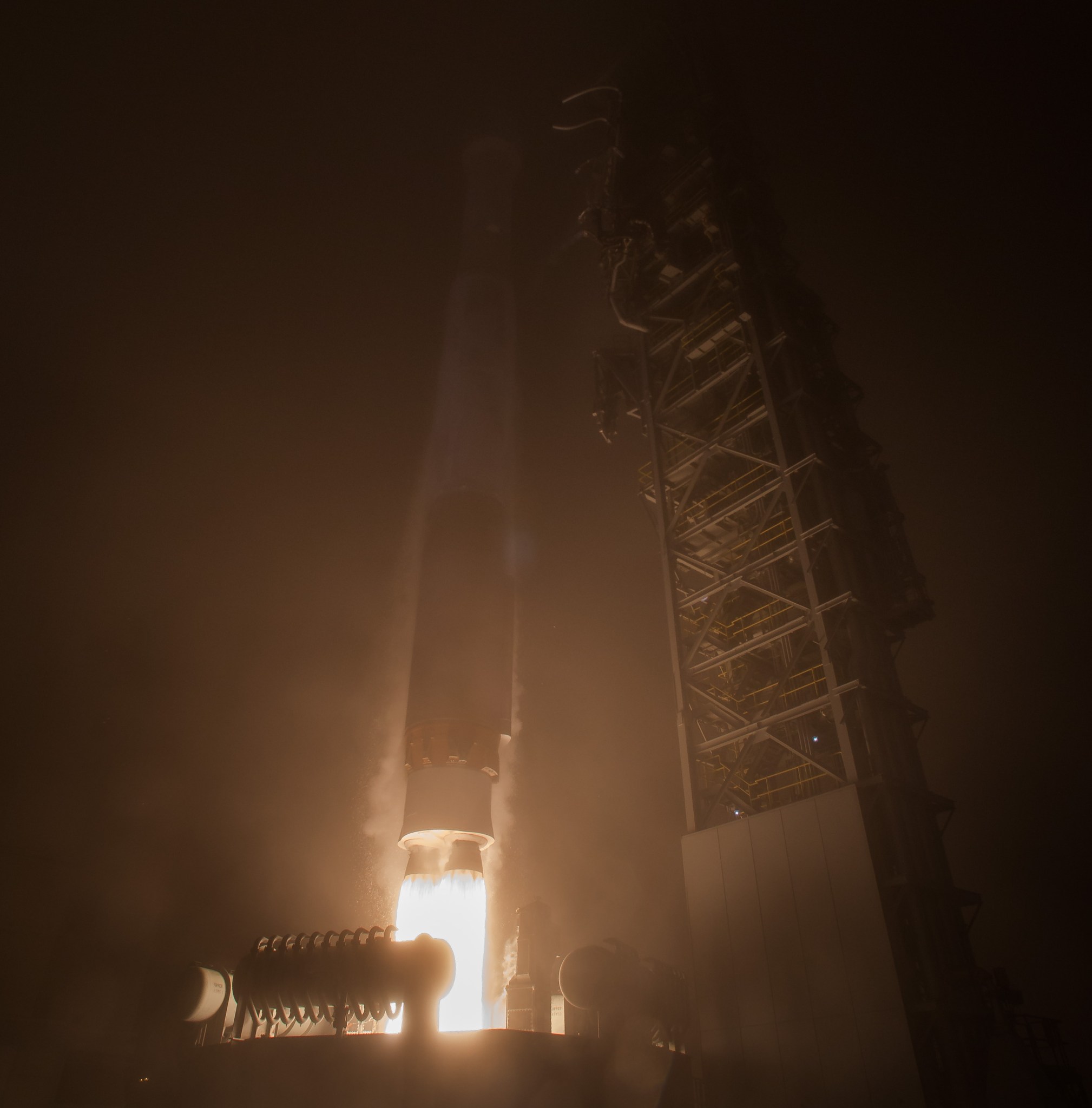

NASA’s Mars InSight Lander Successfully Launches

The predawn sky of coastal California was brightly lit on the morning of May 5 as NASA’s newest lander — InSight — rode a column of smoke and fire into space as it launched from Vandenberg Air Force Base. Launching at 6:05 a.m. CDT, the spacecraft is carrying instruments that will delve into the mysteries of the Red Planet’s interior to help scientists understand the structure, complexion and evolution of Mars and, ultimately, other rocky planets such as Earth. InSight is scheduled to arrive at Mars on Nov. 26. The mission is managed by NASA’s Marshall Space Flight Center as part of the Discovery Program. Mission coverage can be followed on NASA’s Eyes on the Solar System, as well as https://www.nasa.gov/insight and @NASAInSight on Facebook and Twitter. (Credit: NASA/Bill Ingalls)

I am Building SLS: Beth St. Peter

Years before NASA’s Space Launch System soars off the launch pad, teams are planning how to capture images documenting this historic launch using photogrammetry, or the use of photography to measure distances between objects. Meet Beth St. Peter, NASA SLS Imagery integration lead, who is working to make that happen.

Capturing photographs of historical moments can teach us a lot, especially when it comes to launching the world’s most powerful rocket, NASA’s Space Launch System. As the SLS imagery integration lead, my team and I use data and information from these images to improve future missions.

Years before SLS soars off the launch pad, my team plans how we will capture the images NASA needs not only to document this historic launch but also to capture important engineering data. We coordinate with engineers at the agency’s Kennedy Space Center, Johnson Space Center and Langley Research Center to use the cameras on the rocket, on the ground and in the air to determine how the rocket lifts off, clears the mobile launcher and travels during ascent. What we do is called photogrammetry, or the use of photography to measure distances between objects, for the SLS program.

Our team at NASA’s Marshall Space Flight Center designed and built the SLS onboard cameras for Exploration Mission-1, the first flight of SLS and the Orion spacecraft. We also came up with the photo markings designs on SLS — the checkerboard patterns you see on the rocket — to make important observations. We can see how the pieces of the rocket separate from each other and how close the solid rocket boosters come to the core stage when they are jettisoned. Because this will be the inaugural flight of the rocket, engineers have computer models telling them where the boosters will be in space relative to the core stage. But real-world photogrammetric data will tell them exactly where the boosters are relative to the core stage.

I began my career at Kennedy before transferring to Johnson, where I got involved with imagery. Now at Marshall, I work with our small team to successfully communicate with technicians and engineers to accomplish our mission.

Outside of my job with NASA, I take many other photographs, mainly of my four daughters, all under the age of 10. My husband and I spend a lot of time at softball games and piano recitals, and we love to explore the outdoors as a family. I tell my daughters that every piece of the puzzle counts and every member of the team matters — not only the astronauts who will be launched on the rocket, but also the engineers doing important work before the rocket leaves Earth. Thousands of people are working together to build America’s new rocket to go to the Moon, Mars and beyond — and I’ll be there to capture it on camera — well, actually, multiple cameras!

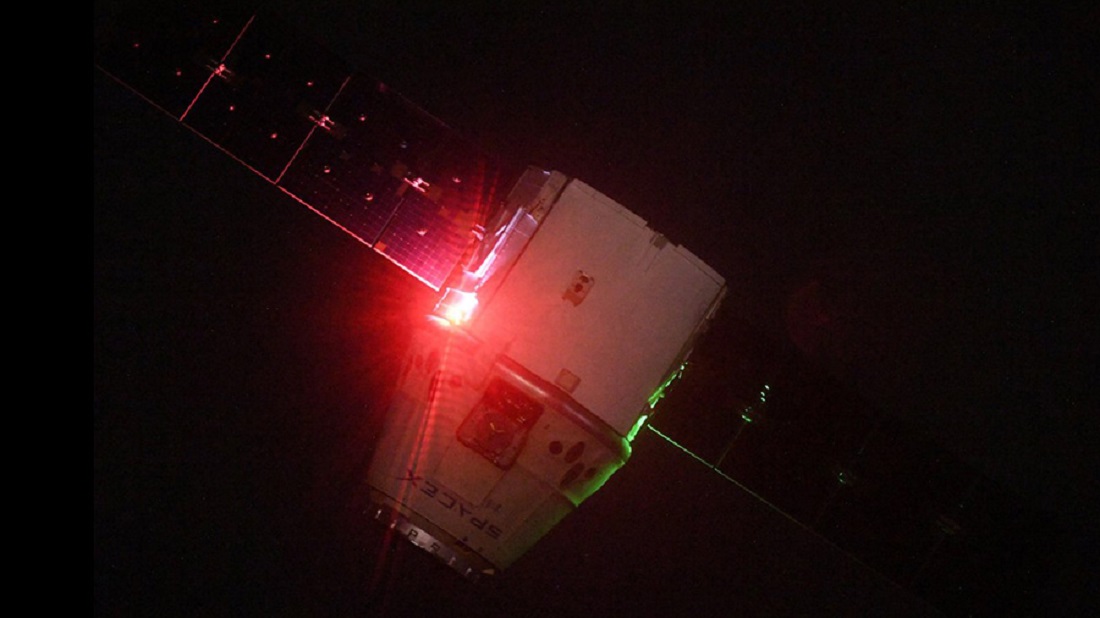

Doing It for the Science: SpaceX Dragon Capsule Departs ISS

On the afternoon of May 5, just hours after NASA’s InSight Lander left the California coast on a voyage to Mars, SpaceX’s Dragon cargo capsule departed from the International Space Station and splashed down in the Pacific Ocean, carrying over 4,000 pounds of science and technology payloads. The capsule, which had been docked to the space station since April 4, was recovered and taken to Long Beach, California, where time-sensitive experiments were unloaded. Dragon will now be transported to SpaceX’s McGregor, Texas, facility where the rest of its cargo will be unloaded and the spacecraft processed. Cosmonaut Oleg Artemyev posted this image on Twitter of the SpaceX Dragon resupply ship shortly after it was released from the grips of the Canadarm2 robotic arm. (Credit: Oleg Artemyev/@OlegMKS)

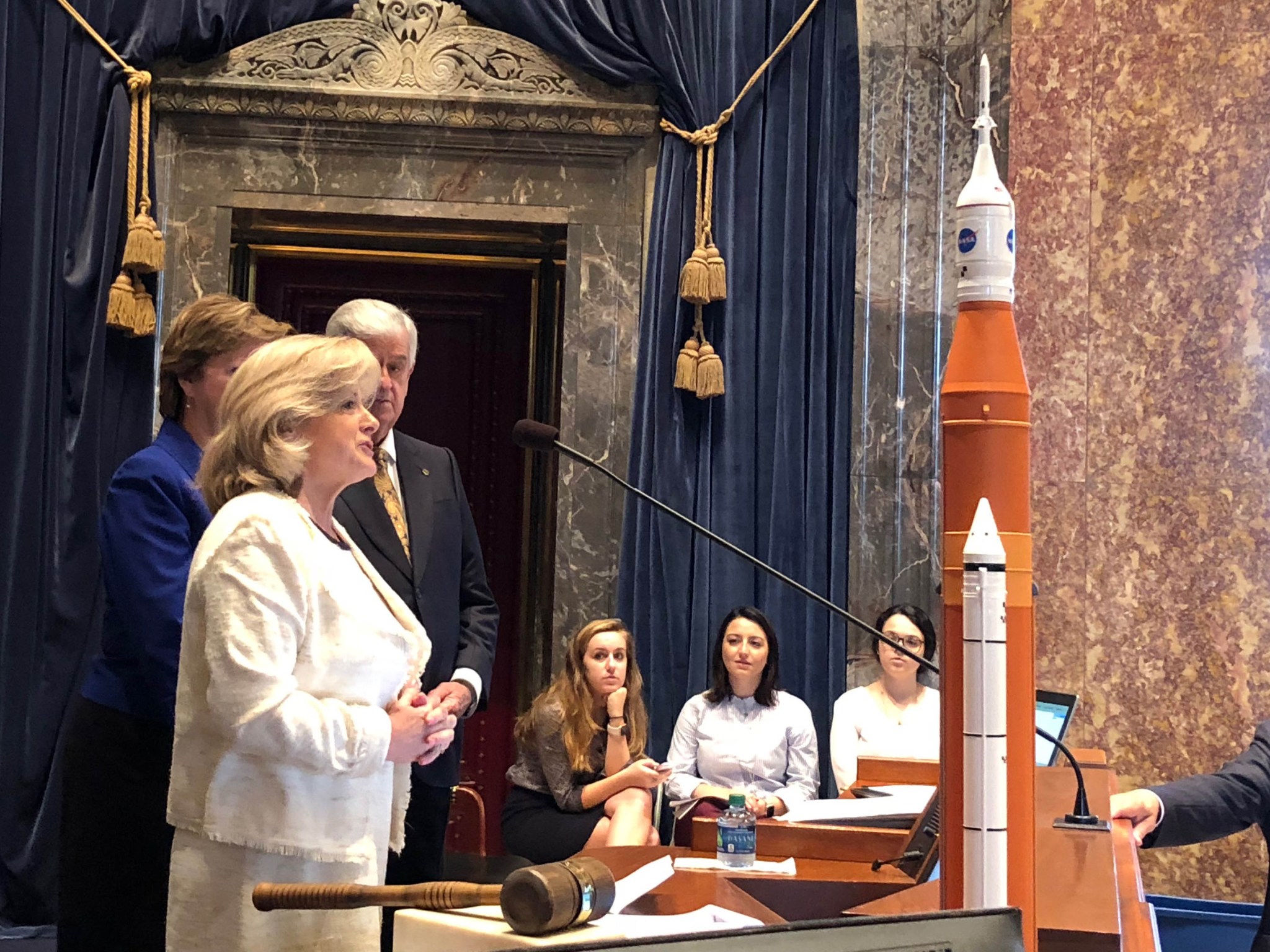

NASA Day in Baton Rouge Honors Louisiana’s Contributions to Space Exploration; Engages Over 1,800 Students in Outreach Events

Jody Singer, deputy director of NASA’s Marshall Space Flight Center, addresses the Louisiana State Senate and a balcony full of students at NASA Day in Baton Rouge, held at the State House on May 3. Singer spoke about Louisiana’s role in space exploration and the importance of recruiting the next generation of students to study science, technology, engineering and mathematics. NASA Day in Baton Rouge recognizes the space agency’s partnerships with the state of Louisiana. The highly skilled workforce at the nearby NASA Michoud Assembly Facility provides vital support to the agency’s exploration mission by building elements for NASA’s Space Launch System and Orion spacecraft. During NASA Day in Baton Rouge events, Michoud was awarded the Certified Louisiana logo for its work on SLS by the Department of Agriculture and Forestry — a designation given to products manufactured in the state of Louisiana. (NASA/MSFC/Amanda Adams)

NASA astronaut Mark Vande Hei shares his experiences aboard the International Space Station with a kindergarten class at Louisiana State University’s Laboratory School in Baton Rouge, as part of NASA Day in Baton Rouge. Throughout the day, Vande Hei, along with fellow Expedition 53 and 54 astronaut Joseph Acaba and Marshall leadership, visited with more than 1,800 students in kindergarten through eighth grade. (NASA/MSFC/Amanda Adams)

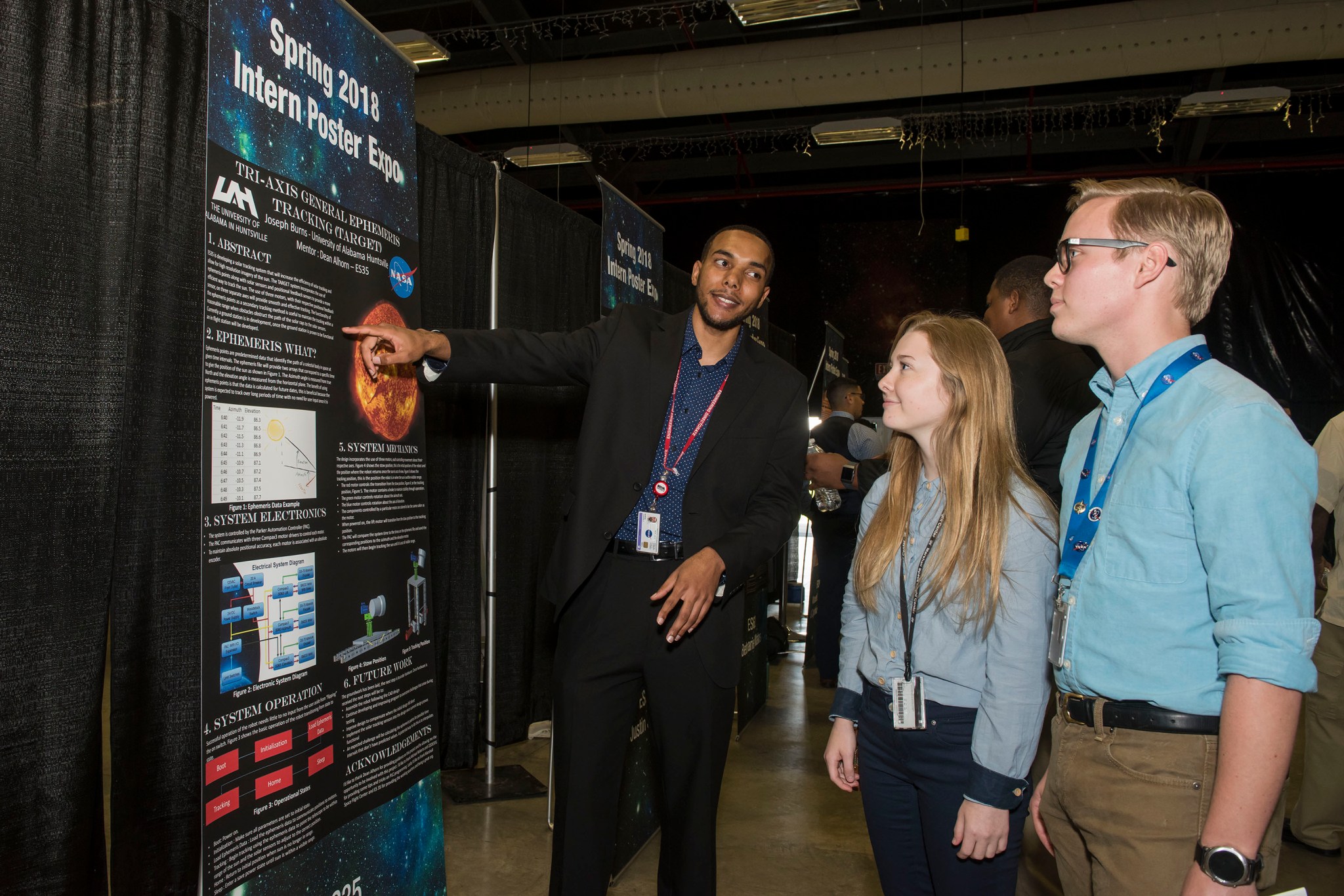

Marshall Showcases Work of Spring Interns at ‘Poster Day’ Event May 2

Joseph Burns, left, a mechanical engineering student at the University of Alabama in Huntsville, shares his poster highlighting the findings of his spring internship at NASA’s Marshall Space Flight Center with Amber Rampey, center, and David Hunter, who support Marshall’s Office of Human Capital. Burns spent his spring internship in Marshall’s Engineering Directorate designing a robotic means of tracking solar activity regardless of obstructions to the path of solar rays. He was among some 50 Marshall interns who took part in the end-of-term “Poster Day” event May 2 in Activities Building 4316. The interns, who displayed the results of their intensive research studies and applied engineering activities, discussed their experiences with the Marshall workforce. NASA Pathways Programs provide student internships and other career opportunities in a variety of science, engineering and technology fields. (NASA/MSFC/Charles Beason)

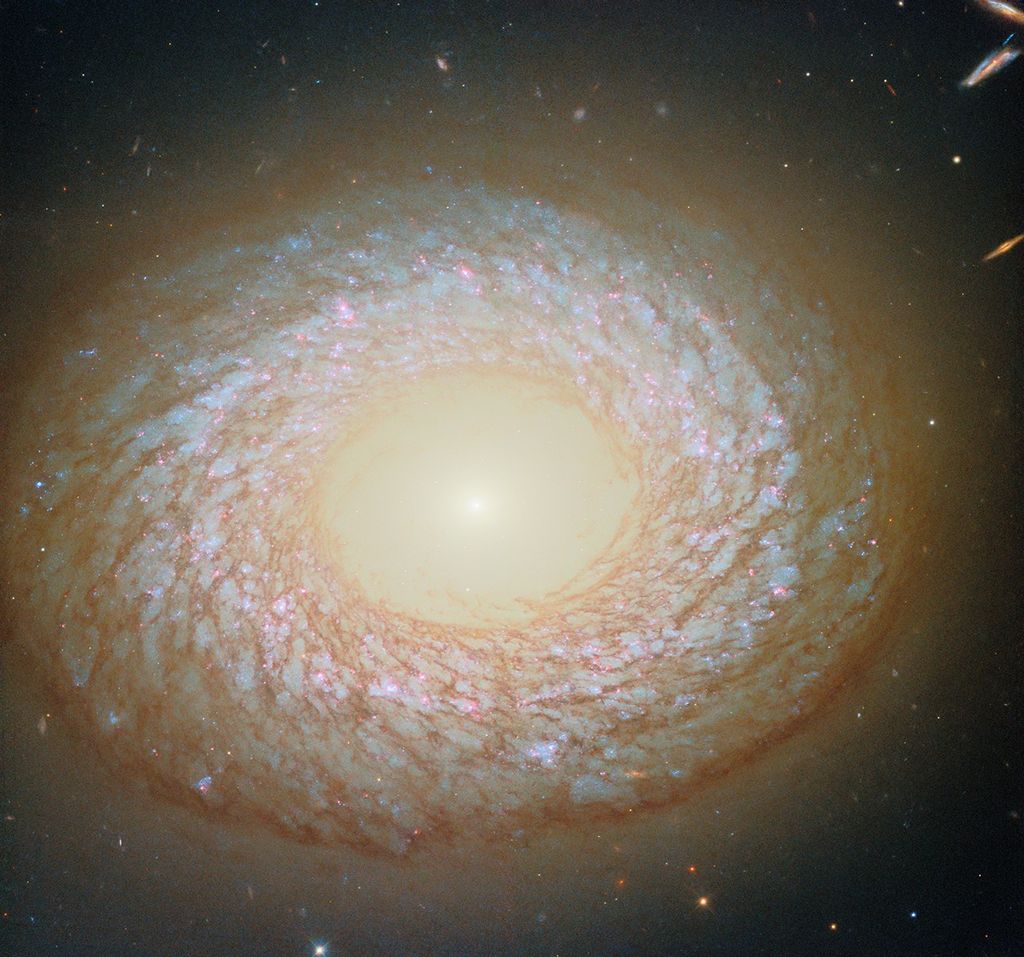

This Week in NASA History: STS-125 Launches on Final Hubble Servicing Mission – May 11, 2009

This week in 2009, the space shuttle Atlantis, mission STS-125, launched from NASA’s Kennedy Space Center on the fifth and final Hubble Space Telescope servicing mission. During the mission, astronauts successfully installed two new instruments and repaired two others, replaced gyroscopes and batteries, and added new thermal insulation panels to protect the orbiting observatory. NASA’s Marshall Space Flight Center was responsible for the overall design, development and construction of the observatory. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)