Autonomous Ribbon Re-Feeding System for Stress-Annealing Soft-Magnetic Nanocomposites

Nickolaus M. Bruno (LMA0)

Project Background / Description

Stress-annealing processes currently define the state-of-the-art for manufacturing high efficiency gapless filter inductors comprised of nanocrystalline soft-magnetic alloys. However, a continuous in-line process is often difficult to attain due to ribbon embrittlement and mode-1 fracture that originates at cast defects on the ribbon edges. At NASA Glenn Research Center (GRC), when the ribbon breaks during spooling, it must be spliced to the processed spool prior to continuation. This proposed design project seeks a modular subsystem that will automate re-feeding broken brittle ribbon between two spools while winding, either entering or exiting a furnace under tension. Rewinding is performed at room temperature.

Challenge Objectives

Design a standalone re-feeding assembly that can be integrated into NASA GRC’s in-line stress-annealing machine.

- Complete literature review of winding physics and explore the problem definition.

- Complete several design iterations and employ decision matrices to down select the most promising options.

- Complete prototype testing of the re-feeding assembly with ribbon provided by GRC.

Mission Performance/Requirements.

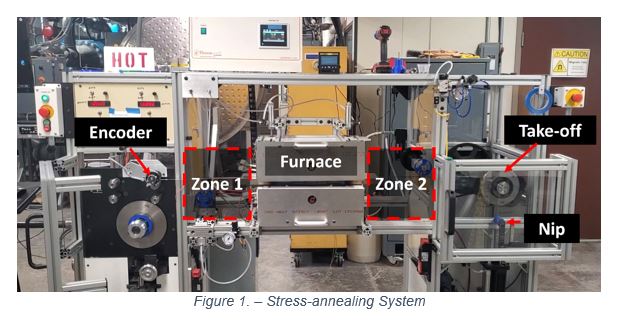

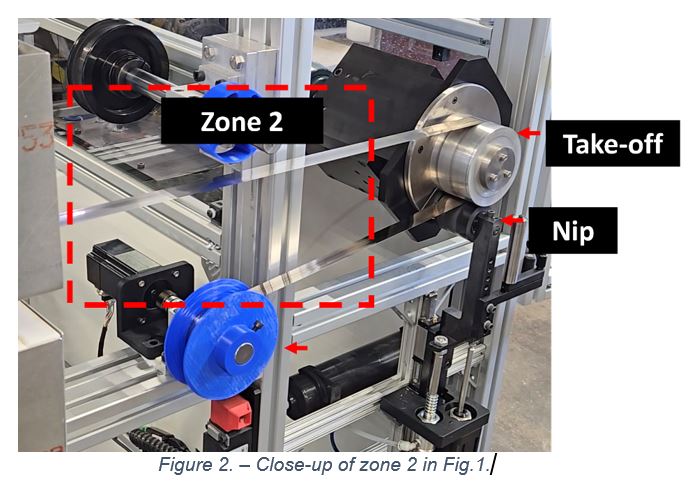

- The re-feeding assembly shall be compact and fit between a furnace at 650 °C and the take-off assembly (in zone 2) or a rotation encoder (zone 1) in Fig. 1.

- The assembly’s transducers and actuators shall be electronic (120V AC) or pneumatic and capable of pinching and/or catching 20 μm thick and 1-inch-wide ribbon after a break occurs in zone 1 or 2 and then splicing it to pre-processed ribbon.

- Breaks shall be monitored by sensing ribbon tension or with video. Automation shall be trigged when a ribbon break occurs, or manually controlled.

Key Considerations

- Ribbon is metallic, 20 μm thick, and smooth. Therefore, roller coating must be capable of spooling ribbon under tension via friction or pinching. If pinching is used, the pinch force must be controlled to prevent brittle ribbon from fracture.

- As the ribbon breaks it will fall, or shatter. Compressed air may be useful in cleaning debris from rollers and re-feeding the ribbon to the next set of nip rollers.

- The system shall operate independently removed from the stress-annealing system in Fig. 1 but shall be designed for modular installation.

- The system shall operate autonomously using sensors, a splicing knife and tape, and offer a manual control option.

System Design

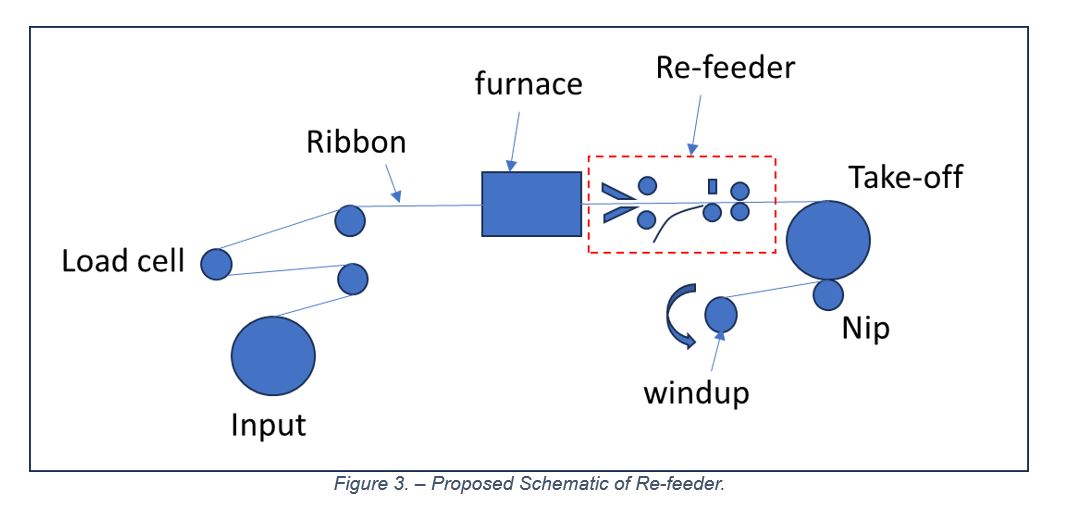

This work will decrease the processing time of large inductor cores. Currently, ribbon breaks require manual re-feeding and splicing which can take a significant amount of time.

The ideal re-feeding system would sense ribbon breaks, then employ a system of actuation arms and compressed air to reposition, re-feed, and tape (splice) ribbon to the pre-existing processed end.

By designing a modular and independent subsystem, diagnostics can be performed prior to installing and integrating the system into the current stress-annealing line.

Literature Resources

J. Duffin, “Method of refeeding electrical discharge machining electrodes”, U.S. Patent No. 5,177,336 (1993).

J. Hayakawa, “Wire cut electrical discharge machine”, U.S. Patent No. 5,874,702 (1999).

J.K. Good. Review: Winding and unwinding webs: A review of the state of the science in 2005. In Advances in Paper Science and Technology, Trans. Of the XIIIth Fund. Res. Symp. Cambridge, 2005, (S.J.I’Anson, ed.), pp 307-406, FRC, Manchester, 2018. DOI: 10.15376/frc.2005.1.307.

See web videos on “Tapematic Duplicator Splicing” or user manuals for cassette duplication machines.

Application/Registration Information

Contact Information

Jeresha Nixon

Education Program Specialist

Email: grc-university-design-challenge@mail.nasa.gov

Glenn Research Center – Office of STEM Engagement

Phone: (216) 433-6656

Email: grc-university-design-challenge@mail.nasa.gov

Latest Content

Stay up-to-date with the latest content from NASA as we explore the universe and discover more about our home planet.

Capturing the high-stakes work behind NASA’s Airborne Science Program takes more than just technical skill – it takes vision. At…

On March 28, 80 college students filed into Colorado State University’s (CSU) Nancy Richardson Design Center to receive pizza and…

The stately and inclined spiral galaxy NGC 3511 is the subject of this NASA/ESA Hubble Space Telescope image. The galaxy…