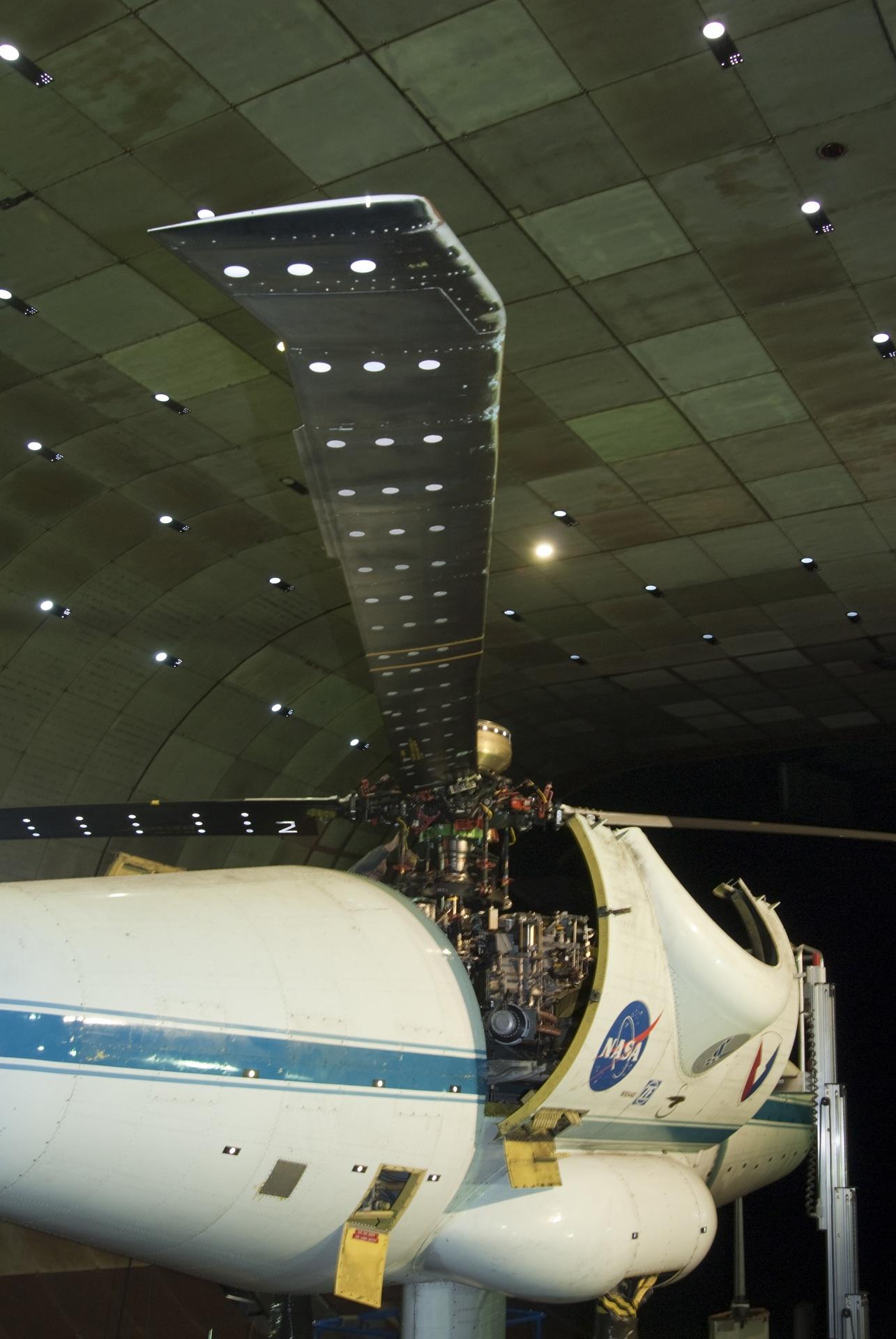

“Smooth” and “quiet” are two words not usually associated with a helicopter ride, but NASA is working to change that. A full-size UH-60A Blackhawk helicopter rotor was the subject of tests the agency’s Subsonic Rotary Wing Project recently completed in collaboration with the U.S. Army and the U.S. Air Force at NASA’s Ames Research Center in Moffett Field, Calif.

The test series, conducted from January to May 2010, was designed to gather data on the rotor blades and air movement that the blades create. Since most helicopter noise and vibration can be blamed on the interactions between the blades and the air, the data will be extremely valuable to rotor researchers trying to understand these effects.

Ultimately, the data gathered in the tests can be used to design advanced helicopters in the future.

“NASA hopes to make those new designs quieter, faster, more fuel efficient, and capable of carrying more people and cargo,” said Tom Norman, the researcher for the project test team.

The test included routine flight conditions for the rotor, but also explored what happens if the rotor system is operated above and beyond its normal flight conditions. This included testing at very high speed and at conditions designed to simulate a much heavier helicopter, and provided data that will help NASA design helicopters that can fly faster speeds and carry more payload.

To obtain the data, NASA designed new measurement techniques for the rotor system and for the world’s largest wind tunnel, the National Full-Scale Aerodynamic Complex, or NFAC, in which the rotor system was tested.

NASA researchers needed to develop techniques to make measurements over large distances both on and around the rotating blades, so they customized a system that uses laser light to measure the air flow without touching the blades. This technique, called particle image velocimetry, is commonly used, but not over areas this large. The blade area of 4 feet by 13 feet, approximately the size of two twin mattresses end to end, was the largest measurement area ever attempted using this technique.

Researchers measured the wake of the rotor using a technique known as retro-reflective background oriented schlieren. This technique shoots light across the wind tunnel to visualize the air as it rotates and provides a complementary view of the rotor wake.

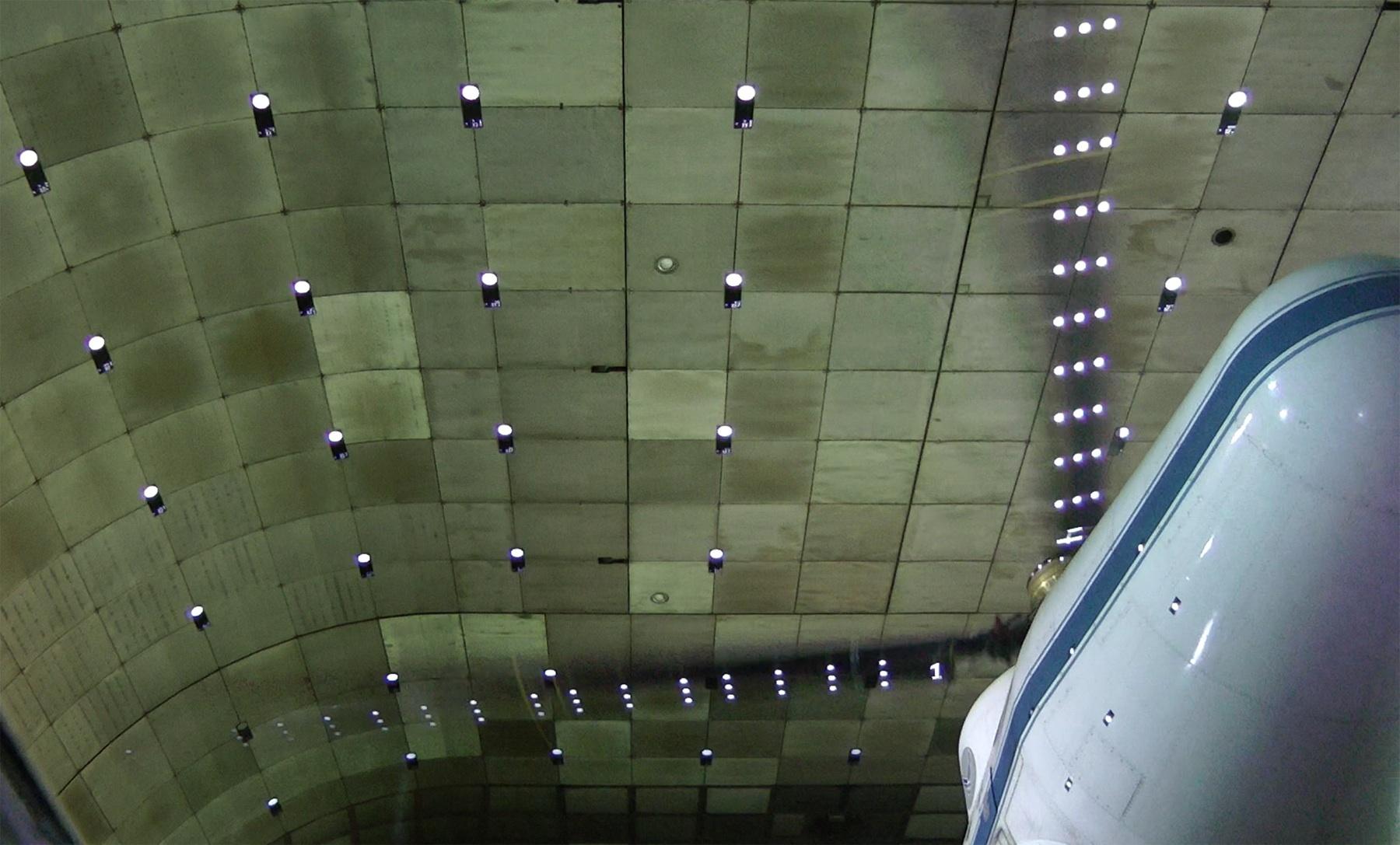

Rotor blades twist and turn in air as they spin, making it difficult to measure their movement. To avoid touching or interfering with the spinning blades, NASA used a third technique, called photogrammetry, to identify the blades’ shape, It employed high speed cameras to take pictures of small reflective targets on the blades and the wind tunnel ceiling.

On the rotor blade itself, more than 200 sensors were used to measure pressure that creates the rotor lift. Having so many sensors is difficult because the team has to keep all of the complex systems working to get accurate results.

“This was the most highly-instrumented rotor test ever conducted in the NFAC, and the team pushed the operation of the rotor system to its limits to acquire this unique data,” said Norman.

“Thanks to the hard work by the whole team, we were able to accomplish our goals,” said Norman.